ASTM C582-09

(Specification)Standard Specification for Contact-Molded Reinforced Thermosetting Plastic (RTP) Laminates for Corrosion-Resistant Equipment

Standard Specification for Contact-Molded Reinforced Thermosetting Plastic (RTP) Laminates for Corrosion-Resistant Equipment

ABSTRACT

This specification covers composition, thickness, fabricating procedures, and physical property requirements for glass fiber reinforced thermoset polyester, vinyl ester, or other qualified thermosetting resin laminates comprising the materials of construction for RTP corrosion-resistant tanks, piping, and equipment. This specification is limited to fabrication by contact molding. Laminates shall be classified according to type, class, and grade: Types I and II; Classes P and V. Tensile strength and tangent modulus of elasticity, flexural strength, glass content, thickness, hardness, chemical resistance, and surface flame-spread classification tests shall be performed to conform to the specified requirements.

SCOPE

1.1 This specification covers composition, thickness, fabricating procedures, and physical property requirements for glass fiber reinforced thermoset polyester, vinyl ester, or other qualified thermosetting resin laminates comprising the materials of construction for RTP corrosion-resistant tanks, piping, and equipment. This specification is limited to fabrication by contact molding.

Note 1—The laminates covered by this specification are manufactured during fabrication of contact-molded RTP tanks, piping, and other equipment.

Note 2—There is no known ISO equivalent to this standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C582 −09 AnAmerican National Standard

Standard Specification for

Contact-Molded Reinforced Thermosetting Plastic (RTP)

1

Laminates for Corrosion-Resistant Equipment

This standard is issued under the fixed designation C582; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

1.1 This specification covers composition, thickness, fabri-

als

catingprocedures,andphysicalpropertyrequirementsforglass

D883 Terminology Relating to Plastics

fiber reinforced thermoset polyester, vinyl ester, or other

D2583 Test Method for Indentation Hardness of Rigid Plas-

qualified thermosetting resin laminates comprising the materi-

tics by Means of a Barcol Impressor

als of construction for RTP corrosion-resistant tanks, piping,

D2584 Test Method for Ignition Loss of Cured Reinforced

and equipment. This specification is limited to fabrication by

Resins

contact molding.

D3681 Test Method for Chemical Resistance of “Fiberglass”

NOTE 1—The laminates covered by this specification are manufactured

(Glass–Fiber–Reinforced Thermosetting-Resin) Pipe in a

during fabrication of contact-molded RTP tanks, piping, and other

Deflected Condition

equipment.

E84 Test Method for Surface Burning Characteristics of

NOTE 2—There is no known ISO equivalent to this standard.

Building Materials

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3. Definitions

conversions to SI units that are provided for information only

3.1 Definitions used in this specification are in accordance

and are not considered standard.

with Terminology D883 unless otherwise indicated. The ab-

1.3 The following safety hazards caveat pertains only to the breviation for reinforced thermoset plastic is RTP.

test method portion, Section 8, of this specification: This

3.2 polyester—resins produced by the polycondensation of

standard does not purport to address all of the safety concerns,

dihydroxyderivatives and dibasic organic acids or anhydrides,

if any, associated with its use. It is the responsibility of the user

wherein at least one component contributes ethylenic unsatu-

of this standard to establish appropriate safety and health

ration yielding resins that can be compounded with styryl

practices and determine the applicability of regulatory limita-

monomers and reacted to give highly crosslinked thermoset

tions prior to use.

copolymers.

2. Referenced Documents

3.3 vinyl ester—resins characterized by reactive unsatura-

2

tion located predominately in terminal positions that can be

2.1 ASTM Standards:

compounded with styryl monomers and reacted to give highly

C581 Practice for Determining Chemical Resistance of

crosslinked thermoset copolymers.

Thermosetting Resins Used in Glass-Fiber-Reinforced

Structures Intended for Liquid Service

NOTE 3—These resins are handled in the same way as polyesters in

D638 Test Method for Tensile Properties of Plastics fabrication of RTP components.

D695 Test Method for Compressive Properties of Rigid

3.4 contact molding—a method of fabrication wherein the

Plastics

glass-fiber reinforcement is applied to the mold, in the form of

chopped strand mat or woven roving, by hand or from a reel,

1

This specification is under the jurisdiction of ASTM Committee D20 on

or in the form of chopped strands of continuous-filament glass

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

from a chopper-spray gun. The resin matrix is applied by

Plastic Piping Systems and Chemical Equipment.

various methods, including brush, roller, or spray gun. Con-

Current edition approved April 1, 2009. Published April 2009. Originally

approved in 1965. Last previous edition approved in 2002 as C582 – 02. DOI:

solidation of the composite laminate is by rolling.

10.1520/C0582-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4. Classification

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 Laminates shall be classified according to type, class,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and grade.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C582−09

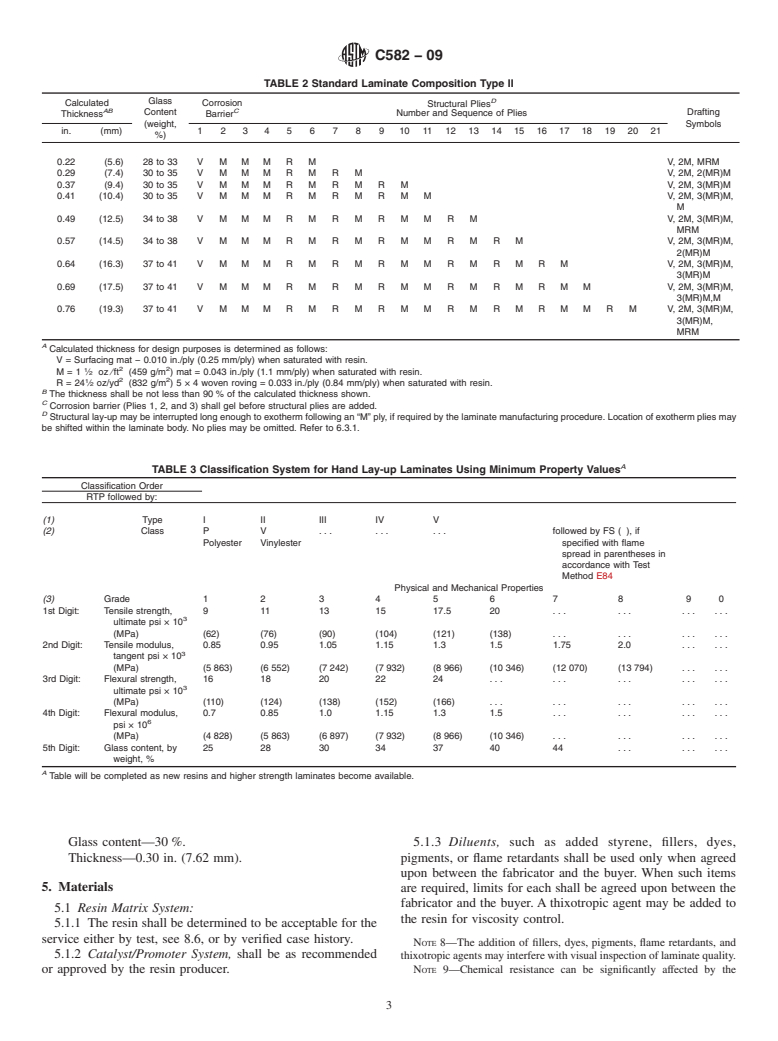

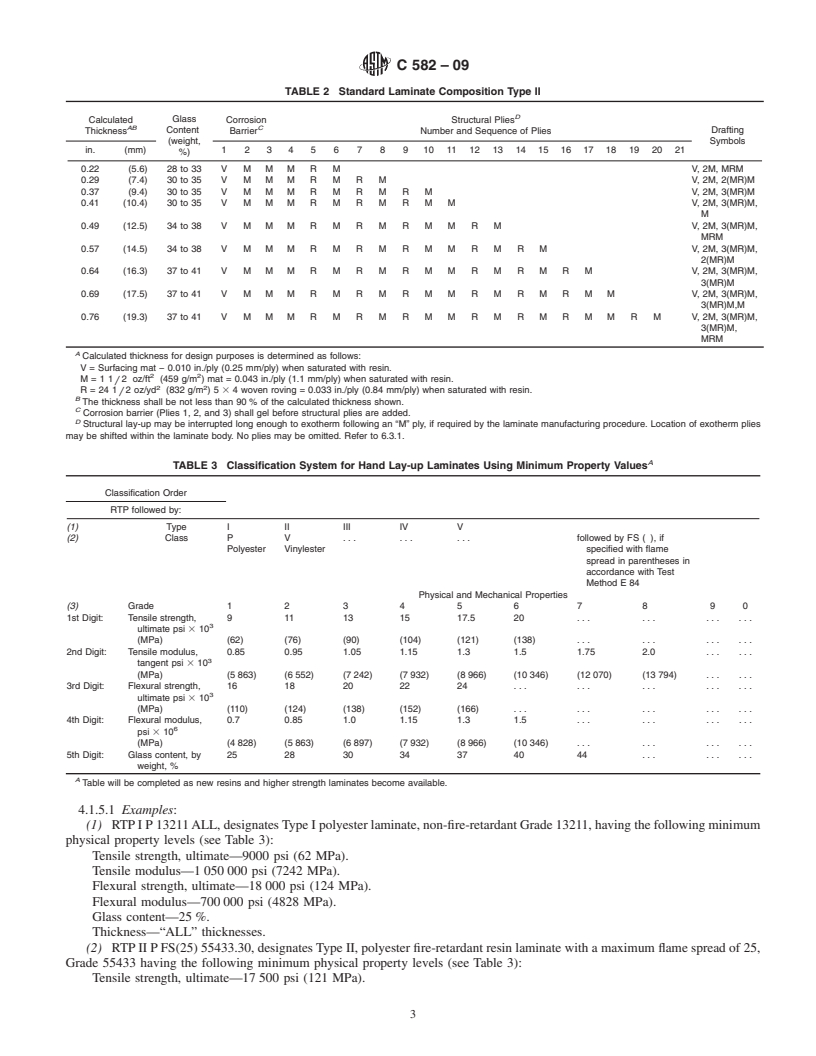

4.1.1 Type—In Roman numerals, shall designate the rein- 4.1.4 Thickness—Nominal, shall

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:C 582–02 Designation: C 582 – 09

Standard Specification for

Contact-Molded Reinforced Thermosetting Plastic (RTP)

1

Laminates for Corrosion-Resistant Equipment

This standard is issued under the fixed designation C 582; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers composition, thickness, fabricating procedures, and physical property requirements for glass fiber

reinforcedthermosetpolyester,vinylester,orotherqualifiedthermosettingresinlaminatescomprisingthematerialsofconstruction

for RTP corrosion-resistant tanks, piping, and equipment. This specification is limited to fabrication by contact molding.

NOTE 1—The laminates covered by this specification are manufactured during fabrication of contact-molded RTP tanks, piping, and other equipment.

NOTE2—There is no similar or equivalent ISO standard.

1.2 2—There is no known ISO equivalent to this standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 581 Practice for Determining Chemical Resistance of Thermosetting Resins Used in Glass-Fiber-Reinforced Structures

Intended for Liquid Service

D 638 Test Method for Tensile Properties of Plastics

D 695 Test Method for Compressive Properties of Rigid Plastics

D 790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D 883 Terminology Relating to Plastics

D 2583 Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

D 2584 Test Method for Ignition Loss of Cured Reinforced Resins

D 3681 Test Method for Chemical Resistance of “Fiberglass” (Glass-Fiber-ReinforcedFiberglass (GlassFiberReinforced

Thermosetting-Resin) Pipe in a Deflected Condition

E84 Test Method for Surface Burning Characteristics of Building Materials

3. Definitions

3.1 Definitions used in this specification are in accordance with Terminology D 883 unless otherwise indicated. The

abbreviation for reinforced thermoset plastic is RTP.

3.2 polyester—resins produced by the polycondensation of dihydroxyderivatives and dibasic organic acids or anhydrides,

wherein at least one component contributes ethylenic unsaturation yielding resins that can be compounded with styryl monomers

and reacted to give highly crosslinked thermoset copolymers.

3.3 vinyl ester—resins characterized by reactive unsaturation located predominately in terminal positions that can be

compounded with styryl monomers and reacted to give highly crosslinked thermoset copolymers.

NOTE 3—These resins are handled in the same way as polyesters in fabrication of RTP components.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved Nov. 10, 2002. Published January 2003. Originally approved in 1965. Last previous edition approved in 1995 as C582–95.

Current edition approved April 1, 2009. Published April 2009. Originally approved in 1965. Last previous edition approved in 2002 as C 582 – 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.04.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 582–09

3.4 contact molding—a method of fabrication wherein the glass-fiber reinforcement is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.