SIST EN 16282-2:2017

(Main)Equipment for commercial kitchens - Components for ventilation in commercial kitchens - Part 2: Kitchen ventilation hoods; design and safety requirements

Equipment for commercial kitchens - Components for ventilation in commercial kitchens - Part 2: Kitchen ventilation hoods; design and safety requirements

This European Standard specifies requirements for the design, construction and operation of kitchen ventilation hoods, including technical safety, ergonomic and hygienic features.

This European Standard is applicable to ventilation systems in commercial kitchens, associated areas and other installations processing foodstuffs intended for commercial use. Kitchens and associated areas are special rooms in which meals are prepared, where tableware and equipment is washed, cleaned, food is stored and food waste areas.

This European Standard is applicable to ventilation hoods except those used in domestic kitchens.

A method of verification of each requirement is also specified. Unless otherwise specified, the requirements of this standard need to be checked by way of inspection and/or measurement.

NOTE Please note the possible existence of additional or alternative local national regulations on installation, appliance requirements and inspection, maintenance and operation.

Bauelemente in gewerblichen Küchen - Einrichtungen zur Be- und Entlüftung - Teil 2: Küchenlüftungshauben; Gestaltungs- und Sicherheitsanforderungen

Diese Europäische Norm legt Anforderungen für die Gestaltung, die Konstruktion und den Betrieb von Küchenlüftungshauben fest, einschließlich der technischen Sicherheit, der Ergonomie und hygienischer Aspekte.

Diese Europäische Norm gilt für Lüftungsanlagen in gewerblich genutzten Küchen, dazugehörende Bereiche und andere Installationen in der Lebensmittelverarbeitung. Küchen sowie dazugehörige Bereiche sind spezielle Räume, in denen Speisen zubereitet, Geschirr/Geräte gewaschen bzw. gesäubert werden und Lebensmittel gelagert und entsorgt werden.

Diese Europäische Norm gilt für alle Lüftungshauben. Ausgenommen sind Lüftungshauben, die für Küchen im Privathaushalt bestimmt sind.

An einzelnen Stellen sind Verfahren zur Überprüfung der Anforderungen definiert. Sofern nicht anders festgelegt, sind die Anforderungen dieser Norm durch Begutachtung und/oder Nachmessen zu überprüfen.

ANMERKUNG Bitte beachten Sie die mögliche Existenz zusätzlicher oder alternativer lokaler oder nationaler Vorschriften über Installation, Geräteanforderungen und Inspektion, Wartung und Betrieb.

Équipement pour cuisines professionnelles - Éléments de ventilation pour cuisines professionnelles - Partie 2: Hottes de ventilation pour cuisine - Conception et exigences de sécurité

La présente Norme européenne spécifie les exigences relatives à la conception, la construction et au fonctionnement des hottes de ventilation de cuisine, y compris les caractéristiques techniques de sécurité, d'ergonomie et d'hygiène.

La présente Norme européenne s'applique aux systèmes de ventilation installés dans les cuisines professionnelles, les zones associées et les autres installations de transformation de produits alimentaires destinées à un usage professionnel. Les cuisines et les zones associées sont des pièces spéciales dans lesquelles les repas sont préparés, la vaisselle et les ustensiles sont lavés et nettoyés, les produits alimentaires sont stockés et comprenant des zones de déchets alimentaires.

La présente Norme européenne s'applique aux hottes de ventilation à l’exception de celles utilisées dans des cuisines domestiques.

Une méthode de vérification de chaque exigence est également spécifiée. Sauf spécification contraire, les exigences de la présente norme nécessitent une vérification par inspection et/ou mesurage.

NOTE Noter l'existence possible de réglementations nationales locales complémentaires ou alternatives concernant l'installation, les exigences relatives aux appareils, l'inspection, la maintenance et le fonctionnement.

Oprema za profesionalne kuhinje - Sestavni deli za prezračevanje v kuhinjah - 2. del: Kuhinjske prezračevalne nape - Projektiranje in varnostne zahteve

Ta evropski standard določa zahteve za projektiranje, izdelavo in delovanje kuhinjskih prezračevalnih nap, vključno s tehnično varnostjo, ergonomičnostjo in higieničnostjo. Ta evropski standard se uporablja za prezračevalne sisteme v kuhinjah, povezane prostore in druge naprave za predelavo živil, namenjenih komercialni uporabi. Kuhinje in povezani prostori so posebni prostori, namenjeni za pripravo jedi, pranje in čiščenje jedilnega pribora in opreme, shranjevanje hrane ter odlaganje živilskih odpadkov. Ta evropski standard se ne uporablja za nape, ki se uporabljajo v hišnih gospodinjstvih. Podana je tudi metoda za preverjanje posamezne zahteve. Če ni drugače določeno, se zahteve tega standarda preverjajo s pregledom in/ali meritvami. OPOMBA Upoštevajte morebitne dodatne ali alternativne lokalne nacionalne predpise o namestitvi, zahtevah glede aparatov ter o pregledu, vzdrževanju in obratovanju.

General Information

- Status

- Published

- Public Enquiry End Date

- 04-Jan-2015

- Publication Date

- 07-Mar-2017

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Feb-2017

- Due Date

- 09-Apr-2017

- Completion Date

- 08-Mar-2017

Relations

- Effective Date

- 01-Apr-2017

Overview

EN 16282-2:2016 - "Equipment for commercial kitchens - Components for ventilation in commercial kitchens - Part 2: Kitchen ventilation hoods; design and safety requirements" is a European Standard published by CEN. It specifies design, construction and operational requirements for kitchen ventilation hoods used in commercial kitchens and associated food-processing areas. The standard addresses technical safety, ergonomics and hygienic features and defines a method of verification (inspection and/or measurement) for each requirement. It does not apply to domestic kitchen hoods and notes that national regulations may impose additional requirements.

Key topics and technical requirements

The standard covers practical, technical and safety aspects of kitchen ventilation hoods including:

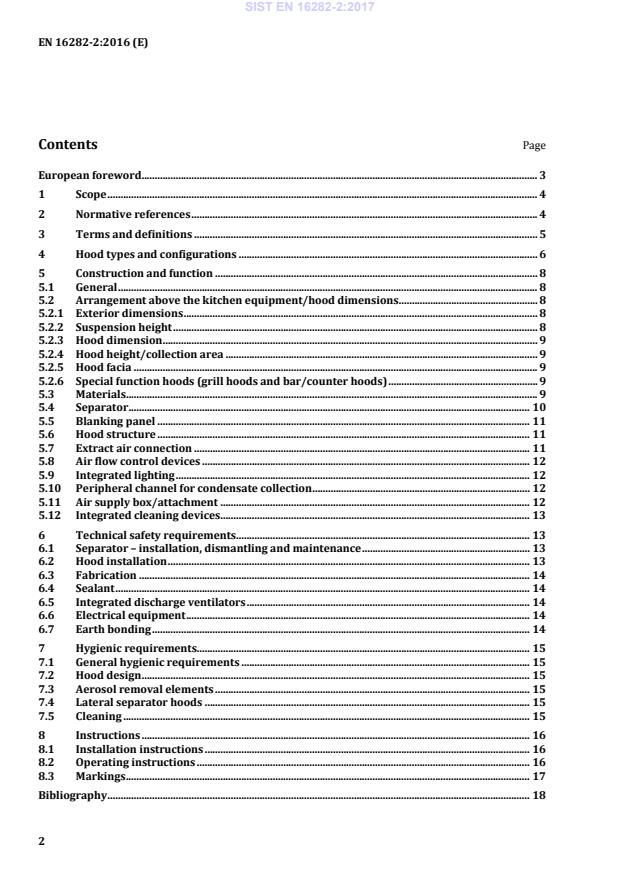

- Hood types and configurations - typical classifications and examples (wall hoods, central hoods, bar/counter hoods, grill hoods) and sample designators (e.g., EN 16282‑2‑B1 … B12).

- Design and dimensions - external dimensions, suspension height, collection area and facia considerations to ensure effective capture of cooking effluent.

- Materials and fabrication - guidance on suitable materials, seals and construction practices to meet durability and hygiene expectations.

- Aerosol separators and filters - placement, maintenance access and separation performance for grease/oil/water aerosols.

- Extract air connections and airflow control - duct connection, blanking panels, and air supply plenums to support correct system balancing.

- Ancillary features - integrated lighting, peripheral condensate collection channels, integrated cleaning devices and discharge devices.

- Technical safety - installation, maintenance access, electrical equipment safety, earth bonding and verification procedures.

- Hygienic requirements - smooth internal surfaces, accessible cleaning paths, aerosol removal elements and cleaning/inspection guidance.

- Documentation and markings - required installation and operating instructions, and product markings for safe use and maintenance.

Verification for requirements is typically by inspection and measurement; the standard lists normative references and related testing/measurement standards.

Applications and users

Who uses EN 16282-2:2016:

- Kitchen equipment manufacturers and hood designers specifying compliance and safe construction

- Mechanical engineers, HVAC consultants and system designers sizing and integrating hoods into ventilation systems

- Architects and foodservice planners ensuring regulatory and hygienic compliance in commercial kitchens

- Installers, facility managers and service technicians for correct installation, inspection and maintenance

- Compliance officers, fire protection planners and inspection bodies assessing safety and operation

Practical benefits include improved capture efficiency, safer electrical and grease-handling design, easier cleaning and maintenance, and clearer guidance for testing and verification.

Related standards

- EN 16282 series: Part 1 (general requirements & calculation), Part 3 (ventilation ceilings), Part 6 (aerosol separators), Part 7 (fixed fire suppression systems), Part 8 (treatment of cooking fumes)

- Normative references cited (examples): EN 1717, EN 60204-1, EN 60529, EN 12464-1 - these cover potable water protection, electrical safety, IP ratings and lighting requirements.

Note: Always check for applicable national regulations and additional local installation or inspection requirements.

Frequently Asked Questions

SIST EN 16282-2:2017 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Equipment for commercial kitchens - Components for ventilation in commercial kitchens - Part 2: Kitchen ventilation hoods; design and safety requirements". This standard covers: This European Standard specifies requirements for the design, construction and operation of kitchen ventilation hoods, including technical safety, ergonomic and hygienic features. This European Standard is applicable to ventilation systems in commercial kitchens, associated areas and other installations processing foodstuffs intended for commercial use. Kitchens and associated areas are special rooms in which meals are prepared, where tableware and equipment is washed, cleaned, food is stored and food waste areas. This European Standard is applicable to ventilation hoods except those used in domestic kitchens. A method of verification of each requirement is also specified. Unless otherwise specified, the requirements of this standard need to be checked by way of inspection and/or measurement. NOTE Please note the possible existence of additional or alternative local national regulations on installation, appliance requirements and inspection, maintenance and operation.

This European Standard specifies requirements for the design, construction and operation of kitchen ventilation hoods, including technical safety, ergonomic and hygienic features. This European Standard is applicable to ventilation systems in commercial kitchens, associated areas and other installations processing foodstuffs intended for commercial use. Kitchens and associated areas are special rooms in which meals are prepared, where tableware and equipment is washed, cleaned, food is stored and food waste areas. This European Standard is applicable to ventilation hoods except those used in domestic kitchens. A method of verification of each requirement is also specified. Unless otherwise specified, the requirements of this standard need to be checked by way of inspection and/or measurement. NOTE Please note the possible existence of additional or alternative local national regulations on installation, appliance requirements and inspection, maintenance and operation.

SIST EN 16282-2:2017 is classified under the following ICS (International Classification for Standards) categories: 91.140.30 - Ventilation and air-conditioning systems; 97.040.99 - Other kitchen equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16282-2:2017 has the following relationships with other standards: It is inter standard links to oSIST prEN 16282-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase SIST EN 16282-2:2017 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.KWHYHBauelemente in gewerblichen Küchen - Einrichtungen zur Be- und Entlüftung - Teil 2: Küchenlüftungshauben; Gestaltungs- und SicherheitsanforderungenÉquipement pour cuisines professionnelles - Éléments de ventilation pour cuisines professionnelles - Partie 2: Hottes de ventilation pour cuisine - Conception et exigences de sécuritéEquipment for commercial kitchens - Components for ventilation in commercial kitchens - Part 2: Kitchen ventilation hoods; design and safety requirements97.040.99Druga kuhinjska opremaOther kitchen equipment91.140.30VLVWHPLVentilation and air-conditioning systemsICS:Ta slovenski standard je istoveten z:EN 16282-2:2016SIST EN 16282-2:2017en,fr,de01-april-2017SIST EN 16282-2:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16282-2

November

t r s x ICS

{ yä r v rä { { English Version

Equipment for commercial kitchens æ Components for ventilation in commercial kitchens æ Part

tã Kitchen ventilation hoodsâ design and safety requirements Équipement pour cuisines professionnelles æ Éléments de ventilation pour cuisines professionnelles æ Partie

tã Hottes de ventilation pour cuisine æ Conception et exigences de sécurité

Bauelemente in gewerblichen Küchen æ Einrichtungen zur Beæ und Entlüftung æ Teil

tã Küchenlüftungshaubenâ Gestaltungsæ und Sicherheitsanforderungen This European Standard was approved by CEN on

t t July

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x t z tæ tã t r s x ESIST EN 16282-2:2017

Kitchen ventilation hood EN 16282–2 -B1 Lateral extraction wall hood as box

Kitchen ventilation hood EN 16282–2 -B2

Induction wall hood as box

Kitchen ventilation hood EN 16282–2 -B3 Induction wall hood as box / hood with additional supply air

Kitchen ventilation hood EN 16282–2 -B4 Wall hood as box / hood with additional supply air

Kitchen ventilation hood EN 16282–2 -B5 Central hood as box / hood, central suction

Kitchen ventilation hood EN 16282–2 -B6 Standard central hood as box / hood, both sides suction at side

Kitchen ventilation hood EN 16282–2 -B7 Lateral extraction central hood as box / hood

Kitchen ventilation hood EN 16282–2 -B8 Induction central hood as box / hood

Kitchen ventilation hood EN 16282–2 -B9 Induction central hood as box / hood with additional supply air

Kitchen ventilation hood EN 16282–2 -B10 Bar hood/counter hood

Kitchen ventilation hood EN 16282–2 -B11 Grill hood

Kitchen ventilation hood EN 16282–2 -B12 SIST EN 16282-2:2017

Key a minimum installation height b height of the equipment

angle 15° (The angle describes the clear internal dimensions) Z detail X overhang Figure 1 — Hood dimensions 5.2.2 Suspension height The suspension height of installation for a hood, a, as specified in Figure 1 (lower edge of the hood, see Figure 1) shall be no less than 2,0 m and no greater than 2,5 m above floor level. Installation heights deviating from this range are permitted for special function hoods e.g. grill hood and bar/counter hood. SIST EN 16282-2:2017

...

記事のタイトル: SIST EN 16282-2:2017 - 商業用キッチン設備 - 商業用キッチンの換気構成要素 - 第2部: キッチン換気フードのデザインと安全要件 記事内容: このヨーロッパ標準では、キッチン換気フードの設計、建設、運用に関する要件を技術的安全性、人間工学的および衛生的な特徴を含んで規定しています。 このヨーロッパ標準は、商業キッチン、関連するエリア、商業用に食品を処理する他の設備に適用されます。キッチンおよび関連するエリアは、食事の準備が行われ食器や設備が洗われ、清掃され、食品が保存され、食品廃棄物の処理が行われる特別な部屋です。 このヨーロッパ標準は、家庭用キッチンで使用されるフードには適用されません。 各要件の検証方法も指定されています。それ以外の場合、この標準の要件は点検および/または測定によって確認する必要があります。 注意:設置、機器の要件および点検、保守、運用に関する追加または代替の地域規制が存在する可能性について留意してください。

기사 제목: SIST EN 16282-2:2017 - 상업용 주방 설비 - 상업용 주방 환기 구성요소 - 제2부: 주방 환기 후드; 디자인 및 안전 요구사항 기사 내용: 이 유럽 표준은 주방 환기 후드의 디자인, 구축, 운영을 위한 요구사항을 규정하며, 기술적 안전, 인체공학적 및 위생적 특징을 포함합니다. 이 유럽 표준은 상업용 주방, 관련 영역 및 상업 목적의 식품 가공을 위한 기타 설치물에 적용됩니다. 주방과 관련된 영역은 식사가 준비되는 특수 공간으로서 식기 및 장비가 세척, 청소되며 음식이 저장되고 음식 폐기물 처리지 등이 포함됩니다. 이 유럽 표준은 가정용 주방에서 사용되는 후드에는 적용되지 않습니다. 각 요구사항의 확인 방법도 명시됩니다. 그렇지 않은 경우, 이 표준의 요구사항은 점검 및/또는 측정을 통해 확인되어야 합니다. 참고: 설치, 기기 요구사항 및 점검, 유지 보수 및 운영에 대한 추가 또는 대체 지역 규정의 가능성을 참고해주십시오.

The article discusses the SIST EN 16282-2:2017, a European Standard that sets out design and safety requirements for kitchen ventilation hoods in commercial kitchens. The standard covers technical safety, ergonomic, and hygienic features of these hoods. It applies to ventilation systems in commercial kitchens, associated areas, and installations involved in food processing for commercial purposes. However, it does not apply to hoods used in domestic kitchens. The article also mentions that there may be additional local regulations on installation, appliance requirements, and inspection, maintenance, and operation. The standard provides a method for verifying compliance with its requirements, which typically involve inspection and/or measurement.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...