ASTM E831-00

(Test Method)Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

SCOPE

1.1 This test method covers determination of linear thermal expansion of solid materials using thermomechanical analysis techniques.

1.2 This test method is applicable to solid materials that exhibit sufficient rigidity over the test temperature range such that the sensing probe does not produce indentation of the specimen.

1.3 The lower limit of coefficient of linear thermal expansion measured with this test method is 5 [mu]m/(m[dot]°C). The test method may be used at lower (or negative) expansion levels with decreased accuracy and precision (see Section 11).

1.4 This test method is applicable to the temperature range from -120°C to 600°C. The temperature range may be extended depending upon the instrumentation and calibration materials used.

1.5 Computer or electronic based instruments, techniques, or data treatment equivalent to this test method may also be used. Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user to determine the necessary equivalency prior to use. In the case of dispute, only the manual procedures described in this test method are to be considered valid.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 831 – 00

Standard Test Method for

Linear Thermal Expansion of Solid Materials by

Thermomechanical Analysis

This standard is issued under the fixed designation E 831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Expansion of Electrical Insulating Materials

E 228 Test Method for Linear Thermal Expansion of Solid

1.1 This test method covers determination of linear thermal

Materials with a Vitreous Silica Dilatometer

expansion of solid materials using thermomechanical analysis

E 473 Terminology Relating to Thermal Analysis

techniques. Related information can be found in Refs. (1-2) .

E 1142 Terminology Relating to Thermophysical Proper-

1.2 This test method is applicable to solid materials that

ties

exhibit sufficient rigidity over the test temperature range such

E 1363 Test Method for Temperature Calibration of Ther-

that the sensing probe does not produce indentation of the

momechanical Analyzers

specimen.

2.2 ISO Standards:

1.3 The lower limit of coefficient of linear thermal expan-

ISO 11359-2 Plastics—Thermomechanical Analysis

sion measured with this test method is 5 μm/(m·°C). The test

(TMA)—Part 2: Determination of Coefficient of Linear

method may be used at lower (or negative) expansion levels

Thermal Expansion and Glass Transition Temperature

with decreased accuracy and precision (see Section 11).

1.4 This test method is applicable to the temperature range

3. Terminology

from −120 to 600°C. The temperature range may be extended

3.1 Definitions—Thermal analysis terms in Terminologies

depending upon the instrumentation and calibration materials

E 473 and E 1142 shall apply to this test method.

used.

1.5 Computer or electronic based instruments, techniques,

4. Summary of Test Method

or data treatment equivalent to this test method may also be

4.1 This test method uses a thermomechanical analyzer or

used.

similar device to determine the linear thermal expansion of

NOTE 1—Users of this test method are expressly advised that all such

solid materials when subjected to a constant heating rate.

instruments or techniques may not be equivalent. It is the responsibility of

4.2 The change of the specimen length is electronically

the user to determine the necessary equivalency prior to use.

recorded as a function of temperature. The coefficient of linear

1.6 SI values are the standard.

thermal expansion can be calculated from these recorded data.

1.7 This test method is related to ISO 11359-2 but is

5. Significance and Use

significantly different in technical detail.

1.8 This standard does not purport to address all of the

5.1 Coefficients of linear thermal expansion are used, for

safety problems, if any, associated with its use. It is the

example, for design purposes and to determine if failure by

responsibility of the user of this standard to establish appro-

thermal stress may occur when a solid body composed of two

priate safety and health practices and determine the applica-

different materials is subjected to temperature variations.

bility of regulatory limitations prior to use.

5.2 This test method is comparable to Test Method D 3386

for testing electrical insulation materials, but it covers a more

2. Referenced Documents

general group of solid materials and it defines test conditions

2.1 ASTM Standards:

more specifically. This test method uses a smaller specimen

D 696 Test Method for Coefficient of Linear Thermal Ex-

than Test Methods E 228 and D 696.

pansion of Plastics Between − 30°C and 30°C

6. Apparatus

D 3386 Test Method for Coefficient of Linear Thermal

6.1 Thermomechanical Analyzers (TMA)—The essential in-

strumentation required providing minimum thermomechanical

This test method is under the jurisdiction of ASTM Committee E-37 on

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on

Test Methods and Recommended Practices.

Current edition approved March 10, 2000. Published June 2000. Originally

published as E 831 – 81. Last previous edition E 831 – 93. Annual Book of ASTM Standards, Vol 10.02.

2 5

The boldface numbers in parentheses refer to the list of references at the end of Annual Book of ASTM Standards, Vol 14.02.

this standard. Available from the American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 831

treatment to condition the specimen prior to test to relieve stresses or

analytical or thermodilatometric capability for this test method

distortions. Such heat treatment must be included in the report.

includes:

6.1.1 Rigid Specimen Holder, of inert, low expansivity

8. Calibration

material (# 0.5 μm/(m • K)) to center the specimen in the

8.1 Calibrate the temperature and length changes signals

furnace and to fix the specimen to mechanical ground.

according to the procedures in the manufacturer’s operation

6.1.2 Rigid Expansion Probe, of inert, low expansivity

manual.

material (#0.5 μm/(m • K)) that contacts the specimen with an

8.2 Calibrate the temperature signal using Test Method

applied compressive force.

E 1363.

6.1.3 Sensing Element, linear over a minimum range of 2

8.3 The length change measuring and recording system can

mm to measure the displacement of the rigid expansion probe

be calibrated by measuring the linear expansion of a material

to within 6 50 nm resulting from changes in length of the

having a known expansion when heated at the same rate as the

specimen.

test specimens. The observed expansion must be corrected for

6.1.4 Weight or Force Transducer, to generate a constant

the difference in expansion between the specimen holder and

force of 1 to 100 mN (0.1 to 10 g) that is applied through the

probe obtained from a blank run in which either no sample or

rigid expansion probe to the specimen.

a specimen of the material of construction of the probe is run

6.1.5 Furnace, capable of providing uniform controlled

(see 10.1).

heating (cooling) of a specimen to a constant temperature or at

8.4 The linear expansions of high-purity aluminum, com-

a constant rate between 2 and 10°C/min within the applicable

monly supplied by instrument manufacturers and useful as a

temperatures range of between –120 and 600°C.

working standard, are tabulated in Table 1 along with those for

6.1.6 Temperature Controller, capable of executing a spe-

platinum.

cific temperature program by operating the furnace between

selected temperature limits at a rate of temperature change of

9. Procedure

2 to 10°C/min constant to within 6 0.1°C/min or at an

9.1 Measure the initial specimen length in the direction of

isothermal temperature constant to 6 0.5°C.

the expansion test to 6 25 μm at 20 to 25°C.

6.1.7 Temperature Sensor, that can be attached to, in contact

with, or reproducibly positioned in close proximity to the

NOTE 5—Direct readout of zero position and specimen length using the

analyzer sensing element, where available, with a sufficient range has been

specimen to indicate the specimen/furnace temperature to 6

found to be an accurate means of length determination.

0.5°C.

6.1.8 A means of sustaining an environment around the

9.2 Place the specimen in the specimen holder under the

specimen of inert gas at a purge gas rate of 10 to 50 mL/min.

probe. Place the specimen temperature sensor in contact with

the specimen or as near to the specimen as possible.

NOTE 2—Typically, greater than 99 % pure nitrogen, argon, or helium

9.3 Move the furnace to enclose the specimen holder. If

is used when oxidation in air is a concern. Unless effects of moisture are

measurements at subambient temperature are to be made, cool

to be studied, use of dry purge gas is recommended and is essential for

operation at subambient temperatures.

the specimen to at least 20°C below the lowest temperature of

interest. The refrigerant used for cooling shall not come into

6.1.9 Recording Device, either digital or analog, capable of

direct contact with the specimen.

recording and displaying any fraction of the specimen dimen-

9.4 Apply an appropriate load force to the sensing probe to

sion signal (TMA curve), including signal noise, on the Y-axis

versus any fraction of the temperature signal, including noise,

A

TABLE 1 Expansion Coefficients

on the X-axis.

Aluminum Mean Coefficient Platinum Mean Coefficient

6.2 Cooling Capability, to sustain a subambient specimen

Of Linear Thermal Of Linear Thermal

temperature (if subambient measurements are to be made) or to Temperature,° C

Expansion, Expansion,

hasten cool down of the specimen from elevated temperatures.

μm/(m·°C) (3-7) μm/(m·°C) (8-10)

6.3 Micrometer, or other length-measuring device with a

range of up to 10 mm to determine specimen dimensions to 700 10.75

600 10.42

within 6 25 μm.

550 35.3

500 33.2 10.15

7. Test Specimens

450 31.8

7.1 Specimens shall be between 2 and 10 mm in length and

400 30.3 9.92

350 29.2

have flat and parallel ends to within 6 25 μm. Lateral

300 27.8 9.68

dimensions shall not exceed 10 mm. Other lengths may be

250 26.8

used, but must be noted in the report.

200 26.2 9.42

150 25.5

NOTE 3—This level of flatness and parallelness may be difficultly

100 24.5 9.17

obtained with some materials. Specimens that do not meet these require- 50 23.6 9.05

0 22.6 8.85

ments may be used, but these may result in increased imprecision.

−50 20.9 8.53

7.2 The specimens are ordinarily measured as received.

−100 18.8 8.10

−150

Where some heat or mechanical treatment is applied to the

A

Mean coefficient of linear thermal expansion values are calculated for 6 50°C

specimen prior to test, this should be noted in the report.

from the indicated temperature except in the case of platinum where values are for

NOTE 4—Some materials, particularly composites, may require heat 6 100°C of the indicated temperature for the range of between 200 and 700°C.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 831

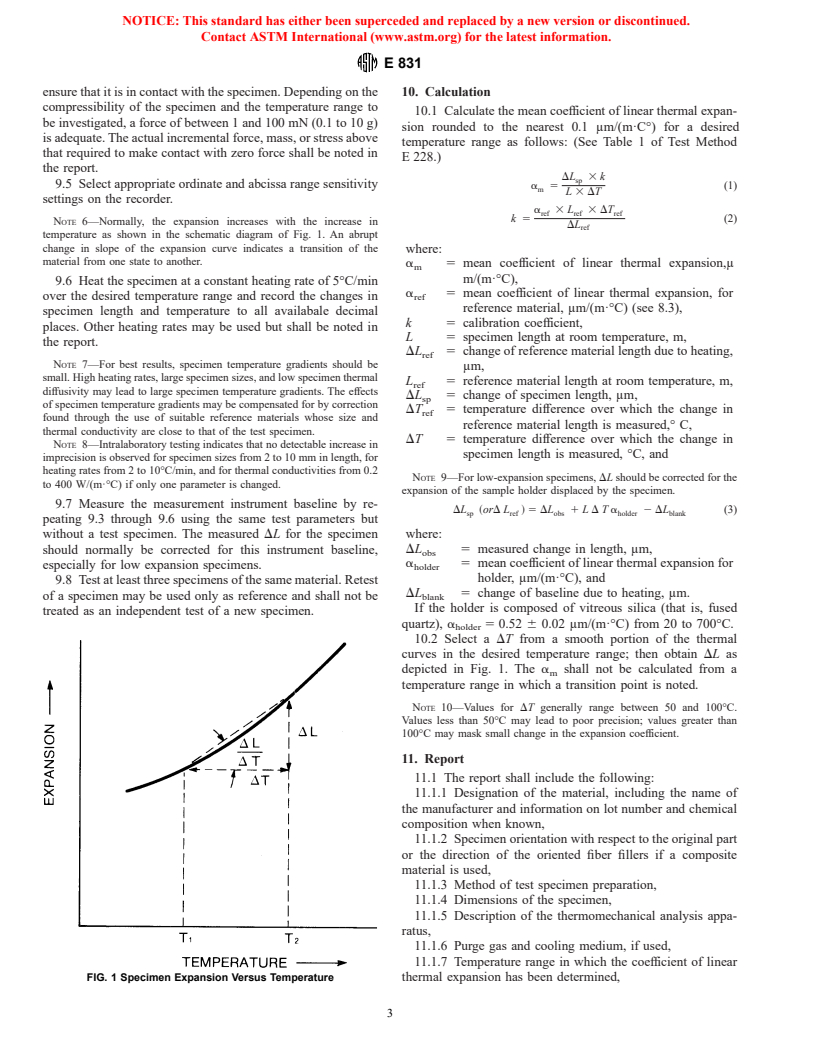

ensure that it is in contact with the specimen. Depending on the 10. Calculation

compressibility of the specimen and the temperature range to

10.1 Calculate the mean coefficient of linear thermal expan-

be investigated, a force of between 1 and 100 mN (0.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.