SIST ISO 21111-4:2020:2021

(Main)Road vehicles -- In-vehicle Ethernet

Road vehicles -- In-vehicle Ethernet

This document specifies the optical components requirements and test methods for optical gigabit transmission of in-vehicle Ethernet. Safety (electrical safety, protection, fire, etc.) and electromagnetic compatibility (EMC) requirements are outside the scope of this document.

Véhicules routiers -- Ethernet embarqué

[Not translated]

General Information

Standards Content (sample)

INTERNATIONAL ISO

STANDARD 21111-4

First edition

2020-03

Road vehicles — In-vehicle Ethernet —

Part 4:

General requirements and test

methods of optical gigabit Ethernet

components

Véhicules routiers — Ethernet embarqué —

Partie 4: Exigences générales et méthodes de test des composants

optiques pour l'Ethernet gigabit

Reference number

ISO 21111-4:2020(E)

ISO 2020

---------------------- Page: 1 ----------------------

ISO 21111-4:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 21111-4:2020(E)

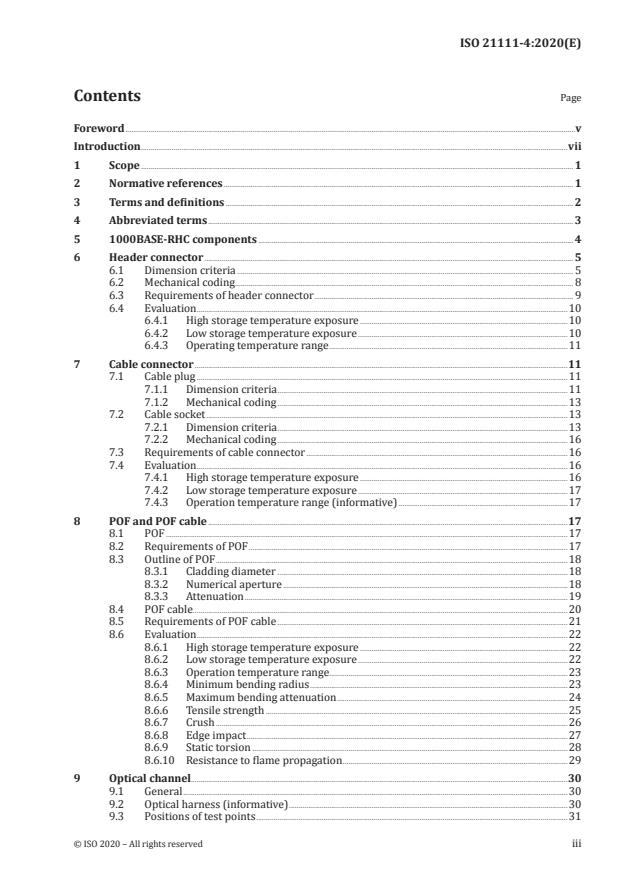

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ..............................................................................................................................................................................................................................vii

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 2

4 Abbreviated terms .............................................................................................................................................................................................. 3

5 1000BASE-RHC components .................................................................................................................................................................... 4

6 Header connector ................................................................................................................................................................................................ 5

6.1 Dimension criteria ............................................................................................................................................................................... 5

6.2 Mechanical coding ................................................................................................................................................................................ 8

6.3 Requirements of header connector ....................................................................................................................................... 9

6.4 Evaluation .................................................................................................................................................................................................10

6.4.1 High storage temperature exposure ............................................................................................................10

6.4.2 Low storage temperature exposure .............................................................................................................10

6.4.3 Operating temperature range ............................................................................................................................11

7 Cable connector ..................................................................................................................................................................................................11

7.1 Cable plug .................................................................................................................................................................................................11

7.1.1 Dimension criteria .......................................................................................................................................................11

7.1.2 Mechanical coding .......................................................................................................................................................13

7.2 Cable socket ............................................................................................................................................................................................13

7.2.1 Dimension criteria .......................................................................................................................................................13

7.2.2 Mechanical coding .......................................................................................................................................................16

7.3 Requirements of cable connector ........................................................................................................................................16

7.4 Evaluation .................................................................................................................................................................................................16

7.4.1 High storage temperature exposure ............................................................................................................16

7.4.2 Low storage temperature exposure .............................................................................................................17

7.4.3 Operation temperature range (informative) ........................................................................................17

8 POF and POF cable ...........................................................................................................................................................................................17

8.1 POF .................................................................................................................................................................................................................17

8.2 Requirements of POF ......................................................................................................................................................................17

8.3 Outline of POF .......................................................................................................................................................................................18

8.3.1 Cladding diameter .......................................................................................................................................................18

8.3.2 Numerical aperture ....................................................................................................................................................18

8.3.3 Attenuation ........................................................................................................................................................................19

8.4 POF cable ...................................................................................................................................................................................................20

8.5 Requirements of POF cable .......................................................................................................................................................21

8.6 Evaluation .................................................................................................................................................................................................22

8.6.1 High storage temperature exposure ............................................................................................................22

8.6.2 Low storage temperature exposure .............................................................................................................22

8.6.3 Operation temperature range ............................................................................................................................23

8.6.4 Minimum bending radius ......................................................................................................................................23

8.6.5 Maximum bending attenuation ........................................................................................................................24

8.6.6 Tensile strength .............................................................................................................................................................25

8.6.7 Crush .......................................................................................................................................................................................26

8.6.8 Edge impact .......................................................................................................................................................................27

8.6.9 Static torsion ....................................................................................................................................................................28

8.6.10 Resistance to flame propagation .....................................................................................................................29

9 Optical channel....................................................................................................................................................................................................30

9.1 General ........................................................................................................................................................................................................30

9.2 Optical harness (informative) .................................................................................................................................................30

9.3 Positions of test points ..................................................................................................................................................................31

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO 21111-4:2020(E)

9.4 Requirements ........................................................................................................................................................................................31

9.4.1 Electrical characteristics ........................................................................................................................................31

9.4.2 Optical characteristics ..............................................................................................................................................32

9.4.3 Physical characteristics ...........................................................................................................................................32

9.4.4 Temperature environmental characteristics ........................................................................................33

9.4.5 Combined environment examination .........................................................................................................33

9.4.6 Specific environmental examination ...........................................................................................................33

9.5 Methodology (informative) .......................................................................................................................................................34

9.5.1 Light source setup .......................................................................................................................................................34

9.5.2 Excitation, test setup and measurement equipment .....................................................................34

9.5.3 Harness setup ..................................................................................................................................................................35

9.6 Evaluation (characteristics of photoelectric conversion) ...............................................................................36

9.6.1 Optical PMD transmitter input electrical interface .........................................................................36

9.6.2 Optical PMD receiver output electrical interface ..............................................................................38

9.7 Evaluation (optical characteristics) ...................................................................................................................................40

9.7.1 Minimum average output power at TP2 ...................................................................................................40

9.7.2 Extinction ratio at TP2 .............................................................................................................................................40

9.7.3 EAF profile at TP2 ........................................................................................................................................................41

9.7.4 Minimum average output power at TP2’ .................................................................................................41

9.7.5 Minimum average output power at TP3 ...................................................................................................43

9.7.6 Range of optical input power at TP3’ ..........................................................................................................43

9.7.7 Maximum coupling attenuation at optical in-line ............................................................................45

9.8 Evaluation (physical characteristics)................................................................................................................................46

9.8.1 Minimum retention force ......................................................................................................................................46

9.8.2 Maximum insertion force ......................................................................................................................................47

9.8.3 Maximum unlock and release force ..............................................................................................................48

9.8.4 Durability of repeated mating and unmating .................. .....................................................................48

9.8.5 Maximum cable holding force ...........................................................................................................................49

9.9 Evaluation (temperature environmental characteristics) ..............................................................................49

9.9.1 High storage temperature exposure ............................................................................................................49

9.9.2 Low storage temperature exposure .............................................................................................................50

9.9.3 High operation temperature exposure ......................................................................................................50

9.9.4 Low operation temperature exposure .......................................................................................................51

9.10 Evaluation (combined environmental examination) ..........................................................................................51

9.10.1 General...................................................................................................................................................................................51

9.10.2 Flow chart of environmental load tests for optical PMD transmitter .............................51

9.10.3 Operation test after durability of mate and un-mate ....................................................................52

9.10.4 Operation test after high temperature exposure ..............................................................................52

9.10.5 Operation test after temperature and vibration ................................................................................53

9.10.6 Operation test after heat shock ........................................................................................................................53

9.10.7 Operation test after humidity/temperature cycle procedure ................................................54

9.10.8 Operation test after specific vibration profile .....................................................................................54

9.10.9 Requirement of combined environmental examination .............................................................54

9.11 Evaluation (specific environmental examination) ................................................................................................55

9.11.1 General...................................................................................................................................................................................55

9.11.2 Individual environmental load tests for optical harness ...........................................................55

9.11.3 Operation test after specific physical impact .......................................................................................55

9.11.4 Operation test after chemical durability procedure .......................................................................55

9.11.5 Operation test after Noxious gas exposure ............................................................................................56

9.11.6 Operation test after specific dust condition exposure .................................................................56

9.11.7 Operation test after specific drop procedure .......................................................................................56

9.11.8 Requirements of specific environmental examination ................................................................57

Annex A (informative) System power budget ...........................................................................................................................................58

Annex B (informative) Mode filter .......................................................................................................................................................................60

Bibliography .............................................................................................................................................................................................................................62

iv © ISO 2020 – All rights reserved---------------------- Page: 4 ----------------------

ISO 21111-4:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see

www .iso .org/ iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 32,

Electrical and electronic components and general system aspects.A list of all parts in the ISO 21111 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 21111-4:2020(E)

vi © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 21111-4:2020(E)

Introduction

The ISO 21111 series includes in-vehicle Ethernet requirements and test plans that are disseminated in

other International Standards and complements them with additional test methods and requirements.

The resulting requirement and test plans are structured in different documents following the Open

Systems Interconnection (OSI) reference model and grouping the documents that depend on the

physical media and bit rate used.In general, the Ethernet requirements are specified in ISO/IEC/IEEE 8802-3. The ISO 21111 series

provides supplemental specifications (e.g. wake-up, I/O functionality), which are required for in-vehicle

Ethernet applications. In road vehicles, Ethernet networks are used for different purposes requiring

different bit-rates. Currently, the ISO 21111 series specifies the 1-Gbit/s optical and 100-Mbit/s

electrical physical layer.The ISO 21111 series contains requirement specifications and test methods related to the in-vehicle

Ethernet. This includes requirement specifications for physical layer entity (e.g. connectors, physical

layer implementations) providers, device (e.g. electronic control units, gateway units) suppliers, and

system (e.g. network systems) designers. Additionally, there are test methods specified for conformance

testing and for interoperability testing.Safety (electrical safety, protection, fire, etc.) and electromagnetic compatibility (EMC) requirements

are out of the scope of the ISO 21111 series.The structure of the specifications given in the ISO 21111 series complies with the Open Systems

[13] [14]Interconnection (OSI) reference model specified in ISO/IEC 7498-1 and ISO/IEC 10731 .

ISO 21111-1 defines the terms which are used in this series of standards and provides an overview of

the standards for in-vehicle Ethernet including the complementary relations to ISO/IEC/IEEE 8802-3,

the document structure, type of physical entities, in-vehicle Ethernet specific functionalities and so on.

ISO 21111-2 specifies the interface between reconciliation sublayer and physical entity including

reduced gigabit media independent interface (RGMII), and the common physical entity wake-up and

synchronized link sleep functionalities, independent from physical media and bit rate.

ISO 21111-3 specifies supplemental requirements to a physical layer capable of transmitting

1-Gbit/s over plastic optical fibre compliant with ISO/IEC/IEEE 8802-3, with specific application to

communications inside road vehicles, and a test plan for physical entity conformance testing.

This document specifies the optical components requirements and test methods for 1-Gbit/s optical in-

vehicle Ethernet.ISO 21111-5 specifies, for 1-Gbit/s optical in-vehicle Ethernet, requirements on the physical layer at

system level, requirements on the interoperability test set-ups, the interoperability test plan that checks

the requirements for the physical layer at system level, requirements on the device-level physical layer

conformance test set-ups, and device-level physical layer conformance test plan that checks a set of

requirements for the OSI physical layer that are relevant for device vendors.ISO 21111-6 specifies advanced features of an ISO/IEC/IEEE 8802-3 in-vehicle Ethernet physical layer

(often also called transceiver), e.g. for diagnostic purposes for in-vehicle Ethernet physical layers. It

specifies advanced physical layer features, wake-up and sleep features, physical layer test suite,

physical layer control requirements and conformance test plan, physical sublayers test suite and

physical sublayers requirements and conformance test plan.ISO 21111-7 specifies the implementation for ISO/IEC/IEEE 8802-3:2017/Amd 1:2017, which defines

the interface implementation for automotive applications together with requirements on components

used to realize this Bus Interface Network (BIN). ISO 21111-7 also defines further testing and system

requirements for systems implemented according to the system specification. In addition, ISO 21111-7

defines the channels for tests of transceivers with a test wiring harness that simulates various electrical

communication channels.© ISO 2020 – All rights reserved vii

---------------------- Page: 7 ----------------------

ISO 21111-4:2020(E)

ISO 21111-8 specifies the transmission media, the channel performance and the tests for

ISO/IEC/IEEE 8802-3 in-vehicle Ethernet.ISO 21111-9 specifies the data link layer requirements and conformance test plan. It specifies the

requirements and test plan for devices and systems with bridge functionality.ISO 21111-10 specifies the application to network layer requirements and test plan. It specifies the

requirements and test plan for devices and systems that include functionality related with OSI layers

from 3 to 7.Figure 1 shows the parts of the ISO 21111 series and the document structure.

Figure 1 — In-vehicle Ethernet document reference according to OSI model

viii © ISO 2020 – All rights reserved

---------------------- Page: 8 ----------------------

INTERNATIONAL STANDARD ISO 21111-4:2020(E)

Road vehicles — In-vehicle Ethernet —

Part 4:

General requirements and test methods of optical gigabit

Ethernet components

1 Scope

This document specifies the optical components requirements and test methods for optical gigabit

transmission of in-vehicle Ethernet. Safety (electrical safety, protection, fire, etc.) and electromagnetic

compatibility (EMC) requirements are outside the scope of this document.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC/IEEE 8802-3:2017/Amd 9:2018, Physical Layer Specifications and Management Parameters for

1000 Mb/s Operation over Plastic Optical FibreISO 8092-2, Road vehicles — Connections for on-board electrical wiring harnesses — Part 2: Definitions,

test methods and general performance requirementsISO 8092-3, Road vehicles — Connections for on-board electrical wiring harnesses — Part 3: Tabs for multi-

pole connections — Dimensions and specific requirementsISO 16750-1, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 1: GeneralISO 16750-3:2012, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 3: Mechanical loadsISO 16750-4:2010, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 4: Climatic loadsISO 16750-5, Road vehicles — Environmental conditions and testing for electrical and electronic

equipment — Part 5: Chemical loadsISO 21111-1, Road vehicles — In-vehicle Ethernet —General information and definitions

IEC 60068-2-60, Environmental testing — Part 2: Tests — Test Ke: Flowing mixed gas corrosion test

IEC 60793-1-20, Optical fibres — Part 1-20: Measurement methods and test procedures — Fibre geometry

IEC 60793-1-21, Optical fibres — Part 1-21: Measurement methods and test procedures — Coating geometry

IEC 60793-1-40, Optical fibres — Part 1-40: Attenuation measurement methodsIEC 60793-2-40, Optical fibres — Part 2-40: Product specifications — Sectional specification for category

A4 multimode fibresIEC 60793-1-43, Optical fibres — Part 1-43: Measurement methods and test procedures — Numerical

aperture measurement© ISO 2020 – All rights reserved 1

---------------------- Page: 9 ----------------------

ISO 21111-4:2020(E)

IEC 60793-1-51, Optical fibres — Part 1-51: Measurement methods and test procedure – Dry heat (steady

state) testsIEC 60794-1-21, Optic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.