ISO/PRF 24294

(Main)Timber -- Round and sawn timber -- Vocabulary

Timber -- Round and sawn timber -- Vocabulary

Bois -- Bois ronds et bois sciés -- Vocabulaire

General Information

Standards Content (sample)

INTERNATIONAL ISO

STANDARD 24294

Second edition

Timber — Round and sawn timber —

Vocabulary

Bois — Bois ronds et bois sciés — Vocabulaire

PROOF/ÉPREUVE

Reference number

ISO 24294:2021(E)

ISO 2021

---------------------- Page: 1 ----------------------

ISO 24294:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 24294:2021(E)

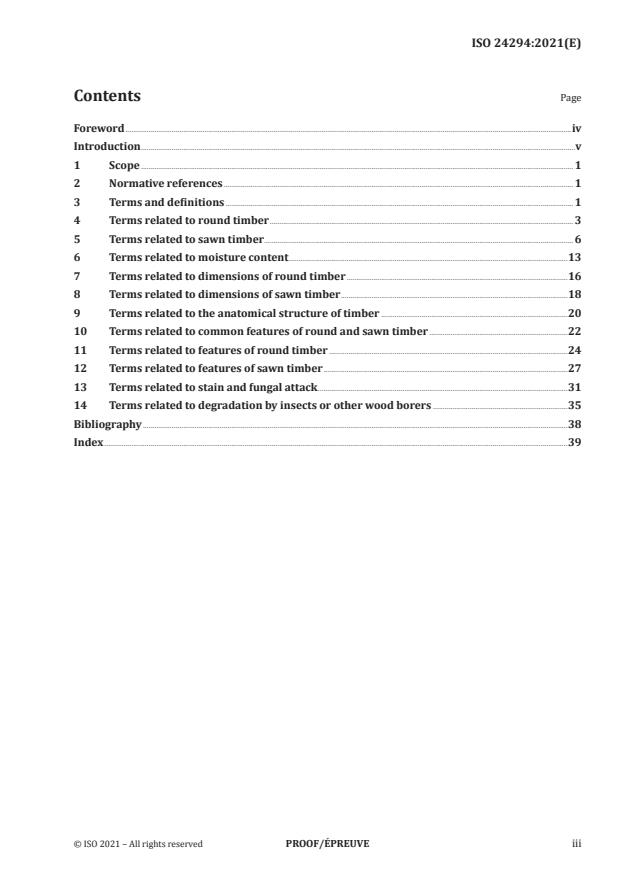

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Terms related to round timber .............................................................................................................................................................. 3

5 Terms related to sawn timber ................................................................................................................................................................. 6

6 Terms related to moisture content .................................................................................................................................................13

7 Terms related to dimensions of round timber ...................................................................................................................16

8 Terms related to dimensions of sawn timber ......................................................................................................................18

9 Terms related to the anatomical structure of timber .................................................................................................20

10 Terms related to common features of round and sawn timber ........................................................................22

11 Terms related to features of round timber ............................................................................................................................24

12 Terms related to features of sawn timber ...............................................................................................................................27

13 Terms related to stain and fungal attack ..................................................................................................................................31

14 Terms related to degradation by insects or other wood borers ......................................................................35

Bibliography .............................................................................................................................................................................................................................38

Index .................................................................................................................................................................................................................................................39

© ISO 2021 – All rights reserved PROOF/ÉPREUVE iii---------------------- Page: 3 ----------------------

ISO 24294:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 218, Timber.

This second edition of ISO 24294 cancels and replaces ISO 24294:2013 and ISO 1032:1974, which have

been technically revised. The main changes compared to the previous editions are as follows:

— updated, corrected and clarified definitions;— re-ordered term categories and terms within categories to match the subject matter.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 24294:2021(E)

Introduction

Wood is a naturally occurring resource and is the only major construction material that is renewable.

Because it is renewable, the use of wood and the many different timber products made from wood,

contributes to overall sustainable development. Many of these timber products are intended specifically

for use both as structural and non-structural elements in the construction of timber-framed or

platform-frame buildings. Properties of wood are affected by species, natural growth characteristics

and moisture content and with its unique cell structure; wood has different strength properties in

different grain directions.This document defines terms related to the physical and mechanical characteristics of the many

different hardwood and softwood round, sawn and processed timbers in a manner that is consistent

and recognized globally. This document has been prepared by the various groups involved in the timber

industry, such as manufacturers, builders, wholesalers and importers, as well as research organizations,

academia, national regulatory bodies, standards developers and professional design organizations.

Understanding the nature of the various physical characteristics and features of round and sawn timber

enables effective communication related to sawn and processed timber, in a manner that is consistently

understood by and equitable to all active and potential traders/users. Its use alongside other standards

also aids harmonization and provide a basis for specialist terminology.© ISO 2021 – All rights reserved PROOF/ÉPREUVE v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 24294:2021(E)

Timber — Round and sawn timber — Vocabulary

1 Scope

This document defines terms related to round and sawn timber. It applies to identification of a tree

and its components, stages of processing in round and sawn forms, and timber grading, dimensions,

anatomical structure, features, moisture content and conditions relating to stain, fungal and insect

attack. It does not apply to terms related to strength properties of wood, engineered timber products or

timber structures.2 Normative references

There are no normative references in this document.

3 Terms and definitions

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1

wood

lignocellulosic substance between the pith (9.14) and bark (9.5) of a tree or a shrub

Note 1 to entry: Lignified materials from bamboo, cork, rattan, palm trees and other monocotyledons are not

wood.Note 2 to entry: Internationally, the terms “wood” and timber (3.2) are often used interchangeably to represent

the basic material of wood products.3.2

timber

wood (3.1) in the form of standing or felled trees, or a solid wood product of these after processing (3.10)

Note 1 to entry: In the case of processed solid wood products, refers to round timber (4.1) and sawn timber (5.1).

Does not apply to other wood products, such as wood-based panels, veneer, wood pulp, chips (3.11) or sawdust

(3.12).Note 2 to entry: Internationally, the terms “timber” and “wood” are often used interchangeably to represent the

basic material of wood products.Note 3 to entry: In Canada and the U.S., there is a homograph for the term “timber”. See 5.6.

3.3species

botanical category classifying a group of distinct trees with a significant level of genetic similarity

EXAMPLE Douglas-fir (Pseudotsuga menziesii) and Norway spruce (Picea abies).Note 1 to entry: Usually referred to by a common name and identified by a botanical name that is based on a

Linnaean binomial of its genus and species.© ISO 2021 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 6 ----------------------

ISO 24294:2021(E)

3.3.1

species group

species combination, en CA, U.S.

population of two or more tree species (3.3) or multiple populations of the same tree species combined

into a single marketing group on the basis of similar properties using criteria appropriate for the

intended end useEXAMPLE Spruce-pine-fir (S-P-F).

Note 1 to entry: Evaluated to develop combined species properties so that the wood products from species within

the group can be used interchangeably.Note 2 to entry: Trees of the same species group may originate from one or more growth or production regions.

3.4hardwood

wood (3.1) of trees of the botanical class Angiospermae, subclass Dicotyledonae

Note 1 to entry: The term has no reference to the actual hardness of the wood.

Note 2 to entry: Generally deciduous trees with broad leaves and enclosed seeds.

3.5

softwood

wood (3.1) of trees of the botanical class Gymnospermae, subclass Coniferophytae

Note 1 to entry: The term has no reference to the actual hardness of the wood.

Note 2 to entry: Generally evergreen trees with needle or scale-like leaves and unenclosed seeds, also known as

conifers.3.6

feature

physical, morphological or growth characteristic of timber (3.2) that could affect its use

3.7defect

feature (3.6) that results in lower quality of timber (3.2) which causes restrictions in use

3.8grading

separation or sorting of timber (3.2) by end-use, tree species (3.3), appearance, mechanical or working

properties, sizes or some combination thereof3.9

batch

lot

specified quantity of a product

3.10

processing

function or a combination of functions other than felling (4.26) that change the form of the material

without changing its solid wood (3.1) structureNote 1 to entry: May include debarking (4.14), sawing, re-sawing, planing (surfacing), cross-cutting and trimming

at the sawmill, but does not include gluing.Note 2 to entry: May be supplemented by drying (6.10) at various stages of production.

2 PROOF/ÉPREUVE © ISO 2021 – All rights reserved---------------------- Page: 7 ----------------------

ISO 24294:2021(E)

3.11

chips

small flakes of wood (3.1) produced during a fragmentation process

Note 1 to entry: Generally utilized for pulp, wood-based products or fuel.

3.12

sawdust

fine particles of wood (3.1) produced during the process of sawing

3.13

cross-section

virtual section at a right angle to the longitudinal axis

3.14

length

shortest distance between the ends of a piece of timber (3.2)

4 Terms related to round timber

4.1

round timber

felled tree after delimbing and removal of top, that may or may not have been cross-cut

4.1.1long pole

round timber (4.1) that has not been cross-cut

4.1.2

log

cross-cut portion of round timber (4.1)

4.1.3

butt log

log (4.1.2) produced from the larger end of a long pole (4.1.1)

4.1.4

middle log

log (4.1.2) produced from the portion of a long pole (4.1.1) between the butt log (4.1.3) and the top end

log (4.1.5)Note 1 to entry: More than one middle log may be obtained from one long pole.

4.1.5

top end log

log (4.1.2) produced from the smaller end of a long pole (4.1.1)

4.1.6

cylindrical log

perfect round log

log (4.1.2) that has a cross-section (3.12) on both ends that represents a true circle

Note 1 to entry: The roundness of a log is determined by measuring the largest diameter (7.1) and the diameter at

right angles to it, at the least round end and calculating the ratio of the lesser and greater diameters, expressed as

a percentage. The roundness of 100 % is rarely achieved naturally.4.2

crown

upper portion of a tree with branches

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 3

---------------------- Page: 8 ----------------------

ISO 24294:2021(E)

4.3

spring of the crown

zone of the stem (4.4) from where the lowest branches of the crown (4.1) grow out

4.4stem

portion of a tree above ground, excluding branches

Note 1 to entry: Sometimes refers to trees in general, i.e. stems per unit area.

4.5

trunk

portion of a stem (4.4) used for valuing a standing tree

Note 1 to entry: Usually specified by stating the minimum top diameter (7.1.3).

4.6

butt swelling

flared base part of the stem (4.4)

4.7

buttress

projecting rib at the lower end of the stem (4.4)

4.8

stump

portion of the tree that remains above and below ground level after felling (4.26)

Note 1 to entry: Does not apply to uprooted trees (4.26.1).4.9

branch whorl

zone of the stem (4.4) where several branches or knots (10.1) occur at approximately the same cross-

section (3.12)4.10

de-sapped round timber

round timber (4.1) that has had all sapwood (9.1) thoroughly removed

Note 1 to entry: The sapwood is removed generally to prevent biodeterioration (13.1).

4.11pruned timber

timber (3.2) from a tree that had its lower branches removed by pruning (4.11.1)

4.11.1

pruning

removal of live or dead branches or of multiple leaders of shoots from standing trees

[SOURCE: ISO 6814:2009, 2.19]4.12

stop

portion of a stem (4.4) where there is a marked reduction in diameter (7.1)

Note 1 to entry: Can occur at a thick branch or at a branch whorl (4.9) in some tree species (3.3).

4.13cross-cut point

location on round timber (4.1) where it will be cross-cut

4 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 24294:2021(E)

4.13.1

theoretical cross-cut point

point at which a trunk (4.5) or round timber (4.1) is visually assessed for cross-cutting for grading (3.8)

purposes4.14

debarking

removing bark (9.5) from trees or round timber (4.1)

4.14.1

rough debarking

partial removing of bark (9.5)

4.14.2

bundle debarking

simultaneous debarking (4.14) of a group of round timbers (4.1)

4.14.3

piece-by-piece debarking

debarking (4.14) of individual round timbers (4.1)

4.14.4

patch debarking

rough debarking (4.14.2) resulting in spots or patches of remaining bark (9.5) on the surface of round

timber (4.1)4.14.5

clean debarking

complete removal of bark (9.5) and any remnants of branches and branch wood

4.15

ring barking

girdling, en CA, U.S.

removing a narrow strip of bark (9.5) around the stem (4.4) of a living tree to weaken it or cause death

Note 1 to entry: Not to be confused with debarking (4.14) for the purpose of processing (3.10) round timber (4.1).

4.16sawlog

log (4.1.2) for processing (3.10) into sawn timber (5.1)

4.17

veneer log

log (4.1.2) for conversion into veneer

4.18

pulpwood

log (4.1.2) or logs used for mechanical or chemical conversion into pulp for paper or wood panel

products4.19

pit prop

round timber (4.1) intended for supporting mine works

4.20

special assortment log

log (4.1.2) specified by length (3.14) or diameter (7.1), or both, for a specific end-use

4.21regularized round timber

round timber (4.1) processed to obtain a cylindrical or conical shape

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 5

---------------------- Page: 10 ----------------------

ISO 24294:2021(E)

4.22

pole

long round timber (4.1) for use in a free-standing application

4.23

stake

round timber (4.1) of small diameter (7.1) usually pointed at one end

Note 1 to entry: May also be split or sawn.

4.24

bundle

group of evenly placed logs (4.1.2), bundled by strapping or other packaging means

4.25pile

stack, en CA, U.S.

deck, en CA, U.S.

group of logs (4.1.2) stacked in a row or several parallel rows

Note 1 to entry: Can be located at a forest landing, road-side landing or mill yard.

4.26felling

separating the stem (4.4) of a tree from its root system

Note 1 to entry: Done by cutting a standing tree near ground level to leave a stump (4.8) or by cutting off a root

ball of an uprooted tree (4.26.1).4.26.1

uprooted tree

tree that is blown over as a result of wind or mechanically pushed over with the root ball still attached

5 Terms related to sawn timber5.1

sawn timber

lumber, en CA, U.S.

sawn lumber, en CA, U.S.

solid wood (3.1) product obtained by the longitudinal sawing of logs (4.1.2), having at least two parallel

planesNote 1 to entry: Often supplemented by additional processing (3.10) and/or drying (6.10).

Note 2 to entry: Does not include any products obtained by end, face (5.17) or edge (5.18) gluing of sawn timber

components.5.1.1

rough sawn timber

sawn timber (5.1) without any additional processing (3.10)

5.1.2

regularized green timber

regularized green lumber, en CA, U.S.

sawn timber (5.1), in a green state, processed to specified permitted deviations (8.9)

5.1.3prepared timber

blank

sawn timber (5.1) that, at the end-use moisture content (6.7), has been processed to permitted deviations

(8.9) under special agreement between buyer and seller6 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 24294:2021(E)

5.2

regularized dried timber

regularized dried lumber, en CA, U.S.

regularized dry timber

sawn timber (5.1) that, after drying (6.10) to the end-use moisture content (6.7), has been processed to

specified permitted deviations (8.9)5.3

planed timber

planed lumber, en CA, U.S.

dressed lumber, en CA, U.S.

surfaced lumber, en CA, U.S.

sawn timber (5.1) that, at the end-use moisture content (6.7), has been processed for its full length (3.14)

and width (8.2) on at least one face (5.17) to obtain a smooth surfaceNote 1 to entry: The end-use moisture content forming part of a specification for planed lumber is typically

specified as either an average moisture content (6.1) with a limit on the variation, or as a moisture content limit,

which a large portion of the production shall not exceed.5.4

profiled timber

profiled lumber, en CA, U.S.

sawn timber (5.1) that, at the end-use moisture content (6.7), has been processed to obtain a specified,

non-rectangular cross-section (3.13)5.5

boule

set of pieces of unedged timber (5.14), resulting from cutting a log (4.1.2) longitudinally by successive

parallel cuts, and reassembled into the original log form without the slabs (5.15)

5.6baulk

timber, en CA, U.S.

large scantling, en MY

large sawn timber (5.1) of square or rectangular cross-section (3.13)

Note 1 to entry: In Canada and the U.S., the minimum dimensions of the cross-section of a timber are

114 mm × 114 mm (nominal 5 in × 5 in).Note 2 to entry: In Malaysia, the minimum dimensions of the cross-section of a large scantling are nominal

10 in × 6 in.Note 3 to entry: In Belarus, Russia and Ukraine, the minimum dimensions of the cross-section of a baulk are

100 mm × 100 mm.Note 4 to entry: In the EU, the minimum thickness (8.1) of a baulk is 80 mm and the sum of the thickness and

width (8.2) shall be greater than or equal to 200 mm.Note 5 to entry: In Canada and the U.S., there is a homograph for the term “timber”. See 3.2.

5.7board

piece of sawn timber (5.1) of smaller dimensions

Note 1 to entry: In Malaysia, at least 141 mm (nominal 6 in) in width (8.2).

Note 2 to entry: In Belarus, Russia and Ukraine, less than 100 mm thick with the width at least twice the thickness

(8.1).Note 3 to entry: In Great Britain/UK, at least 100 mm (nominal 4 in) in width.

Note 4 to entry: In Japan, less than 75 mm thick with the width at least four times the thickness.

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 7---------------------- Page: 12 ----------------------

ISO 24294:2021(E)

Note 5 to entry: In Canada and the U.S., less than 38 mm (nominal 2 in.) thick and 38 mm (nominal 2 in.) or more

in width.5.8

lath

slat, en CA, U.S.

strip, en MY

thin, narrow strip of sawn timber (5.1)

Note 1 to entry: Typically, 9 mm (3/8 in) to 12,5 mm (1/2 in) in thickness (8.1) and 38 mm (1-1/2 in) in width (8.2).

Note 2 to entry: In Malaysia, the width can be up to 141 mm (nominal 6 in).Note 3 to entry: Typically used as backing for wall plaster and sometimes for fences.

5.9scantling

piece of sawn timber (5.1) of rectangular cross-section (3.13) whose thickness (8.1) usually equals or

exceeds half its width (8.2)EXAMPLE 1 Small scantlings have sizes such as 3 in × 2 in, 4 in × 2 in, 4 in × 3 in, 6 in × 4 in, etc.

EXAMPLE 2 Large scantlings have sizes such as 10 in × 6 in, 12 in × 8 in, 12 in × 12 in, etc.

Note 1 to entry: In Malaysia, the minimum dimensions of the cross-section of a large scantling (5.6) are nominal

10 in × 6 in.Note 2 to entry: In Belarus, Russia and Ukraine, the thickness of a small scantling is less than 100 mm.

5.10cant

flitch, en CA, U.S.

log (4.1.2) sawn on at least one side

Note 1 to entry: Usually intended for further processing (3.10).

Note 2 to entry: In some countries, may be specified as having at least two flat sides.

5.11square-edged timber

square-cornered timber, en CA, U.S.

sawn timber (5.1) of rectangular cross-section (3.13)

Note 1 to entry: Wane (5.13), in specified amounts, is permitted in some cases.

Note 2 to entry: In Canada and the U.S., the term “square-edged” refers to sawn timber free of wane and without

eased edges/eased arrises (5.19.3).Note 3 to entry: In Canada and the U.S., the term “square cornered” refers to sawn timber with an allowance for

wane (5.13) in some cases but without eased edges/eased arrises.5.12

taper-edged timber

sawn timber (5.1) processed so that the edges (5.18) are not parallel

5.13

wane

absence of wood (3.1) in the cross-section (3.13) of sawn timber (5.1) due to the original rounded surface

of a log (4.1.2), with or without bark (9.5), on any face (5.17) or edge (5.18) and extending along the

longitudinal axis of the piece8 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 13 ----------------------

ISO 24294:2021(E)

5.14

unedged timber

sawn timber (5.1) with parallel faces (5.17) and with one or both edges (5.18) left unsawn

5.15slab

thin longitudinal exterior slice of a log (4.1.2) obtained by the first sawcut

Note 1 to entry: May be further processed.

5.16

squared end

end of sawn timber (5.1) that has a plane surface at a right angle to the longitudinal axis of the piece

5.17face

either of the two wider longitudinal opposite surfaces of sawn timber (5.1) or any of the longitudinal

surfaces if the piece has a square cross-section (3.13)5.17.1

outside face

face (5.17) furthest away from the pith (9.14)

5.17.2

inside face

face (5.17) nearer to the pith (9.14)

5.17.3

better face

face (5.17) that, using a specific rule for grading (3.8), is judged to be of a higher grade than the other

face5.17.4

worse face

face (5.17) that, using a specific rule for grading (3.8), is judged to be of a lower grade than the other

face5.18

edge

either one of the narrow longitudinal surfaces of square-edged timber (5.11)

Note 1 to entry: In Canada and the U.S., also applies to the part of the face (5.17) nearest to the arris (5.19) defined

for the purpose of grading (3.8).Note 2 to entry: In Canada and the U.S., there is a homograph for the term “edge”. See 5.19.

5.19arris

edge, en CA, U.S.

line of intersection of two faces (5.17) or a face and an edge (5.18)

Note 1 to entry: In Canada and the U.S., there is a homograph for the term “edge”. See 5.18.

5.19.1waney arris

waney edge, en CA, U.S.

arris (5.19) that contains wane (5.13) in one or more places

5.19.2

sharp arris

sharp edge, en CA, U.S.

arris (5.19) free of wane (5.13)

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 9

---------------------- Page: 14 ----------------------

ISO 24294:2021(E)

5.19.3

eased arris

eased edge, en CA, U.S.

arris (5.19) that has a slightly rounded surface

5.20

plain sawn timber

sawn timber (5.1) that has a face (5.17) normal or approximately normal to the rays (9.20)

Note 1 to entry: Limits on the angle between rays depend on the species (3.3) and on other factors; e.g. for oak, the

angle between the rays and the face are between 60° and 90°. Other limits can be specified in rules for grading

(3.8).5.21

plain sawn timber

sawn timber (5.1) that has a face (5.17) tangential or approximately tangential to the

growth rings (9.8)Note 1 to entry: Limits species (3.3) where the rays are not visible are 0° and 30° for the angle between the

growth rings and the face. Other limits can be specified in rules for grading (3.8).

5.22quarter sawn timber

sawn timber (5.1) that has a face (5.17) tangential or approximately tangential to the rays

(9.20)Note 1 to entry: Limits on the angle between rays depend on the species (3.3) and on other factors; e.g. for oak,

the angle between the rays and the face are between 0° and 30°. Other limits can be specified in rules for grading

(3.8).5.23

quarter sawn timber

sawn timber (5.1) that has a face (5.17) normal or approximately normal to the growth

rings (9.8)Note 1 to entry: Limits for species (3.3) where the rays are not visible are 90° and 60° for the angle between the

growth rings and the face. Other limits can be specified in rules for grading (3.8).

Note 2 to entry: In Canada and the U.S., the term “quarter sawn” refers to timber (3.2) sawn so that the growth

rings form angles of 45° to 90° with the face of the piece.5.24

fully quarter sawn timber

sawn timber (5.1) where the angle between the rays (9.20) and a face (5.17) is 10° or less

5.25fully quarter sawn timber

sawn timber (5.1) where the angle between the growth rings (9.8) and a face (5.17) is

80° or more5.26

grain

fibres (9.18) in wood (3.1) and their direction, size, arrangement, appearance or quality

Note 1 to entry: In English, there is a homograph for the term “grain”. See 9.19.

5.26.1diagonal grain

deviation of grain (5.26) from a line parallel to the edges (5.18), through the thickness (8.1) of the piece.

Note 1 to entry: See also slope of grain (12.7).10 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 15 ----------------------

ISO 24294:2021(E)

5.26.2

flat grain

FG, en CA, U.S.

slash grain

SG, en CA, U.S.

timber (3.2) sawn approximately parallel to the growth rings (9.8) so that all or some of the growth

rings form an angle of less than 45° with either face (5.17) of the pieceNote 1 to entry: A piece of sawn timber (5.1) containing both vertical grain (5.26.4) and flat grain is classified as

flat grain.5.26.3

mixed grain

MG, en CA, U.S.

sawn timber (5.1) with any mixture of vertical grain (5.26.4) and flat grain (5.26.2)

5.26.4vertical grain

VG, en CA, U.S.

edge grain

EG, en CA, U.S.

rift grain

timber (3.2) sawn at approximate right angles to the growth rings (9.8) so that they form an angle of 45°

or more with either face (5.17) of the piece5.27

exposed pith

pith (9.14) that is visible on a part or the full length (3.14) of a face (5.17) or an edge (5.18)

5.28boxed heart

pith (9.14) that is present and not visible on any face (5.17) or edge (5.18)

5.29

free of heart centre

FOHC, en CA, U.S.

side cut

piece of sawn timber (5.1) that does not contain the pith (9.14

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.