ASTM F1476-95a

(Specification)Standard Specification for Performance of Gasketed Mechanical Couplings for Use in Piping Applications

Standard Specification for Performance of Gasketed Mechanical Couplings for Use in Piping Applications

SCOPE

1.1 This standard provides the performance characteristics and qualification tests required for gasketed mechanical couplings including grooved-type mechanical couplings for grooved end pipe, mechanical restraint couplings for plain end pipe and mechanical compression couplings for plain end pipe. These couplings are for use at temperatures within the recommended temperature range of their respective gaskets. Consult manufacturer for details.

1.2 The values stated in metric units (SI) are to be regarded as the standard. The values given in parentheses (inch/pound) are provided for information purposes.

1.3 Measuring and test equipment (MTE) used in the performance of the tests described herein shall be calibrated using equipment which is traceable to the National Institute of Standards and Technology (NIST) or calibrated in accordance with the requirements detailed in BS5781 Part 1 against standards traceable to National Standards.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 As this is not a dimensional standard, nor does it contain component dimensions, the intermixing of sub-components such as gaskets and housings between manufacturers is not recommended and constitutes non-conformance with this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1476 – 95a An American National Standard

Standard Specification for

Performance of Gasketed Mechanical Couplings for Use in

Piping Applications

This standard is issued under the fixed designation F 1476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 153 Specification for Zinc Coating (Hot-Dip) on Iron and

Steel Hardware

1.1 This standard provides the performance characteristics

A 183 Specification for Carbon Steel Track Bolts and Nuts

and qualification tests required for gasketed mechanical cou-

A 193 Specification for Alloy-Steel and Stainless Steel

plings including grooved-type mechanical couplings for

Bolting Materials for High-Temperature Service

grooved end pipe, mechanical restraint couplings for plain end

A 194 Specification for Carbon and Alloy Steel Nuts for

pipe and mechanical compression couplings for plain end pipe.

Bolts for High-Pressure and High-Temperature Service

These couplings are for use at temperatures within the recom-

A 325 Specification for Structural Bolts, Steel, Heat-

mended temperature range of their respective gaskets. Consult

Treated, 120/105 ksi Minimum Tensile Strength

manufacturer for details.

A 536 Specification for Ductile Iron Castings

1.2 The values stated in metric units (SI) are to be regarded

A 563 Specification for Carbon and Alloy Steel Nuts

as the standard. The values given in parentheses (inch/pound)

A 574 Specification for Alloy Steel Socket-Hand Cup

are provided for information purposes.

Screws

1.3 Measuring and test equipment (M&TE) used in the

A 743/A743M Specification for Castings, Iron-Chromium,

performance of the tests described herein shall be calibrated

Iron-Chromium-Nickel, Corrosion Resistant, for General

using equipment which is traceable to the National Institute of

Application

Standards and Technology (NIST) or calibrated in accordance

B 26/B26M Specification for Aluminum-Alloy Sand Cast-

with the requirements detailed in BS5781 Part 1 against

ings

standards traceable to National Standards.

B 88 Specification for Seamless Copper Water Tube

1.4 This standard does not purport to address all of the

B 633 Specification for Electrodeposited Coatings of Zinc

safety concerns, if any, associated with its use. It is the

on Iron and Steel

responsibility of the user of this standard to establish appro-

D 2000 Classification System for Rubber Products in Auto-

priate safety and health practices and determine the applica-

motive Applications

bility of regulatory limitations prior to use.

F 837 Specification for Stainless Steel Socket Head Cap

1.5 As this is not a dimensional standard, nor does it contain

Screws

component dimensions, the intermixing of sub-components

2.2 ANSI or ANSI/AWWA Standards:

such as gaskets and housings between manufacturers is not

B 36.10—Welded and Seamless Wrought Steel Pipe

recommended and constitutes non-conformance with this stan-

B 36.19—Stainless Steel Pipe

dard.

C 151/A21.51—Ductile-Iron Pipe, Centrifugally Cast in

2. Referenced Documents

Metal Molds or Sand-Lined Molds, for Water or Other

Liquids

2.1 ASTM Standards:

C 606-87—Grooved and Shouldered Joints

A 47 Specification for Ferritic Malleable Iron Castings

2.3 NFPA Standards:

A 53 Specification for Pipe, Steel, Black and Hot-Dipped,

NFPA 13—Sprinkler Systems

Zinc-Coated Welded and Seamless

A 135 Specification for Electric-Resistance-Welded Steel

Pipe

Annual Book of ASTM Standards, Vol 01.06.

Annual Book of ASTM Standards, Vol 01.04.

Annual Book of ASTM Standards, Vol 15.08.

Annual Book of ASTM Standards, Vol 02.02.

1 8

This specification is under the jurisdiction of ASTM Committee F-25 on Annual Book of ASTM Standards, Vol 02.01.

Shipbuilding and is the direct responsibility of Subcommittee F25.13 on Piping Annual Book of ASTM Standards, Vol 02.05.

Systems. Annual Book of ASTM Standards, Vol 09.01.

Current edition approved Aug. 15, 1995. Published October 1995. Originally Available from American National Standards Institute, 11 West 42nd Street,

published as F 1476 – 93. Last previous edition F 1476 – 95. 13th Floor, New York, NY 10036.

2 12

Annual Book of ASTM Standards, Vol 01.02. Available from National Fire Protection Association, Batterymarch Park,

Annual Book of ASTM Standards, Vol 01.01. Quincy, MA 02269.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1476

2.4 Military Standards:

MIL-STD-105—Sampling Procedures and Tables for In-

spection by Attributes

MIL-STD-45662—Calibration Systems Requirements

MIL-A-8625—Anodic Coatings, For Aluminum and Alu-

minum Alloys

MIL-T-704—Treatment and Painting of Material

2.5 British Standards:

BS 1706 Method for Specifying Electro Plated Coatings of

Zinc and Cadmium on Iron and Steel

BS 2494 Specification for Elastomeric Seals for Joints in

Pipework and Pipelines

BS 5781 (IEC 550) Measurement and Calibration Sys-

tems

BS 6104 Mechanical Properties of Fasteners

BS 6105 (ISO 3506) Corrosion Resistant Stainless Steel

Fasteners

3. Terminology

3.1 Definitions:

FIG. 1 Type I Typical Construction

3.1.1 class—differentiates joint characteristics such as rigid,

flexible, restrained and unrestrained.

3.1.7.1 grooved mechanical coupling housing—the struc-

3.1.2 failure—any leakage or joint separation, unless other-

tural parts of a grooved mechanical coupling which mechani-

wise determined to be due to a pipe or fitting defect.

cally fit into pipe or fitting grooves providing mechanical pipe

3.1.3 fitting—a device used to change pipe direction, size or

or fitting restraint and enclosure of the gasket.

adapt to other joining methods. This device is used with pipe or

3.1.8 plain end mechanical coupling:

other fittings to create a working system. Shapes such as

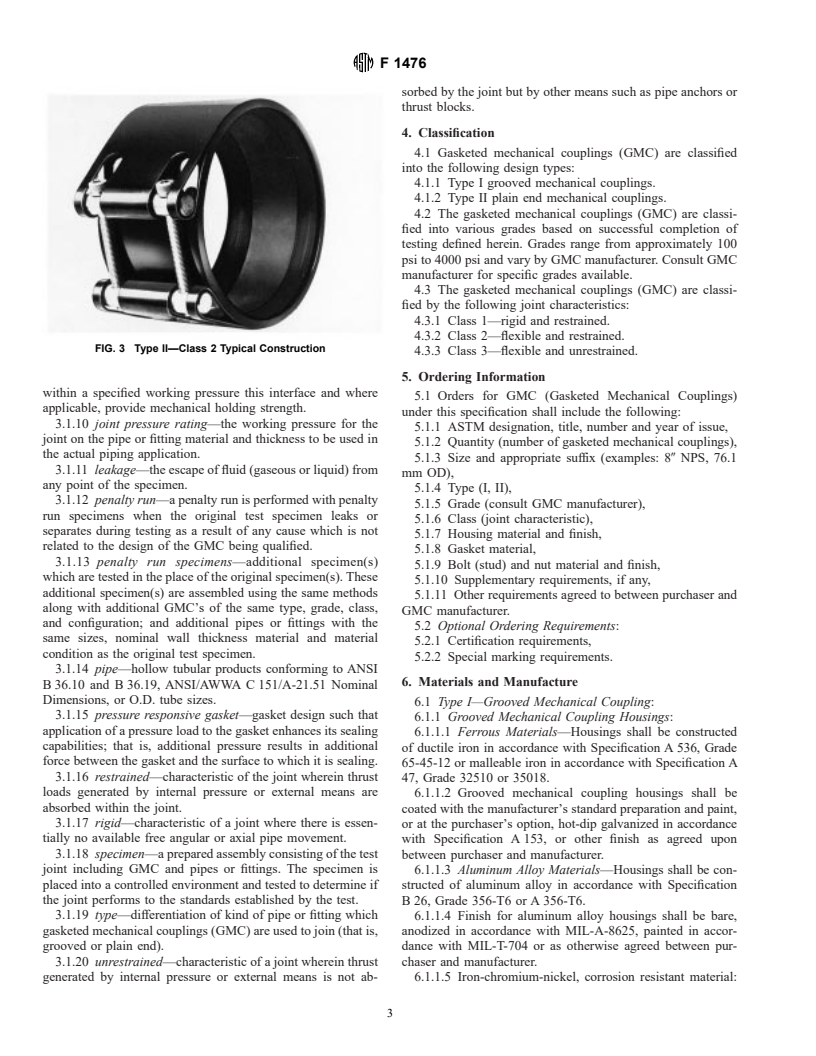

3.1.8.1 (Type II—Classes 1 and 2)—Device consisting of

elbows, tees, crosses, reducers and special shapes are used as

gasket(s), housing(s), sleeve(s), end rings, threaded fasteners,

needed to fulfill system design specifications.

pipe or fitting anchoring (gripping) features and seal retainers

3.1.4 flexible—characteristic of a joint wherein there is

as applicable. These devices are used to create a seal and

available limited angular and axial pipe movement.

restrain plain end pipe or fittings. See Fig. 2 and Fig. 3.

3.1.5 gasketed mechanical coupling (GMC)—a device used

3.1.8.2 (Type II—Class 3)—Device consisting of gasket(s),

to join pipe to pipe, pipe to fitting, or fitting to fitting wherein

housing(s), sleeve, end rings and threaded fasteners as appli-

an elastomeric (gasket) is used to seal the joint. Coupling may

cable. Tightening of the fasteners compresses the gasket(s),

or may not provide mechanical restraint of the pipe or fitting.

creating a seal on the outside of the plain end pipe. See Fig. 4.

3.1.6 grade—the joint working pressure as established by

3.1.9 joint—interface formed between pipe and pipe, pipe

tests using representative pipe or tube and the gasketed

and fitting, or fitting and fitting where a GMC is used to seal

mechanical coupling (GMC). Test pipe or tube shall be:

NPS—Standard Weight Steel Pipe per ANSI B 36.10 and

Specification A 53 Grade B, or Specification A 135 Grade B.

AWWA—Class 53 Ductile Iron Pipe per ANSI/AWWA

C 151/A-21.51 for 39–169. For other sizes, consult manufac-

turer.

Tubing—Type K Copper Tube per Specification B 88.

Other—As agreed to by GMC manufacturer and purchaser.

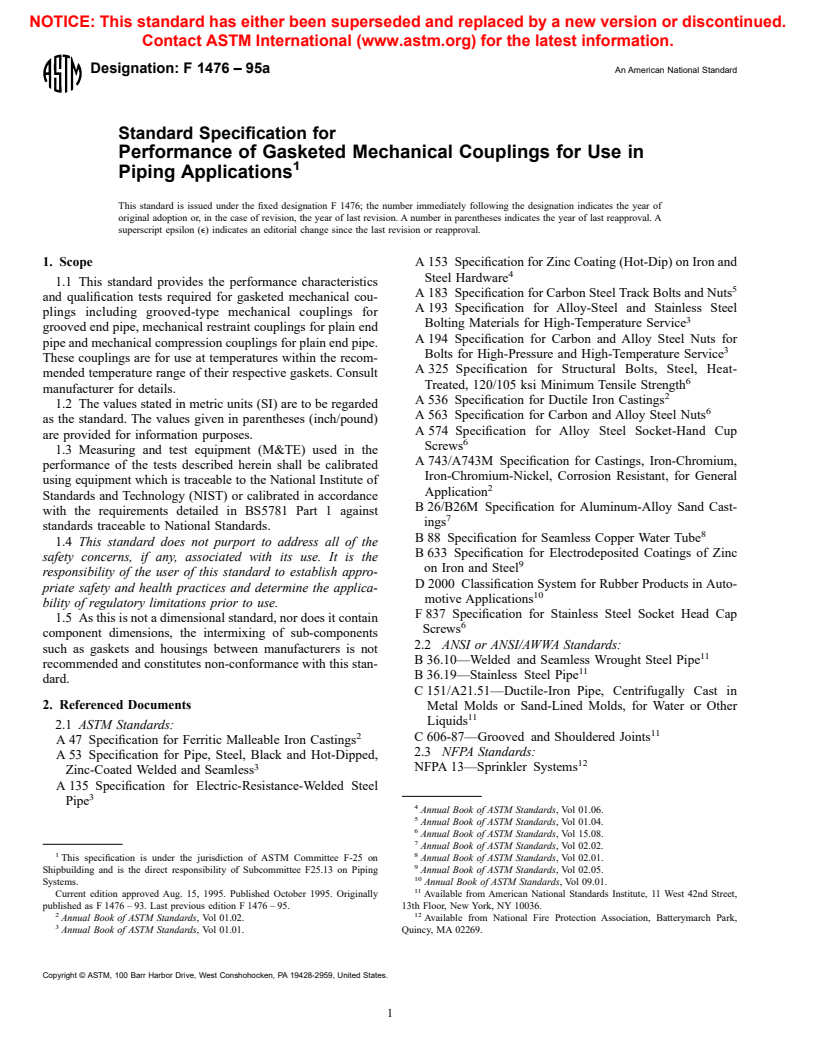

3.1.7 grooved mechanical coupling (Type I)—a device

which consists of two or more housings, closure members such

as sets of bolts and nuts or pins, and a pressure-responsive

gasket. It is used to mechanically join and seal grooved pipe or

fitting, forming a joint. Grooves conform to ANSI/AWWA

Standard C 606 as applicable. Groove dimensions for tubing

and other sizes and types of pipes shall be as specified by the

manufacturer. See Fig. 1.

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094. Attn: NPODS.

Available from British Standards Institute, 2 Park Street, London, England

W 1A2B5. FIG. 2 Type II—Class 1 Typical Construction

F 1476

sorbed by the joint but by other means such as pipe anchors or

thrust blocks.

4. Classification

4.1 Gasketed mechanical couplings (GMC) are classified

into the following design types:

4.1.1 Type I grooved mechanical couplings.

4.1.2 Type II plain end mechanical couplings.

4.2 The gasketed mechanical couplings (GMC) are classi-

fied into various grades based on successful completion of

testing defined herein. Grades range from approximately 100

psi to 4000 psi and vary by GMC manufacturer. Consult GMC

manufacturer for specific grades available.

4.3 The gasketed mechanical couplings (GMC) are classi-

fied by the following joint characteristics:

4.3.1 Class 1—rigid and restrained.

4.3.2 Class 2—flexible and restrained.

FIG. 3 Type II—Class 2 Typical Construction

4.3.3 Class 3—flexible and unrestrained.

5. Ordering Information

within a specified working pressure this interface and where

5.1 Orders for GMC (Gasketed Mechanical Couplings)

applicable, provide mechanical holding strength.

under this specification shall include the following:

3.1.10 joint pressure rating—the working pressure for the

5.1.1 ASTM designation, title, number and year of issue,

joint on the pipe or fitting material and thickness to be used in

5.1.2 Quantity (number of gasketed mechanical couplings),

the actual piping application.

5.1.3 Size and appropriate suffix (examples: 89 NPS, 76.1

3.1.11 leakage—the escape of fluid (gaseous or liquid) from

mm OD),

any point of the specimen.

5.1.4 Type (I, II),

3.1.12 penalty run—a penalty run is performed with penalty

5.1.5 Grade (consult GMC manufacturer),

run specimens when the original test specimen leaks or

5.1.6 Class (joint characteristic),

separates during testing as a result of any cause which is not

5.1.7 Housing material and finish,

related to the design of the GMC being qualified.

5.1.8 Gasket material,

3.1.13 penalty run specimens—additional specimen(s)

5.1.9 Bolt (stud) and nut material and finish,

which are tested in the place of the original specimen(s). These

5.1.10 Supplementary requirements, if any,

additional specimen(s) are assembled using the same methods

5.1.11 Other requirements agreed to between purchaser and

along with additional GMC’s of the same type, grade, class,

GMC manufacturer.

and configuration; and additional pipes or fittings with the

5.2 Optional Ordering Requirements:

same sizes, nominal wall thickness material and material

5.2.1 Certification requirements,

condition as the original test specimen.

5.2.2 Special marking requirements.

3.1.14 pipe—hollow tubular products conforming to ANSI

6. Materials and Manufacture

B 36.10 and B 36.19, ANSI/AWWA C 151/A-21.51 Nominal

Dimensions, or O.D. tube sizes.

6.1 Type I—Grooved Mechanical Coupling:

3.1.15 pressure responsive gasket—gasket design such that

6.1.1 Grooved Mechanical Coupling Housings:

application of a pressure load to the gasket enhances its sealing

6.1.1.1 Ferrous Materials—Housings shall be constructed

capabilities; that is, additional pressure results in additional

of ductile iron in accordance with Specification A 536, Grade

force between the gasket and the surface to which it is sealing.

65-45-12 or malleable iron in accordance with Specification A

3.1.16 restrained—characteristic of the joint wherein thrust

47, Grade 32510 or 35018.

loads generated by internal pressure or external means are

6.1.1.2 Grooved mechanical coupling housings shall be

absorbed within the joint.

coated with the manufacturer’s standard preparation and paint,

3.1.17 rigid—characteristic of a joint where there is essen-

or at the purchaser’s option, hot-dip galvanized in accordance

tially no available free angular or axial pipe movement.

with Specification A 153, or other finish as agreed upon

3.1.18 specimen—a prepared assembly consisting of the test

between purchaser and manufacturer.

joint including GMC and pipes or fittings. The specimen is

6.1.1.3 Aluminum Alloy Materials—Housings shall be con-

placed into a controlled environment and tested to determine if structed of aluminum alloy in accordance with Specification

the joint performs to the standards established by the test.

B 26, Grade 356-T6 or A 356-T6.

3.1.19 type—differentiation of kind of pipe or fitting which 6.1.1.4 Finish for aluminum alloy housings shall be bare,

gasketed mechanical couplings (GMC) are used to join (that is, anodized in accordance with MIL-A-8625, painted in accor-

grooved or plain end). dance with MIL-T-704 or as otherwise agreed between pur-

3.1.20 unrestrained—characteristic of a joint wherein thrust chaser and manufacturer.

generated by internal pressure or external means is not ab- 6.1.1.5 Iron-chromium-nickel, corrosion resistant material:

F 1476

FIG. 4 Type II—Class 3 Typical Construction

Housings shall be constructed of iron-chromium-nickel alloy in 6.2.2 Plain End Mechanical Coupling—Gaskets shall be of

accordance with Specification A 743/A 743M, Grade CF-8 or materials suitable for the intended service (consult manufac-

Grade CF-8M. turer for recommendation). Elastomer shall comply with Clas-

6.1.1.6 Finish for iron-chromium-nickel shall be bare or sification System D 2000 or BS 2494.

otherwise agreed between purchaser and manufacturer. 6.2.3 Plain End Mechanical Coupling—Bolting:

6.1.2 Grooved Mechanical Coupling—Gaskets shall be of 6.2.3.1 Carbon Steel Material—Bolts shall be in accor-

materials suitable for the intended service. Elastomers shall dance with Specification A 183, Grade 2, Oval Neck or

comply with Classification System D 2000. Specification A 325—Type 2 Heavy Hex; Cap screws shall be

6.1.3 Grooved Mechanical Coupling—Bolting: in accordance with Specification A 574 or BS 6104; Female

6.1.3.1 Carbon Steel Material—Bolts shall be in accor- threaded parts, other than nuts, shall be in accordance with

dance with Specification A 183, Grade 2, Oval Neck. Nuts Specification A 183, Grade 2; Nuts, if required, shall conform

shall be in accordance with Specification A 194, Grade 2. to Specification A 183, Grade 2 or Specification A 563—Grade

Finish shall be black or at the purchaser’s option, zinc C or DH , or as otherwise agreed by purchaser and manufac-

3 3

electroplated to Specification B 633. turer. Finish shall be zinc electroplated to Specification B 633

6.1.3.2 Corrosion Resistant Material—Bolts shall be in or BS 1706.

accordance wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.