SIST ISO/DIS 1920-11:2012

Testing of concrete -- Part 11: Determination of the chloride resistance of concrete, unidirectional diffusion

Testing of concrete -- Part 11: Determination of the chloride resistance of concrete, unidirectional diffusion

ISO 1920-11:2013 specifies a method for determining the unidirectional non-steady-state chloride penetration parameters of conditioned specimens of hardened concrete. The test method enables the determination of the chloride penetration at a specified age, e.g. for ranking of concrete quality by comparative testing.

Essais du béton -- Partie 11: Détermination de la résistance du béton à la pénétration des chlorures, diffusion unidirectionnelle

[Not translated]

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 1920-11

First edition

2013-05-01

Testing of concrete —

Part 11:

Determination of the chloride

resistance of concrete, unidirectional

diffusion

Essais du béton —

Partie 11: Détermination de la résistance du béton à la pénétration

des chlorures, diffusion unidirectionnelle

Reference number

ISO 1920-11:2013(E)

©

ISO 2013

---------------------- Page: 1 ----------------------

ISO 1920-11:2013(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 1920-11:2013(E)

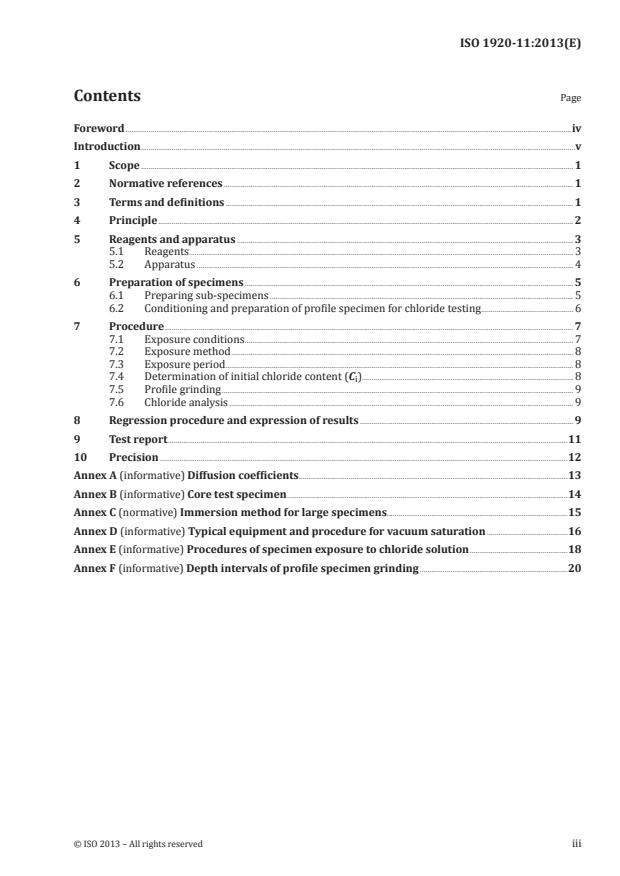

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 2

5 Reagents and apparatus . 3

5.1 Reagents. 3

5.2 Apparatus . 4

6 Preparation of specimens . 5

6.1 Preparing sub-specimens . 5

6.2 Conditioning and preparation of profile specimen for chloride testing . 6

7 Procedure. 7

7.1 Exposure conditions . 7

7.2 Exposure method . 8

7.3 Exposure period . 8

7.4 Determination of initial chloride content (C ) . 8

i

7.5 Profile grinding . 9

7.6 Chloride analysis . 9

8 Regression procedure and expression of results . 9

9 Test report .11

10 Precision .12

Annex A (informative) Diffusion coefficients.13

Annex B (informative) Core test specimen .14

Annex C (normative) Immersion method for large specimens .15

Annex D (informative) Typical equipment and procedure for vacuum saturation .16

Annex E (informative) Procedures of specimen exposure to chloride solution .18

Annex F (informative) Depth intervals of profile specimen grinding .20

© ISO 2013 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 1920-11:2013(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

The committee responsible for this document is ISO/TC 71, Concrete, reinforced concrete and prestressed

concrete, Subcommittee SC 1, Test methods for concrete.

ISO 1920 consists of the following parts, under the general title Testing of concrete:

Part 1: Sampling of fresh concrete

Part 2: Properties of fresh concrete

Part 3: Making and curing test specimens

Part 4: Strength of hardened concrete

Part 5: Properties of hardened concrete other than strength

Part 6: Sampling, preparing and testing of concrete cores

Part 7: Non-destructive tests on hardened concrete

Part 8: Determination of drying shrinkage of concrete for samples prepared in the field or in the laboratory

Part 9: Determination of creep of concrete cylinders in compression

Part 10: Determination of static modulus of elasticity in compression

Part 11: Determination of the chloride resistance of concrete, unidirectional diffusion

Part 12: Determination of the carbonation resistance of concrete — Accelerated carbonation method

iv © ISO 2013 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 1920-11:2013(E)

Introduction

Steel reinforced concrete structures exposed to the ingress of chloride, either from seawater or other

sources, need to be durable for at least the intended service life. The possibility of reinforcement

corrosion is significantly increased as the chloride level at the embedded reinforcement increases. For

this reason, the chloride diffusivity or chloride penetrability of the concrete is an important property to

measure and this International Standard sets out a test method that may be applied to specimens cast

to assess the potential chloride resistance of a concrete mix.

NOTE This test method takes a minimum of 119 days comprising a minimum age of the specimen prior to

testing of 28 days, a minimum of one day to prepare and condition the specimen and then 90 days to expose the

specimen to the chloride solution. Different periods of curing and exposure may be set (and stated in the test

report) in order to adjust the test duration.

© ISO 2013 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 1920-11:2013(E)

Testing of concrete —

Part 11:

Determination of the chloride resistance of concrete,

unidirectional diffusion

1 Scope

This part of ISO 1920 specifies a method for determining the unidirectional non-steady-state chloride

penetration parameters of conditioned specimens of hardened concrete. The test method enables the

determination of the chloride penetration at a specified age, e.g. for ranking of concrete quality by

comparative testing.

NOTE 1 The aim of the test is to assess the potential resistance to chloride ingress for a concrete mix.

NOTE 2 Since resistance to chloride penetration depends on ageing, due to the effects of continual hydration of

the concrete, the ranking may also change with age.

2 Normative references

The following referenced documents are essential for the application of this part of ISO 1920. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 1920-3, Testing of concrete — Part 3: Making and curing test specimens

ISO 1920-6, Testing of concrete — Part 6: Sampling, preparing and testing of concrete cores

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

as-cast surface

surface of a concrete element exposed in the construction works to a chloride environment

3.2

acid-soluble chloride content

amount of acid-soluble chloride expressed in percent by mass of concrete

3.3

chloride penetration

ingress of chlorides into concrete due to exposure to external chloride sources

3.4

diffusion

movement of molecules or ions under a concentration gradient, from a zone of high concentration to a

zone with a lower concentration

© ISO 2013 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 1920-11:2013(E)

3.5

diffusion coefficient

proportionality between the molecular flux (e.g. rate of flow of chloride ions) and the concentration

gradient in the diffusion equation

Note 1 to entry: In this part of ISO 1920, Fick’s Law is adopted as a valid mathematical representation of the

chloride ingress mechanism.

Note 2 to entry: See Annex A.

3.6

initial chloride content, C

i

chloride content at a distance sufficiently remote from the surface as to not have been influenced by

penetration of the chloride exposure solution

Note 1 to entry: It reflects the initial chloride content that came from the constituents when the concrete was mixed.

3.7

non-steady state diffusion coefficient, D

nss

diffusion coefficient that takes into account simultaneous chloride binding

Note 1 to entry: This reflects the rate of diffusion of chloride into a concrete when part of the chloride is being

bound by the cement.

Note 2 to entry: See Annex A.

Note 3 to entry: The steady-state chloride diffusion coefficient is measured on water saturated samples where

chloride diffuses through a thin specimen between two reservoirs of chloride solution, where one reservoir is

at a higher concentration than the other. This steady-state chloride diffusion is not covered by this test method.

The steady-state chloride diffusion coefficient only reflects the ionic transport diffusion through concrete, as the

concrete is unable to bind any more chloride ion.

3.8

profile grinding

dry process grinding a concrete specimen in thin successive layers

3.9

vacuum saturated condition

specimen that is vacuum saturated with water

4 Principle

A specimen, either a cylinder or cube, is cast and cured in accordance with ISO 1920-3 (see also

amendments of the curing conditions in 6.1), for a standard curing period of 28 days.

NOTE 1 A curing period of less than 28 days may be set, depending on the type of cement and purpose of the test.

Annex B gives guidance on the testing of core specimens, where the core may be sampled from a test

element, a precast concrete element or a structure.

The specimen is divided into two sub-specimens: a “profile specimen” that is used to determine the

chloride profile after exposure to unidirectional chloride ingress, and an initial chloride sub-specimen

that is used to determine the initial chloride level, C . This initial figure is taken as the chloride level of

i

the cast concrete.

The profile specimen is vacuum saturated with distilled or demineralized water, coated on all sides but

one and then the uncoated face is exposed to a chloride exposure solution. The exposure is achieved by

total immersion of the specimen in the chloride exposure solution.

NOTE 2 The test can be performed without vacuum saturating the profile specimen in water; this should be

stated in the test report.

2 © ISO 2013 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 1920-11:2013(E)

NOTE 3 The exposure can be achieved by alternative methods, that are:

a) ponding the uncoated face of the specimen in the chloride exposure solution;

b) inverting the specimen and having the uncoated face immersed in the chloride exposure solution.

NOTE 4 The use of large fully immersed specimens is described in Annex C.

The standard reference solution is a 3 % by mass, sodium chloride (NaCl) solution, for an exposure

period of 90 days. The solution concentration will be kept constant during the test.

NOTE 5 Other concentrations or solutions, e.g. artificial seawater, and exposure periods other than 90

days, may be set.

After the specified period of exposure, at least eight parallel layers of the chloride exposed surface are

ground off the profile specimen. The acid-soluble chloride content of each layer and the average depth

of the layer from the surface of the concrete exposed to the chloride solution are determined. The initial

chloride content is determined by grinding a sample from the other sub-specimen and having the acid-

soluble chloride content determined.

The surface chloride content (C ) and the non-steady-state chloride diffusion coefficient (D ) are

s nss

determined by nonlinear regression analysis using the least squares curve fitting procedure.

Because of the high coefficient of variation, approximately 15 % for D for the test, testing of three

nss

specimens is required and the results reported separately.

NOTE 6 The chloride diffusion coefficient varies with the age of the concrete and the period of exposure.

NOTE 7 The diffusion test described in this part of ISO 1920 is only valid for a constant initial chloride content.

NOTE 8 When precision information is available for this test, a check on the validity of the two or more results

will be introduced plus the determination of the average value.

5 Reagents and apparatus

5.1 Reagents

Reagents of analytical quality shall be used.

NOTE Unless otherwise stated, “percent” means percent by mass.

5.1.1 Calcium hydroxide, Ca(OH)

2

5.1.2 Chloride exposure solution

a) Reference solution

Dissolve 30 g of analytical quality NaCl in 970 g of distilled or demineralized water having an

−1

electrical conductivity ≤ 0,5 mSm at 20 °C to produce a 3 % by mass NaCl solution. Store it in a

clean container.

NOTE This NaCl solution has a similar chloride concentration to that of seawater.

b) Other exposure solutions

Where the concentration of the chloride exposure solution is other than that in 5.1.2 a), the

concentration shall be recorded and reported. Where a different solution is used, the composition

of the solution shall be recorded and reported.

NOTE 1 Natural and artificial seawater have been used to reflect the exposure of the construction works.

© ISO 2013 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 1920-11:2013(E)

NOTE 2 Higher concentrations of NaCl, such as 16,5 %, and shorter exposure periods (e.g. 35 days) may be

used to accelerate the development of a chloride profile.

5.1.3 Chloride impervious barrier system

A polyurethane or epoxy-based paint or equivalent barrier system highly resistant to chloride diffusion,

to be used in sealing the sides of the specimen.

5.1.4 Chemicals for chloride analysis, complying to a national standard valid in the place of use. The

reference number of the national standard shall be stated in the test report.

−1

5.1.5 Distilled or demineralized water, having an electrical conductivity ≤ 0,5 mSm .

5.2 Apparatus

5.2.1 Water cooled diamond saw

5.2.2 Balance for weighing NaCl and water, capable of weighing to an accuracy of ± 0,1 g.

5.2.3 Thermometer, capable of measuring to an accuracy of ± 1 °C.

5.2.4 Temperature controlled chamber, capable of keeping a temperature of (20 ± 2) °C.

5.2.5 Where used, a polyethylene container with airtight lid for immersion of the profile

specimen. The volume of the exposure solution shall exceed the volume of the specimen by not less

than 12,5 ml per square centimetre of exposed surface. A container may contain more than one sample

provided the ratio of exposure solution to exposed surface shall be recorded and reported.

NOTE During the test, the chloride concentration of the chloride exposure solution reduces and if the ratio of

the volume of chloride exposure solution to exposure surface varies, the rate of reduction will vary with nominally

identical concrete. For this reason if a direct comparison of results from different specimens is required, the ratio

of the volume of chloride exposure solution to exposed surface should be constant.

5.2.6 Where used, pond to be attached to profile specimen. The ponds shall have a constant

diameter and initial depth not less than 125 mm.

5.2.7 Equipment for grinding off and collecting concrete powder in layers 1 mm or more deep,

2

capable of grinding a surface area of at least 4000 mm and not grinding within 10 mm of the edge of

the test area.

5.2.8 Compressed air or air blower, to clean dust from specimen and equipment between grinding layers.

5.2.9 Dust collecting bags

5.2.10 Equipment for chloride content testing, in accordance with a national standard valid in the

place of use. The reference number of the national standard shall be stated in the test report.

5.2.11 Calliper, measuring to an accuracy of ± 0,1 mm.

5.2.12 Vacuum container, capable of containing at least three specimens.

5.2.13 Vacuum pump, capable of maintaining an absolute pressure of less than 50 mbar (5 kPa) in the

container, e.g. a water-jet pump.

4 © ISO 2013 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 1920-11:2013(E)

6 Preparation of specimens

6.1 Preparing sub-specimens

A specimen size shall be selected such that after cutting, the minimum dimension of the sub-specimens

used to determine a chloride profile is at least three times the nominal maximum aggregate size. Three

specimens, either cylinders, 100 mm or greater in diameter or cubes, 100 mm or greater are cast, and

cured for a period of 28 days in a water filled bath with a temperature of (20 ± 2) °C, in accordance

with ISO 1920-3. In hot climate locations, the curing conditions after removal of the specimen from the

mould can be different from those mentioned in ISO 1920-3. In this case, the specimens may be stored in

water at a temperature of (27 ± 2) °C or in a chamber having a temperature of (27 ± 2) °C and a relative

humidity of at least 95 %.

NOTE A curing period other than 28 days may be set, depending on the type of cement and purpose of the test.

After 28 days of standard curing or the specified curing period (see the above note), each cylinder or

cube is cut into two sub-specimens using the water cooled diamond saw. Cylindrical specimens are cut

in the direction parallel to the flat surface and cubical specimens are cut in the direction parallel to the

top (trowelled) surface as shown in Figure 1. No dimension of the sub-specimens used to determine a

chloride profile shall be less than three times the nominal maximum aggregate size. One sub-specimen

(called the “profile specimen”) is used to determine the chloride profile, and the initial chloride sub-

specimen is used to determine the initial chloride content. This initial chloride content is taken as being

the chloride content of the cast concrete. The adjacent sawn faces are used to determine these values.

NOTE 2 Where a chloride profile is required that incorporates the effect of a formed surface then a formed

surface from a cube specimen may be specified as the surface for chloride exposure. However, the results from

such a procedure are difficult to interpret due to concentrations of cement paste and chloride at the formed

surface. The use of this approach should be reported under Clause 9, m), as it is a non-standard test condition.

Key

1 trowelled surface

2 cut to separate specimens and produce exposure surface

Figure 1 — Specimen preparation

After sawing, the sub-specimen to be used to determine the initial chloride content shall be placed in a

close fitting sealed plastic bag or tested immediately.

Where needed, the sub-specimens may be cut to reduce their size to aid handling, but the sub-specimen

for determining the chloride profile shall not have a dimension less than three times the nominal

maximum aggregate size.

© ISO 2013 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 1920-11:2013(E)

6.2 Conditioning and preparation of profile specimen for chloride testing

6.2.1 Vacuum saturation of the profile specimens

After sawing the specimens, vacuum saturate the profile specimens with water. Annex D shows a typical

arrangement for vacuum saturation. Place the profile specimens in the vacuum container and reduce

the absolute pressure to a value between 10 mbar and 50 mbar (1 kPa to 5 kPa) within a few minutes

of closing the container. Maintain this absolute pressure for 3 h and then with the vacuum pump still

running, fill the container with distilled or demineralized water so that all the profile specimens are

immersed. Maintain the absolute pressure for a further hour before allowing air to re-enter the container.

Leave the profile specimens immersed in water until the process of surface sealing starts.

The test may be carried out without vacuum saturating the profile specimen in water, as described in

this clause. If the profile specimen is not vacuum saturated in water, this shall be mentioned in the test

report in order to allow comparison of the test results obtained by the same procedure.

6.2.2 Sealing surfaces other than the surface to be exposed

6.2.2.1 General

Start the sealing within 24 h of completing the vacuum saturation or the standard curing (if no vacuum

saturation was carried out). All surfaces of the profile specimen except for the sawn face shall be sealed,

see Annex C for an exception. After sealing the surfaces, place the specimens in saturated calcium

hydroxide solution for at least 18 h.

NOTE The purpose of sealing the faces other than the face exposed to the chloride solution is to ensure

that the ingress of chloride ions into the concrete is a pure unidirectional diffusion process and not a mixture of

diffusion and other processes, e.g. capillary suction.

6.2.2.2 Sealing procedures

a) Specimens exposed to chloride solution by immersion – standard reference method.

The profile specimen shall be dried in laboratory air until its surface is “white-dry”.

NOTE This usually takes between 2 h and 4 h.

All faces except the face to be exposed to the chloride solution shall be coated with a layer of epoxy

or polyurethane or equivalent making sure that the surface to be tested remains free of the coating

material. The coating material shall be applied and cured in accordance with the recommendations of

the manufacturer.

b) Specimens exposed to the chloride solution by alternate methods.

1) Exposure by ponding:

i) as described in 6.2.2.2 a) for specimens exposed by immersion, or

ii) dry the surfaces with a cloth to remove free water and wrap the surface with one or

three layers of a polymeric or composite self-amalgamating tape with a low water vapour

transmission rate (for instance aluminium foil tape or parafinated polymeric film), ensuring

sufficient overlap of joints.

NOTE If one layer is applied, 7.2.2 b) requires additional protection.

2) Exposure by inversion:

i) as described in 6.2.2.2 a) for specimens exposed by immersion.

6.2.3 Exposure of specimens to the chloride solution

6 © ISO 2013 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 1920-11:2013(E)

a) Profile specimen for immersion – standard reference method.

After storage in saturated calcium hydroxide solution, the specimen shall be transferred directly to

exposure without surface drying. A suitable arrangement is shown in Annex E.

b) Profile specimen for exposure by alternative methods.

1) Profile specimen for ponding:

After storage in saturated calcium hydroxide solution, a pond is sealed to the surface of the

specimen in a manner that prevents leakage of the chloride exposure solution. A suitable

arrangement is shown in Annex E, noting that the volume of the pond is as defined in 5.2.6.

The external border between the plastic tube and specimen is sealed to prevent leakage. The

diameter of the tube used to form the pond may be 10 mm to 20 mm less than the diameter of

the specimen to allow the formation of a watertight seal. The surface not covered by the pond

shall be completely sealed using the sealant or the tape defined in 6.2.2.2 b).

NOTE At the edge of such specimens, there will not be unidirectional chloride ingress.

An alternative technique is to use a slightly larger tube and a rubber gasket between the tube

and the sealed side of the specimen.

2) Profile specimen for inversion:

After sealing in accordance with 6.2.2 and storage in the calcium hydroxide solution, the

specimen shall be transferred directly to the inversion exposure apparatus without surface

drying. A suitable arrangement is shown in Annex E. The volume of the exposure solution shall

not be less than 12,5 ml per square centimetre of exposed surface.

7 Procedure

7.1 Exposure conditions

7.1.1 Chloride exposure solution

Unless specified otherwise, the chloride exposure solution shall be a 3 % NaCl solution in accordance

with 5.1.2 a) If the chloride exposure solution is other than the reference solution [see 5.1.2 b)], it shall

be reported. The chloride exposure solution concentration after use shall be measured and recorded.

NOTE 1 Where testing is related to the intended use in a specific exposure condition, the chloride exposure

solution should reflect the exposure conditions taking into account the expected depletion of chloride.

NOTE 2 During the test period the concentration of the chloride exposure solution will reduce. The volume of

chloride exposure solution has been selected so that it does not have to be replaced during a test lasting 90 days.

If a longer test period is required, the chloride exposure solution should be replaced at 91 day intervals.

NOTE 3 Fick’s Law is based on the assumption that the external chloride concentration remains constant

during the duration of the test. In the normal test situation, the error introduced by assuming that the chloride

concentration remains constant at the initial concentration is small.

7.1.2 Exposure temperature

Where used, the temperature of the water bath for the immersion specimen, the temperature of the

chloride exposure solution in the inversion method and the temperature of the chamber used

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.