ASTM D1298-12a

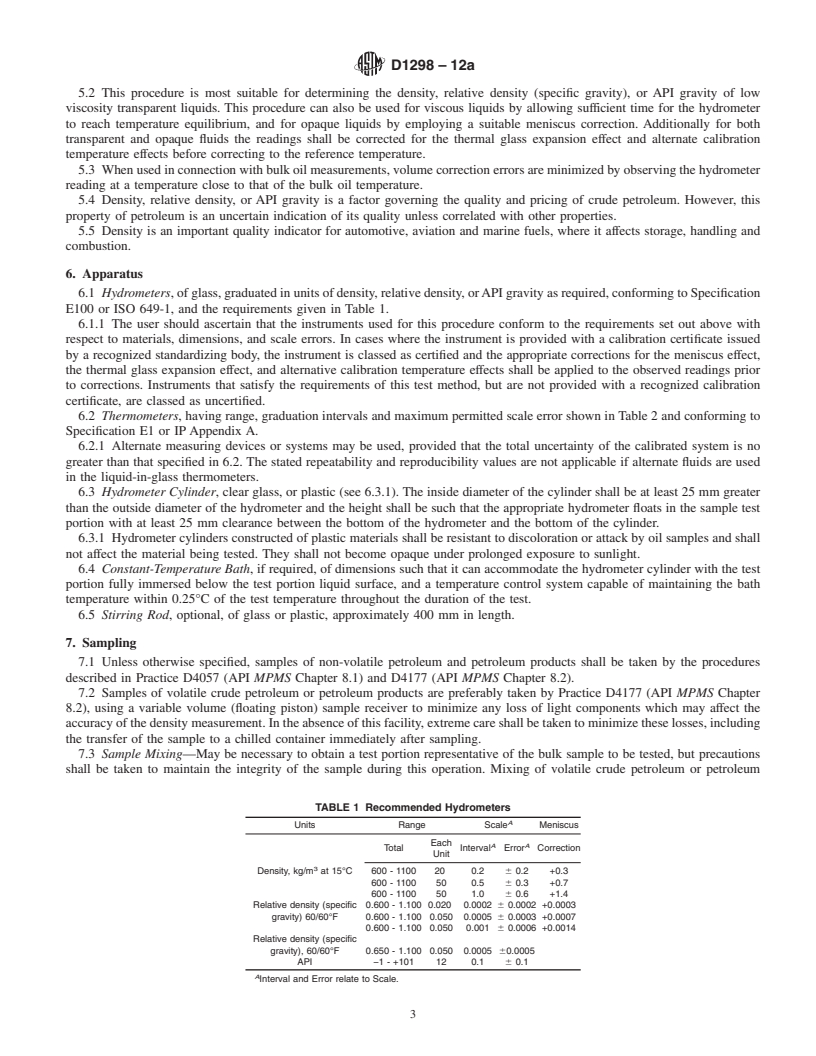

(Test Method)Standard Test Method for Density, Relative Density (Specific Gravity), or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method

Standard Test Method for Density, Relative Density (Specific Gravity), or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method

SIGNIFICANCE AND USE

Accurate determination of the density, relative density (specific gravity), or API gravity of petroleum and its products is necessary for the conversion of measured volumes to volumes or masses, or both, at the standard reference temperatures of 15°C or 60°F during custody transfer.

This procedure is most suitable for determining the density, relative density (specific gravity), or API gravity of low viscosity transparent liquids. This procedure can also be used for viscous liquids by allowing sufficient time for the hydrometer to reach temperature equilibrium, and for opaque liquids by employing a suitable meniscus correction. Additionally for both transparent and opaque fluids the readings shall be corrected for the thermal glass expansion effect and alternate calibration temperature effects before correcting to the reference temperature.

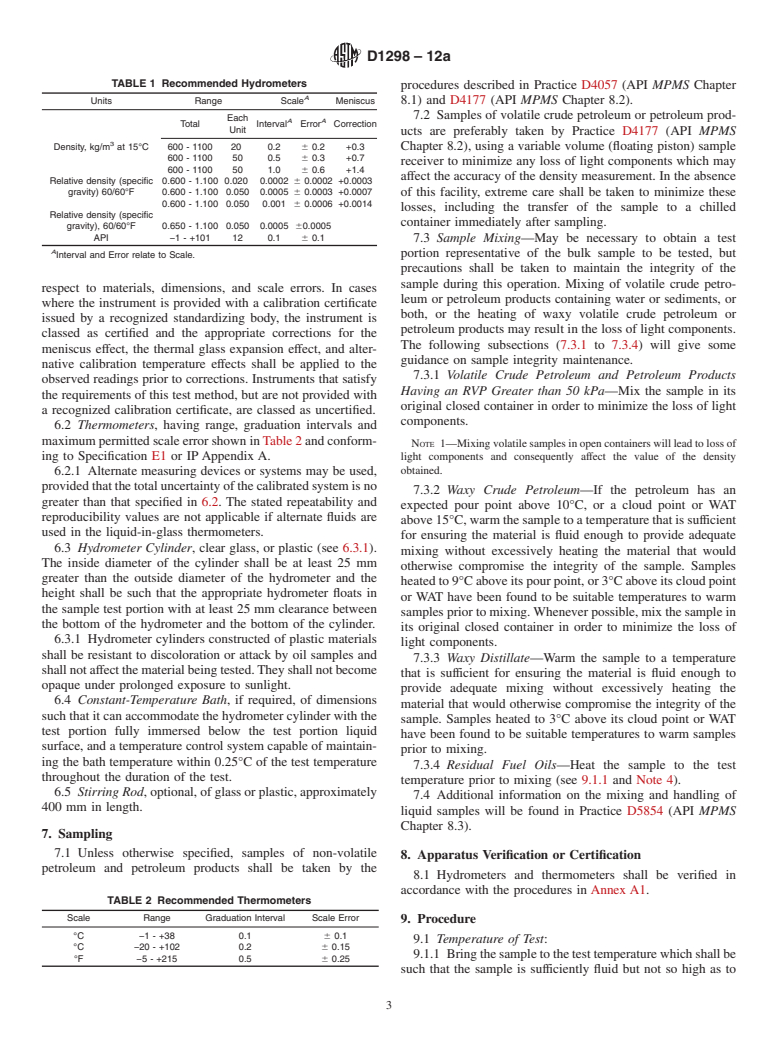

When used in connection with bulk oil measurements, volume correction errors are minimized by observing the hydrometer reading at a temperature close to that of the bulk oil temperature.

Density, relative density, or API gravity is a factor governing the quality and pricing of crude petroleum. However, this property of petroleum is an uncertain indication of its quality unless correlated with other properties.

Density is an important quality indicator for automotive, aviation and marine fuels, where it affects storage, handling and combustion.

SCOPE

1.1 This test method covers the laboratory determination using a glass hydrometer in conjunction with a series of calculations, of the density, relative density, or API gravity of crude petroleum, petroleum products, or mixtures of petroleum and nonpetroleum products normally handled as liquids, and having a Reid vapor pressure of 101.325 kPa (14.696 psi) or less. Values are determined at existing temperatures and corrected to 15°C or 60°F by means of a series of calculations and international standard tables.

1.2 The initial hydrometer readings obtained are uncorrected hydrometer readings and not density measurements. Readings are measured on a hydrometer at either the reference temperature or at another convenient temperature, and readings are corrected for the meniscus effect, the thermal glass expansion effect, alternate calibration temperature effects and to the reference temperature by means of the Petroleum Measurement Tables; values obtained at other than the reference temperature being hydrometer readings and not density measurements.

1.3 Readings determined as density, relative density, or API gravity can be converted to equivalent values in the other units or alternate reference temperatures by means of Interconversion Procedures, or Adjunct to D1250 Guide for Petroleum Measurement Tables (API MPMS Chapter 11.1), or both, or tables, as applicable.

1.4 The initial hydrometer readings determined in the laboratory shall be recorded before performing any calculations. The calculations required in Section 10 shall be applied to the initial hydrometer reading with observations and results reported as required by Section 11 prior to use in a subsequent calculation procedure (ticket calculation, meter factor calculation, or base prover volume determination).

1.5 Annex A1 contains a procedure for verifying or certifying the equipment for this test method.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

API Designation: Manual of Petroleum Measurement Standards (MPMS), Chapter 9.1

Designation: D1298 – 12a

Designation: 160/99

Standard Test Method for

Density, Relative Density (Specific Gravity), or API Gravity

of Crude Petroleum and Liquid Petroleum Products by

1

Hydrometer Method

This standard is issued under the fixed designation D1298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* calculation procedure (ticket calculation, meter factor calcula-

tion, or base prover volume determination).

1.1 This test method covers the laboratory determination

1.5 AnnexA1 contains a procedure for verifying or certify-

using a glass hydrometer in conjunction with a series of

ing the equipment for this test method.

calculations, of the density, relative density, or API gravity of

1.6 The values stated in SI units are to be regarded as

crude petroleum, petroleum products, or mixtures of petroleum

standard. The values given in parentheses are provided for

and nonpetroleum products normally handled as liquids, and

information only.

having a Reid vapor pressure of 101.325 kPa (14.696 psi) or

1.7 This standard does not purport to address all of the

less. Values are determined at existing temperatures and

safety concerns, if any, associated with its use. It is the

corrected to 15°C or 60°F by means of a series of calculations

responsibility of the user of this standard to establish appro-

and international standard tables.

priate safety and health practices and determine the applica-

1.2 The initial hydrometer readings obtained are uncor-

bility of regulatory limitations prior to use.

rected hydrometer readings and not density measurements.

Readings are measured on a hydrometer at either the reference

2. Referenced Documents

temperatureoratanotherconvenienttemperature,andreadings

2

2.1 ASTM Standards:

are corrected for the meniscus effect, the thermal glass expan-

D1250 GuideforUseofthePetroleumMeasurementTables

sion effect, alternate calibration temperature effects and to the

D4057 Practice for Manual Sampling of Petroleum and

referencetemperaturebymeansofthePetroleumMeasurement

Petroleum Products (API MPMS Chapter 8.1)

Tables; values obtained at other than the reference temperature

D4177 Practice for Automatic Sampling of Petroleum and

being hydrometer readings and not density measurements.

Petroleum Products (API MPMS Chapter 8.2)

1.3 Readings determined as density, relative density, orAPI

D5854 PracticeforMixingandHandlingofLiquidSamples

gravity can be converted to equivalent values in the other units

ofPetroleumandPetroleumProducts(API MPMSChapter

or alternate reference temperatures by means of Interconver-

8.3)

sion Procedures, or Adjunct to D1250 Guide for Petroleum

E1 Specification for ASTM Liquid-in-Glass Thermometers

Measurement Tables (API MPMS Chapter 11.1), or both, or

E100 Specification for ASTM Hydrometers

tables, as applicable.

3

2.2 API Standards:

1.4 The initial hydrometer readings determined in the labo-

MPMS Chapter 8.1 Manual Sampling of Petroleum and

ratory shall be recorded before performing any calculations.

Petroleum Products (ASTM Practice D4057)

The calculations required in Section 10 shall be applied to the

MPMS Chapter 8.2 Automatic Sampling of Petroleum and

initial hydrometer reading with observations and results re-

Petroleum Products (ASTM Practice D4177)

ported as required by Section 11 prior to use in a subsequent

MPMSChapter8.3 MixingandHandlingofLiquidSamples

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products and Lubricants and theAPI Committee on Petroleum Measure- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ment, and is the direct responsibility of D02.02 /COMQ on Hydrocarbon Measure- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ment for Custody Transfer (Joint ASTM-API). Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 15, 2012. Published October 2012. Originally the ASTM website.

3

approved in 1953. Last previous edition approved in 2012 as D1298–12. DOI: Published as Manual of Petroleum Measurement Standards.Available from the

10.1520/D1298-12A. American Petroleum Institute (API), 1220 L St., NW, Washington, DC 20005.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 --

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

API Designation: Manual of Petroleum Measurement Standards (MPMS), Chapter 9.1

Designation:D1298–12 Designation: D1298 – 12a

Designation: 160/99

Standard Test Method for

Density, Relative Density (Specific Gravity), or API Gravity

of Crude Petroleum and Liquid Petroleum Products by

1

Hydrometer Method

This standard is issued under the fixed designation D1298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the laboratory determination using a glass hydrometer in conjunction with a series of calculations,

of the density, relative density, orAPI gravity of crude petroleum, petroleum products, or mixtures of petroleum and nonpetroleum

products normally handled as liquids, and having a Reid vapor pressure of 101.325 kPa (14.696 psi) or less.Values are determined

at existing temperatures and corrected to 15°C or 60°F by means of a series of calculations and international standard tables.

1.2 The initial hydrometer readings obtained are uncorrected hydrometer readings and not density measurements. Readings are

measured on a hydrometer at either the reference temperature or at another convenient temperature, and readings are corrected for

the meniscus effect, the thermal glass expansion effect, alternate calibration temperature effects and to the reference temperature

bymeansofthePetroleumMeasurementTables;valuesobtainedatotherthanthereferencetemperaturebeinghydrometerreadings

and not density measurements.

1.3 Readings determined as density, relative density, orAPI gravity can be converted to equivalent values in the other units or

alternate reference temperatures by means of Interconversion Procedures, orAdjunct to D1250 Guide for Petroleum Measurement

Tables (API MPMS Chapter 11.1), or both, or tables, as applicable.

1.4 The initial hydrometer readings determined in the laboratory shall be recorded before performing any calculations. The

calculations required in Section 10 shall be applied to the initial hydrometer reading with observations and results reported as

required by Section 11 prior to use in a subsequent calculation procedure (ticket calculation, meter factor calculation, or base

prover volume determination).

1.5 Annex A1 contains a procedure for verifying or certifying the equipment for this test method.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information

only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1250 Guide for Use of the Petroleum Measurement Tables

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products (API MPMS Chapter 8.1)

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products (API MPMS Chapter 8.2)

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products (API MPMS Chapter 8.3)

E1 Specification for ASTM Liquid-in-Glass Thermometers

E100 Specification for ASTM Hydrometers

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and the API Committee on Petroleum Measurement, and is

the direct responsibility of D02.02 /COMQ on Hydrocarbon Measurement for Custody Transfer (Joint ASTM-API).

Current edition approved April 1,May 15, 2012. Published AugustOctober 2012. Originally approved in 1953. Last previous edition approved in 20052012 as

D1298–99(2005).D1298–12. DOI: 10.1520/D1298-12A.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1298 – 12a

3

2.2 API Standards:

MPMS Chapter 8.1 Manual Sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.