ISO/DIS 14313

(Main)Petroleum and natural gas industries -- Pipeline transportation systems -- Pipeline valves

Petroleum and natural gas industries -- Pipeline transportation systems -- Pipeline valves

Industries du pétrole et du gaz naturel -- Systèmes de transport par conduites -- Robinets de conduites

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 14313

ISO/TC 67/SC 2 Secretariat: UNI

Voting begins on Voting terminates on

2012-04-18 2012-09-18

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Petroleum and natural gas industries — Pipeline transportationsystems — Pipeline valves

Industries du pétrole et du gaz naturel — Systèmes de transport par conduites — Robinets de conduites

[Revision of second edition (ISO 14313:2007) and ISO 14313:2007/Cor.1:2009]ICS 75.200

To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.© International Organization for Standardization, 2012

---------------------- Page: 1 ----------------------

ISO/DIS 14313

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user’s country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2012 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 14313

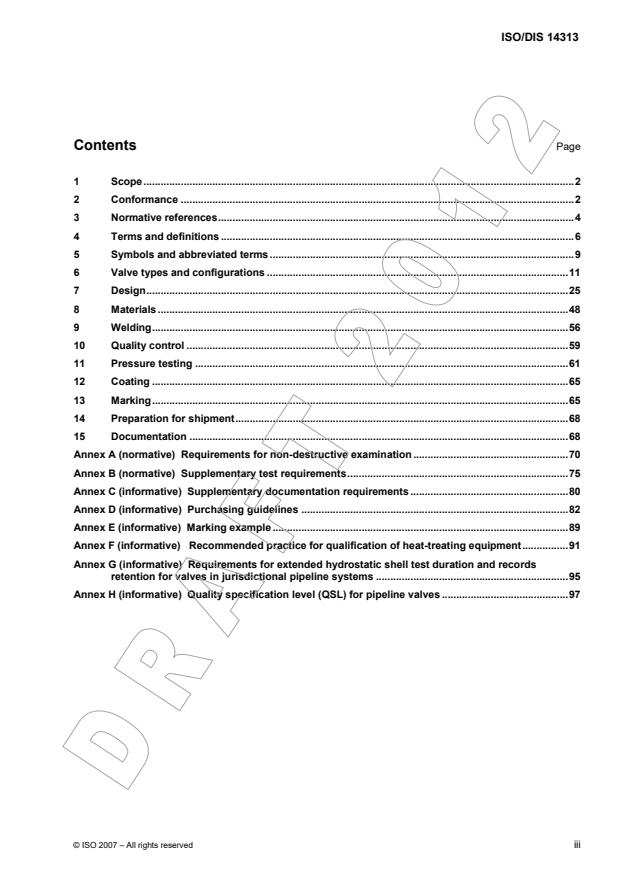

Contents Page

1 Scope......................................................................................................................................................2

2 Conformance .........................................................................................................................................2

3 Normative references............................................................................................................................4

4 Terms and definitions ...........................................................................................................................6

5 Symbols and abbreviated terms ..........................................................................................................9

6 Valve types and configurations .........................................................................................................11

7 Design...................................................................................................................................................25

8 Materials ...............................................................................................................................................48

9 Welding.................................................................................................................................................56

10 Quality control .....................................................................................................................................59

11 Pressure testing ..................................................................................................................................61

12 Coating .................................................................................................................................................65

13 Marking.................................................................................................................................................65

14 Preparation for shipment....................................................................................................................68

15 Documentation ....................................................................................................................................68

Annex A (normative) Requirements for non-destructive examination ......................................................70

Annex B (normative) Supplementary test requirements.............................................................................75

Annex C (informative) Supplementary documentation requirements .......................................................80

Annex D (informative) Purchasing guidelines .............................................................................................82

Annex E (informative) Marking example .......................................................................................................89

Annex F (informative) Recommended practice for qualification of heat-treating equipment................91

Annex G (informative) Requirements for extended hydrostatic shell test duration and records

retention for valves in jurisdictional pipeline systems ...................................................................95

Annex H (informative) Quality specification level (QSL) for pipeline valves ............................................97

© ISO 2007 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 14313

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 14313 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries, Subcommittee SC 2, Pipeline transportation systems.

This third edition cancels and replaces the second edition (ISO 14313:2007), which has been technically

revised, principally by the following Removal of all PN designations

Clause 2.4, add process requiring validation and clarify use of quality management system

Clause 7.20.2 revise requirements for allowable stresses to comply with ASME Sec II part D has been

revised and clarified. Clause 8, add requirements for material processing, material qualification,,impact values, heat treat

furnace calibration and hardness testing Clause 9 add clause for welding consumables, weld repairs, revise clause for hardness method used on

PQR hardness survey. Clause 10, clarify calibration of pressure measuring devices, NDE personnel qualification and add

requirement for mandatory surface NDE of castings and production hardness testing.

Clause 11, seat. Revise table 10 and 11 to add test duration for larger size valves. Add mandatory low

pressure air seat test. Add new Annexes F, G and H.

iv © ISO 2007 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 14313:2007(E)

Introduction

This International Standard is the result of harmonizing the requirements of ISO 14313:2007 and

[5]API Spec 6D-2008 .

The revision of ISO 14313 is developed based on input from both ISO/TC67/SC2/WG2 and

API 6D TG technical experts. The technical revisions have been made In order to accommodate the needs of

industry and to move this International Standard to a higher level of service to the petroleum and natural gas

industry.Users of this International Standard should be aware that further or differing requirements can be needed for

individual applications. This International Standard is not intended to inhibit a manufacturer from offering, or

the purchaser from accepting, alternative equipment or engineering solutions for the individual application.

This may be particularly applicable where there is innovative or developing technology. Where an alternative

is offered, the manufacturer should identify any variations from this International Standard and provide details.

© ISO 2007 – All rights reserved v---------------------- Page: 5 ----------------------

ISO/DIS 14313

Petroleum and natural gas industries — Pipeline transportation

systems — Pipeline valves

1 Scope

This International Standard specifies requirements and provides recommendations for the design,

manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline

systems meeting the requirements of ISO 13623 for the petroleum and natural gas industries.

This International Standard is not applicable to subsea pipeline valves, as they are covered by a separate

International Standard (ISO 14723).This International Standard is not applicable to valves for pressure ratings exceeding Class 2500.

2 Conformance2.1 Units of measurement

In this International Standard, data are expressed in both SI units and USC units. For a specific order item,

unless otherwise stated, only one system of units shall be used, without combining data expressed in the

other system.For data expressed in SI units, a comma is used as the decimal separator and a space is used as the

thousands separator. For data expressed in USC units, a dot (on the line) is used as the decimal separator

and a comma is used as the thousands separator.2.2 Rounding

Except as otherwise required by this International Standard, to determine conformance with the specified

requirements, observed or calculated values shall be rounded to the nearest unit in the last right-hand place of

figures used in expressing the limiting value, in accordance with the rounding method of ISO 80000-1,

Annex B, Rule A.2.3 Compliance to standard

A documented quality system shall be applied to assist compliance with the requirements of this International

Standard.NOTE Documentation of a quality system does not require certification by a third party certification body. Only the

creation or adoption of a written quality system is necessary to meet the requirement of this standard, ISO defers to the

expertise of responsible quality management personnel to create or adopt the system which best reflects the need of each

manufacture. There are many existing quality management systems to which personnel can refer to for guidance in the

development of an appropriate quality system, including ISO/TS 29001[9] and API Spec Q1[9], which contain provisions

specific to the oil and gas industry, or ISO 9001[7], which contains general requirements for quality management systems

that are auditable. This list is not exhaustive and is provided for information only.

© ISO 2007 – All rights reserved---------------------- Page: 6 ----------------------

ISO 14313:2007(E)

The manufacturer shall be responsible for complying with all of the applicable requirements of this

International Standard. It shall be permissible for the purchaser to make any investigation necessary in order

to be assured of compliance by the manufacturer and to reject any material that does not comply.

2.4 Processes requiring validationThe following operations performed during manufacturing shall be validated as the resulting output cannot be

verified by subsequent monitoring or measurement.The following processes shall be validated, by the manufacturer, in accordance with their quality system:

Nondestructive Examination (NDE) (see 10.1); Welding (see Clause 9);

Heat Treating (see 8.1);

Plating, coating or hard-facing that may impact product performance, by agreement.

© ISO 2007 – All rights reserved iii---------------------- Page: 7 ----------------------

ISO/DIS 14313

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments, corrigendum, and maintenance agency output) applies.

ISO 148-1, Metallic materials — Charpy pendulum impact test — Part 1: Test method

ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions,

tolerances and designationISO 5208, Industrial valves — Pressure testing of valves

ISO 6892-1, Metallic materials — Tensile testing — Part 1: Method of test at room temperature

ISO 9606-1, Approval testing of welders — Fusion welding — Part 1: SteelsISO 9712, Non-destructive testing — Qualification and certification of personnel

ISO 10474, Steel and steel products — Inspection documents

ISO 10497, Testing of valves — Fire type-testing requirements

ISO 12490, Mechanical integrity and sizing of actuators and mounting kits for pipeline valves

ISO 15156 (all parts), Petroleum and natural gas industries — Materials for use in H S-containing

environments in oil and gas productionISO 15607, Specification and qualification of welding procedures for metallic materials — General rules

ISO 15609 (all parts), Specification and qualification of welding procedures for metallic materials — Welding

procedure specificationISO 15614-1, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

ISO 23277, Non-destructive testing of welds — Penetrant testing of welds — Acceptance levels

ISO 23278, Non-destructive testing of welds — Magnetic particle testing of welds — Acceptance levels

ISO 80000-1, Quantities and units — Part 1: General principlesASME B1.20.1 , Pipe Threads, General Purpose, Inch

ASME B16.5, Pipe Flanges and Flanged Fittings: NPS 1/2 through 24

ASME B16.10, Face-to-Face and End-to-End Dimensions of Valves

ASME B16.34, Valves, Flanged, Threaded, and Welding End

ASME B16.47, Large Diameter Steel Flanges: NPS 26 Through NPS 60 Metric/Inch Standard

1) American Society of Mechanical Engineers International, 345 East 47 Street, NY 10017-2392, USA

© ISO 2007 – All rights reserved---------------------- Page: 8 ----------------------

ISO 14313:2007(E)

ASME B31.4, Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

ASME B31.8, Gas Transmission and Distribution Piping SystemsASME Boiler and Pressure Vessel Code, Section V: Nondestructive Examination

ASME Boiler and Pressure Vessel Code — Section VIII: Rules for Construction of Pressure Vessels

Division 1, Rules for Construction of Pressure VesselsASME Boiler and Pressure Vessel Code — Section VIII: Rules for Construction of Pressure Vessels

Division 2: Alternative RulesASME Boiler and Pressure Vessel Code — Section IX: Welding and Brazing Qualifications

ASNT SNT-TC-1A , Recommended Practice No. SNT-TC-1A — Personnel Qualification and Certification in

Non-Destructive TestingASTM A320 , Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for Low-

Temperature ServiceASTM A370, Standard Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM A388, Standard Practice for Ultrasonic Examination of Heavy Steel ForgingsASTM A435, Standard Specification for Straight-Beam Ultrasonic Examination of Steel Plates

ASTM A577, Standard Specification for Ultrasonic Angle-Beam Examination of Steel Plates

ASTM E10, Standard Test Method for Brinell Hardness of Metallic MaterialsASTM E18, Standard Test Methods for Rockwell Hardness of Metallic Materials

ASTM E110, Standard Test Method for Indentation Hardness of Metallic Materials by Portable Hardness

TestersAWS QC1 , Standard for AWS Certification of Welding Inspectors

EN 287-1 , Qualification test of welders — Fusion welding — Part 1: Steels

EN 473, Nondestructive testing—Qualification and certification of NDT personnel—General

PrinciplesEN 10204, Metallic products — Type of inspection documents

MSS SP-44, Steel Pipeline Flanges

MSS SP-55, Quality Standard for Steel Castings for Valves, Flanges and Fittings and Other Piping

Components — Visual Method for Evaluation of Surface Irregularities2) American Society of Non-Destructive Testing, P.O. Box 28518, 1711 Arlingate Lane, Columbus, OH 43228-0518,

USA.3) ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, USA.

4) The American Welding Society, 550 NW LeJeune Road, Miami, FL 33126, USA.5) CEN, European Committee for Standardization, Central Secretariat, Rue de Stassart 36, B-1050, Brussels, Belgium.

© ISO 2007 – All rights reserved v---------------------- Page: 9 ----------------------

ISO/DIS 14313

NACE TM0177, Standard test method. Laboratory testing of metals for resistance to specific forms of

environmental cracking in H S environmentsNACE TM0284, Standard Test Method — Evaluation of Pipeline and Pressure Vessel Steels for Resistance to

Hydrogen-Induced Cracking4 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

4.1

ASME rating class

numerical pressure design class defined in ASME B16.34 and used for reference purposes

NOTE The ASME rating class is designated by the word “class” followed by a number.

4.2bi-directional valve

valve designed for blocking the fluid in both downstream and upstream directions

4.3

bleed

drain or vent

4.4

block valve

gate, plug or ball valve that blocks flow into the downstream conduit when in the closed position

NOTE Valves are either single- or double-seated, bi-directional or uni-directional.

4.5breakaway thrust

breakaway torque

maximum thrust or torque required to operate a valve at maximum pressure differential

4.6by agreement

agreed between manufacturer and purchaser

4.7

double-block-and-bleed valve

DBB

single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both

ends of the valve with a means of venting/bleeding the cavity between the seating surfaces

NOTE This valve does not provide positive double isolation when only one side is under pressure. See double-

isolation-and-bleed valve (4.8).4.8

double-isolation-and-bleed valve

DIB

single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure

from a single source, with a means of venting/bleeding the cavity between the seating surfaces

© ISO 2007 – All rights reserved---------------------- Page: 10 ----------------------

ISO 14313:2007(E)

NOTE This feature can be provided in one direction or in both directions.

4.9

drive train

all parts of a valve drive between the operator and the obturator, including the obturator but excluding the

operator4.10

flow coefficient

volumetric flow rate of water at a temperature between 5 °C (40 °F) and 40 °C (104 °F) passing through a

valve and resulting in a pressure loss of 0,1 MPa (1 bar; 14,5 psi)NOTE K is expressed in SI units of cubic metres per hour.

NOTE K is related to the flow coefficient C ,,expressed in USC units of US gallons per minute at 15,6 °C (60 °F)

v vresulting in a 1 psi pressure drop as given by Equation (1):

K (1)

1,156

4.11

full-opening valve

valve with an unobstructed opening, not smaller than the internal bore of the end connections

4.12handwheel

wheel consisting of a rim connected to a hub, for example by spokes, and used to manually operate a valve

requiring multiple turns4.13

locking device

part or an arrangement of parts for securing a valve in the open and/or closed position

4.14manual actuator

manual operator

wrench (lever) or hand-wheel with or without a gearbox

4.15

maximum pressure differential

MPD

maximum pressure difference across the obturator at which the obturator may be operated

4.16nominal pipe size

NPS

numerical imperial designation of size which is common to components in piping systems of any one size

NOTE Nominal pipe size is designated by the abbreviation “NPS” followed by a number.

4.17nominal size

numerical metric designation of size that is common to components in piping systems of any one size

NOTE Nominal size is designated by the abbreviation “DN” followed by a number.© ISO 2007 – All rights reserved vii

---------------------- Page: 11 ----------------------

ISO/DIS 14313

4.18

obturator

closure member

part of a valve, such as a ball, clapper, disc, gate or plug that is positioned in the flow stream to permit or

prevent flow4.19

operator

device (or assembly) for opening or closing a valve

4.20

packing gland

component used to compress the stem packing

4.21

position indicator

device to show the position of the valve obturator

4.22

piggability

capability of a valve to permit the unrestricted passage of a pig

4.23

powered actuator

powered operator

electric, hydraulic or pneumatic device bolted or otherwise attached to the valve for powered opening and

closing of the valve4.24

pressure class

numerical pressure design class expressed in accordance with ASME rating class

4.25

pressure-containing parts

parts whose failure to function as intended results in a release of contained fluid into the environment

4.26pressure-controlling parts

parts, such as seat and obturator, intended to prevent or permit the flow of fluids

4.27process-wetted parts

parts exposed directly to the pipeline fluid

4.28

reduced-opening valve

valve with the opening through the obturator smaller than at the end connection(s)

4.29sealing surfaces

mating contact surfaces required to establish a pressure barrier

4.30

seating surfaces

contact surfaces of the obturator and seat which ensure valve sealing

© ISO 2007 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 14313:2007(E)

4.31

stem

part that connects the obturator to the operator and which can consist of one or more components

4.32stem extension assembly

assembly consisting of the stem extension and the stem extension housing

4.33

support ribs or legs

metal structure that provides a stable footing when the valve is set on a fixed base

4.34through-conduit valve

valve with an unobstructed and continuous cylindrical opening

4.35

uni-directional valve

valve designed for blocking the flow in one direction only

4.36

unless otherwise agreed

modification of the requirements of this International Standard unless the manufacturer and purchaser agree

on a deviation4.37

unless otherwise specified

(modification of the requirements of this International Standard) unless the purchaser specifies otherwise

4.38venturi plug valve

valve with a substantially reduced opening through the plug and a smooth transition from each full-opening

end to the reduced opening5 Symbols and abbreviated terms

5.1 Symbols

C flow coefficient in USC units

D diameter

K flow coefficient in metric units

l length

R radius

t thickness

5.2 Abbreviated terms

BM base metal

CE carbon equivalent

DBB double-block-and-bleed

© ISO 2007 – All rights reserved ix

---------------------- Page: 13 ----------------------

ISO/DIS 14313

DIB double isolation-and-bleed

DN nominal size

ER equivalent round

HAZ heat-affected zone

HBW Brinell hardness, tungsten ball indenter

HRC Rockwell C hardness

HV Vickers hardness

MPD maximum pressure differential

MT magnetic-particle testing

NDE non-destructive examination

NPS nominal pipe size

PQR (weld) procedure qualification record

PT penetrant testing

PWHT post-weld heat treatment

RT radiographic testing

SMYS specified minimum yield strength

TC test coupon

USC United States Customary (units)

UT ultrasonic testing

UTS ultimate tensile strength

WM weld metal

WPS weld procedure specification

WPQ welder performance qualification

© ISO 2007 – All rights reserved

---------------------- Page: 14 ----------------------

ISO 14313:2007(E)

6 Valve types and configurations

6.1 Valve types

6.1.1 Gate valves

Typical configurations for gate valves with flanged and welding ends are shown, for illustration purposes only,

in Figures 1 and 2.Gate valves shall have an obturator that moves in a plane perpendicular to the direction of flow. The gate can

be constructed of one piece for slab-gate valves or of two or more pieces for expanding-gate valves.

Gate valves shall be provided with a back seat or secondary stem sealing feature in addition to the primary

stem seal.6.1.2 Lubricated and non-lubricated plug valves

Typical configurations for plug valves with flanged and welding ends are shown, for illustration purposes only,

in Figure 3.Plug valves shall have a cylindrical or conical obturator that rotates about an axis perpendicular to the

direction of flow.6.1.3 Ball valves

Typical configurations for ball valves with flanged or welding ends are shown, for illustration purposes only, in

Figures 4, 5 and 6.Ball valves shall have a spherical obturator that rotates on an axis perpendicular to the direction of flow.

6.1.4 Check valvesTypical configurations for check valves are shown, for illustration purposes only, in Figures 7 to 13. Check

valves can also be of the wafer, axial flow and lift type. Wafer, axial flow and lift type check valves are

considered non-piggable.Check valves shall have an obturator which responds automatically to block fluid in one direction.

6.2 Valve configurations6.2.1 Full-opening valves

Full-opening flanged-end valves shall be unobstructed in the fully opened position and shall have an internal

bore as specified in Table 1. There is no restriction on the upper limit of valve bore sizes.

Full-opening through-conduit valves shall have a circular bore in the obturator that allows a sphere to pass

with a nominal size not less than that specified in Table 1.Welding-end valves can require a smaller bore at the welding end to mate with the pipe.

Valves with a non-circular opening through the obturator shall not be considered full opening.

6.2.2 Reduced-opening valvesReduced-opening valves with a circular opening through the obturator shall be supplied with a minimum bore

as follows, unless otherwise specified:© ISO 2007 – All rights reserved xi

---------------------- Page: 15 ----------------------

ISO/DIS 14313

valves DN 300 (NPS 12) and below: one size below nominal size of valve with bore according to Table 1;

valves DN 350 (NPS 14) to DN 600 (NPS 24): two sizes below nominal size of valve with bore according

to Table 1; valves above DN 600 (NPS 24): by agreement.

EXAMPLE A DN 400 (NPS 16) – Class 1500 reduced-opening ball valve has a minimum bore of 287 mm.

Valves with non-circular or annular (total or partial) opening through the obturator shall be supplied with a

minimum flow area by agreement.Table 1 — Minimum bore for full-opening valves

Minimum bore by class

DN NPS

Class 150 to 600 Class 900 Class 1500 Class 2500

15 ½ 13 13 13 13

20 ¾ 19 19 19 19

25 1 25 25 25 25

32 1¼ 32 32 32 32

40 1½ 38 38 38 38

50 2 49 49 49 42

65 2½ 62 62 62 52

80 3 74 74 74 62

100 4 100 100 100 87

150 6 150 150 144 131

200 8 201 201 192 179

250 10 252 252 239 223

300 12 303 303 287 265

350 14 334 322 315 292

400 16 385 373 360 333

450 18 436 423 406 374

500 20 487 471 454 419

550 22 538 522 500 —

600 24 589 570 546 —

650 26 633 617 594 —

700 28 684 665 641 —

750 30 735 712 686 —

800 32 779 760 730 —

850 34 830 808 775 —

900 36 874 855 819 —

© ISO 2007 – All rights reserved

---------------------- Page: 16 ----------------------

ISO 14313:2007(E)

Minimum bore by class

DN NPS

Class 150 to 600 Class 900 Class 1500 Class 2500

950 38 925 904 — —

1 000 40 976 956 — —

1 050 42 1 020 1 006 — —

1 200 48 1 166 1 149 — —

1 350 54 1 312 — — —

1 400 56 1 360 — — —

1 500 60 1 458 — — —

© ISO 2007 – All rights reserved xiii

---------------------- Page: 17 ----------------------

ISO/DIS 14313

Key

1 stem indicator

2 stem enclosure

3 hand-wheel

4 yoke nut

5 yoke

6 stem

7 yoke bolting

8 stem packing

9 relief valve

10 bonnet

11 bonnet bolting

12 gate guide

13 gate assembly

14 seat ring

15 body

16 support ribs or legs

17 raised face

18 welding end

19 ring joint

A raised-face face-to-face

dimension

B welding-end end-to-end

dimension

C ring-joint end-to-end

dimension

NOTE See Tables 2 to

6 for dimensions A, B and C.

Figure 1 — Expanding-gate/rising-stem gate valve

© ISO 2007 – All rights reserved

---------------------- Page: 18 ----------------------

ISO 14313:2007(E)

Key

1 stem indicator

2 stem enclosure

3 hand-wheel

4 yoke nut

5 yoke

6 stem

7 yoke bolting

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.