ASTM D5986-96(2019)

(Test Method)Standard Test Method for Determination of Oxygenates, Benzene, Toluene, C8–C12 Aromatics and Total Aromatics in Finished Gasoline by Gas Chromatography/Fourier Transform Infrared Spectroscopy

Standard Test Method for Determination of Oxygenates, Benzene, Toluene, C<inf>8</inf >–C<inf>12</inf> Aromatics and Total Aromatics in Finished Gasoline by Gas Chromatography/Fourier Transform Infrared Spectroscopy

SIGNIFICANCE AND USE

5.1 Test methods to determine oxygenates, benzene, and the aromatic content of gasoline are necessary to assess product quality and to meet new fuel regulations.

5.2 This test method can be used for gasolines that contain oxygenates (alcohols and ethers) as additives. It has been determined that the common oxygenates found in finished gasoline do not interfere with the analysis of benzene and other aromatics by this test method.

SCOPE

1.1 This test method covers the quantitative determination of oxygenates: methyl-t-butylether (MTBE), di-isopropyl ether (DIPE), ethyl-t-butylether (ETBE), t-amylmethyl ether (TAME), methanol (MeOH), ethanol (EtOH), 2-propanol (2-PrOH), t-butanol (t-BuOH), 1-propanol (1-PrOH), 2-butanol (2-BuOH), i-butanol (i-BuOH), 1-butanol (1-BuOH); benzene, toluene and C8–C12 aromatics, and total aromatics in finished motor gasoline by gas chromatography/Fourier Transform infrared spectroscopy (GC/FTIR).

1.2 This test method covers the following concentration ranges: 0.1 % to 20 % by volume per component for ethers and alcohols; 0.1 % to 2 % by volume benzene; 1 % to 15 % by volume for toluene, 10 % to 40 % by volume total (C6–C12) aromatics.

1.3 The method has not been tested by ASTM for refinery individual hydrocarbon process streams, such as reformates, fluid catalytic cracking naphthas, etc., used in blending of gasolines.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5986 − 96 (Reapproved 2019)

Standard Test Method for

Determination of Oxygenates, Benzene, Toluene, C –C

8 12

Aromatics and Total Aromatics in Finished Gasoline by Gas

Chromatography/Fourier Transform Infrared Spectroscopy

This standard is issued under the fixed designation D5986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the quantitative determination 2.1 ASTM Standards:

of oxygenates: methyl-t-butylether (MTBE), di-isopropyl ether D1298 Test Method for Density, Relative Density, or API

(DIPE), ethyl-t-butylether (ETBE), t-amylmethyl ether Gravity of Crude Petroleum and Liquid Petroleum Prod-

(TAME), methanol (MeOH), ethanol (EtOH), 2-propanol (2- ucts by Hydrometer Method

PrOH), t-butanol (t-BuOH), 1-propanol (1-PrOH), 2-butanol D4052 Test Method for Density, Relative Density, and API

(2-BuOH), i-butanol (i-BuOH), 1-butanol (1-BuOH); benzene, Gravity of Liquids by Digital Density Meter

toluene and C –C aromatics, and total aromatics in finished D4057 Practice for Manual Sampling of Petroleum and

8 12

motor gasoline by gas chromatography/Fourier Transform Petroleum Products

infrared spectroscopy (GC/FTIR). D4307 Practice for Preparation of Liquid Blends for Use as

Analytical Standards

1.2 This test method covers the following concentration

ranges: 0.1 % to 20 %byvolumepercomponentforethersand

3. Terminology

alcohols; 0.1 % to 2 % by volume benzene; 1 % to 15 % by

3.1 Definitions of Terms Specific to This Standard:

volume for toluene, 10 % to 40 % by volume total (C –C )

6 12

3.1.1 aromatics—refers to any organic compound contain-

aromatics.

ing a benzene or naphthalene ring.

1.3 The method has not been tested by ASTM for refinery

3.1.2 calibrated aromatic component—in this test method,

individual hydrocarbon process streams, such as reformates,

refers to the individual aromatic components which have a

fluid catalytic cracking naphthas, etc., used in blending of

specific calibration.

gasolines.

3.1.3 cool on-column injector—in gas chromatography,a

1.4 The values stated in SI units are to be regarded as

direct sample introduction system which is set at a temperature

standard. No other units of measurement are included in this

at or below the boiling point of solutes or solvent on injection

standard.

and then heated at a rate equal to or greater than the column.

1.5 This standard does not purport to address all of the

Normally used to eliminate boiling point discrimination on

safety concerns, if any, associated with its use. It is the

injectionortoreduceadsorption,orboth,onglasslinerswithin

responsibility of the user of this standard to establish appro-

injectors. The sample is injected directly into the head of the

priate safety, health, and environmental practices and deter-

capillary column tubing or retention gap.

mine the applicability of regulatory limitations prior to use.

3.1.4 Gram-Schmidt chromatogram—a nonselective sum-

1.6 This international standard was developed in accor-

mation of total intensity from a spectral scan per unit time

dance with internationally recognized principles on standard-

which resembles in profile a flame ionization detector chro-

ization established in the Decision on Principles for the

matogram.

Development of International Standards, Guides and Recom-

3.1.5 retention gap—in gas chromatography, refers to a

mendations issued by the World Trade Organization Technical

deactivated precolumn which acts as a zone of low retention

Barriers to Trade (TBT) Committee.

power for reconcentrating bands in space. The polarity of the

precolumn must be similar to that of the analytical column.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0L on Gas Chromatography Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2019. Published December 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2015 as D5986 – 96 (2015). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D5986-96R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5986 − 96 (2019)

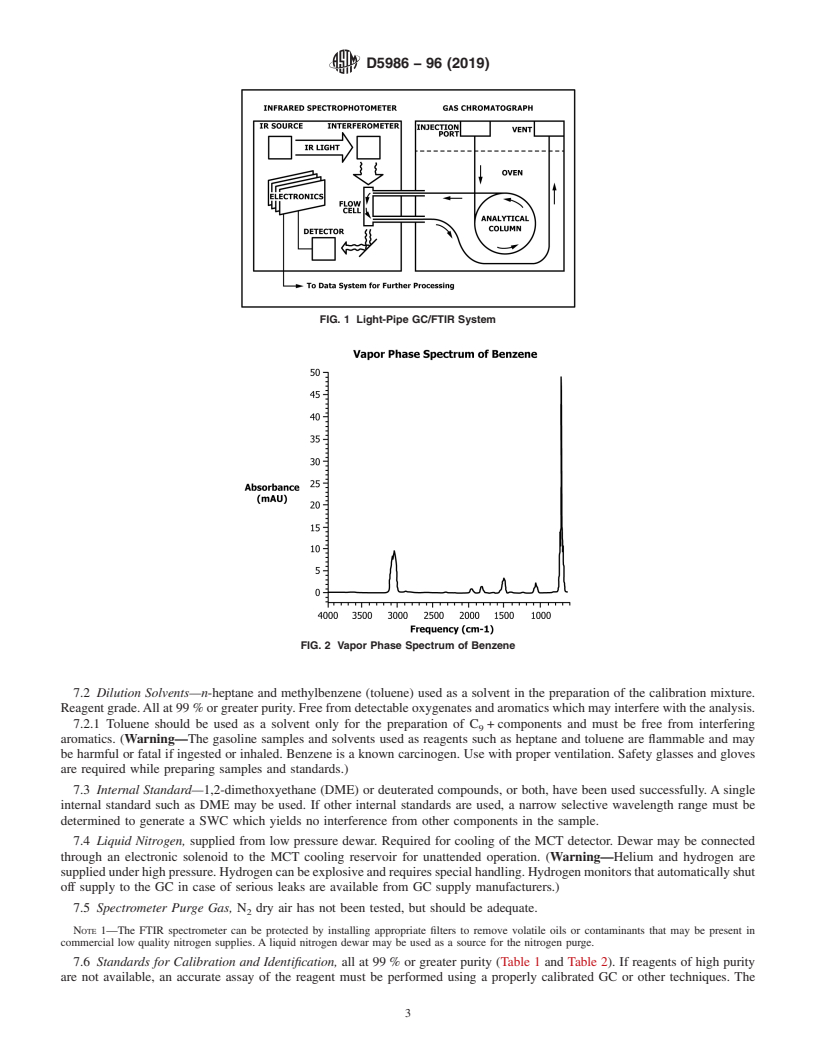

3.1.6 selective wavelength chromatogram (SWC)—in this 6.2.1 This test method requires a light-pipe GC/FTIR sys-

test method, refers to a selective chromatogram obtained by tem (Fig. 1). No data have been acquired with matrix-isolation

summing the spectral intensity in a narrow spectral wavelength or other deposition type systems.

or frequency range as a function of elution time which is 6.2.2 The spectrometer must be equipped with a mercury-

unique to the compound being quantitated. cadmium-telluride(MCT)detectorcapableofdetectingfromat

least 4000 cm-1 to 550 cm-1.

3.1.7 uncalibrated aromatic component—in this test

6.2.3 The lower limit of 550 cm-1 is necessary for the

method,referstoindividualaromaticsforwhichacalibrationis

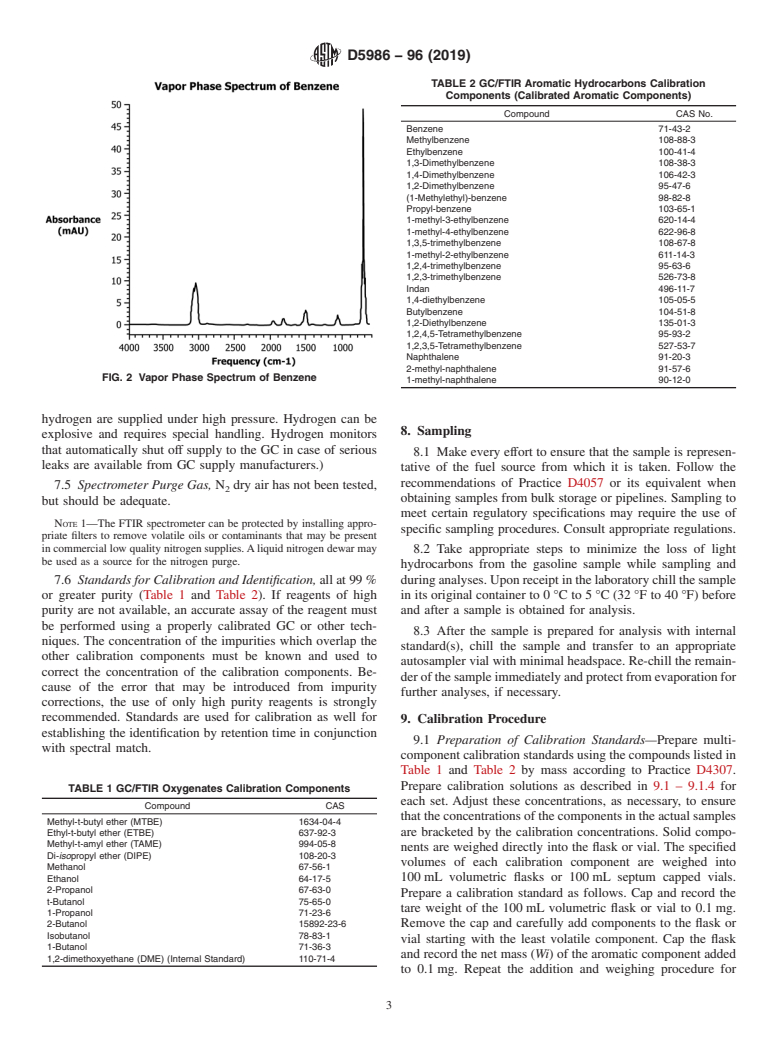

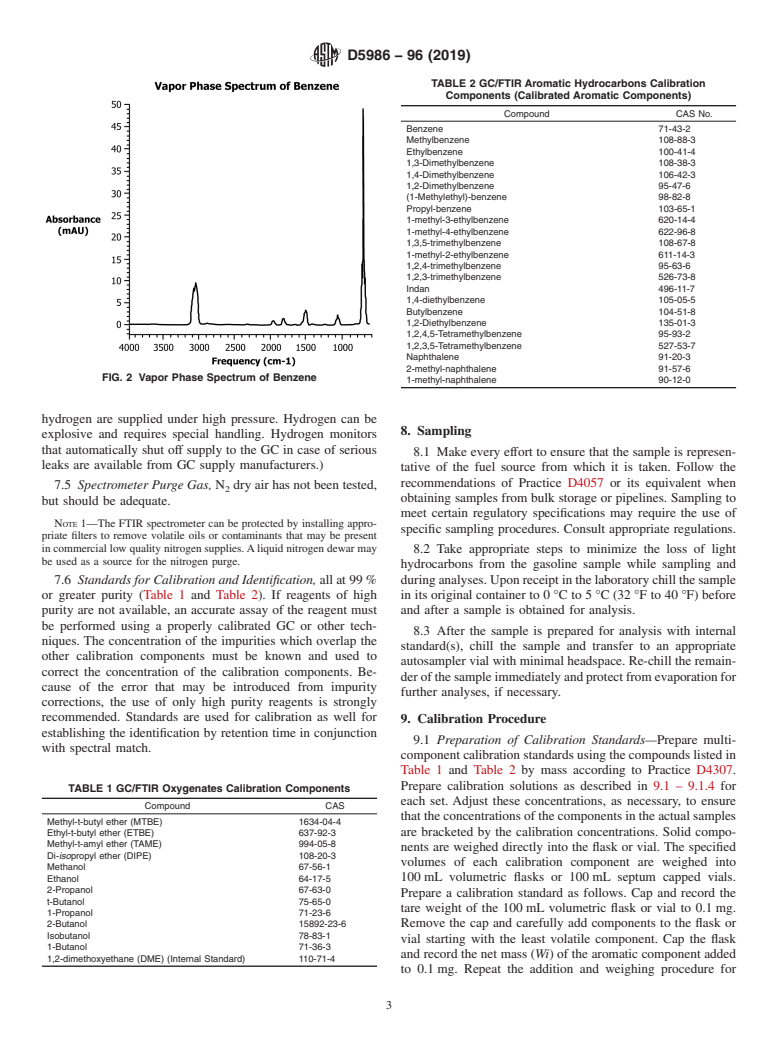

accurate determination of benzene. Fig. 2 gives an acceptable

not available and whose concentrations are estimated from the

infrared spectra of benzene.

response factor of a calibrated aromatic component.

3.1.8 wall coated open tubular (WCOT)—atypeofcapillary

7. Reagents and Materials

column prepared by coating or bonding the inside wall of the

7.1 Carrier Gas—Helium and hydrogen have been used

capillary with a thin film of stationary phase.

successfully. The minimum purity of the carrier gas used must

be 99.85 mole %. Additional purification using commercially

4. Summary of Test Method

available scrubbing reagents is recommended to remove trace

4.1 A gas chromatograph equipped with a methylsilicone

oxygen which may deteriorate the performance of the GC

WCOT column is interfaced to a Fourier transform infrared

WCOT column.

spectrometer.The sample is injected through a cool on-column

7.2 Dilution Solvents—n-heptane and methylbenzene (tolu-

injector capable of injecting a small sample size without

ene) used as a solvent in the preparation of the calibration

overloading the column.

mixture. Reagent grade. All at 99 % or greater purity. Free

4.2 Calibration is performed using mixtures of specified

from detectable oxygenates and aromatics which may interfere

pure oxygenates and aromatic hydrocarbons on a mass basis.

with the analysis.

Volume % data is calculated from the densities of the indi-

7.2.1 Toluene should be used as a solvent only for the

vidual components and the density of the sample. Multipoint

preparation of C + components and must be free from inter-

calibrations consisting of at least five levels and bracketing the

fering aromatics. (Warning—The gasoline samples and sol-

concentration of the specified individual aromatics is required.

vents used as reagents such as heptane and toluene are

Unidentified aromatic hydrocarbons present which have not

flammable and may be harmful or fatal if ingested or inhaled.

been specifically calibrated for are quantitated using the

Benzene is a known carcinogen. Use with proper ventilation.

response factor of 1,2,3,5-tetramethylbenzene and summed

Safety glasses and gloves are required while preparing samples

with the other calibrated aromatic components to obtain a total

and standards.)

aromatic concentration of the sample.

7.3 Internal Standard—1,2-dimethoxyethane (DME) or

4.3 Specified quality control mixture(s) are analyzed to

deuterated compounds, or both, have been used successfully.A

monitor the performance of the calibrated GC/FTIR system.

single internal standard such as DME may be used. If other

internal standards are used, a narrow selective wavelength

5. Significance and Use

range must be determined to generate a SWC which yields no

5.1 Test methods to determine oxygenates, benzene, and the interference from other components in the sample.

aromatic content of gasoline are necessary to assess product

7.4 Liquid Nitrogen, supplied from low pressure dewar.

quality and to meet new fuel regulations.

Required for cooling of the MCT detector. Dewar may be

5.2 This test method can be used for gasolines that contain connected through an electronic solenoid to the MCT cooling

oxygenates (alcohols and ethers) as additives. It has been

reservoir for unattended operation. (Warning—Helium and

determined that the common oxygenates found in finished

gasolinedonotinterferewiththeanalysisofbenzeneandother

aromatics by this test method.

6. Apparatus

6.1 Gas Chromatograph:

6.1.1 System equipped with temperature programmable gas

chromatograph suitable for cool-on-column injections. The

injector must allow the introduction of small (for example,

0.1 µL) sample sizes at the head of the WCOT column or a

retention gap. An autosampler is mandatory.

6.1.2 WCOT column containing a methylsilicone stationary

phase which elutes the aromatic hydrocarbons according to

their boiling points.Acolumn containing a relatively thick film

of stationary phase, such as 4 µm to 5 µm, is recommended to

prevent column sample overload.

6.2 FTIR Spectrometer: FIG. 1 Light-Pipe GC/FTIR System

D5986 − 96 (2019)

TABLE 2 GC/FTIR Aromatic Hydrocarbons Calibration

Components (Calibrated Aromatic Components)

Compound CAS No.

Benzene 71-43-2

Methylbenzene 108-88-3

Ethylbenzene 100-41-4

1,3-Dimethylbenzene 108-38-3

1,4-Dimethylbenzene 106-42-3

1,2-Dimethylbenzene 95-47-6

(1-Methylethyl)-benzene 98-82-8

Propyl-benzene 103-65-1

1-methyl-3-ethylbenzene 620-14-4

1-methyl-4-ethylbenzene 622-96-8

1,3,5-trimethylbenzene 108-67-8

1-methyl-2-ethylbenzene 611-14-3

1,2,4-trimethylbenzene 95-63-6

1,2,3-trimethylbenzene 526-73-8

Indan 496-11-7

1,4-diethylbenzene 105-05-5

Butylbenzene 104-51-8

1,2-Diethylbenzene 135-01-3

1,2,4,5-Tetramethylbenzene 95-93-2

1,2,3,5-Tetramethylbenzene 527-53-7

Naphthalene 91-20-3

2-methyl-naphthalene 91-57-6

FIG. 2 Vapor Phase Spectrum of Benzene

1-methyl-naphthalene 90-12-0

hydrogen are supplied under high pressure. Hydrogen can be

8. Sampling

explosive and requires special handling. Hydrogen monitors

that automatically shut off supply to the GC in case of serious

8.1 Make every effort to ensure that the sample is represen-

leaks are available from GC supply manufacturers.)

tative of the fuel source from which it is taken. Follow the

recommendations of Practice D4057 or its equivalent when

7.5 Spectrometer Purge Gas, N dry air has not been tested,

obtaining samples from bulk storage or pipelines. Sampling to

but should be adequate.

meet certain regulatory specifications may require the use of

NOTE 1—The FTIR spectrometer can be protected by installing appro-

specific sampling procedures. Consult appropriate regulations.

priate filters to remove volatile oils or contaminants that may be present

in commercial low quality nitrogen supplies.Aliquid nitrogen dewar may

8.2 Take appropriate steps to minimize the loss of light

be used as a source for the nitrogen purge.

hydrocarbons from the gasoline sample while sampling and

7.6 Standards for Calibration and Identification, all at 99 % duringanalyses.Uponreceiptinthelaboratorychillthesample

or greater purity (Table 1 and Table 2). If reagents of high in its original container to 0 °C to 5 °C (32 °F to 40 °F) before

purity are not available, an accurate assay of the reagent must and after a sample is obtained for analysis.

be performed using a properly calibrated GC or other tech-

8.3 After the sample is prepared for analysis with internal

niques. The concentration of the impurities which overlap the

standard(s), chill the sample and transfer to an appropriate

other calibration components must be known and used to

autosampler vial with minimal headspace. Re-chill the remain-

correct the concentration of the calibration components. Be-

derofthesampleimmediatelyandprotectfromevaporationfor

cause of the error that may be introduced from impurity

further analyses, if necessary.

corrections, the use of only high purity reagents is strongly

recommended. Standards are used for calibration as well for

9. Calibration Procedure

establishing the identification by retention time in conjunction

9.1 Preparation of Calibration Standards—Prepare multi-

with spectral match.

component calibration standards using the compounds listed in

Table 1 and Table 2 by mass according to Practice D4307.

Prepare calibration solutions as described in 9.1 – 9.1.4 for

TABLE 1 GC/FTIR Oxygenates Calibration Components

each set. Adjust these concentrations, as necessary, to ensure

Compound CAS

thattheconcentrationsofthecomponentsintheactualsamples

Methyl-t-butyl ether (MTBE) 1634-04-4

Ethyl-t-butyl ether (ETBE) 637-92-3 are bracketed by the calibration concentrations. Solid compo-

Methyl-t-amyl ether (TAME) 994-05-8

nents are weighed directly into the flask or vial. The specified

Di-isopropyl ether (DIPE) 108-20-3

volumes of each calibration component are weighed into

Methanol 67-56-1

Ethanol 64-17-5 100 mL volumetric flasks or 100 mL septum capped vials.

2-Propanol 67-63-0

Prepare a calibration standard as follows. Cap and record the

t-Butanol 75-65-0

tare weight of the 100 mL volumetric flask or vial to 0.1 mg.

1-Propanol 71-23-6

2-Butanol 15892-23-6 Remove the cap and carefully add components to the flask or

Isobutanol 78-83-1

vial starting with the least volatile component. Cap the flask

1-Butanol 71-36-3

and record the net mass (Wi) of the aromatic component added

1,2-dimethoxyethane (DME) (Internal Standard) 110-71-4

to 0.1 mg. Repeat the addition and weighing procedure for

D5986 − 96 (2019)

TABLE 3 Relative Densities and Calibration Procedure for

eachcomponent.Similarlyaddtheinternalstandardandrecord

Aromatic Hydrocarbons

its net mass (Ws) to 0.1 mg. Store the capped calibration

Relative Densities

standardsinarefrigeratorat0 °Cto5 °C(32 °Fto40 °F)when

Compound Calibration Set

60 °F ⁄60 °F

not in use.

Benzene 0.8845 Set A

NOTE2—Mixallcalibrationsolutionsforatleast30 sonaVortexmixer Methylbenzene 0.8719 Set A

Ethylbenzene 0.8717 Set A

after preparation or equivalent. Highly precise sample robotic sample

1,3-Dimethylbenzene 0.8687 Set A

preparation systems are available commercially. These systems may be

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5986 − 96 (Reapproved 2019)

Standard Test Method for

Determination of Oxygenates, Benzene, Toluene, C –C

8 12

Aromatics and Total Aromatics in Finished Gasoline by Gas

Chromatography/Fourier Transform Infrared Spectroscopy

This standard is issued under the fixed designation D5986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the quantitative determination 2.1 ASTM Standards:

of oxygenates: methyl-t-butylether (MTBE), di-isopropyl ether D1298 Test Method for Density, Relative Density, or API

(DIPE), ethyl-t-butylether (ETBE), t-amylmethyl ether Gravity of Crude Petroleum and Liquid Petroleum Prod-

(TAME), methanol (MeOH), ethanol (EtOH), 2-propanol (2- ucts by Hydrometer Method

PrOH), t-butanol (t-BuOH), 1-propanol (1-PrOH), 2-butanol D4052 Test Method for Density, Relative Density, and API

(2-BuOH), i-butanol (i-BuOH), 1-butanol (1-BuOH); benzene, Gravity of Liquids by Digital Density Meter

toluene and C –C aromatics, and total aromatics in finished D4057 Practice for Manual Sampling of Petroleum and

8 12

motor gasoline by gas chromatography/Fourier Transform Petroleum Products

infrared spectroscopy (GC/FTIR). D4307 Practice for Preparation of Liquid Blends for Use as

Analytical Standards

1.2 This test method covers the following concentration

ranges: 0.1 % to 20 % by volume per component for ethers and

3. Terminology

alcohols; 0.1 % to 2 % by volume benzene; 1 % to 15 % by

3.1 Definitions of Terms Specific to This Standard:

volume for toluene, 10 % to 40 % by volume total (C –C )

6 12

3.1.1 aromatics—refers to any organic compound contain-

aromatics.

ing a benzene or naphthalene ring.

1.3 The method has not been tested by ASTM for refinery

3.1.2 calibrated aromatic component—in this test method,

individual hydrocarbon process streams, such as reformates,

refers to the individual aromatic components which have a

fluid catalytic cracking naphthas, etc., used in blending of

specific calibration.

gasolines.

3.1.3 cool on-column injector—in gas chromatography, a

1.4 The values stated in SI units are to be regarded as

direct sample introduction system which is set at a temperature

standard. No other units of measurement are included in this

at or below the boiling point of solutes or solvent on injection

standard.

and then heated at a rate equal to or greater than the column.

1.5 This standard does not purport to address all of the

Normally used to eliminate boiling point discrimination on

safety concerns, if any, associated with its use. It is the

injection or to reduce adsorption, or both, on glass liners within

responsibility of the user of this standard to establish appro-

injectors. The sample is injected directly into the head of the

priate safety, health, and environmental practices and deter-

capillary column tubing or retention gap.

mine the applicability of regulatory limitations prior to use.

3.1.4 Gram-Schmidt chromatogram—a nonselective sum-

1.6 This international standard was developed in accor-

mation of total intensity from a spectral scan per unit time

dance with internationally recognized principles on standard-

which resembles in profile a flame ionization detector chro-

ization established in the Decision on Principles for the

matogram.

Development of International Standards, Guides and Recom-

3.1.5 retention gap—in gas chromatography, refers to a

mendations issued by the World Trade Organization Technical

deactivated precolumn which acts as a zone of low retention

Barriers to Trade (TBT) Committee.

power for reconcentrating bands in space. The polarity of the

precolumn must be similar to that of the analytical column.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0L on Gas Chromatography Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2019. Published December 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2015 as D5986 – 96 (2015). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D5986-96R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5986 − 96 (2019)

3.1.6 selective wavelength chromatogram (SWC)—in this 6.2.1 This test method requires a light-pipe GC/FTIR sys-

test method, refers to a selective chromatogram obtained by tem (Fig. 1). No data have been acquired with matrix-isolation

summing the spectral intensity in a narrow spectral wavelength or other deposition type systems.

or frequency range as a function of elution time which is 6.2.2 The spectrometer must be equipped with a mercury-

unique to the compound being quantitated. cadmium-telluride (MCT) detector capable of detecting from at

least 4000 cm-1 to 550 cm-1.

3.1.7 uncalibrated aromatic component—in this test

6.2.3 The lower limit of 550 cm-1 is necessary for the

method, refers to individual aromatics for which a calibration is

accurate determination of benzene. Fig. 2 gives an acceptable

not available and whose concentrations are estimated from the

infrared spectra of benzene.

response factor of a calibrated aromatic component.

3.1.8 wall coated open tubular (WCOT)—a type of capillary

7. Reagents and Materials

column prepared by coating or bonding the inside wall of the

7.1 Carrier Gas—Helium and hydrogen have been used

capillary with a thin film of stationary phase.

successfully. The minimum purity of the carrier gas used must

be 99.85 mole %. Additional purification using commercially

4. Summary of Test Method

available scrubbing reagents is recommended to remove trace

4.1 A gas chromatograph equipped with a methylsilicone

oxygen which may deteriorate the performance of the GC

WCOT column is interfaced to a Fourier transform infrared

WCOT column.

spectrometer. The sample is injected through a cool on-column

7.2 Dilution Solvents—n-heptane and methylbenzene (tolu-

injector capable of injecting a small sample size without

ene) used as a solvent in the preparation of the calibration

overloading the column.

mixture. Reagent grade. All at 99 % or greater purity. Free

4.2 Calibration is performed using mixtures of specified

from detectable oxygenates and aromatics which may interfere

pure oxygenates and aromatic hydrocarbons on a mass basis.

with the analysis.

Volume % data is calculated from the densities of the indi-

7.2.1 Toluene should be used as a solvent only for the

vidual components and the density of the sample. Multipoint

preparation of C + components and must be free from inter-

calibrations consisting of at least five levels and bracketing the

fering aromatics. (Warning—The gasoline samples and sol-

concentration of the specified individual aromatics is required.

vents used as reagents such as heptane and toluene are

Unidentified aromatic hydrocarbons present which have not

flammable and may be harmful or fatal if ingested or inhaled.

been specifically calibrated for are quantitated using the

Benzene is a known carcinogen. Use with proper ventilation.

response factor of 1,2,3,5-tetramethylbenzene and summed

Safety glasses and gloves are required while preparing samples

with the other calibrated aromatic components to obtain a total

and standards.)

aromatic concentration of the sample.

7.3 Internal Standard—1,2-dimethoxyethane (DME) or

4.3 Specified quality control mixture(s) are analyzed to

deuterated compounds, or both, have been used successfully. A

monitor the performance of the calibrated GC/FTIR system.

single internal standard such as DME may be used. If other

internal standards are used, a narrow selective wavelength

5. Significance and Use

range must be determined to generate a SWC which yields no

5.1 Test methods to determine oxygenates, benzene, and the interference from other components in the sample.

aromatic content of gasoline are necessary to assess product

7.4 Liquid Nitrogen, supplied from low pressure dewar.

quality and to meet new fuel regulations.

Required for cooling of the MCT detector. Dewar may be

5.2 This test method can be used for gasolines that contain

connected through an electronic solenoid to the MCT cooling

oxygenates (alcohols and ethers) as additives. It has been reservoir for unattended operation. (Warning—Helium and

determined that the common oxygenates found in finished

gasoline do not interfere with the analysis of benzene and other

aromatics by this test method.

6. Apparatus

6.1 Gas Chromatograph:

6.1.1 System equipped with temperature programmable gas

chromatograph suitable for cool-on-column injections. The

injector must allow the introduction of small (for example,

0.1 µL) sample sizes at the head of the WCOT column or a

retention gap. An autosampler is mandatory.

6.1.2 WCOT column containing a methylsilicone stationary

phase which elutes the aromatic hydrocarbons according to

their boiling points. A column containing a relatively thick film

of stationary phase, such as 4 µm to 5 µm, is recommended to

prevent column sample overload.

6.2 FTIR Spectrometer: FIG. 1 Light-Pipe GC/FTIR System

D5986 − 96 (2019)

TABLE 2 GC/FTIR Aromatic Hydrocarbons Calibration

Components (Calibrated Aromatic Components)

Compound CAS No.

Benzene 71-43-2

Methylbenzene 108-88-3

Ethylbenzene 100-41-4

1,3-Dimethylbenzene 108-38-3

1,4-Dimethylbenzene 106-42-3

1,2-Dimethylbenzene 95-47-6

(1-Methylethyl)-benzene 98-82-8

Propyl-benzene 103-65-1

1-methyl-3-ethylbenzene 620-14-4

1-methyl-4-ethylbenzene 622-96-8

1,3,5-trimethylbenzene 108-67-8

1-methyl-2-ethylbenzene 611-14-3

1,2,4-trimethylbenzene 95-63-6

1,2,3-trimethylbenzene 526-73-8

Indan 496-11-7

1,4-diethylbenzene 105-05-5

Butylbenzene 104-51-8

1,2-Diethylbenzene 135-01-3

1,2,4,5-Tetramethylbenzene 95-93-2

1,2,3,5-Tetramethylbenzene 527-53-7

Naphthalene 91-20-3

2-methyl-naphthalene 91-57-6

FIG. 2 Vapor Phase Spectrum of Benzene

1-methyl-naphthalene 90-12-0

hydrogen are supplied under high pressure. Hydrogen can be

8. Sampling

explosive and requires special handling. Hydrogen monitors

that automatically shut off supply to the GC in case of serious

8.1 Make every effort to ensure that the sample is represen-

leaks are available from GC supply manufacturers.)

tative of the fuel source from which it is taken. Follow the

recommendations of Practice D4057 or its equivalent when

7.5 Spectrometer Purge Gas, N dry air has not been tested,

obtaining samples from bulk storage or pipelines. Sampling to

but should be adequate.

meet certain regulatory specifications may require the use of

NOTE 1—The FTIR spectrometer can be protected by installing appro-

specific sampling procedures. Consult appropriate regulations.

priate filters to remove volatile oils or contaminants that may be present

in commercial low quality nitrogen supplies. A liquid nitrogen dewar may

8.2 Take appropriate steps to minimize the loss of light

be used as a source for the nitrogen purge.

hydrocarbons from the gasoline sample while sampling and

7.6 Standards for Calibration and Identification, all at 99 % during analyses. Upon receipt in the laboratory chill the sample

or greater purity (Table 1 and Table 2). If reagents of high in its original container to 0 °C to 5 °C (32 °F to 40 °F) before

purity are not available, an accurate assay of the reagent must and after a sample is obtained for analysis.

be performed using a properly calibrated GC or other tech-

8.3 After the sample is prepared for analysis with internal

niques. The concentration of the impurities which overlap the

standard(s), chill the sample and transfer to an appropriate

other calibration components must be known and used to

autosampler vial with minimal headspace. Re-chill the remain-

correct the concentration of the calibration components. Be-

der of the sample immediately and protect from evaporation for

cause of the error that may be introduced from impurity

further analyses, if necessary.

corrections, the use of only high purity reagents is strongly

recommended. Standards are used for calibration as well for

9. Calibration Procedure

establishing the identification by retention time in conjunction

9.1 Preparation of Calibration Standards—Prepare multi-

with spectral match.

component calibration standards using the compounds listed in

Table 1 and Table 2 by mass according to Practice D4307.

Prepare calibration solutions as described in 9.1 – 9.1.4 for

TABLE 1 GC/FTIR Oxygenates Calibration Components

each set. Adjust these concentrations, as necessary, to ensure

Compound CAS

that the concentrations of the components in the actual samples

Methyl-t-butyl ether (MTBE) 1634-04-4

are bracketed by the calibration concentrations. Solid compo-

Ethyl-t-butyl ether (ETBE) 637-92-3

Methyl-t-amyl ether (TAME) 994-05-8

nents are weighed directly into the flask or vial. The specified

Di-isopropyl ether (DIPE) 108-20-3

volumes of each calibration component are weighed into

Methanol 67-56-1

Ethanol 64-17-5 100 mL volumetric flasks or 100 mL septum capped vials.

2-Propanol 67-63-0

Prepare a calibration standard as follows. Cap and record the

t-Butanol 75-65-0

tare weight of the 100 mL volumetric flask or vial to 0.1 mg.

1-Propanol 71-23-6

2-Butanol 15892-23-6 Remove the cap and carefully add components to the flask or

Isobutanol 78-83-1

vial starting with the least volatile component. Cap the flask

1-Butanol 71-36-3

and record the net mass (Wi) of the aromatic component added

1,2-dimethoxyethane (DME) (Internal Standard) 110-71-4

to 0.1 mg. Repeat the addition and weighing procedure for

D5986 − 96 (2019)

TABLE 3 Relative Densities and Calibration Procedure for

each component. Similarly add the internal standard and record

Aromatic Hydrocarbons

its net mass (Ws) to 0.1 mg. Store the capped calibration

Relative Densities

standards in a refrigerator at 0 °C to 5 °C (32 °F to 40 °F) when

Compound Calibration Set

60 °F ⁄60 °F

not in use.

Benzene 0.8845 Set A

Methylbenzene 0.8719 Set A

NOTE 2—Mix all calibration solutions for at least 30 s on a Vortex mixer

Ethylbenzene 0.8717 Set A

after preparation or equivalent. Highly precise sample robotic sample

1,3-Dimethylbenzene 0.8687 Set A

preparation systems are available commercially. These systems may be

1,4-Dimethylben

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5986 − 96 (Reapproved 2015) D5986 − 96 (Reapproved 2019)

Standard Test Method for

Determination of Oxygenates, Benzene, Toluene, C –C

8 12

Aromatics and Total Aromatics in Finished Gasoline by Gas

Chromatography/Fourier Transform Infrared Spectroscopy

This standard is issued under the fixed designation D5986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the quantitative determination of oxygenates: methyl-t-butylether (MTBE), di-isopropyl ether

(DIPE), ethyl-t-butylether (ETBE), t-amylmethyl ether (TAME), methanol (MeOH), ethanol (EtOH), 2-propanol (2-PrOH),

t-butanol (t-BuOH), 1-propanol (1-PrOH), 2-butanol (2-BuOH), i-butanol (i-BuOH), 1-butanol (1-BuOH); benzene, toluene and

C –C aromatics, and total aromatics in finished motor gasoline by gas chromatography/Fourier Transform infrared spectroscopy

8 12

(GC/FTIR).

1.2 This test method covers the following concentration ranges: 0.1 volume % to 20 volume % 0.1 % to 20 % by volume per

component for ethers and alcohols; 0.1 volume % to 2 volume % benzene; 1 volume % to 15 volume % for toluene, 10 volume

% to 40 volume % 0.1 % to 2 % by volume benzene; 1 % to 15 % by volume for toluene, 10 % to 40 % by volume total (C –C )

6 12

aromatics.

1.3 The method has not been tested by ASTM for refinery individual hydrocarbon process streams, such as reformates, fluid

catalytic cracking naphthas, etc., used in blending of gasolines.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4307 Practice for Preparation of Liquid Blends for Use as Analytical Standards

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 aromatics—refers to any organic compound containing a benzene or naphthalene ring.

3.1.2 calibrated aromatic component—in this test method, refers to the individual aromatic components which have a specific

calibration.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.04.0L on Gas Chromatography Methods.

Current edition approved Oct. 15, 2015Dec. 1, 2019. Published December 2015December 2019. Originally approved in 1996. Last previous edition approved in 20112015

as D5986 – 96 (2011).(2015). DOI: 10.1520/D5986-96R15.10.1520/D5986-96R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5986 − 96 (2019)

3.1.3 cool on-column injector—in gas chromatography, a direct sample introduction system which is set at a temperature at or

below the boiling point of solutes or solvent on injection and then heated at a rate equal to or greater than the column. Normally

used to eliminate boiling point discrimination on injection or to reduce adsorption, or both, on glass liners within injectors. The

sample is injected directly into the head of the capillary column tubing or retention gap.

3.1.4 Gram-Schmidt chromatogram—a nonselective summation of total intensity from a spectral scan per unit time which

resembles in profile a flame ionization detector chromatogram.

3.1.5 retention gap—in gas chromatography, refers to a deactivated precolumn which acts as a zone of low retention power for

reconcentrating bands in space. The polarity of the precolumn must be similar to that of the analytical column.

3.1.6 selective wavelength chromatogram (SWC)—in this test method, refers to a selective chromatogram obtained by summing

the spectral intensity in a narrow spectral wavelength or frequency range as a function of elution time which is unique to the

compound being quantitated.

3.1.7 uncalibrated aromatic component—in this test method, refers to individual aromatics for which a calibration is not

available and whose concentrations are estimated from the response factor of a calibrated aromatic component.

3.1.8 wall coated open tubular (WCOT)—a type of capillary column prepared by coating or bonding the inside wall of the

capillary with a thin film of stationary phase.

4. Summary of Test Method

4.1 A gas chromatograph equipped with a methylsilicone WCOT column is interfaced to a Fourier transform infrared

spectrometer. The sample is injected through a cool on-column injector capable of injecting a small sample size without

overloading the column.

4.2 Calibration is performed using mixtures of specified pure oxygenates and aromatic hydrocarbons on a mass basis. Volume

% data is calculated from the densities of the individual components and the density of the sample. Multipoint calibrations

consisting of at least five levels and bracketing the concentration of the specified individual aromatics is required. Unidentified

aromatic hydrocarbons present which have not been specifically calibrated for are quantitated using the response factor of

1,2,3,5-tetramethylbenzene and summed with the other calibrated aromatic components to obtain a total aromatic concentration of

the sample.

4.3 Specified quality control mixture(s) are analyzed to monitor the performance of the calibrated GC/FTIR system.

5. Significance and Use

5.1 Test methods to determine oxygenates, benzene, and the aromatic content of gasoline are necessary to assess product quality

and to meet new fuel regulations.

5.2 This test method can be used for gasolines that contain oxygenates (alcohols and ethers) as additives. It has been determined

that the common oxygenates found in finished gasoline do not interfere with the analysis of benzene and other aromatics by this

test method.

6. Apparatus

6.1 Gas Chromatograph:

6.1.1 System equipped with temperature programmable gas chromatograph suitable for cool-on-column injections. The injector

must allow the introduction of small (for example, 0.1 μL) sample sizes at the head of the WCOT column or a retention gap. An

autosampler is mandatory.

6.1.2 WCOT column containing a methylsilicone stationary phase which elutes the aromatic hydrocarbons according to their

boiling points. A column containing a relatively thick film of stationary phase, such as 4 μm to 5 μm, is recommended to prevent

column sample overload.

6.2 FTIR Spectrometer:

6.2.1 This test method requires a light-pipe GC/FTIR system (Fig. 1). No data have been acquired with matrix-isolation or other

deposition type systems.

6.2.2 The spectrometer must be equipped with a mercury-cadmium-telluride (MCT) detector capable of detecting from at least

4000 cm-1 to 550 cm-1.

6.2.3 The lower limit of 550 cm-1 is necessary for the accurate determination of benzene. Fig. 2 gives an acceptable infrared

spectra of benzene.

7. Reagents and Materials

7.1 Carrier Gas—Helium and hydrogen have been used successfully. The minimum purity of the carrier gas used must be 99.85

mole %. Additional purification using commercially available scrubbing reagents is recommended to remove trace oxygen which

may deteriorate the performance of the GC WCOT column.

D5986 − 96 (2019)

FIG. 1 Light-Pipe GC/FTIR System

FIG. 2 Vapor Phase Spectrum of Benzene

7.2 Dilution Solvents—n-heptane and methylbenzene (toluene) used as a solvent in the preparation of the calibration mixture.

Reagent grade. All at 99 % or greater purity. Free from detectable oxygenates and aromatics which may interfere with the analysis.

7.2.1 Toluene should be used as a solvent only for the preparation of C + components and must be free from interfering

aromatics. (Warning—The gasoline samples and solvents used as reagents such as heptane and toluene are flammable and may

be harmful or fatal if ingested or inhaled. Benzene is a known carcinogen. Use with proper ventilation. Safety glasses and gloves

are required while preparing samples and standards.)

7.3 Internal Standard—1,2-dimethoxyethane (DME) or deuterated compounds, or both, have been used successfully. A single

internal standard such as DME may be used. If other internal standards are used, a narrow selective wavelength range must be

determined to generate a SWC which yields no interference from other components in the sample.

7.4 Liquid Nitrogen, supplied from low pressure dewar. Required for cooling of the MCT detector. Dewar may be connected

through an electronic solenoid to the MCT cooling reservoir for unattended operation. (Warning—Helium and hydrogen are

supplied under high pressure. Hydrogen can be explosive and requires special handling. Hydrogen monitors that automatically shut

off supply to the GC in case of serious leaks are available from GC supply manufacturers.)

7.5 Spectrometer Purge Gas, N dry air has not been tested, but should be adequate.

NOTE 1—The FTIR spectrometer can be protected by installing appropriate filters to remove volatile oils or contaminants that may be present in

commercial low quality nitrogen supplies. A liquid nitrogen dewar may be used as a source for the nitrogen purge.

7.6 Standards for Calibration and Identification, all at 99 % or greater purity (Table 1 and Table 2). If reagents of high purity

are not available, an accurate assay of the reagent must be performed using a properly calibrated GC or other techniques. The

D5986 − 96 (2019)

TABLE 1 GC/FTIR Oxygenates Calibration Components

Compound CAS

Methyl-t-butyl ether (MTBE) 1634-04-4

Ethyl-t-butyl ether (ETBE) 637-92-3

Methyl-t-amyl ether (TAME) 994-05-8

Di-isopropyl ether (DIPE) 108-20-3

Methanol 67-56-1

Ethanol 64-17-5

2-Propanol 67-63-0

t-Butanol 75-65-0

1-Propanol 71-23-6

2-Butanol 15892-23-6

Isobutanol 78-83-1

1-Butanol 71-36-3

1,2-dimethoxyethane (DME) (Internal Standard) 110-71-4

TABLE 2 GC/FTIR Aromatic Hydrocarbons Calibration

Components (Calibrated Aromatic Components)

Compound CAS No.

Benzene 71-43-2

Methylbenzene 108-88-3

Ethylbenzene 100-41-4

1,3-Dimethylbenzene 108-38-3

1,4-Dimethylbenzene 106-42-3

1,2-Dimethylbenzene 95-47-6

(1-Methylethyl)-benzene 98-82-8

Propyl-benzene 103-65-1

1-methyl-3-ethylbenzene 620-14-4

1-methyl-4-ethylbenzene 622-96-8

1,3,5-trimethylbenzene 108-67-8

1-methyl-2-ethylbenzene 611-14-3

1,2,4-trimethylbenzene 95-63-6

1,2,3-trimethylbenzene 526-73-8

Indan 496-11-7

1,4-diethylbenzene 105-05-5

Butylbenzene 104-51-8

1,2-Diethylbenzene 135-01-3

1,2,4,5-Tetramethylbenzene 95-93-2

1,2,3,5-Tetramethylbenzene 527-53-7

Naphthalene 91-20-3

2-methyl-naphthalene 91-57-6

1-methyl-naphthalene 90-12-0

concentration of the impurities which overlap the other calibration components must be known and used to correct the

concentration of the calibration components. Because of the error that may be introduced from impurity corrections, the use of only

high purity reagents is strongly recommended. Standards are used for calibration as well for establishing the identification by

retention time in conjunction with spectral match.

8. Sampling

8.1 Make every effort to ensure that the sample is representative of the fuel source from which it is taken. Follow the

recommendations of Practice D4057 or its equivalent when obtaining samples from bulk storage or pipelines. Sampling to meet

certain regulatory specifications may require the use of specific sampling procedures. Consult appropriate regulations.

8.2 Take appropriate steps to minimize the loss of light hydrocarbons from the gasoline sample while sampling and during

analyses. Upon receipt in the laboratory chill the sample in its original container to 0 °C to 5 °C (32 °F to 40 °F) before and after

a sample is obtained for analysis.

8.3 After the sample is prepared for analysis with internal standard(s), chill the sample and transfer to an appropriate

autosampler vial with minimal headspace. Re-chill the remainder of the sample immediately and protect from evaporation for

further analyses, if necessary.

9. Calibration Procedure

9.1 Preparation of Calibration Standards—Prepare multi-component calibration standards using the compounds listed in Table

1 and Table 2 by mass according to Practice D4307. Prepare calibration solutions as described in 9.1 – 9.1.4 for each set. Adjust

these concentrations, as necessary, to ensure that the concentrations of the components in the actual samples are bracketed by the

calibration concentrations. Solid components are weighed directly into the flask or vial. The specified volumes of each calibration

component are weighed into 100 mL volumetric flasks or 100 mL septum capped vials. Prepare a calibration standard as follows.

D5986 − 96 (2019)

Cap and record the tare weight of the 100 mL volumetric flask or vial to 0.1 mg. Remove the cap and carefully add components

to the flask or vial starting with the least volatile component. Cap the flask and record the net mass (Wi) of the aromatic component

added to 0.1 mg. Repeat the addition and weighing procedure for each component. Similarly add the internal standard and record

its net mass (Ws) to 0.1 mg. Store the capped calibration standards in a refrigerator at 0 °C t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.