ISO/DIS 10295-1

(Main)Fire tests for building elements and components -- Fire testing of service installations

Fire tests for building elements and components -- Fire testing of service installations

Essais au feu pour les éléments et composants de bâtiment -- Essai au feu des installations de service

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 10295-1

ISO/TC 92/SC 2 Secretariat: ANSI

Voting begins on: Voting terminates on:

2004-02-19 2004-07-19

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Fire tests for building elements and components — Integrity andinsulation performance testing of service installations —

Part 1:

Penetration seals

Essais au feu pour les éléments et composants de bâtiment — Essai de performance d'intégrité et d'isolation

des installations de service —Partie 1: Pénétration au travers de joints d'étanchéité

ICS 13.220.50; 91.140.01

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2004

---------------------- Page: 1 ----------------------

ISO/DIS 10295-1

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2004 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 10295-1

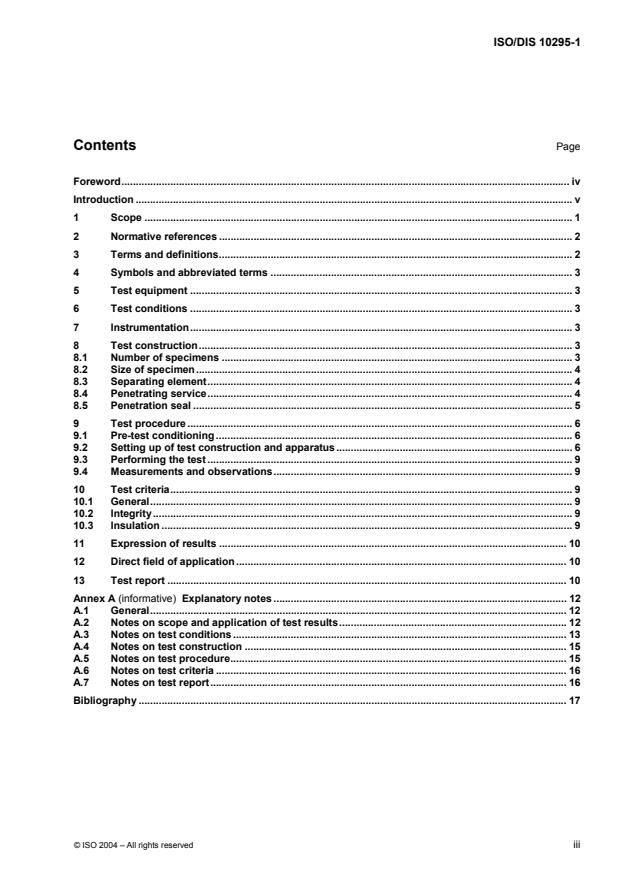

Contents Page

Foreword............................................................................................................................................................ iv

Introduction ........................................................................................................................................................ v

1 Scope ..................................................................................................................................................... 1

2 Normative references ........................................................................................................................... 2

3 Terms and definitions........................................................................................................................... 2

4 Symbols and abbreviated terms ......................................................................................................... 3

5 Test equipment ..................................................................................................................................... 3

6 Test conditions ..................................................................................................................................... 3

7 Instrumentation..................................................................................................................................... 3

8 Test construction.................................................................................................................................. 3

8.1 Number of specimens .......................................................................................................................... 3

8.2 Size of specimen................................................................................................................................... 4

8.3 Separating element............................................................................................................................... 4

8.4 Penetrating service............................................................................................................................... 4

8.5 Penetration seal .................................................................................................................................... 5

9 Test procedure ...................................................................................................................................... 6

9.1 Pre-test conditioning ............................................................................................................................ 6

9.2 Setting up of test construction and apparatus.................................................................................. 6

9.3 Performing the test ............................................................................................................................... 9

9.4 Measurements and observations........................................................................................................ 9

10 Test criteria............................................................................................................................................ 9

10.1 General................................................................................................................................................... 9

10.2 Integrity.................................................................................................................................................. 9

10.3 Insulation ............................................................................................................................................... 9

11 Expression of results ......................................................................................................................... 10

12 Direct field of application................................................................................................................... 10

13 Test report ........................................................................................................................................... 10

Annex A (informative) Explanatory notes ...................................................................................................... 12

A.1 General................................................................................................................................................. 12

A.2 Notes on scope and application of test results............................................................................... 12

A.3 Notes on test conditions .................................................................................................................... 13

A.4 Notes on test construction ................................................................................................................ 15

A.5 Notes on test procedure..................................................................................................................... 15

A.6 Notes on test criteria .......................................................................................................................... 16

A.7 Notes on test report............................................................................................................................ 16

Bibliography ..................................................................................................................................................... 17

© ISO 2004 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 10295-1

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10295-1 was prepared by Technical Committee ISO/TC 2, Fire safety, Subcommittee SC 2, Fire

containment.ISO 10295 consists of the following parts, under the general title Fire tests for building elements and

components — Fire testing of service installations: Part 1: Penetration seals

Part 2: Linear gap seals

Note: There is a document being developed titled: Penetration seals. Guidance on the use of test configurations to

establish direct and extended fields of application, with two subsections: Single component penetration seals and Multi-

component penetration seals.iv © ISO 2004 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 10295-1

Introduction

This part of this International Standard has been prepared to provide a method of test for assessing the

contribution of a penetration sealing system to the fire resistance of separating elements when they have been

penetrated by a service of services. It should be read in conjunction with ISO 834: Part 1. This document

contains specific requirements for fire resistance testing which are unique to the elements of building

construction described as a penetration sealing system. The requirements for these penetration sealing

systems are intended to be applied in appropriate conjunction with the detailed and general requirements

contained in Part 1 of the ISO 834-1.© ISO 2004 – All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 10295-1

Fire tests for building elements and components — Integrity and

insulation performance testing of service installations —

Part 1:

Penetration seals

CAUTION — The attention of all persons concerned with managing and carrying out this fire

resistance test is drawn to the fact that fire testing may be hazardous and that there is a possibility

that toxic and/or harmful smoke and gases may be evolved during the test. Mechanical and

operational hazards may also arise during the construction of the test elements or structures, their

testing and disposal of test residues.An assessment of all potential hazards and risks to health shall be made and safety precautions shall

be identified and provided. Written safety instructions shall be issued. Appropriate training shall be

given to relevant personnel. Laboratory personnel shall ensure that they follow written safety

instructions at all times.1 Scope

1.1 This Part of this International Standard specifies the heating condition, method of test and criteria for

the evaluation of the ability of a penetration sealing system to maintain the integrity and insulation of fire

separating element at the position at which it has been penetrated, for example by a service.

1.2 This International Standard assessa) the effect of such penetrations on the integrity and insulation performance of the element concerned;

b) the integrity and insulation performance of the penetration sealing system;c) the insulation performance of the penetrating service or services, and where necessary, the integrity

failure of a service.1.3 This Part of this International Standard does not provide information concerning the influence of the

inclusion of such penetrations and sealing systems on the loadbearing capacity of the element.

1.4 It is possible that a penetration seal is a component of, or contributes to the performance of, a system to

which special requirements apply. In such cases additional tests, relevant to the system and its function, may

be necessary. Examples are chimneys and fire rated ducts in air distribution systems.

1.5 This Part of this International Standard is not intended to provide quantitative information on the rate of

leakage of smoke and/or hot gases or on the transmission or generation of fumes. Such phenomena are to be

noted in describing the general behaviour of specimens during test.1.6 This Part of this International Standard does not provide information on the ability of the seal to

withstand stresses that might be caused by the movement or displacement of the penetration services in

practice.Explanatory notes are included in Annex A.

© ISO 2004 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 10295-1

2 Normative references

The following standards contain provisions, which through references in this text, constitute provisions of this

International Standard. At the time of publication, the editions indicated were valid. All standards are subject to

revisions, and parties to agreements based on this International Standard are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. Members of the IEC and ISO

maintain registers of currently valid International Standards.ISO 13943, Fire tests — Vocabulary

ISO 834-1, Fire resistance tests — Elements of building construction – Part 1: General requirement for fire

resistance testingISO/TR 12470, Fire resistance tests — Guidance on the application and extension of results

3 Terms and definitionsFor the purposes of this part of ISO 10295-1, the terms and definitions given in ISO 13943 and ISO 834-1 and

the following apply.3.1

fire separating element

floors, walls and other separating elements of construction having a period of fire resistance determined in

accordance with ISO 834: Part 13.2

penetration

an aperture within a fire separating element usually present to accommodate the passage of a service through

that element3.3

service

a penetrating item for example a cable, conduit, pipe with or without any insulation, duct, chimney, or trunking;

excluding air ventilation systems and fire rated ventilation ducts, smoke extract ducts and fire rated service

ducts and shafts3.4

penetration seal

the system used to maintain the fire resistance of the fire separating element at the position where there is

provision for services to pass through the element3.5

penetration sealing system

the assembly for test consisting of the penetrating service or services and the penetration seal, materials or

devices, together with any service support construction, designed to maintain the integrity and insulation

performance of the separating element for the duration of the fire test3.6

service support construction

mechanical support provided in the form of clips, ties, hangers, ladder racks of trays, or any device designed

to carry the load of the penetrating services3.7

blank penetration seal

the system where an aperture of specified size in the fire separating element is sealed or closed by the

specified seal without incorporation of penetrating services2 © ISO 2004 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 10295-1

3.8

test construction

the complete assembly, consisting of the separating element and penetration sealing system

4 Symbols and abbreviated termsSymbols and designations appropriate to this test are given in ISO 834-1.

5 Test equipment

5.1 Equipment employed in the conduct of this test consists of a furnace, restraint and support frames and

instrumentation as specified in ISO 834-1 and this international standard.5.2 The internal dimensions of the test furnace shall have a minimum size of 1 m x 1 m x 1 m and shall be

such that a distance of at least 200 mm exists between any point of the periphery of any penetration seal and

the wall of the furnace.6 Test conditions

6.1 The heating conditions and the furnace atmosphere shall conform to those given in ISO 834-1.

6.2 Where a penetration sealing system is intended for use in both floors and walls then each orientation

shall be tested.6.3 A pressure of (20 ± 2) Pa shall be established at the lowest point of the lowest vertical penetration.

6.4 For horizontal elements a static pressure of (20 ± 2) Pa in the horizontal plane (100 ± 10) mm below the

underside of the separating element shall exist.7 Instrumentation

The control, monitoring and recording equipment necessary to carry out tests in accordance with this

Standard shall be as described in ISO 834: Part 1.8 Test construction

8.1 Number of specimens

8.1.1 In the case of vertical elements, two tests shall be carried out; one from each direction of exposure. If

in practice the fire risk can be identified as from one side only, or where the penetration sealing system is fully

symmetrical, only one specimen is required to be tested with the appropriate face exposed to the heating

regime.8.1.2 Where it can be established clearly in a non-symmetrical construction that there is a weaker direction

of exposure, only the weaker is required to be tested. A full justification for the procedure adopted shall be

included in the report.8.1.3 In the case of horizontal elements, the test specimen shall be exposed to heating from the underside.

© ISO 2004 – All rights reserved 3---------------------- Page: 8 ----------------------

ISO/DIS 10295-1

8.2 Size of specimen

8.2.1 A penetration and the accompanying penetration seal shall be full size. In order to avoid boundary

effects, the distance between the perimeter of the penetration sealing system and the outer perimeter of the

heated part of the separating element shall be not less than 200 mm at any point.

8.2.2 In cases where multiple penetrations are included in a single test construction, the minimum distance

between adjacent fire seals shall be not less than 200 mm. Each penetration with its associated service(s) and

penetration sealing system(s) shall be the subject of a separate evaluation providing the specified conditions

are maintained with respect to the penetration being evaluated.8.3 Separating element

8.3.1 The separating elements shall be of known fire resistance and representative of that used in practice.

A rating obtained on such a specific separating element shall apply only to that particular type of separating

element.8.3.4 Standard separating elements

8.3.4.1 Wall constructions

The constructions depend on the period of fire resistance required. For concrete and masonry elements the

wall shall be constructed from materials having a density of 650 ± 200 kg/m and a thickness of not less than

70 mm.8.3.4.2 Floor constructions

The floor constructions for concrete elements should have a density of (650 ± 200) kg/m or (2200 ± 250)

kg/m and a thickness ‘d’ of not less than 100 mm.8.4 Penetrating service

8.4.1 Selection of service

8.4.1.1 The type of service of services passing through the penetration in the fire resisting element shall

be selected so as to be representative of the services which the penetration seal is designed to accommodate.

Standard service configurations for various applications are the subject of a separate document, which is in

preparation.8.4.1.2 When more than one penetration is incorporated into a test on a single separating element whilst

remaining within the requirements of 6.3, 6.4, 6.5, 6.6 and 8.2, care shall be taken to ensure that there is no

interaction between different penetrations. Examples are where, for instance, the early failure at one of the

penetrations invalidates the time-temperature or pressure conditions specified; or where on penetration

sealing system directly influences another, e.g. by flaming or melting.8.4.2 Installation of service

8.4.2.1 The service(s) shall be installed so that it projects 500 mm on each side of the supporting

construction with a minimum of 300 mm extending beyond the extremities of the penetration sealing system.

In this context the penetration sealing system shall include any coating, wrapping or other protection to the

services. In addition, the length of unprotected service on the unexposed face shall be not greater than 500

mm.8.4.2.2 At the start of the test there shall be a minimum separation of 200 mm between extremities

adjacent penetrations and between any penetration and the internal surface of the furnace.

4 © ISO 2004 – All rights reserved---------------------- Page: 9 ----------------------

ISO/DIS 10295-1

8.4.2.3 For the purpose of test, the possibilities for support provided to the services are as follows:

a) unsupported condition;b) notional support, agreed between the sponsor and the laboratory;

c) either full scale simulation (representative of practical conditions); or

d) the calculation and application of a load to simulate practical conditions. This will determine the field of

direct application.8.4.2.4 In each case the procedure adopted and the validity of the test result shall be fully described in

the report.8.4.2.5 In the case of pipes, pipe end situations may be selected according to table 1 and the conditions

used shall be considered in the corresponding classification of the test result.Table 1 — Pipe end situation

Pipe end situation

Test inside outside

Condition the furnace the furnace

A uncapped uncapped

B capped uncapped

C uncapped capped

D capped capped

8.4.2.6 The capping of pipes shall be carried out by closing the pipe end with a mineral wool or ceramic

fibre disc of a thickness of (50 ± 10) mm and a density of (150 ± 50) kg fixed in place with an appropriate

adhesive (eg sodium silicate adhesive, ceramic adhesive). Alternatively, pipes may be sealed by welding a

disc of the same material as the pipe to the end. In cases where vertical pipes are tested the mineral wool or

ceramic fibre discs shall be fixed additionally by mechanical means.8.5 Penetration seal

8.5.1 Installation of penetration seal

The penetration sealing system shall be installed, together with chosen services, in accordance with the

manufacturer’s instructions or in a manner representative of site practice. The installation procedures shall be

described in the test report.8.5.2 Addition of services

In the case where a penetration sealing system is designed to allow for the alteration of the service content

after first installation, a representative penetration sealing system shall be prepared and fully conditioned.

After this period any required modifications shall be made to the service loading and a further conditioning

period shall be allowed if necessary. Such procedures shall be fully described in the report.

8.5.3 Blank sealWhen it is believed that a seal may perform adversely in the absence of a service then the integrity of

insulation of the blank seal shall be determined.© ISO 2004 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 10295-1

9 Test procedure

9.1 Pre-test conditioning

After completion of the test construction, it shall be subject to a conditioning procedure in accordance with ISO

834: Part 1.9.2 Setting up of test construction and apparatus

9.2.1 Installation of test construction

When the conditioning procedures are satisfied the test construction shall be mounted to form the vertical or

horizontal face of the test furnace as appropriate. Measuring equipment and ancillary apparatus shall be

provided in accordance with the provisions of this Standard.9.2.2 Furnace temperature thermocouples

Thermocouples in accordance with ISO 834: Part 1 for the measurement and control of furnace temperature

shall be uniformly distributed so as to give a reliable indication of the average gas temperature in the vicinity of

the heated face of the test construction. The hot junctions shall be located initially in a plane (100 ± 10) mm

from the exposed face of the separating element. In addition no junction shall be closer than 100 mm to any

projecting part of the seal, a penetrating service or any part of the furnace at the start of the test. At least one

thermocouple shall be provided for every 1.5 m of the heated area of the test construction, subject to a

minimum number of four thermocouples for each test construction.9.2.3 Unexposed face temperature measurement

9.2.3.1 Generally surface temperature measurements shall be made using thermocouples in accordance

with ISO 834: Part 1. In the case of non-planar surfaces, the disc and pad shall be deformed to follow the

surface profile. If there is difficulty in fixing the standard pad, the size of the pad shall be reduced in size

subject to a minimum dimension of 12 mm.9.2.3.2 Thermocouples in accordance with ISO 834: Part 1 for the measurement of unexposed face

surface temperatures shall be provided in the following locations (for example as in figure 1).

6 © ISO 2004 – All rights reserved---------------------- Page: 11 ----------------------

ISO/DIS 10295-1

Figure 1 — Typical thermocouple locations

a) Type A On the surface of the service protruding from the unexposed face, at a position corresponding to

a distance of 25 mm from the point where the service emerges from the penetration seal. At this location,

a measurement shall be made on each different type and/or size of penetrating service included in the

penetration. On each selected service one thermocouple as described above shall be provided per 500

mm perimeter of the service. In the case of tightly bunched or grouped services the grouped assembly shall be treated as a single

service. Thermocouples at the specified positions shall be evenly distributed around the perimeters

of the service. If the service passes through a vertical element one of these thermocouples shall be

attached to the uppermost surface of the service. Also, in the case of vertical elements, when similar

services are included in the penetration the service nearest the top of the penetration shall be chosen

for temperature measurement. Surface thermocouples shall also be placed on the service at a distance of 25 mm from the

termination of any coating or insulation extending along the surface from the penetration.

b) Type B On the surface of the penetration seal at the following locations:© ISO 2004 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/DIS 10295-1

1) If possible, 25 mm from each type of penetrating service (or group of services) with a minimum of

one thermocouple provided for each 500 mm perimeter of the service.2) If appropriate, equidistant from the perimeter of the service to the edge of the penetration where this

distance is a maximum or, in the case where there is more than one penetrating service, at the

nominal mid-position of what in the judgement of the tested is the largest uninterrupted area of seal.

c) Type C At the mid-section of the unexposed surface on any supporting frame at the periphery of the

penetration. In the case of vertical elements this measurement shall be made at the top of the penetration.

d) Type D On the surface of each rack, tray or any service support construction that passes through the fire

seal at distances of 25 mm from the point of emergence from the seal.e) Type E On the surface of the separating element 25 mm from the edge of the penetration with a

minimum of one thermocouple per penetration.f) Type F If, in the opinion of the laboratory, potential weak spots can be identified; additional fixed

thermocouples shall be attached at those points.9.2.3.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.