ISO/TS 17996:2023

(Main)Cheese — Determination of rheological properties by uniaxial compression at constant displacement rate

Cheese — Determination of rheological properties by uniaxial compression at constant displacement rate

This document specifies a method for the determination of rheological properties by uniaxial compression at constant displacement rate in hard and semi-hard cheeses. The method provides standard conditions for sampling and testing, for data representation and general principles of calculation. NOTE Sampling can be difficult with some cheese varieties, e.g. caused by shortness, brittleness, stickiness and soft consistency. In these cases, reliable results cannot be achieved.

Fromage — Détermination des propriétés rhéologiques par compression uniaxiale à vitesse constante de translation

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 17996

IDF/RM 205

Second edition

2023-02

Cheese — Determination of

rheological properties by uniaxial

compression at constant displacement

rate

Fromage — Détermination des propriétés rhéologiques par

compression uniaxiale à vitesse constante de translation

Reference numbers

IDF/RM 205 :2023(E)

IDF/RM 205 :2023(E)

© ISO and IDF 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office International Dairy Federation

CP 401 • Ch. de Blandonnet 8 Silver Building • Bd Auguste Reyers 70/B

CH-1214 Vernier, Geneva B-1030 Brussels

Phone: +41 22 749 01 11 Phone: +32 2 325 67 40

Fax: +32 2 325 67 41

Email: copyright@iso.org Email: info@fil-idf.org

Website: www.iso.org Website: www.fil-idf.org

Published in Switzerland

ii

IDF/RM 205 :2023(E)

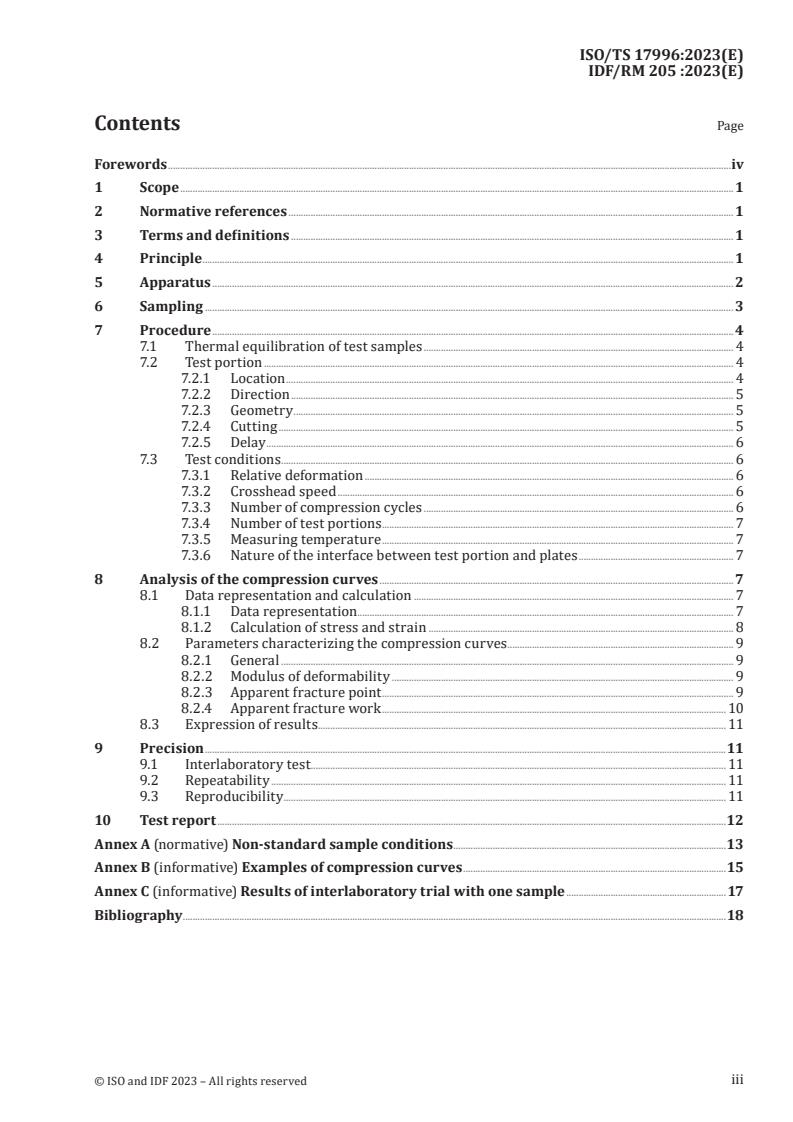

Contents Page

Forewords .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 1

5 Apparatus . 2

6 Sampling . 3

7 Procedure .4

7.1 Thermal equilibration of test samples . 4

7.2 Test portion . 4

7.2.1 Location . 4

7.2.2 Direction . 5

7.2.3 Geometry . 5

7.2.4 Cutting . 5

7.2.5 Delay . 6

7.3 Test conditions . 6

7.3.1 Relative deformation . 6

7.3.2 Crosshead speed . 6

7.3.3 Number of compression cycles . 6

7.3.4 Number of test portions . 7

7.3.5 Measuring temperature . 7

7.3.6 Nature of the interface between test portion and plates . 7

8 Analysis of the compression curves .7

8.1 Data representation and calculation . 7

8.1.1 Data representation . 7

8.1.2 Calculation of stress and strain . 8

8.2 Parameters characterizing the compression curves . 9

8.2.1 General . 9

8.2.2 Modulus of deformability . 9

8.2.3 Apparent fracture point . 9

8.2.4 Apparent fracture work . 10

8.3 Expression of results . 11

9 Precision .11

9.1 Interlaboratory test . . 11

9.2 Repeatability . 11

9.3 Reproducibility . 11

10 Test report .12

Annex A (normative) Non-standard sample conditions .13

Annex B (informative) Examples of compression curves .15

Annex C (informative) Results of interlaboratory trial with one sample .17

Bibliography .18

iii

IDF/RM 205 :2023(E)

Forewords

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which

a technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part

in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 34, Food products, Subcommittee SC 5,

Milk and milk products, and the International Dairy Federation (IDF). It is being published jointly by ISO

and IDF.

This second edition cancels and replaces the first edition (ISO/TS 17996:2006 | IDF/RM 205:2006),

which has been technically revised, with the following changes:

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

IDF/RM 205 :2023(E)

IDF (the International Dairy Federation) is a non-profit private sector organization representing the

interests of various stakeholders in dairying at the global level. IDF members are organized in National

Committees, which are national associations composed of representatives of dairy-related national

interest groups including dairy farmers, dairy processing industry, dairy suppliers, academics and

governments/food control authorities.

ISO and IDF collaborate closely on all matters of standardization relating to methods of analysis

and sampling for milk and milk products. Since 2001, ISO and IDF jointly publish their International

Standards using the logos and reference numbers of both organizations.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. IDF shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

This document was prepared by the IDF Standing Committee on Analytical Methods for Processing Aids

and Indicators and ISO Technical Committee ISO/TC 34, Food products, Subcommittee SC 5, Milk and

milk products. It is being published jointly by ISO and IDF.

The work was carried out by the IDF/ISO Action Team on P18 of the Standing Committee on Analytical

Methods for Processing Aids and Indicators under the aegis of its project leader Mr P. Watkinson (NZ).

v

TECHNICAL SPECIFICATION

IDF/RM 205 :2023(E)

Cheese — Determination of rheological properties by

uniaxial compression at constant displacement rate

1 Scope

This document specifies a method for the determination of rheological properties by uniaxial

compression at constant displacement rate in hard and semi-hard cheeses.

The method provides standard conditions for sampling and testing, for data representation and general

principles of calculation.

NOTE Sampling can be difficult with some cheese varieties, e.g. caused by shortness, brittleness, stickiness

and soft consistency. In these cases, reliable results cannot be achieved.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

rheological properties

deformation under compression of the test sample

Note 1 to entry: In accordance with the procedure specified in this document.

4 Principle

A cylindrical test sample, of defined dimensions, is compressed at a constant crosshead speed with a

compression tool up to a relative deformation sufficient to determine the apparent fracture point. The

force, which is the resistance of the cheese sample during compression, is measured with a load cell.

The displacement may be measured either from the position of the cross head or calculated from the

elapsed time multiplied by the displacement rate.

A schematic representation of the principle of the test is given in Figure 1.

IDF/RM 205 :2023(E)

Key

X displacement V constant displacement rate of the compression tool

Y force H initial sample height

1 compression tool ΔH variation in sample height

a

2 sample Apparent fracture point.

3 fixed base

Figure 1 — Schematic principle of uniaxial compression at constant displacement rate

5 Apparatus

Usual laboratory equipment and, in particular, the following.

5.1 Cork-borer, such as that shown in Figure 2 as an example.

It is recommended to mount the cork-borer on a drill-stand in order to drive it slowly and steadily

through the test sample.

IDF/RM 205 :2023(E)

Key

1 cork borer

2 cheese plug

Example A: d external diameter (d = 25 mm)

e e

d internal diameter (d = 23 mm)

i i

D cutting head diameter (D = 20 mm)

Example B: d external diameter (d = 16,5 mm)

e e

D cutting head diameter (D = d is the internal diameter of 15,3 mm)

i

Figure 2 — Cork-borers for cutting cylindrical cheese plug

5.2 Parallel-wire cutting device, with a wire of diameter less than or equal to 0,4 mm and with a

system to keep the two wires parallel to each other and perpendicular to the plug. It should also include

a mechanically driven cutting system to cut the test sample to the required height.

5.3 Measuring cell, with a support and compression plate of the same stiff material, with smooth

and parallel surfaces, e.g. stainless steel, aluminium or polytetrafluoroethylene (PTFE), of diameter

larger (by 20 %) than that of the deformed test portion when at maximum compression. The load cell

capacity shall have a reasonable relationship to the expected maximum force.

5.4 Compression instrument, providing compression functions typically consisting of two (or

one) vertical columns on a platform and a crosshead connected perpendicular to these columns. This

crosshead is driven vertically up and down by a motor. The load cell is typically directly connected to

this crosshead and fixed to the compression tool (top plate) as shown in Figure 1. The fixed base in

Figure 1 (bottom plate) is connected to the platform.

6 Sampling

A representative sample should have been sent to the laboratory. It should not have been damaged or

changed during transport or storage.

Sampling is not part of the method specified in this document. A recommended sampling method is

[1]

given in ISO 707 | IDF 50 .

IDF/RM 205 :2023(E)

7 Procedure

7.1 Thermal equilibration of test samples

If the storage temperature of the loaf of cheese is above that of the measuring temperature, then the loaf

of cheese shall be equilibrated at the measuring temperature for at least 50 h before further preparation

of the test sample because of the slow crystallization of milk fat in the cheese.

If the storage temperature of the loaf of cheese is below that of the measuring temperature, before any

preparation, store the loaf of cheese at the measuring temperature for at least 12 h. If there are specific

difficulties that can occur during the sample preparation at the measuring temperature, then sample at

the lower storage temperature and then equilibrate the test samples to the measurement temperature.

In this case, the sample thermal equilibration time may be less than 12 h.

NOTE Examples of specific sampling difficulties are that the cheese is hard to cut, or a heated loaf of cheese

changes the storage regime and therefore stops the use of the unsampled portions of the loaf of cheese for future

measurements.

The following shall be avoided:

a) dehydration of the test sample during the period of thermal equilibration;

b) deformation of the test sample due to its own mass.

7.2 Test portion

7.2.1 Location

Take the test portion from the loaf of the cheese with a plug about half a radius, either along a circle of a

cylindrical cheese, or along one side of a rectangular cheese (see Figure 3).

Cut the test portion in the plug in the area representing around half of the length (see Figure 4, plug A).

If the height of cheese is sufficient, two portions can be taken as shown in Figure 4, plug B and plug C.

a) Cheese with cylindrical form b) Cheese with parallelepipedal form

Key

R radius • plug in case 1

W width ° plug in case 2

L length

Figure 3 — Location of plug for cheese sampling

IDF/RM 205 :2023(E)

Key

1 sample

Figure 4 — Three types of sampling in plug

7.2.2 Direction

The standard direction for taking the test portion is parallel to the pressure axis in cheese making. See

Annex B for non-standard sampling conditions.

7.2.3 Geometry

The shape of the test portion shall be a cylinder with initial height/diameter ratio (h /d ) of between

0 0

1,1 and 1,5.

The initial height, h , of the test portion shall range from 12,5 mm to 25 mm. The diameter, d , for a

0 0

given height follows the above-mentioned ratio.

7.2.4 Cutting

Remove the rind or the plastic cover. Take a test portion using a cork-borer (5.1) with shapes shown in

Figure 2. For sticky cheeses, samples are easier to take with corer A than corer B. For cheese varieties

showing shortness or brittleness, form B as shown in Figure 2 is more appropriate than form A. It is

recommended to use a cork-borer mounted on a drill-stand in order to drive it slowly and steadily

through the test sample.

If it is difficult to obtain a good cylindrical form, it is recommended to use mineral oil of low viscosity

1)

(e.g. Vaseline® oil) to lubricate the cork-borer. Do not test samples with cracks, holes or other visible

defects.

1) Vaseline® is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by ISO of this product.

IDF/RM 205 :2023(E)

Use a parallel-wire cutting device to cut the test sample to the required height. The wire diameter shall

be less than or equal to 0,4 mm. It is essential to have a system that keeps the two wires parallel to

each other and perpendicular to the plug. Preferably, use a mechanically driven cu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...