ASTM E289-04(2016)

(Test Method)Standard Test Method for Linear Thermal Expansion of Rigid Solids with Interferometry

Standard Test Method for Linear Thermal Expansion of Rigid Solids with Interferometry

SIGNIFICANCE AND USE

5.1 Coefficients of linear expansion are required for design purposes and are used particularly to determine thermal stresses that can occur when a solid artifact composed of different materials may fail when it is subjected to a temperature excursion(s).

5.2 Many new composites are being produced that have very low thermal expansion coefficients for use in applications where very precise and critical alignment of components is necessary. Push rod dilatometry such as Test Methods D696, E228, and TMA methods such as Test Methods E831 are not sufficiently precise for reliable measurements either on such material and systems, or on very short specimens of materials having higher coefficients.

5.3 The precision of the absolute method allows for its use to:

5.3.1 Measure very small changes in length;

5.3.2 Develop reference materials and transfer standards for calibration of other less precise techniques;

5.3.3 Measure and compare precisely the differences in coefficient of “matched” materials.

5.4 The precise measurement of thermal expansion involves two parameters; change of length and change of temperature. Since precise measurements of the first parameter can be made by this test method, it is essential that great attention is also paid to the second, in order to ensure that calculated expansion coefficients are based on the required temperature difference. Thus in order to ensure the necessary uniformity in temperature of the specimen, it is essential that the uniform temperature zone of the surrounding furnace or environmental chamber shall be made significantly longer than the combined length of specimen and mirrors.

5.5 This test method contains essential details of the design principles, specimen configurations, and procedures to provide precise values of thermal expansion. It is not practical in a method of this type to try to establish specific details of design, construction, and procedures to cover all contingencies that might present di...

SCOPE

1.1 This test method covers the determination of linear thermal expansion of rigid solids using either a Michelson or Fizeau interferometer.

1.2 For this purpose, a rigid solid is defined as a material which, at test temperature and under the stresses imposed by instrumentation, has a negligible creep, insofar as significantly affecting the precision of thermal length change measurements.

1.3 It is recognized that many rigid solids require detailed preconditioning and specific thermal test schedules for correct evaluation of linear thermal expansion behavior for certain material applications. Since a general method of test cannot cover all specific requirements, details of this nature should be discussed in the particular material specifications.

1.4 This test method is applicable to the approximate temperature range −150 to 700°C. The temperature range may be extended depending on the instrumentation and calibration materials used.

1.5 The precision of measurement of this absolute method (better than ±40 nm/(m·K)) is significantly higher than that of comparative methods such as push rod dilatometry (for example, Test Methods D696 and E228) and thermomechanical analysis (for example, Test Method E831) techniques. It is applicable to materials having low and either positive or negative coefficients of expansion (below 5 μm/(m·K)) and where only very limited lengths or thickness of other higher expansion coefficient materials are available.

1.6 Computer or electronic based instrumentation, techniques and data analysis systems equivalent to this test method can be used. Users of the test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user to determine the necessary equivalency prior to use.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This sta...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E289 −04 (Reapproved 2016)

Standard Test Method for

Linear Thermal Expansion of Rigid Solids with

Interferometry

This standard is issued under the fixed designation E289; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This test method covers the determination of linear

standard.

thermal expansion of rigid solids using either a Michelson or

Fizeau interferometer.

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.2 For this purpose, a rigid solid is defined as a material

responsibility of the user of this standard to establish appro-

which, at test temperature and under the stresses imposed by

priate safety and health practices and determine the applica-

instrumentation, has a negligible creep, insofar as significantly

bility of regulatory limitations prior to use.

affectingtheprecisionofthermallengthchangemeasurements.

1.3 It is recognized that many rigid solids require detailed

2. Referenced Documents

preconditioning and specific thermal test schedules for correct

2.1 ASTM Standards:

evaluation of linear thermal expansion behavior for certain

D696TestMethodforCoefficientofLinearThermalExpan-

material applications. Since a general method of test cannot

sion of Plastics Between −30°C and 30°C with a Vitreous

cover all specific requirements, details of this nature should be

Silica Dilatometer

discussed in the particular material specifications.

E220Test Method for Calibration of Thermocouples By

1.4 This test method is applicable to the approximate

Comparison Techniques

temperature range −150 to 700°C. The temperature range may

E228Test Method for Linear Thermal Expansion of Solid

be extended depending on the instrumentation and calibration

Materials With a Push-Rod Dilatometer

materials used.

E473Terminology Relating to Thermal Analysis and Rhe-

1.5 The precision of measurement of this absolute method

ology

(better than 640 nm/(m·K)) is significantly higher than that of

E831Test Method for Linear Thermal Expansion of Solid

comparative methods such as push rod dilatometry (for

Materials by Thermomechanical Analysis

example, Test Methods D696 and E228) and thermomechani-

E1142Terminology Relating to Thermophysical Properties

cal analysis (for example, Test Method E831) techniques. It is

applicable to materials having low and either positive or

3. Terminology

negative coefficients of expansion (below 5 µm/(m·K)) and

3.1 Definitions:

where only very limited lengths or thickness of other higher

3.1.1 The following terms are applicable to this document

expansion coefficient materials are available.

and are listed in Terminology E473 and E1142: coeffıcient of

1.6 Computer or electronic based instrumentation, tech-

linear thermal expansion, thermodilatometry, and thermome-

niquesanddataanalysissystemsequivalenttothistestmethod

chanical analysis.

canbeused.Usersofthetestmethodareexpresslyadvisedthat

3.2 Definitions of Terms Specific to This Standard:

all such instruments or techniques may not be equivalent. It is

3.2.1 mean coeffıcient of linear thermal expansion, α —the

m

the responsibility of the user to determine the necessary

average change in length relative to the length of the specimen

equivalency prior to use.

accompanying a change in temperature between temperatures

T and T , expressed as follows:

1 2

This test method is under jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.05 on Thermo-

physical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2016. Published September 2016. Originally contact ASTM Customer service at service@astm.org. For Annual Book of ASTM

approved in 1965. Last previous edition approved in 2010 as E289–04 (2010). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0289-04R16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E289−04 (2016)

1 L 2 L 1 ∆L

2 1

αm 5 · 5 · (1)

L T 2 T L ∆T

0 2 1 o

where α is obtained by dividing the linear thermal expan-

m

sion (∆L/L ) by the change of temperature (∆T). It is nor-

mally expressed as µm/m·K. Dimensions (L) are normally

expressed in mm and wavelength (λ)innm.

3.2.2 thermal expansivity, α —at temperature T, is calcu-

T

lated as follows from slope of length v temperature curve:

1 L 2 L 1 dL

2 1

limit

α 5 5 withT ,T ,T (2)

T T →T 1 i 2

2 1

L T 2 T L dT

i 2 1 i

and expressed as µm/m·K.

3.2.2.1 Discussion—Thermal expansivity is sometimes re-

ferred to as instantaneous coefficient of linear expansion.

3.3 Symbols:

α = mean coefficient of linear thermal expansion, see

m

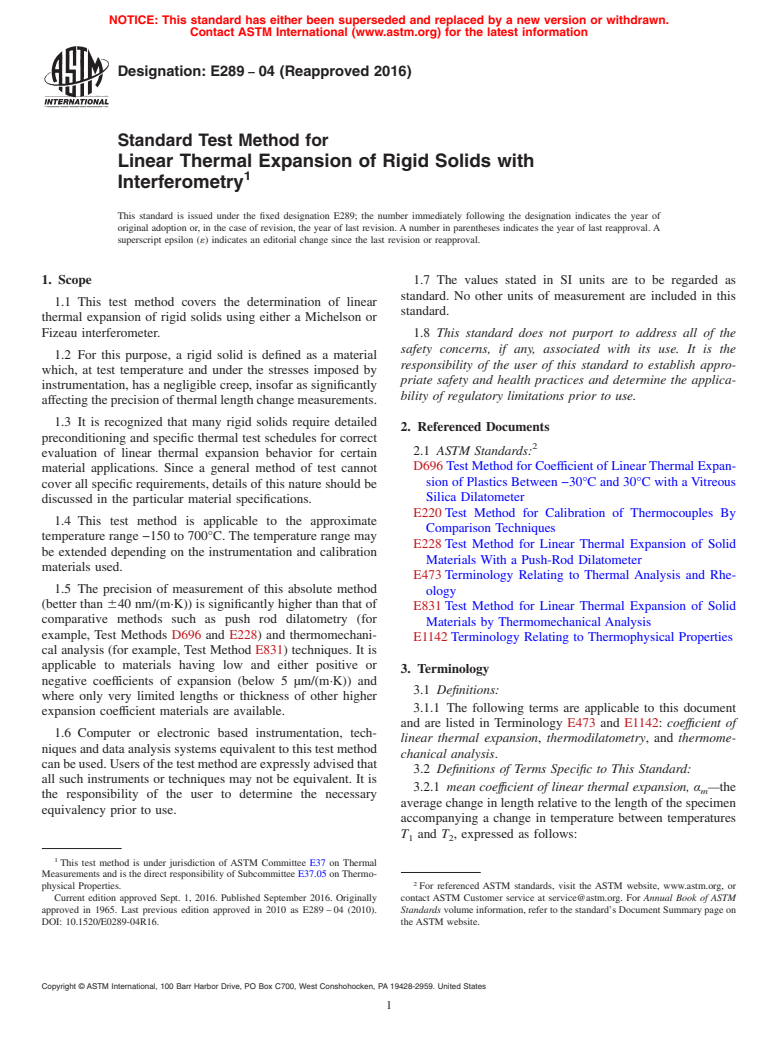

FIG. 1 Typical Specimen Configurations (a) Michelson Type,

3.2.2,/K

(b–d) Fizeau Type

α = expansivity at temperature T, see 3.2.1,/ K

T

L = original length of specimen at temperature T,mm

0 0

length change from which the expansion and expansion coef-

L = length at temperature T,mm

1 1 3

ficient can be determined (1-5).

L = length at temperature T,mm

2 2

∆L = change in length of specimen between tempera-

5. Significance and Use

tures T and T,nm

1 2

5.1 Coefficients of linear expansion are required for design

∆L = change in length of reference specimen between T

s 1

purposes and are used particularly to determine thermal

and T,mm

stresses that can occur when a solid artifact composed of

N = numberoffringesincludingfractionalpartsthatare

different materials may fail when it is subjected to a tempera-

measured on changing temperature from T to T

1 2

ture excursion(s).

n = index of refraction of gas at temperature T and

pressure, P

5.2 Many new composites are being produced that have

n = index of refraction of gas at reference condition of

r

very low thermal expansion coefficients for use in applications

temperature 288K and pressure of 100 kPa

where very precise and critical alignment of components is

n,n = index of refractive of gas at temperature T and T ,

1 2 1 2

necessary. Push rod dilatometry such as Test Methods D696,

and pressure, P

E228, and TMA methods such as Test Methods E831 are not

P = average pressure of gas during test, torr

sufficiently precise for reliable measurements either on such

T = temperature at which initial length is L , K

0 0

material and systems, or on very short specimens of materials

T,T = twotemperaturesatwhichmeasurementsaremade,

1 2

having higher coefficients.

K

∆T = temperature difference between T and T , K 5.3 The precision of the absolute method allows for its use

2 1

λ = wavelength of light used to produce fringes, nm

to:

v

5.3.1 Measure very small changes in length;

4. Summary of Test Method

5.3.2 Developreferencematerialsandtransferstandardsfor

calibration of other less precise techniques;

4.1 A specimen of known geometry can be given polished

5.3.3 Measure and compare precisely the differences in

reflective ends or placed between two flat reflecting surfaces

coefficient of “matched” materials.

(mirrors). Typical configurations, as shown in Fig. 1, are a

5.4 Theprecisemeasurementofthermalexpansioninvolves

cylindricaltubeorarodwithhemisphericalorflatparallelends

two parameters; change of length and change of temperature.

or machined to provide a 3-point support. The mirrors consist

Sinceprecisemeasurementsofthefirstparametercanbemade

of flat-uniform thickness pieces of silica or sapphire with the

by this test method, it is essential that great attention is also

surfaces partially coated with gold or other high reflectance

paidtothesecond,inordertoensurethatcalculatedexpansion

metal. Light, either parallel laser beam (Michelson, see Fig. 2

coefficients are based on the required temperature difference.

and Fig. 3) or from a point monochromatic source (Fizeau, see

Thusinordertoensurethenecessaryuniformityintemperature

Fig. 4) illuminates each surface simultaneously to produce a

of the specimen, it is essential that the uniform temperature

fringe pattern.As the specimen is heated or cooled, expansion

or contraction of the specimen causes a change in the fringe

pattern due to the optical pathlength difference between the

The boldface numbers in parentheses refer to a list of references at the end of

reflecting surfaces. This change is detected and converted into this standard.

E289−04 (2016)

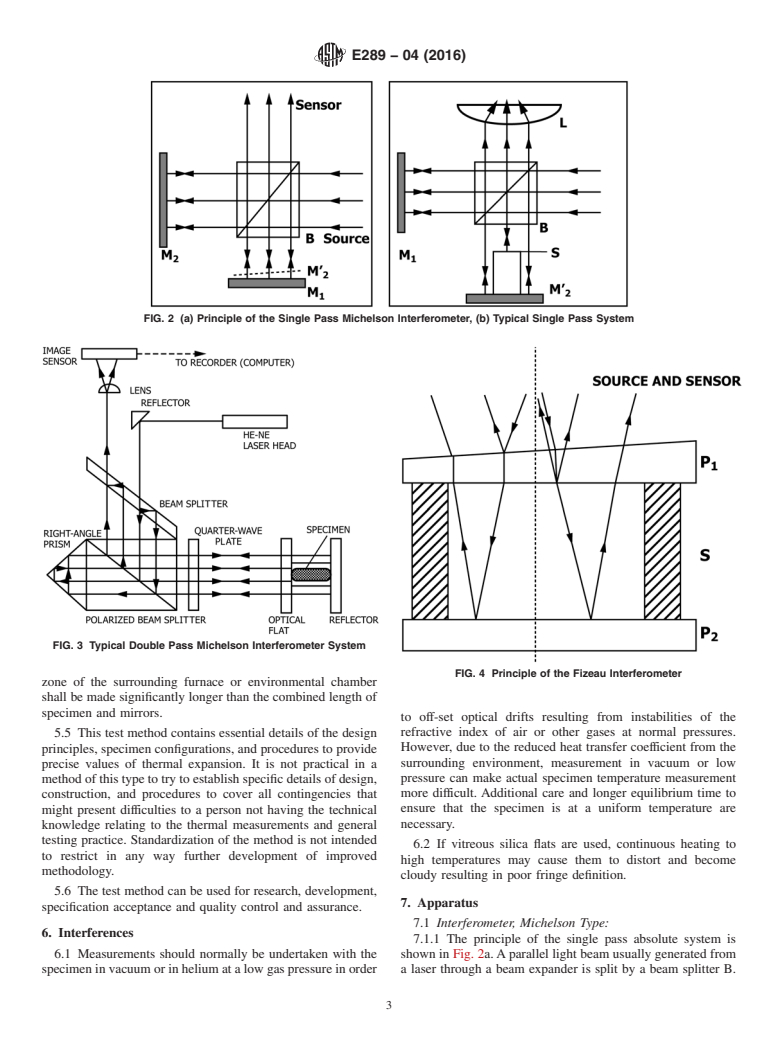

FIG. 2 (a) Principle of the Single Pass Michelson Interferometer, (b) Typical Single Pass System

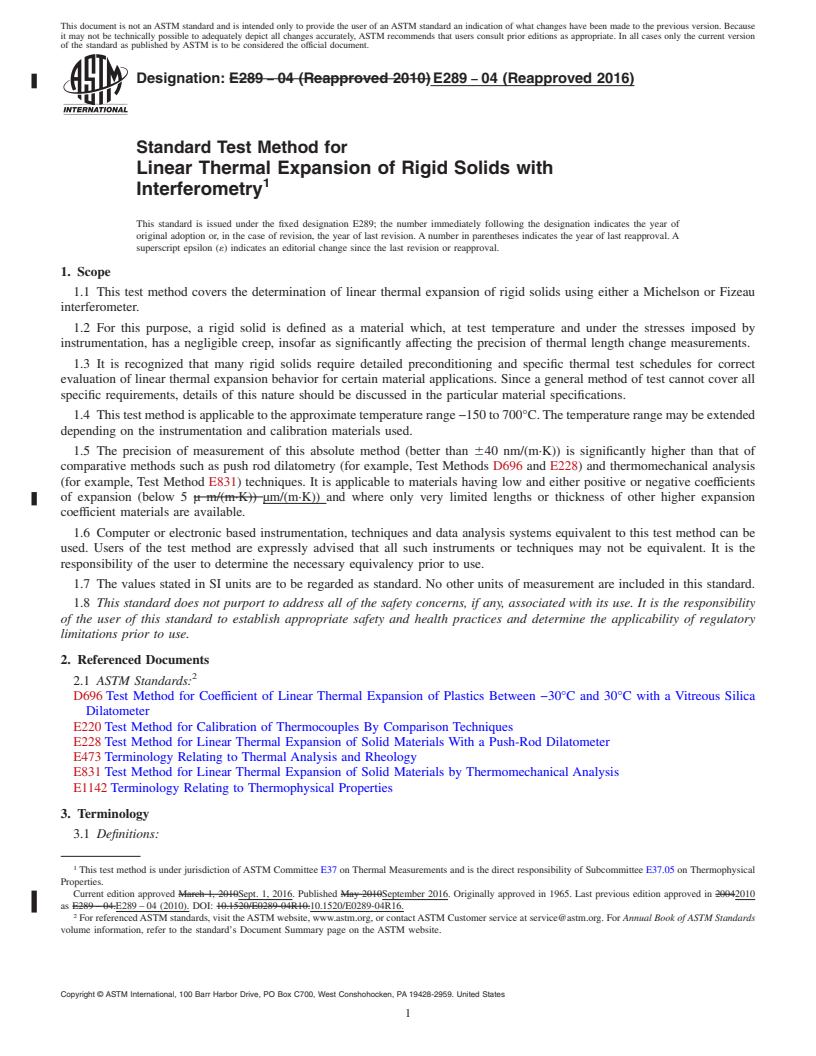

FIG. 3 Typical Double Pass Michelson Interferometer System

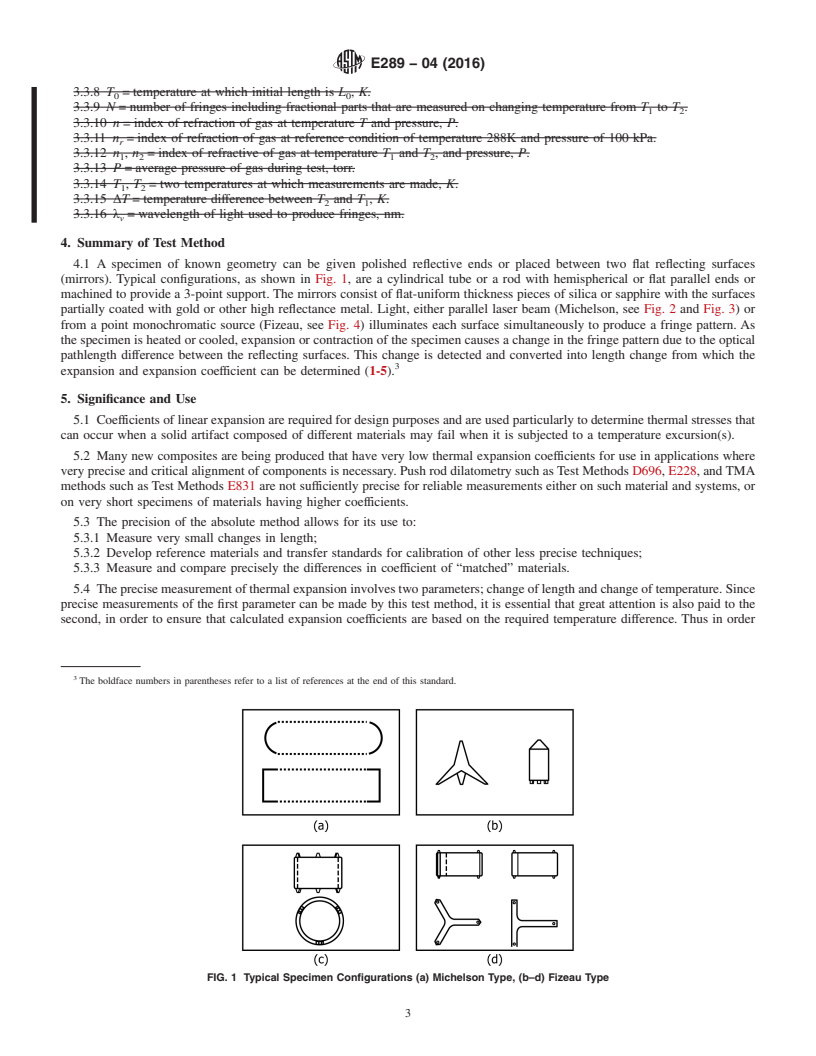

FIG. 4 Principle of the Fizeau Interferometer

zone of the surrounding furnace or environmental chamber

shall be made significantly longer than the combined length of

specimen and mirrors.

to off-set optical drifts resulting from instabilities of the

refractive index of air or other gases at normal pressures.

5.5 This test method contains essential details of the design

However, due to the reduced heat transfer coefficient from the

principles, specimen configurations, and procedures to provide

surrounding environment, measurement in vacuum or low

precise values of thermal expansion. It is not practical in a

methodofthistypetotrytoestablishspecificdetailsofdesign, pressure can make actual specimen temperature measurement

more difficult. Additional care and longer equilibrium time to

construction, and procedures to cover all contingencies that

might present difficulties to a person not having the technical ensure that the specimen is at a uniform temperature are

necessary.

knowledge relating to the thermal measurements and general

testing practice. Standardization of the method is not intended

6.2 If vitreous silica flats are used, continuous heating to

to restrict in any way further development of improved

high temperatures may cause them to distort and become

methodology.

cloudy resulting in poor fringe definition.

5.6 The test method can be used for research, development,

7. Apparatus

specification acceptance and quality control and assurance.

7.1 Interferometer, Michelson Type:

6. Interferences

7.1.1 The principle of the single pass absolute system is

6.1 Measurements should normally be undertaken with the shown in Fig. 2a.Aparallel light beam usually generated from

specimeninvacuumorinheliumatalowgaspressureinorder a laser through a beam expander is split by a beam splitter B.

E289−04 (2016)

The resulting beams are reflected by mirrors M and M and

1 2

recombinedonB.IfM' isinclinedslightlyoverthelight-beam

its mirror image M' forms a small angle with M producing

2 1

fringes of equal thickness located on the virtual face M' .

7.1.2 One example of a single contact type is shown in Fig.

2b.Aprism or a polished very flat faced cylindrical specimen

is placed on one mirror with one face also offered to the

incident light. An interference pattern is generated and this is

divided into two fields corresponding to each end of the

specimen.The lens, L, projects the image of the fringes onto a

plane where two detectors are placed one on the specimen and

the other on the baseplate fields.As the specimen is heated or

cooled,boththespecimenandsupportchangeoflengthscause

the surface S and M to move relative to M at different rates.

2 1

Thedifferenceinthefringecountprovidesameasureofthenet

absolute expansion.

7.1.3 The principle of the double pass system is essentially

similartothesinglepasswiththreeimportantdistinctions.The

specimen can be a relatively simple cylinder with hemispheri-

cal or flat ends and requiring less precise machining, the

interfering beams are reflected twice from each face to the

specimen thus giving twice the sensitivity of the single pass,

and no reference arm is required. One example of the double

FIG. 5 Typical Furnace

pass form is shown in Fig. 3.

7.1.4 It is common practice to use polarized laser light and

quarter wave plates to generate circularly polarized light. In

this way detectors combined with appropriate analyzers gen-

eratesignalseitherwithinformationonfringenumber,fraction

and motion sense for each beam or linear array data of light

intensity, which indicate the profile of the instantaneous whole

fringe pattern. The array data provides complete information

(position of fringe and distance between fringes) to determine

theabsolutelengthchangeofthespecimendependinguponthe

system. These signals are normally processed electronically.

7.2 Fizeau Type:

7.2.1 This type is available in both absolute and compara-

tive versions.

7.2.2 The principle of the absolute method is illustrated in

Fig. 4. The specimen is retained between two parallel plates

and illuminated by the point source. Expansion or contraction

ofthespecimencausesspatialvariationbetweentheplatesand

radial motion of the circular fringe pattern.

7.2.3 The difference in the fringe counts yields the net

absolute expansion of the specimen.

7.2.4 In practice, P is wedge shaped (less than 30 min of

arc) such that light reflected by the upper face is diverted from

the viewing field, while the lower face of P is made to absorb

FIG. 6 Typical Low-Temperature Cryostat

the incident light, depending upon the total separation of the

flats.

7.4 Temperature Measurement System:

7.2.5 For use in the comparative mode, two forms are

7.4.1 The temperature measurement system shall consist of

available. These are described in detailed in Annex A1.

a calibrated sensor or sensors together with manual, electronic

7.3 Furnace/Cryostat:

or equivalent read-out such that the indicated temperature can

7.3.1 Fig.5andFig.6illustratetheconstructionofatypical

be determined better than 60.5°C.

vertical type of furnace and cryostat that are suitable for use in

7.4.1.1 Since this method is used over a broad temperature

undertaking these measurements. For the double pass Michel-

range, different types of sensors may have to be used to cover

son system, horizontal forms of furnace and cryostat can be

the complete range. The common sensor(s) is a fine gage (32

used.

AWG or smaller wire) or thin foil thermocouples calibrated in

accordance with Test Method E220.

E289−04 (2016)

7.4.1.2 TypesEandTarerecommendedforthetemperature 9. Verification

range −190 to 350°C and Types K and S and Nicrosil for the

9.1 The Michelson and Fizeau interferometers determine

temperature range from 0 to 800°C. If Type

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E289 − 04 (Reapproved 2010) E289 − 04 (Reapproved 2016)

Standard Test Method for

Linear Thermal Expansion of Rigid Solids with

Interferometry

This standard is issued under the fixed designation E289; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of linear thermal expansion of rigid solids using either a Michelson or Fizeau

interferometer.

1.2 For this purpose, a rigid solid is defined as a material which, at test temperature and under the stresses imposed by

instrumentation, has a negligible creep, insofar as significantly affecting the precision of thermal length change measurements.

1.3 It is recognized that many rigid solids require detailed preconditioning and specific thermal test schedules for correct

evaluation of linear thermal expansion behavior for certain material applications. Since a general method of test cannot cover all

specific requirements, details of this nature should be discussed in the particular material specifications.

1.4 This test method is applicable to the approximate temperature range −150 to 700°C. The temperature range may be extended

depending on the instrumentation and calibration materials used.

1.5 The precision of measurement of this absolute method (better than 640 nm/(m·K)) is significantly higher than that of

comparative methods such as push rod dilatometry (for example, Test Methods D696 and E228) and thermomechanical analysis

(for example, Test Method E831) techniques. It is applicable to materials having low and either positive or negative coefficients

of expansion (below 5 μ m/(m·K)) μm/(m·K)) and where only very limited lengths or thickness of other higher expansion

coefficient materials are available.

1.6 Computer or electronic based instrumentation, techniques and data analysis systems equivalent to this test method can be

used. Users of the test method are expressly advised that all such instruments or techniques may not be equivalent. It is the

responsibility of the user to determine the necessary equivalency prior to use.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D696 Test Method for Coefficient of Linear Thermal Expansion of Plastics Between −30°C and 30°C with a Vitreous Silica

Dilatometer

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E228 Test Method for Linear Thermal Expansion of Solid Materials With a Push-Rod Dilatometer

E473 Terminology Relating to Thermal Analysis and Rheology

E831 Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

E1142 Terminology Relating to Thermophysical Properties

3. Terminology

3.1 Definitions:

This test method is under jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.05 on Thermophysical

Properties.

Current edition approved March 1, 2010Sept. 1, 2016. Published May 2010September 2016. Originally approved in 1965. Last previous edition approved in 20042010

as E289 – 04.E289 – 04 (2010). DOI: 10.1520/E0289-04R10.10.1520/E0289-04R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E289 − 04 (2016)

3.1.1 The following terms are applicable to this document and are listed in Terminology E473 and E1142: coeffıcient of linear

thermal expansion,thermodilatometry, thermodilatometry,and thermomechanical analysis.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 mean coeffıcient of linear thermal expansion, α , the average change in length relative to the length of the specimen

m

accompanying a change in temperature between temperatures T and T , expressed as follows:

1 2

1 L 2 L 1 ΔL

2 1

αm 5 · 5 · (1)

L T 2 T L ΔT

0 2 1 o

where:

α is obtained by dividing the linear thermal expansion (ΔL/L ) by the change of temperature (ΔT). It is normally expressed as

m 0

μm/m·K. Dimensions (L) are normally expressed in mm and wavelength (λ) in nm.

3.2.1 mean coeffıcient of linear thermal expansion, α —the average change in length relative to the length of the specimen

m

accompanying a change in temperature between temperatures T and T , expressed as follows:

1 2

1 L 2 L 1 ΔL

2 1

αm 5 · 5 · (1)

L T 2 T L ΔT

0 2 1 o

where α is obtained by dividing the linear thermal expansion (ΔL/L ) by the change of temperature (ΔT). It is normally

m 0

expressed as μm/m·K. Dimensions (L) are normally expressed in mm and wavelength (λ) in nm.

3.2.2 thermal expansivity, α , at temperature T, is calculated as follows from slope of length v temperature curve:

T

1 L 2 L 1 dL

2 1

limit

α 5 5 with T ,T ,T (2)

T T →T 1 i 2

2 1

L T 2 T L dT

i 2 1 i

and expressed as μm/m·K.

NOTE 1—Thermal expansivity is sometimes referred to as instantaneous coefficient of linear expansion.

3.2.2 thermal expansivity, α —at temperature T, is calculated as follows from slope of length v temperature curve:

T

1 L 2 L 1 dL

2 1

limit

α 5 5 with T ,T ,T (2)

T T →T 1 i 2

2 1

L T 2 T L dT

i 2 1 i

and expressed as μm/m·K.

3.2.2.1 Discussion—

Thermal expansivity is sometimes referred to as instantaneous coefficient of linear expansion.

3.3 Symbols:

3.3.1 α = mean coefficient of linear thermal expansion, see 3.2.2, /K .

m

α = mean coefficient of linear thermal expansion, see 3.2.2, /K

m

α = expansivity at temperature T, see 3.2.1, / K

T

L = original length of specimen at temperature T , mm

0 0

L = length at temperature T , mm

1 1

L = length at temperature T , mm

2 2

ΔL = change in length of specimen between temperatures T and T , nm

1 2

ΔL = change in length of reference specimen between T and T , mm

s 1 2

N = number of fringes including fractional parts that are measured on changing temperature from T to T

1 2

n = index of refraction of gas at temperature T and pressure, P

n = index of refraction of gas at reference condition of temperature 288K and pressure of 100 kPa

r

n , n = index of refractive of gas at temperature T and T , and pressure, P

1 2 1 2

P = average pressure of gas during test, torr

T = temperature at which initial length is L , K

0 0

T , T = two temperatures at which measurements are made, K

1 2

ΔT = temperature difference between T and T , K

2 1

λ = wavelength of light used to produce fringes, nm

v

3.3.2 α = expansivity at temperature T, see 3.2.1, / K .

T

3.3.3 L = original length of specimen at temperature T , mm.

0 0

3.3.4 L = length at temperature T , mm.

1 1

3.3.5 L = length at temperature T , mm.

2 2

3.3.6 ΔL = change in length of specimen between temperatures T and T , nm.

1 2

3.3.7 ΔL = change in length of reference specimen between T and T , mm.

s 1 2

E289 − 04 (2016)

3.3.8 T = temperature at which initial length is L , K.

0 0

3.3.9 N = number of fringes including fractional parts that are measured on changing temperature from T to T .

1 2

3.3.10 n = index of refraction of gas at temperature T and pressure, P.

3.3.11 n = index of refraction of gas at reference condition of temperature 288K and pressure of 100 kPa.

r

3.3.12 n , n = index of refractive of gas at temperature T and T , and pressure, P.

1 2 1 2

3.3.13 P = average pressure of gas during test, torr.

3.3.14 T , T = two temperatures at which measurements are made, K.

1 2

3.3.15 ΔT = temperature difference between T and T , K.

2 1

3.3.16 λ = wavelength of light used to produce fringes, nm.

v

4. Summary of Test Method

4.1 A specimen of known geometry can be given polished reflective ends or placed between two flat reflecting surfaces

(mirrors). Typical configurations, as shown in Fig. 1, are a cylindrical tube or a rod with hemispherical or flat parallel ends or

machined to provide a 3-point support. The mirrors consist of flat-uniform thickness pieces of silica or sapphire with the surfaces

partially coated with gold or other high reflectance metal. Light, either parallel laser beam (Michelson, see Fig. 2 and Fig. 3) or

from a point monochromatic source (Fizeau, see Fig. 4) illuminates each surface simultaneously to produce a fringe pattern. As

the specimen is heated or cooled, expansion or contraction of the specimen causes a change in the fringe pattern due to the optical

pathlength difference between the reflecting surfaces. This change is detected and converted into length change from which the

expansion and expansion coefficient can be determined (1-5).

5. Significance and Use

5.1 Coefficients of linear expansion are required for design purposes and are used particularly to determine thermal stresses that

can occur when a solid artifact composed of different materials may fail when it is subjected to a temperature excursion(s).

5.2 Many new composites are being produced that have very low thermal expansion coefficients for use in applications where

very precise and critical alignment of components is necessary. Push rod dilatometry such as Test Methods D696, E228, and TMA

methods such as Test Methods E831 are not sufficiently precise for reliable measurements either on such material and systems, or

on very short specimens of materials having higher coefficients.

5.3 The precision of the absolute method allows for its use to:

5.3.1 Measure very small changes in length;

5.3.2 Develop reference materials and transfer standards for calibration of other less precise techniques;

5.3.3 Measure and compare precisely the differences in coefficient of “matched” materials.

5.4 The precise measurement of thermal expansion involves two parameters; change of length and change of temperature. Since

precise measurements of the first parameter can be made by this test method, it is essential that great attention is also paid to the

second, in order to ensure that calculated expansion coefficients are based on the required temperature difference. Thus in order

The boldface numbers in parentheses refer to a list of references at the end of this standard.

FIG. 1 Typical Specimen Configurations (a) Michelson Type, (b–d) Fizeau Type

E289 − 04 (2016)

FIG. 2 (a) Principle of the Single Pass Michelson Interferometer, (b) Typical Single Pass System

FIG. 3 Typical Double Pass Michelson Interferometer System

to ensure the necessary uniformity in temperature of the specimen, it is essential that the uniform temperature zone of the

surrounding furnace or environmental chamber shall be made significantly longer than the combined length of specimen and

mirrors.

5.5 This test method contains essential details of the design principles, specimen configurations, and procedures to provide

precise values of thermal expansion. It is not practical in a method of this type to try to establish specific details of design,

construction, and procedures to cover all contingencies that might present difficulties to a person not having the technical

knowledge relating to the thermal measurements and general testing practice. Standardization of the method is not intended to

restrict in any way further development of improved methodology.

5.6 The test method can be used for research, development, specification acceptance and quality control and assurance.

6. Interferences

6.1 Measurements should normally be undertaken with the specimen in vacuum or in helium at a low gas pressure in order to

off-set optical drifts resulting from instabilities of the refractive index of air or other gases at normal pressures. However, due to

the reduced heat transfer coefficient from the surrounding environment, measurement in vacuum or low pressure can make actual

specimen temperature measurement more difficult. Additional care and longer equilibrium time to ensure that the specimen is at

a uniform temperature are necessary.

6.2 If vitreous silica flats are used, continuous heating to high temperatures may cause them to distort and become cloudy

resulting in poor fringe definition.

E289 − 04 (2016)

FIG. 4 Principle of the Fizeau Interferometer

7. Apparatus

7.1 Interferometer, Michelson Type:

7.1.1 The principle of the single pass absolute system is shown in Fig. 2a. A parallel light beam usually generated from a laser

through a beam expander is split by a beam splitter B. The resulting beams are reflected by mirrors M and M and recombined

1 2

on B. If M' is inclined slightly over the light-beam its mirror image M' forms a small angle with M producing fringes of equal

2 2 1

thickness located on the virtual face M' .

7.1.2 One example of a single contact type is shown in Fig. 2b. A prism or a polished very flat faced cylindrical specimen is

placed on one mirror with one face also offered to the incident light. An interference pattern is generated and this is divided into

two fields corresponding to each end of the specimen. The lens, L, projects the image of the fringes onto a plane where two

detectors are placed one on the specimen and the other on the baseplate fields. As the specimen is heated or cooled, both the

specimen and support change of lengths cause the surface S and M to move relative to M at different rates. The difference in

2 1

the fringe count provides a measure of the net absolute expansion.

7.1.3 The principle of the double pass system is essentially similar to the single pass with three important distinctions. The

specimen can be a relatively simple cylinder with hemispherical or flat ends and requiring less precise machining, the interfering

beams are reflected twice from each face to the specimen thus giving twice the sensitivity of the single pass, and no reference arm

is required. One example of the double pass form is shown in Fig. 3.

7.1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.