EN 12953-9:2007

(Main)Shell boilers - Part 9: Requirements for limiting devices of the boiler and accessories

Shell boilers - Part 9: Requirements for limiting devices of the boiler and accessories

This European Standard specifies requirements for limiters (or limiting devices) which are incorporated into safety systems for shell boilers as defined in EN 12953-1.

A limiter (or limiting device) can be either:

- a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3, and needs to include the safety logic and final actuator, or

- one element of a safety system, for example, a self-monitoring water level sensor used as part of a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3. The overall boiler protection function needs to be provided in association with additional safety logic (where appropriate) and a final actuator.

The design requirements and examination of functional capability for the limiters are covered in this European Standard.

For an explanation of the extent of the limiter (or limiting device) see Figure A.1.

Großwasserraumkessel - Teil 9: Anforderungen an Begrenzungseinrichtungen an Kessel und Zubehör

Diese Europäische Norm legt die Anforderungen an Begrenzer (oder Begrenzungseinrichtungen) fest, die in Sicherheitssystemen für Großwasserraumkessel nach EN 12953 1 eingebaut sind.

Ein Begrenzer (oder eine Begrenzungseinrichtung) kann entweder

ein Ausrüstungsteil mit Sicherheitsfunktion sein, wie in der Druckgeräterichtlinie, Artikel 1, 2.1.3, festgelegt, das mit einer Sicherheitskette und einem Stellglied versehen ist, oder

ein Element eines Sicherheitssystems sein, z. B. ein selbstüberwachender Wasserstandfühler als Teil eines Ausrüstungsteils mit Sicherheitsfunktion nach der Festlegung in der Druckgeräterichtlinie, Artikel 1, 2.1.3. Die Schutzfunktion für den gesamten Kessel wird mit einer zusätzlichen Sicherheitskette (wo angemessen) und einem Stellglied abgedeckt.

Diese Europäische Norm umfasst die Anforderungen an die Ausführung und die Prüfung der Funktions¬sicherheit der Begrenzer.

Der Funktionsumfang des Begrenzers (oder der Begrenzungseinrichtung) ist in Bild A.1 verdeutlicht.

Chaudières à tubes de fumée - Partie 9: Exigences pour les dispositifs de limitation de la chaudière et de ses accessoires

Mnogovodni kotli - 9. del: Zahteve za omejilne naprave kotla in opremo

General Information

- Status

- Withdrawn

- Publication Date

- 03-Jul-2007

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 3 - Equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Dec-2024

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 19-Jan-2023

Frequently Asked Questions

EN 12953-9:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shell boilers - Part 9: Requirements for limiting devices of the boiler and accessories". This standard covers: This European Standard specifies requirements for limiters (or limiting devices) which are incorporated into safety systems for shell boilers as defined in EN 12953-1. A limiter (or limiting device) can be either: - a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3, and needs to include the safety logic and final actuator, or - one element of a safety system, for example, a self-monitoring water level sensor used as part of a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3. The overall boiler protection function needs to be provided in association with additional safety logic (where appropriate) and a final actuator. The design requirements and examination of functional capability for the limiters are covered in this European Standard. For an explanation of the extent of the limiter (or limiting device) see Figure A.1.

This European Standard specifies requirements for limiters (or limiting devices) which are incorporated into safety systems for shell boilers as defined in EN 12953-1. A limiter (or limiting device) can be either: - a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3, and needs to include the safety logic and final actuator, or - one element of a safety system, for example, a self-monitoring water level sensor used as part of a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3. The overall boiler protection function needs to be provided in association with additional safety logic (where appropriate) and a final actuator. The design requirements and examination of functional capability for the limiters are covered in this European Standard. For an explanation of the extent of the limiter (or limiting device) see Figure A.1.

EN 12953-9:2007 is classified under the following ICS (International Classification for Standards) categories: 27.060.30 - Boilers and heat exchangers. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12953-9:2007 has the following relationships with other standards: It is inter standard links to EN 12953-9:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12953-9:2007 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 12953-9:2007 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2007

Mnogovodni kotli - 9. del: Zahteve za omejilne naprave kotla in opremo

Shell boilers - Part 9: Requirements for limiting devices of the boiler and accessories

Großwasserraumkessel - Teil 9: Anforderungen an Begrenzungseinrichtungen an Kessel

und Zubehör

Chaudieres a tubes de fumée - Partie 9: Exigences pour les dispositifs de limitation de la

chaudiere et de ses accessoires

Ta slovenski standard je istoveten z: EN 12953-9:2007

ICS:

27.060.30 Grelniki vode in prenosniki Boilers and heat exchangers

toplote

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 12953-9

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2007

ICS 27.060.30

English Version

Shell boilers - Part 9: Requirements for limiting devices of the

boiler and accessories

Chaudières à tubes de fumée - Partie 9: Exigences pour Großwasserraumkessel - Teil 9: Anforderungen an

les dispositifs de limitation de la chaudière et de ses Begrenzungseinrichtungen an Kessel und Zubehör

accessoires

This European Standard was approved by CEN on 26 May 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2007 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12953-9:2007: E

worldwide for CEN national Members.

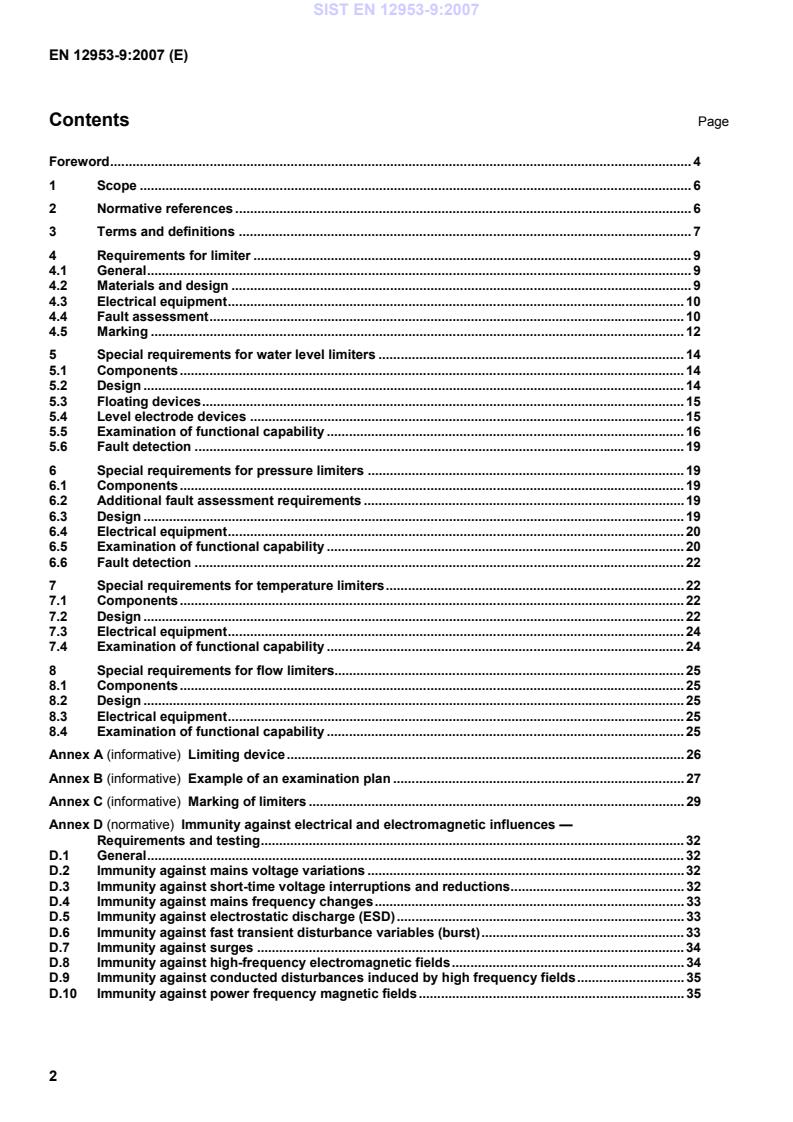

Contents Page

Foreword. 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Requirements for limiter . 9

4.1 General. 9

4.2 Materials and design . 9

4.3 Electrical equipment. 10

4.4 Fault assessment. 10

4.5 Marking . 12

5 Special requirements for water level limiters .14

5.1 Components. 14

5.2 Design . 14

5.3 Floating devices. 15

5.4 Level electrode devices . 15

5.5 Examination of functional capability . 16

5.6 Fault detection . 19

6 Special requirements for pressure limiters .19

6.1 Components. 19

6.2 Additional fault assessment requirements .19

6.3 Design . 19

6.4 Electrical equipment. 20

6.5 Examination of functional capability . 20

6.6 Fault detection . 22

7 Special requirements for temperature limiters. 22

7.1 Components. 22

7.2 Design . 22

7.3 Electrical equipment. 24

7.4 Examination of functional capability . 24

8 Special requirements for flow limiters. 25

8.1 Components. 25

8.2 Design . 25

8.3 Electrical equipment. 25

8.4 Examination of functional capability . 25

Annex A (informative) Limiting device. 26

Annex B (informative) Example of an examination plan . 27

Annex C (informative) Marking of limiters . 29

Annex D (normative) Immunity against electrical and electromagnetic influences —

Requirements and testing. 32

D.1 General. 32

D.2 Immunity against mains voltage variations .32

D.3 Immunity against short-time voltage interruptions and reductions. 32

D.4 Immunity against mains frequency changes. 33

D.5 Immunity against electrostatic discharge (ESD). 33

D.6 Immunity against fast transient disturbance variables (burst). 33

D.7 Immunity against surges . 34

D.8 Immunity against high-frequency electromagnetic fields. 34

D.9 Immunity against conducted disturbances induced by high frequency fields. 35

D.10 Immunity against power frequency magnetic fields. 35

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 97/23/EC. 36

Bibliography. 37

Foreword

This document (EN 12953-9:2007) has been prepared by Technical Committee CEN/TC 269 “Shell and

water-tube boilers”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by January 2008 and conflicting national standards shall be withdrawn at

the latest by January 2008.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

The European Standard EN 12953 concerning shell boilers consists of the following Parts:

Part 1: General

Part 2: Materials for pressure parts of boilers and accessories

Part 3: Design and calculation for pressure parts

Part 4: Workmanship and construction of pressure parts of the boiler

Part 5: Inspection during construction, documentation and marking of pressure parts of the boiler

Part 6: Requirements for equipment for the boiler

Part 7: Requirements for firing systems for liquid and gaseous fuels for the boiler

Part 8: Requirements for safeguards against excessive pressure

Part 9: Requirements for limiting devices of the boiler and accessories

Part 10: Requirements for feedwater and boiler water quality

Part 11: Acceptance tests

Part 12: Requirements for grate firing systems for solid fuels for the boiler

Part 13: Operating instructions

CR 12953 Part 14: Guideline for the involvement of an inspection body independent of the manufacturer.

Although these Parts may be obtained separately, it should be recognised that the Parts are interdependent. As

such, the design and manufacture of shell boilers requires the application of more than one Part in order for the

requirements of the European Standard to be satisfactorily fulfilled.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain,

Sweden, Switzerland and United Kingdom.

Introduction

The types of limiters which shall be fitted to boilers are specified in EN 12953-6 and the design of the safety

systems are specified in EN 50156-1.

A limiter (or limiting device) is one element of a shell boiler safety system. It comprises a sensor and

monitoring elements to achieve the desired level of reliability.

In order to provide the necessary safety function, for example, to cut off the heat supply to the boiler in the

event of a low water fault, the limiter is connected to other elements in the safety system such as actuators

and safety logic circuits.

1 Scope

This European Standard specifies requirements for limiters (or limiting devices) which are incorporated into

safety systems for shell boilers as defined in EN 12953-1.

A limiter (or limiting device) can be either:

a safety accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3, and needs to

include the safety logic and final actuator, or

one element of a safety system, for example, a self-monitoring water level sensor used as part of a safety

accessory as defined in the Pressure Equipment Directive, Article 1, clause 2.1.3. The overall boiler

protection function needs to be provided in association with additional safety logic (where appropriate)

and a final actuator.

The design requirements and examination of functional capability for the limiters are covered in this European

Standard.

For an explanation of the extent of the limiter (or limiting device) see Figure A.1.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 298:2003, Automatic gas burner control systems for gas burners and gas burning appliances with or

without fans

EN 50156-1:2004, Electrical equipment for furnaces and ancillary equipment — Part 1: Requirements for

application design and installation

EN 60529:1991, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989)

EN 60664-1:2003, Insulation coordination for equipment within low-voltage systems — Part 1: Principles,

requirements and tests (IEC 60664-1:1992 + A1:2000 + A2:2002)

EN 60730-1:2000, Automatic electrical controls for household and similar use — Part 1: General requirements

(IEC 60730-1:1999, modified)

EN 61000-4-2:1995, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 2: Electrostatic discharge immunity test — Basic EMC publication (IEC 61000-4-2:1995)

EN 61000-4-3:2006, Electromagnetic compatibility (EMC) — Part 4-3: Testing and measurement techniques

— Radiated, radio-frequency, electromagnetic field immunity test (IEC 61000-4-3:2006)

EN 61000-4-4:2004, Electromagnetic compatibility (EMC) — Part 4-4: Testing and measurement techniques

— Electrical fast transient/burst immunity test (IEC 61000-4-4:2004)

EN 61000-4-5:2006, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 5: Surge immunity test (IEC 61000-4-5:2005)

EN 61000-4-6:1996, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 6: Immunity to conducted disturbances, induced by radio-frequency fields (IEC 61000-4-6:1996)

EN 61000-4-8:1993, Electromagnetic compatibility (EMC) — Part 4: Testing and measurement techniques —

Section 8: Power frequency magnetic field immunity test; basic EMC publication (IEC 61000-4-8:1993)

EN 61000-4-11:2004, Electromagnetic compatibility (EMC) — Part 4-11: Testing and measurement

techniques — Voltage dips, short interruptions and voltage variations immunity tests (IEC 61000-4-11:2004)

EN 61000-6-2:2005, Electromagnetic compatibility (EMC) — Part 6-2: Generic standards — Immunity for

industrial environments (IEC 61000-6-2:2005)

EN 61508-3:2001, Functional safety of electrical/electronic/programmable electronic safety-related systems —

Part 3: Software requirements (IEC 61508-3:1998 + Corrigendum 1999)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

limiter

limiting device that, on reaching a fixed value (e.g. pressure, temperature, flow, water level) is used to

interrupt and lock-out the energy supply

NOTE Limiting device comprises:

a measuring or detection function and

an activation function for correction, or shutdown, or shutdown and lockout, and which is used to carry out

safety related functions as defined in the PED, on its own or as part of a safety (protective) system (e.g.

sensors, limiters) (see also Figure 1). If this is achieved by multi channel systems, then all items or limiters

for safety purposes are included within the safety (protective) system

Figure 1 — Protective devices and safety accessories according to Directive 97/23/EC (PED)

3.2

actuating element

component which produces changes in other electrical circuits or volume flows (e.g. fuel, air) as a result of the

effect of changes in signal

NOTE For example, a gas shut off valve is not an actuating element.

3.3

fail-safe

limiter is fail-safe if it possesses the capability of remaining in a safe condition or transferring immediately to

another safe condition in the event of certain faults occurring

3.4

self-monitoring

regular and automatic determination that all chosen components of a safety system are capable of functioning

as required

3.5

redundancy

provision of more than one device or system which, in the event of a fault, will still be provided by the

necessary facilities

3.6

diversity

provision of different means of performing the required function, e.g. other physical principles or other ways of

solving the same problem

3.7

complex electronics

assemblies which use electronic components with more than one functional output

3.8

safety shut-down

process which is effected immediately following the detection of a fault within the limiter or caused by exceeding

the threshold of the process value limit resulting in a defined state with deactivated terminals of the safety

output(s)

3.9

lock-out

safety shut-down condition of the limiter, such that a restart can only be accomplished by a manual reset of

the limiter or by a manual reset of the safety logic and by no other means

NOTE This will be achieved by a competent operator taking account of the physical situation

3.10

sensor

transducer which, on reaching a defined limit value, outputs a signal and/or cuts out and only reverses the

output signal in the event of a specific change in the performance quantity (e.g. pressure, temperature, flow,

level)

NOTE Sensors are used for signalling or for triggering control processes

4 Requirements for limiter

4.1 General

4.1.1 The requirements set out below have been established to ensure uniform assessment of different

devices.

A limiter shall be such that a single fault in any related part shall not lead to a loss of the safety function. This

shall be achieved by fault avoidance techniques such as self-monitoring with redundancy, diversity or a

combination of these methods. Fault assessment for the electrical components shall be in accordance

with 4.4. The fault assessment chart, see Figure 2 shall also be applied for faults in hydraulic, pneumatic and

mechanical components.

NOTE The various elements of limiters are given in Annex A.

4.1.2 Limiters shall function independently of each other and of controls unless their safety function

cannot be affected by other such functions. Manual resetting can be realised as a part of the limiter or as a

part of the safety logic. Instructions shall be delivered together with the limiter including necessary precautions

for a safe installation of it.

4.2 Materials and design

4.2.1 The use of materials with significant differences in their electrochemical potential shall be avoided in

order to prevent corrosion which could affect the function of the limiter.

4.2.2 Care shall be taken that if magnetic materials are chosen, they do not adversely affect the working of

the limiter.

4.2.3 Parts of the limiter shall be designed to comply with the applicable European Standards.

4.2.4 Limiters shall be capable of withstanding the thermal, mechanical, chemical and electrical loads that

can occur during operation.

4.2.5 Limiters shall be designed such that changes in critical circuit component values (such as those

affecting timing) within the component manufacturer's declared worst case tolerances, including the long term

stability, shall result in the system continuing to function in accordance with this standard. Compliance shall be

checked by worst case analysis.

4.2.6 Limiters using complex electronics

For limiters using complex electronics the following requirements apply additionally:

• General

Systematic errors (built into the design) shall be avoided and random faults (component faults) shall be

controlled by techniques such as self-monitoring with redundancy, diversity or a combination of these methods.

• Fault avoidance and fault tolerance

The design of the software and hardware shall be based on the functional analysis of the limiter resulting in a

structured design explicitly incorporating the control flow, data flow and time related functions required by the

application. In the case of custom-chips special attention is required with regard to measures taken to

minimise systematic errors.

Software shall be designed using EN 61508-3 to a SIL level (Safety Integrity Level) as determined by analysis

according to EN 50156-1.

4.3 Electrical equipment

4.3.1 All wiring and electrical equipment in connection with the limiter shall be adequately protected against

the ingress of moisture and the effect of temperature (see also [2], [3]).

4.3.2 The function of the limiter and the associated electrical circuit responsible for shutting down and

locking out the heat supply system shall not be affected by other electrical circuits in their proximity. Screened

cables shall be used where necessary (see also [2], [3]).

4.3.3 Electrical components within units directly attached to the boiler shall be capable of withstanding a

temperature environment resulting from surrounding temperatures of up to 70 °C. Components within units not

directly attached to the boiler shall be capable of withstanding an ambient temperature of up to 55 °C. Any

equipment that is in contact with parts carrying steam or hot water shall be capable of withstanding the

temperature of those parts.

4.3.4 Devices shall have, as a minimum, a protection rating to IP 54 in accordance with EN 60529. When

units are installed inside an enclosure or control box, the IP rating required for the box shall be considered

adequate.

4.3.5 All mechanical output contacts of the device shall be of the snap action type. Semi-conductor

switches shall have similar characteristics.

4.3.6 The limiter shall tolerate electrical and electromagnetical influences as defined in Annex D.

4.4 Fault assessment

4.4.1 General

The limiter, excluding the stored programme section, shall be so constructed that the fault assessment

analysis in accordance with Figure 2 results in termination. Power failure, breaks in connecting cables and

short circuits shall also be considered and included in the fault assessment analysis.

4.4.2 Fault models and exclusions

4.4.2.1 General

With fault assessment in accordance with Figure 2, it shall be assumed that certain faults do not occur. Such

assumptions are justified by describing the failure mechanism as well as by stating the conditions relating to

design, construction, environment etc. for the conductors, components and equipment.

Faults which shall be taken into account are based in EN 298:2003, Annex A with consideration of the

following faults which may be excluded without further justification:

4.4.2.2 Conductor-to-conductor short circuit fault

This fault may be excluded if:

a) cables and conductors as specified in EN 50156-1 are used;

b) components are encapsulated so that they are moisture resistant or, if they are hermetically sealed and

they are capable of withstanding the test specified in EN 50156-1;

c) clearance between live parts shall be designed according to overvoltage category III and pollution

degree 3 and the creepage distance shall be designed according to pollution degree 3 but at least for the

nominal voltage of 63 V as specified in EN 60664-1;

d) printed conductors (tracks) shall be varnished so that they are resistant to ageing by virtue of the distance

between printed conductors being equivalent to at least the values specified in EN 60664-1:2003, Table 4

for pollution degree 1, and with a minimum nominal voltage of 32 V (minimum creepage distance of

0,14 mm).

4.4.2.3 Short circuit in wound film resistors

This fault may be excluded if the wound film resistors shall be used with a varnished or encapsulated resistive

layer and axial terminations. The possibility of condensation shall be excluded during operation. The limits, e.g.

voltage limit, power, shall not be exceeded even under worst case conditions.

4.4.2.4 Short circuit in wire-wound resistors

This fault may be excluded if the winding is a single layer winding and shall be secured by means of a glaze or

embedded in a sealing compound.

4.4.2.5 Non-opening of contact elements due to permanent welding

This fault may be excluded if contactors, relays or auxiliary switches for example, shall be protected against the

effects of short circuits by the appropriate overcurrent protective or current limiting devices. In rating the

overcurrent protective device, the nominal current of the device as stated by the manufacturer, shall be

multiplied by a safety factor of 0,6. Fault exclusion is also permissible if the prospective short circuit current is

less than the nominal current for the contact element concerned. Where contact elements are connected in

series, the contact element with the lowest overcurrent strength shall be the deciding factor.

Reed contacts shall not be used.

4.4.2.6 Mechanical failure of switching devices

This fault may be excluded if the switching devices are type tested to demonstrate they shall be still be operative

after at least 250 000 switching cycles under conditions similar to operating conditions. Contactors and relays

shall, in addition, be capable of a mechanical endurance of 3 000 000 switching cycles, except for pressure

limiters, see Table 2.

NOTE The term "conditions similar to operating conditions" covers chemical and climatic influences as well as

electrical and mechanical stresses.

4.4.2.7 Faults in components for safe isolation

Faults in components which are provided for safe isolation of electrical circuits (e.g. power circuits and telecom-

munications circuits) in accordance with EN 61140 may be excluded. These include:

a) inter-winding short circuits in transformers (e.g. primary-secondary).

Transformers shall comply with the electrical and mechanical requirements of EN 60742. In deviation

from EN 60742, for transformers with working voltages up to 200 V, insulation between windings and

insulation against the core shall be designed for a test voltage of 2 kV rms. Transformers shall as a

minimum be short-circuit proof. Displacement of windings, turns and connection lines shall be prevented,

e.g. by vacuum impregnation or encapsulation;

b) transient voltage of switching devices like relays, contactors or auxiliary contacts between contacts and

between coil and contacts.

The insulation between contacts or between coil and contact shall be designed for nominal voltages U up

b

to 200 V for a test voltage of 2 kV rms; at nominal voltages 200 V < U < 500 V for a test voltage of

b

3,75 kV rms. By special design features (e.g. caps, ribs, encapsulation, banding) at contacts and coils,

safe isolation shall also be guaranteed against faults such as spring breakage;

c) short-circuiting of isolating distances in optocouplers.

The clearance and creepage distances of the optocoupler in its installed position shall fulfil the relevant

conditions of EN 60664-1:2003, 3.1 and 3.2.

4.5 Marking

The limiters shall be marked with the following:

manufacturer´s name and/or trademark;

year of manufacture;

maximum/minimum allowable design limits;

unique type reference.

NOTE Other markings may be added by the limiter manufacturer or placed in the operating instructions, see

Annex C.

Key

1 reassessment

Figure 2 — Fault assessment chart for limiters excluding the stored programme section

5 Special requirements for water level limiters

5.1 Components

This limiter shall consist of one or more units needed to provide the necessary safety function. The limiter shall

comprise of the following elements where applicable: sensor, protection tube or external chamber (see NOTE),

timing element, testing devices and other associated equipment up to the terminals of the switching output

contacts as shown in Annex A.

NOTE Protection tubes and external chambers may be considered to be part of the boiler and in these cases it will

be necessary for the limiter manufacturer and the boiler manufacturer to agree on the design and manufacturing

requirements to ensure that the limiter system performs as intended. Examples of water level sensor are: float level

switch, electrode probe, conductivity sensor.

5.2 Design

5.2.1 General

Chambers, connecting pipes and protection tubes shall be designed so that they:

allow free movement in the tube to equalise with the water level in the boiler;

can be cleaned and inspected;

prevent the build up of sludge in the tubes/chambers.

5.2.2 Internal protection tubes

5.2.2.1 Openings on the protection tube, which are necessary to ensure level equalisation, shall have a

minimum diameter of 20 mm or equivalent area but not greater than one-third of the clear bore of the

protection tube, except where specific type approval permits other dimensions.

5.2.2.2 The openings shall be positioned at the lowest point of the bottom and at the highest practicable

point of the protection tube.

5.2.3 External chambers

5.2.3.1 The pipe connections to external chambers shall not be less than 20 mm clear bore. It shall be

possible to blow down the chambers and connecting pipes to ensure that they do not become blocked.

Where applicable, blowdown systems should be fitted with a timing element which prevents the blow down

period exceeding a predetermined maximum safe time and monitors the complete move next of the relevant

valves and the function of the limiter output contact.

5.2.3.2 If isolating valves are fitted on the connecting pipes to external chambers, an interlock system

shall be installed to shut off the heat supply when valves are not fully open.

5.2.3.3 The drain connection of the chamber shall be 15 mm minimum clear bore.

5.2.3.4 Chambers can be considered as being an integral part of the boiler and need not be blown down

if:

a) the connecting pipes shall be 100 mm minimum clear bore on the water side and 40 mm minimum clear

bore on the steam side and

b) the connection pipes shall be less than one metre long and

c) there shall be no isolating valves fitted on the connecting pipes.

Limiters fitted in such a chamber may be deemed to be inside the boiler.

5.3 Floating devices

5.3.1 The float shall be guided and shall be able to move freely.

5.3.2 As the actuating force is small, it shall be converted to a positive movement with a minimum of friction.

5.3.3 Mechanical transfer shall be performed in such a way that no sticking can occur.

5.3.4 The magnets shall be protected against the influence of the boiler water (e.g. suspended magnetic

particles) by positioning them above the highest operational water level or by the use of an additional shield.

5.3.5 The magnetic materials shall be selected with regard to the temperature and operating conditions,

such that the magnetic properties of the materials will not decrease by more than 3 % over a 10 year period. It

shall be possible to prove by means of testing equipment integral with the water limiter system, that the

magnetic interaction remains adequate to operate the switch.

5.3.6 Stray magnetic fields shall not adversely influence the magnetic transfer.

5.3.7 The test force for float devices at 15 °C shall be no greater than the total weight of the float and the

parts attached to it.

5.4 Level electrode devices

5.4.1 The level electrodes shall be designed, positioned installed and protected in such a way that their

proper functioning is not affected by:

a) foam and turbulence from the boiler water;

b) dirt build up;

c) mechanical influences during operation (e.g. vibration);

d) positional changes relative to the protection tube and or to other electrodes which could result in a short

circuit.

5.4.2 Unless the manufacturers fault assessment shows that an equivalent degree of safety is maintained:

the minimum air distance between measuring electrodes to earth and to each other inside the pressure

part shall be 14 mm;

level electrode devices shall be installed vertically or at inclinations of up to 45° from the vertical.

5.4.3 Devices that are used to support or restrict movement of the electrode shall be included in the

examination of functional capability (5.5).

5.4.4 The maximum operating voltage of electrodes shall be 50 V a.c. rms without a d.c. component which

could cause significant polarisation effects. If galvanic isolation from the mains supply is required, it shall be

provided by a safety transformer in accordance with EN 60742, meeting the requirements of class of

protection II (double insulation).

5.4.5 The earth return connection shall be as close as possible to the electrode.

5.4.6 The manufacturer of the limiter shall define the limits of application with respect to the water

conductivity.

5.4.7 The insulation resistance of the electrode and the cable shall be monitored. In the case of low

insulation resistance caused for example, by dirt build up on the insulator or internal leakage of the electrode,

the system shall go into a safe state.

5.4.9 Only one low water limiter shall be permitted to be installed within the protection tube or an external

chamber. It is acceptable, however, to install additional electrodes for control and other alarm functions.

5.5 Examination of functional capability

The examination of the functional capability of the limiter shall be in accordance with the procedures given in

Table 1.

Table 1 — Examination of functional capability of water level limits

Pos. Description Verification Acceptance criteria

A FUNCTIONAL TESTS

A.1 Environmental influences Check operation of the water level limiter under the following conditions,

either by certified test document review, simulation, on a test boiler or in

any combination.

— power supply variation test; Annex D

— power supply interruption test; EN 50156-1

— frequency variation test;

— EMC immunity test;

— ambient temperature test;

— IP rating.

A.2 Test of independent When common components are shared, a failure of the second limiter or The safety function of the

functioning the control circuit(s) shall be simulated. limiter shall not be affected.

A.3 Thermal cycle test The whole limiter assembly shall be subjected to at least 100 thermal No steam leak shall be

cycles at full pressure by the manufacturer. permitted.

During each cycle, the limiter shall be shown to operate to the The resistance shall be

manufacturer's specification at the lowest temperature and highest

more than 10 MΩ at test

temperature, allowing sufficient soak time at both these conditions.

voltage of 500 V d.c. under

room conditions.

In the case of electrode devices, immediately after completing the cyclic

test, the insulation resistance of all insulated parts of the electrode shall

be measured.

A.4 Final performance test This shall consist of a comprehensive series of measurements and The water level limiter shall

observations of the characteristics and performance of the water level initiate alarm signals when

limiter to demonstrate that no unacceptable deterioration has occurred as the level drops below the

a result of previous tests. Tests shall be done at ambient temperature at low water level at for each

normal voltages and subsequently with the worst combination of supply of the max and min. water

voltages. In the case of electrode devices, the water level limiter shall be conductivities.

checked for correct operation within the maximum and minimum water

conductivities as specified by the manufacturer.

Table 1 — Examination of functional capability of water level limits (concluded)

Pos. Description Verification Acceptance criteria

B LEVEL ELECTRODE

DEVICES

B.1 Testing of internal faults Failure of each critical component shall be simulated and a check shall Compliance with 4.4.

be made to show that the water level limiter goes to a safe state in

accordance with the relevant fault assessment charts. By way of

examples "Internal Faults" are:

a) short circuit or interruptions in components such as in resistors,

capacitors, discrete and integrated semi-conductor elements etc.;

b) faulty oscillations of electrical circuits;

c) non-opening or non closing of electromagnetic components, such as

contactors, relays etc.;

d) short circuits or interruptions in control circuits, such as broken wires,

earth fault and conductor-to-conductor short circuit etc.;

e) software errors;

f) systematic hardware faults in integrated circuit components.

B.2 Insulation resistance test A check shall be made of the resistance between all insulated parts of The resistance shall be

the limiter circuits, which includes contacts of switches, relays or

more than 10 MΩ at test

contactors for isolation functions. voltage of 500 V d.c. under

room conditions.

B.3 Test for maximum operating Electrode shall be subjected to maximum voltage. 50 V a.c. rms maximum.

voltage

C FLOATING DEVICES

C.1 Durability test on Electromechanical switches shall be life tested to at least 100 000 The electromechanical

electromechanical switches operations at full rated temperature and full rated electrical load. At least switches shall still be

one sample shall be with the maximum rated a.c. inductive load, and functional at the end of

another with the maximum rated d.c. load. the test cycle.

C.2 Test for free movement of the The difference in diameter between the outside of the float and the inside The difference shall not be

float of the chamber or guide tube shall be checked. less than 10 mm.

C.3 Test for positive movement of A check shall be made to ensure that the mechanical parts which are The limiter shall not

the float subjected to wear shall be shown to work for a minimum of 250 000 malfunction during the test

operations within the full range of the mechanical movement. cycle.

5.6 Fault detection

5.6.1 The limiter shall be tested automatically and periodically during use to ensure that the safety is not

impaired by at least one of the following methods:

a) incorporating a self testing device;

b) lowering the water level;

c) sinking the float device.

5.6.2 The safety shutdown signal shall be initiated if the test sequence fails.

5.6.3 Manual functional testing of the limiters shall be possible at any time under any operating conditions, e.g.

by simulation where appropriate. The result of the test shall be clearly indicated to the boiler operator.

6 Special requirements for pressure limiters

6.1 Components

The limiter shall consist of one or more units needed to provide the necessary safety function. The limiter shall

comprise the following units where applicable: connecting piping, body, sensor, external chamber, timing element,

testing devices and other associated equipment up to the terminals of the switching output contacts as shown in

Annex A.

6.2 Additional fault assessment requirements

In addition to the requirements in 4.4, it may be assumed that failure of the component shall not occur where a

mechanical component of the pressure limiter has been designed for a dynamic load and has been successfully

tested for 2 000 000 cycles over its full range of mechanical movement.

6.3 Design

6.3.1 The limiter shall be capable of withstanding an overload of at least 1,5 times its maximum adjustable

pressure without detriment to its accuracy. The manufacturer may state a higher overload pressure.

6.3.2 The adjustment of the set pressure shall only be possible by means of a tool. Any adjustment shall be

capable of being secured so that it does not alter due to any environmental influence, e.g. vibration. The set

pressure shall be indicated on a scale.

6.3.3 It shall not be possible to adjust the set pressure to such an extent that the limiter loses its function (e.g. by

the spring becoming coil-bound).

6.3.4 Connecting pipes for the limiter on steam boilers shall be connected to the steam space of the boiler. If

necessary the limiter shall be protected from the steam temperature by a water seal. For fully flooded hot water

generators the limiter shall be connected to the supply pipe before the first shut-off valve.

If isolating valves are fitted on the connecting pipes, an interlock system shall be installed to shut off the heat

supply when valves are not fully open.

6.3.5 If there is the possibility of sludge build-up in the connecting pipe it shall be possible to purge the pipe.

Such purging shall not remove the water seal or introduce dirt into the water seal.

6.3.6 The limiter body shall be installed vertically so that dirt does not enter the limiter.

6.3.7 Connecting pipes and the boiler connection for the limiter shall be designed so that they can be cleaned

and inspected. The connecting pipe and its boiler connection shall have a clear bore of at least the following unless

the manufacturers fault assessment shows that an equivalent degree of safety is maintained:

a) 8 mm where the pipe is less than 1 m long and the pipe supplies only the limiter or

b) 15 mm where the pipe is gr

...

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Shell boilers - Part 9: Requirements for limiting devices of the boiler and accessoriesMnogovodni kotli - 9. del: Zahteve za omejevalne naprave kotla in opremeChaudieres a tubes de fumée - Partie 9: Exigences pour les dispositifs de limitation de la chaudiere et de ses accessoiresGroßwasserraumkessel - Teil 9: Anforderungen an Begrenzungseinrichtungen an Kessel und ZubehörTa slovenski standard je istoveten z:EN 12953-9:2007SIST EN 12953-9:2007en,fr,de27.060.30Grelniki vode in prenosniki toploteBoilers and heat exchangersICS:SLOVENSKI

STANDARDSIST EN 12953-9:200701-september-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12953-9July 2007ICS 27.060.30 English VersionShell boilers - Part 9: Requirements for limiting devices of theboiler and accessoriesChaudières à tubes de fumée - Partie 9: Exigences pourles dispositifs de limitation de la chaudière et de sesaccessoiresGroßwasserraumkessel - Teil 9: Anforderungen anBegrenzungseinrichtungen an Kessel und ZubehörThis European Standard was approved by CEN on 26 May 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12953-9:2007: E

Limiting device.26 Annex B (informative)

Example of an examination plan.27 Annex C (informative)

Marking of limiters.29 Annex D (normative)

Immunity against electrical and electromagnetic influences —

Requirements and testing.32 D.1 General.32 D.2 Immunity against mains voltage variations.32 D.3 Immunity against short-time voltage interruptions and reductions.32 D.4 Immunity against mains frequency changes.33 D.5 Immunity against electrostatic discharge (ESD).33 D.6 Immunity against fast transient disturbance variables (burst).33 D.7 Immunity against surges.34 D.8 Immunity against high-frequency electromagnetic fields.34 D.9 Immunity against conducted disturbances induced by high frequency fields.35 D.10 Immunity against power frequency magnetic fields.35

Relationship between this European Standard and the Essential Requirements of EU Directive 97/23/EC.36 Bibliography.37

Figure 1 — Protective devices and safety accessories according to Directive 97/23/EC (PED) 3.2 actuating element component which produces changes in other electrical circuits or volume flows (e.g. fuel, air) as a result of the effect of changes in signal NOTE For example, a gas shut off valve is not an actuating element. 3.3 fail-safe limiter is fail-safe if it possesses the capability of remaining in a safe condition or transferring immediately to

another safe condition in the event of certain faults occurring

affecting timing) within the component manufacturer's declared worst case tolerances, including the long term stability, shall result in the system continuing to function in accordance with this standard. Compliance shall be checked by worst case analysis. 4.2.6 Limiters using complex electronics For limiters using complex electronics the following requirements apply additionally: • General Systematic errors (built into the design) shall be avoided and random faults (component faults) shall be controlled by techniques such as self-monitoring with redundancy, diversity or a combination of these methods. • Fault avoidance and fault tolerance The design of the software and hardware shall be based on the functional analysis of the limiter resulting in a structured design explicitly incorporating the control flow, data flow and time related functions required by the application. In the case of custom-chips special attention is required with regard to measures taken to minimise systematic errors. Software shall be designed using EN 61508-3 to a SIL level (Safety Integrity Level) as determined by analysis according to EN 50156-1.

temperature environment resulting from surrounding temperatures of up to 70 °C. Components within units not

directly attached to the boiler shall be capable of withstanding an ambient temperature of up to 55 °C. Any equipment that is in contact with parts carrying steam or hot water shall be capable of withstanding the temperature of those parts. 4.3.4 Devices shall have, as a minimum, a protection rating to IP 54 in accordance with EN 60529. When units are installed inside an enclosure or control box, the IP rating required for the box shall be considered adequate. 4.3.5 All mechanical output contacts of the device shall be of the snap action type. Semi-conductor switches shall have similar characteristics. 4.3.6 The limiter shall tolerate electrical and electromagnetical influences as defined in Annex D. 4.4 Fault assessment 4.4.1 General The limiter, excluding the stored programme section, shall be so constructed that the fault assessment analysis in accordance with Figure 2 results in termination. Power failure, breaks in connecting cables and short circuits shall also be considered and included in the fault assessment analysis. 4.4.2 Fault models and exclusions 4.4.2.1 General With fault assessment in accordance with Figure 2, it shall be assumed that certain faults do not occur. Such assumptions are justified by describing the failure mechanism as well as by stating the conditions relating to design, construction, environment etc. for the conductors, components and equipment. Faults which shall be taken into account are based in EN 298:2003, Annex A with consideration of the following faults which may be excluded without further justification: 4.4.2.2 Conductor-to-conductor short circuit fault This fault may be excluded if: a) cables and conductors as specified in EN 50156-1 are used; b) components are encapsulated so that they are moisture resistant or, if they are hermetically sealed and they are capable of withstanding the test specified in EN 50156-1; c) clearance between live parts shall be designed according to overvoltage category III and pollution degree 3 and the creepage distance shall be designed according to pollution degree 3 but at least for the nominal voltage of 63 V as specified in EN 60664-1;

between coil and contacts. The insulation between contacts or between coil and contact shall be designed for nominal voltages Ub up to 200 V for a test voltage of 2 kV rms; at nominal voltages 200 V < Ub < 500 V for a test voltage of 3,75 kV rms. By special design features (e.g. caps, ribs, encapsulation, banding) at contacts and coils, safe isolation shall also be guaranteed against faults such as spring breakage;

Annex C.

Key 1 reassessment Figure 2 — Fault assessment chart for limiters excluding the stored programme section

particles) by positioning them above the highest operational water level or by the use of an additional shield. 5.3.5 The magnetic materials shall be selected with regard to the temperature and operating conditions, such that the magnetic properties of the materials will not decrease by more than 3 % over a 10 year period. It shall be possible to prove by means of testing equipment integral with the water limiter system, that the magnetic interaction remains adequate to operate the switch. 5.3.6 Stray magnetic fields shall not adversely influence the magnetic transfer. 5.3.7 The test force for float devices at 15 °C shall be no greater than the total weight of the float and the parts attached to it. 5.4 Level electrode devices 5.4.1 The level electrodes shall be designed, positioned installed and protected in such a way that their proper functioning is not affected by: a) foam and turbulence from the boiler water; b) dirt build up; c) mechanical influences during operation (e.g. vibration); d) positional changes relative to the protection tube and or to other electrodes which could result in a short circuit. 5.4.2 Unless the manufacturers fault assessment shows that an equivalent degree of safety is maintained: the minimum air distance between measuring electrodes to earth and to each other inside the pressure part shall be 14 mm; level electrode devices shall be installed vertically or at inclinations of up to 45° from the vertical. 5.4.3 Devices that are used to support or restrict movement of the electrode shall be included in the examination of functional capability (5.5). 5.4.4 The maximum operating voltage of electrodes shall be 50 V a.c. rms without a d.c. component which could cause significant polarisation effects. If galvanic isolation from the mains supply is required, it shall be provided by a safety transformer in accordance with EN 60742, meeting the requirements of class of protection II (double insulation). 5.4.5 The earth return connection shall be as close as possible to the electrode. 5.4.6 The manufacturer of the limiter shall define the limits of application with respect to the water conductivity.

A.1 Environmental influences Check operation of the water level limiter under the following conditions, either by certified test document review, simulation, on a test boiler or in any combination.

— power supply variation test; — power supply interruption test; — frequency variation test; — EMC immunity test; — ambient temperature test; — IP rating. Annex D EN 50156-1 A.2 Test of independent functioning When common components are shared, a failure of the second limiter or the control circuit(s) shall be simulated. The safety function of the

limiter shall not be affected. A.3 Thermal cycle test The whole limiter assembly shall be subjected to at least 100 thermal cycles at full pressure by the manufacturer.

During each cycle, the limiter shall be shown to operate to the manufacturer's specification at the lowest temperature and highest temperature, allowing sufficient soak time at both these conditions.

In the case of electrode devices, immediately after completing the cyclic test, the insulation resistance of all insulated parts of the electrode shall be measured. No steam leak shall be

permitted.

The resistance shall be more than 10 MΩ at test voltage of 500 V d.c. under room conditions. A.4 Final performance test This shall consist of a comprehensive series of measurements and observations of the characteristics and performance of the water level limiter to demonstrate that no unacceptable deterioration has occurred as a result of previous tests. Tests shall be done at ambient temperature at normal voltages and subsequently with the worst combination of supply voltages. In the case of electrode devices, the water level limiter shall be checked for correct operation within the maximum and minimum water conductivities as specified by the manufacturer. The water level limiter shall

initiate alarm signals when the level drops below the low water level at for each of the max and min. water conductivities.

B.1 Testing of internal faults Failure of each critical component shall be simulated and a check shall be made to show that the water level limiter goes to a safe state in accordance with the relevant fault assessment charts. By way of examples "Internal Faults" are: a) short circuit or interruptions in components such as in resistors,

capacitors, discrete and integrated semi-conductor elements etc.; b) faulty oscillations of electrical circuits; c) non-opening or non closing of electromagnetic components, such as contactors, relays etc.; d) short circuits or interruptions in control circuits, such as broken wires,

earth fault and conductor-to-conductor short circuit etc.; e) software errors; f) systematic hardware faults in integrated circuit components. Compliance with 4.4. B.2 Insulation resistance test A check shall be made of the resistance between all insulated parts of the limiter circuits, which includes contacts of switches, relays or contactors for isolation functions. The resistance shall be more than 10 MΩ at test voltage of 500 V d.c. under room conditions. B.3 Test for maximum operating

voltage Electrode shall be subjected to maximum voltage. 50 V a.c. rms maximum. C FLOATING DEVICES

C.1 Durability test on electromechanical switches Electromechanical switches shall be life tested to at least 100 000 operations at full rated temperature and full rated electrical load. At least one sample shall be with the maximum rated a.c. inductive load, and another with the maximum rated d.c. load. The electromechanical switches shall still be

functional at the end of

the test cycle. C.2 Test for free movement of the float The difference in diameter between the outside of the float and the inside of the chamber or guide tube shall be checked. The difference shall not be less than 10 mm. C.3 Test for positive movement of the float A check shall be made to ensure that the mechanical parts which are subjected to wear shall be shown to work for a minimum of 250 000 operations within the full range of the mechanical movement. The limiter shall not malfunction during the test

cycle.

± 0,04 bar. The span is the difference between the lowest and the highest set pressure indicated on the scale. Full scale means the highest set pressure indicated on the scale. 6.5.2 The test required for the test procedure shall be in accordance with Table 2 and Figure 3. Table 2 — Test procedure Clause reference Adjustment Number of cycles Pressure TemperatureUpper Switching Point (USP) high pressure limiter Lower Switching Point (LSP) low pressure limiter Requirementsin accordancewith 6.5.1 20 °C USP 1 LSP 1

6.5.4 Lowest value Minimum 1 Switching pressure 70 °C USP 2 LSP 2 Compare USP 1/USP 2or LSP 1/LSP 2 20 °C USP 3 LSP 3

6.5.5 Highest value Minimum 1 Switching pressure 70 °C USP 4 LSP 4 Compare USP 3/USP 4or LSP 3/LSP 4 Minimum 1 Switching pressure 20 °C USP 5 LSP 5

6.5.6 Lowest value 100 Maximum overload 20 °C USP 6 LSP 6 Compare USP 5/USP 6or LSP 5/LSP 6

6.2 Mid point of the span 2 × 106 To give full mechanical movement 20 °C — — No mechanical damage

Key 1 pressure 2 falling pressure 3 rising pressure USP is the Upper Switching Point (relevant for high pressure limiter) LSP is the Lower Switching Point (relevant for low pressure limiter) Figure 3 — Switching point for pressure limiter 6.5.3 The repeatability shall be within the limits stated in 6.5.1 when the tests detailed in 6.5.4, 6.5.5 and 6.5.6 are carried out using air as the test medium. The pressure shall not be changed at a rate faster than the span of the limiter in one minute. 6.5.4 The set pressure shall be adjusted to the lower end of the set pressure scale and the switching pressure measured at an ambient temperature of 20 °C. The ambient temperature shall be raised to 70 °C and the switching pressure measured. 6.5.5 The test in 6.5.4 shall be repeated with the set pressure at the upper end of the set pressure sca

...

The standard EN 12953-9:2007 plays a crucial role in the safety management of shell boilers, specifically focusing on the requirements for limiting devices and their integration into safety systems. The scope of this European Standard explicitly outlines the necessary criteria for limiters, which are essential components in ensuring the safe operation of shell boilers as defined in EN 12953-1. One of the major strengths of this standard is its clear differentiation between types of limiters-classifying them as either safety accessories, in accordance with the Pressure Equipment Directive, or as integral parts of a safety system. This nuanced approach allows for a comprehensive understanding of how limiters function within the broader safety mechanisms of shell boilers. The inclusion of safety logic and final actuators within the definitions establishes a fundamental framework for ensuring that safety systems are effectively designed and implemented. Furthermore, the standard meticulously addresses the design requirements and functional capability examination of limiters, ensuring that they meet stringent safety criteria. This is particularly important in the context of operational integrity and reliability. By emphasizing the need for additional safety logic and actuators, the standard reinforces a robust safety culture in boiler operation, protecting personnel and equipment alike. Additionally, the inclusion of visual aids, such as Figure A.1, enhances the understanding of the extent of limiters, providing practical guidance for engineers and safety professionals. This visual representation complements the text and aids in bridging theoretical requirements with real-world application. Overall, EN 12953-9:2007 stands out as a relevant and essential standard for industry professionals involved in the design and operation of shell boilers. Its comprehensive scope, clear definitions, and emphasis on safety mechanisms establish it as a significant reference point in maintaining high safety standards within this sector.

SIST EN 12953-9:2007 표준은 쉘 보일러 및 부속 장치에 관한 제한 장치의 요구 사항을 명확히 규정하고 있습니다. 이 표준의 범위는 안전 시스템에 통합된 제한 장치(또는 제한 장치)의 요건을 명시하며, EN 12953-1에서 정의된 쉘 보일러의 특성과 관련이 깊습니다. 본 표준의 강점 중 하나는 제한 장치가 안전 부속품 또는 안전 시스템의 일환으로 기능할 수 있도록 다양한 형태를 인정한다는 점입니다. 이는 압력 장비 지침(Pressure Equipment Directive) 제1조 제2.1.3항에 따라 안전 로직과 최종 액추에이터를 포함해야 하는 부속품의 정의를 따릅니다. 이로 인해 사용자와 전문가 모두에게 안전성을 갖춘 시스템 설계가 가능해집니다. 또한, 이 표준은 제한 장치의 설계 요구 사항과 기능적 능력에 대한 검사 방법을 상세히 설명하고 있습니다. 이는 제한 장치가 실제로 어떤 방식으로 작동하며, 보일러 보호 기능을 어떻게 확보하는지를 명확히 하는 데 기여합니다. 더불어, 안전 로직과 최종 액추에이터가 적절하게 결합되어 보일러의 전반적인 안전성을 높이는 방안을 제시하고 있어, 사용자에게 신뢰성 있는 지침을 제공합니다. SIST EN 12953-9:2007 표준의 정밀한 요구 사항과 설계 지침은 쉘 보일러 운영자와 설계자에게 필수적이며, 업계에서는 안전과 효율성을 동시에 강조하는 매우 중요한 기준으로 자리잡고 있습니다.

SIST EN 12953-9:2007は、シェルボイラーおよびその付属品のための制限装置に関する要件を詳細に定義した欧州標準です。この標準の範囲は、シェルボイラーの安全システムに組み込まれるリミッター(または制限装置)に関するものであり、EN 12953-1により定義されたシェルボイラーに焦点を当てています。 この標準の強みは、圧力機器指令第1条第2.1.3項に従って、リミッターが安全アクセサリーとしての機能を果たす必要があることを明確に規定している点です。また、リミッターが安全システムの一部としても機能することを認めており、例えば自己監視型水位センサーのように、必要に応じて追加の安全論理と最終アクチュエーターを併せて使用することが求められます。このアプローチにより、ボイラーの保護機能を総合的に確保することができます。 さらに、この標準では、リミッターの設計要件や機能能力の検査が体系的に取り扱われており、実用的な設計と運用の基盤を提供します。リミッター(または制限装置)の範囲については、附属図A.1で視覚的に説明されており、より深い理解を促している点も特筆すべきです。 以上のように、SIST EN 12953-9:2007は、シェルボイラーの安全性を確保するための重要な基準を提供し、安全アクセサリーや安全システムに関連するリミッターの要件を明確に定めています。この標準は、業界における安全性の向上に貢献する極めて重要なドキュメントと言えます。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...