ASTM D1283-85(1995)e1

(Test Method)Standard Test Method for Alkali-Soluability of Wools

Standard Test Method for Alkali-Soluability of Wools

SCOPE

1.1 This test method covers a chemical procedure for determination of the amount of wool substance soluble in alkali under standard conditions and is applicable to wool in scoured fiber form, or as fiber obtained from yarn or from woven or nonwoven fabric.

1.2 The values stated in inch-pound are to be regarded as standard. The values stated in SI units are provided for information only.

Note 1--This test method is applicable to other animal fibers although the level of alkali-solubility may be different from wool. With individual animal fibers, undamaged solubility should be determined before attempting to assess damage on an unknown sample.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 1283 – 85 (Reapproved 1995)

Standard Test Method for

Alkali-Soluability of Wools

This standard is issued under the fixed designation D 1283; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout June 1995.

1. Scope 3.1.2 wool, n—the fibrous covering of the sheep, Ovis

species.

1.1 This test method covers a chemical procedure for

3.1.3 For definitions of textile terms used in this test

determination of the amount of wool substance soluble in alkali

method, refer to Terminology D 123.

under standard conditions and is applicable to wool in scoured

fiber form, or as fiber obtained from yarn or from woven or

4. Summary of Test Method

nonwoven fabric.

4.1 Specimens are maintained at a stipulated constant tem-

1.2 The values stated in inch-pound are to be regarded as

perature in a caustic solution for a specified period of time. The

standard. The values stated in SI units are provided for

percentage of alkali-solubility is calculated from the loss in

information only.

mass of the specimen.

NOTE 1—This test method is applicable to other animal fibers although

the level of alkali-solubility may be different from wool. With individual

5. Significance and Use

animal fibers, undamaged solubility should be determined before attempt-

5.1 Alkali-solubility is an indication of the degree of dam-

ing to assess damage on an unknown sample.

age to wool resulting from certain chemical treatments, par-

1.3 This standard does not purport to address all of the

ticularly when test results on the same wool, before such

safety concerns, if any, associated with its use. It is the

treatment, are available.

responsibility of the user of this standard to establish appro-

5.1.1 Undamaged scoured wool has typical alkali-solubility

priate safety and health practices and determine the applica-

in the range of 9 to 15 %. Fine, undamaged wool normally will

bility of regulatory limitations prior to use.

exhibit higher solubility than coarse wool, because of greater

surface area per unit mass of fiber.

2. Referenced Documents

5.2 This test method is not recommended for use on wool

2.1 ASTM Standards:

known to have sustained alkali damage.

D 123 Terminology Relating to Textiles

5.2.1 Alkali-damaged wool has had material solubilized that

D 1060 Practice for Core Sampling of Raw Wool in Pack-

ordinarily would be included in the alkali-solubility test results.

ages for Determination of Percentage of Clean Wool Fiber

5.3 Although results in one laboratory cannot usually be

Present

verified in another laboratory, this test method is considered

D 1193 Specification for Reagent Water

satisfactory for acceptance testing because it has been used

E 1 Specification for ASTM Thermometers

extensively in the trade for this purpose and because it is the

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

only available method for assessing damage to wool by an

poses

alkali solubility procedure. Comparative tests as directed in

5.3.1 are advisable before Test Method D 1283 is used for

3. Terminology

acceptance testing.

3.1 Definitions:

5.3.1 In case of a dispute arising from differences in

3.1.1 alkali-solubility, n—in wool, the percent of clean wool

reported test results when using Test Method D 1283 for

that is soluble in a specified alkaline solution under controlled

acceptance testing of commercial shipments, the purchaser and

conditions of temperature and time.

the supplier should conduct comparative tests to determine if

there is a statistical bias between their laboratories. Competent

statistical assistance is recommended for the investigation of

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt. bias. As a minimum, the two parties should take a group of test

Current edition approved July 26, 1985. Published September 1985. Originally

specimens which are as homogeneous as possible and which

published as D 1283 – 53 T. Last previous edition D 1283 – 84.

are from a lot of material of the type in question. The test

Annual Book of ASTM Standards, Vol 07.01.

specimens should then be randomly assigned in equal numbers

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 14.03.

to each laboratory for testing. The average result from the two

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

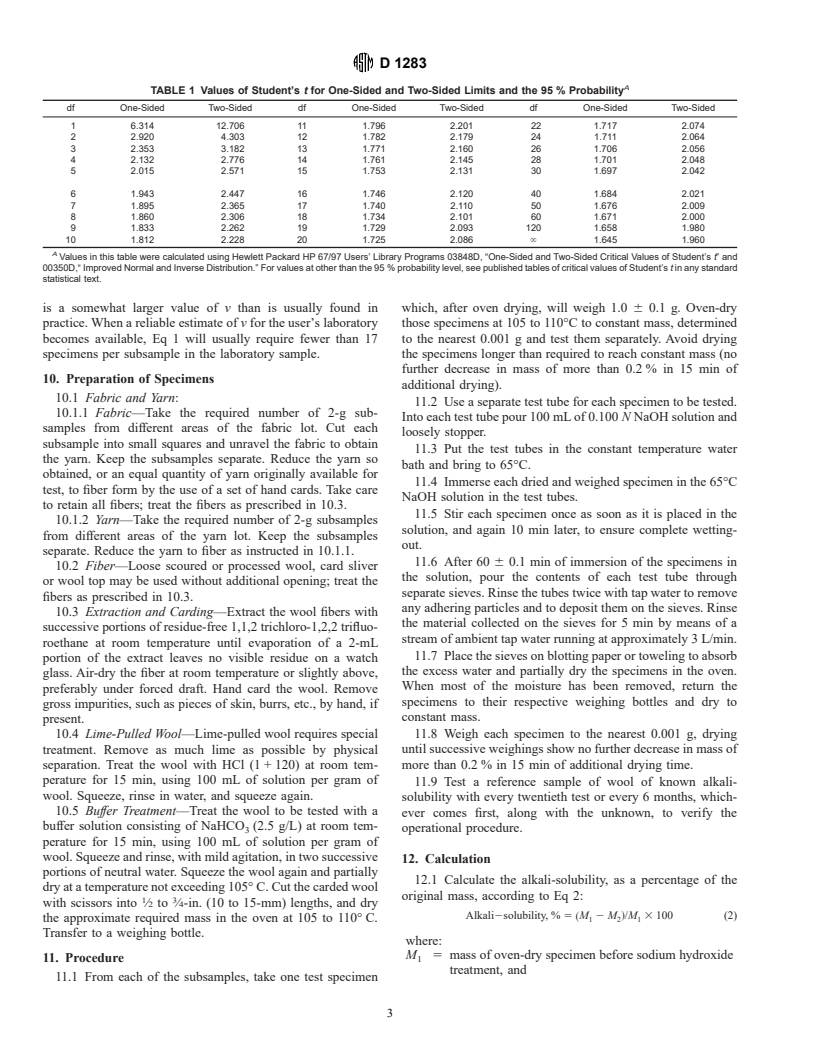

D 1283

laboratories should be compared using Student’s t-test for take at random the number of shipping containers directed in

unpaired data and an acceptable probability level chosen by the an applicable material specification or other agreement be-

two parties before testing is begun. If a bias is found, either its tween the purchaser and the supplier, such as an agreement to

cause must be found and corrected or the purchaser and the use Practice D 1060. Consider shipping containers to be the

supplier must agree to interpret future test results in the light of primary sampling units.

the known bias.

NOTE 2—A realistic specification or other agreement between the

purchaser and the supplier requires taking into account the variability

6. Apparatus

between shipping containers, between laboratory samples within a ship-

6.1 Test Tubes—Glass test tubes 1.5 in. (38 mm) by 7.9 in.

ping container, and between specimens within a laboratory sample so as to

(200 mm) with cork stoppers.

provide a sampling plan which at the specified level of the property of

interest has a meaningful producer’s risk, consumer’s risk, acceptable

6.2 Constant-Temperature Bath—A bath equipped to main-

quality level, and limiting quality level.

tain a temperature of 65 6 0.5° C throughout.

6.3 Thermometer—ASTM Aniline Point Thermometer,

8.2 Laboratory Sample—As a laboratory sample for accep-

having a range from 25 to 105° C and conforming to the

tance testing, take the number of subsamples from each

requirements for Thermometer 34C as prescribed in Specifi-

package in the lot sample as directed in an applicable material

cation E 1.

specification or other agreement between the purchaser and the

6.4 Weighing Bottles—Glass bottles of approximately 30 to

supplier, such as an agreement to use Practice D 1060 if baled

35-mL capacity, fitted with ground glass covers.

or bagged wool is to be tested.

6.5 Constant-Temperature Drying Oven, to be maintained at

8.3 Test Specimens—As directed in Section 9, determine the

105 to 110° C, preferably employing a forced draft.

number of specimens to be tested from each subsample in the

6.6 Sieves —No. 100 (150-μm) approximately 1.75 in. (45 laboratory sample.

mm) in diameter and 1.75 in. (45 mm) high.

9. Number of Specimens per Subsample

6.7 Hand Cards.

6.8 Analytical Balance—The balance must be capable of

9.1 Control or Non-Critical Testing—For routine control

weighing to 0.001 g.

testing or other non-critical purpose where acceptance testing

is not involved, four specimens, randomly chosen from a lot,

7. Reagents and Materials

may be tested as directed in Sections 10 and 11.

7.1 Purity of Reagents—Reagent grade chemicals shall be

9.2 Acceptance Testing:

used in all tests. Unless otherwise indicated, it is intended that

9.2.1 Take a number of specimens per subsample in the

all reagents shall conform to the specifications of the Commit-

laboratory sample, such that the user may expect at the 95 %

tee on Analytical Reagents of the American Chemical Society.

probability level that the test result for a subsample in the

Other grades may be used, provided it is first ascertained that

laboratory sample is not more than 2.0 % above or below the

the reagent is of sufficiently high purity to permit its use

true average of the subsample in the laboratory sample (see

without lessening the accuracy of the determination.

Table 1). Determine the number of specimens per subsample in

7.2 Purity of Water—Unless otherwise indicated, references

the laboratory sample as follows:

to water shall be understood to mean reagent water conforming

9.2.1.1 Reliable Estimate of v—When there is a reliable

to Specification D 1193.

estimate of v based upon extensive past records for similar

7.3 1,1,2 Trichloro-1,2,2 Trifluoroethane

materials tested in the user’s laboratory as directed in the

7.4 Hydrochloric Acid (1 + 120)—Mix 1 volume of concen-

method, calculate the required number of specimens per

trated hydrochloric acid (HCl, sp gr 1.19) with 120 volumes of

subsample in the laboratory sample using Eq 1:

water.

n 5 ~tv/A! (1)

7.5 Sodium Bicarbonate Solution (2.5 g/L)—Dissolve 2.5 g

of sodium bicarbonate (NaHCO ) in water and dilute to 1 L.

where:

7.6 Sodium Hydroxide, Standard Solution (0.100 N)—

n 5 number of specimens per subsample in the laboratory

Prepare and standardize a 0.100 N solution of sodium hydrox-

sample (rounded upward to a whole number),

ide (NaOH) in carbon dioxide-free water, kept free from access

v 5 reliable estimate of the coefficient of variation of

by CO from the air, and dilute to 1 L.

2 individual observations on similar materials in the

7.7 Working Reference Wool Samples—Samples of undam-

user’s laboratory under conditions of single-operator

aged scoured wool of known alkali-solubility.

precision,

t 5 the value of Student’s t for two-sided limits, a 95 %

8. Sampling

probability level, and the degrees of freedom associ-

8.1 Lot Sample—As a lot sample for acceptance testing,

ated with the estimate of v, and

A 5 2.0 % of the average, the value of the allowable

6 variation.

Detailed requirements for these sieves are given in Specification E

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.