ASTM D4057-95(2000)

(Practice)Standard Practice for Manual Sampling of Petroleum and Petroleum Products

Standard Practice for Manual Sampling of Petroleum and Petroleum Products

SCOPE

1.1 This practice covers procedures for manually obtaining representative samples of petroleum products of a liquid, semi-liquid, or solid state whose vapor pressure at ambient conditions is below 101 kPa (14.7 psia). If sampling is for the precise determination of volatility, use Practice D5842 in conjunction with this practice. For sample mixing and handling of samples, refer to Practice D5854. The practice does not cover sampling of electrical insulating oils and hydraulic fluids. A summary of the manual sampling procedures and their applications is presented in Table 1. Note 1-The procedures described in this method may also be applicable in sampling most noncorrosive liquid industrial chemicals, provided that all safety precautions specific to these chemicals are strictly followed. Note 2-The procedure for sampling liquified petroleum gases is described in Practice D1265; the procedure for sampling fluid power hydraulic fluids is covered in ANSI B93.19 and B93.44; the procedure for sampling insulating oils is described in Test Method D923; and the procedure for sampling natural gas is described in Test Method D1145. Note 3-The procedure for special fuel samples for trace metal analysis is described in an appendix to Specification D2880.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4057–95 (Reapproved 2000) AnAmerican National Standard

|MPMS (Chapter 8.1)

Standard Practice for

Manual Sampling of Petroleum and Petroleum Products

This standard is issued under the fixed designation D4057; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committees and accepted by the Cooperating Societies in accordance with

established procedures. This method was issued as a joint ASTM-API standard in 1981.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Coatings and Materials

D323 Test Method for Vapor Pressure of Petroleum Prod-

1.1 This practice covers procedures for manually obtaining

ucts (Reid Method)

representative samples of petroleum products of a liquid,

D346 Practice for Collection and Preparation of Coke

semi-liquid, or solid state whose vapor pressure at ambient

Samples for Laboratory Analysis

conditions is below 101 kPa (14.7 psia). If sampling is for the

D525 Test Method for Oxidation Stability of Gasoline

precise determination of volatility, use Practice D5842 in

(Induction Period Method)

conjunctionwiththispractice.Forsamplemixingandhandling

D873 TestMethodforOxidationStabilityofAviationFuels

of samples, refer to Practice D5854. The practice does not

(Potential Residue Method)

cover sampling of electrical insulating oils and hydraulic

D923 Test Method for Sampling Electrical Insulating Liq-

fluids.Asummaryofthemanualsamplingproceduresandtheir

uids

applications is presented in Table 1.

D977 Specification for Emulsified Asphalt

NOTE 1—The procedures described in this method may also be appli- 7

D1145 Test Method for Sampling Natural Gas

cableinsamplingmostnoncorrosiveliquidindustrialchemicals,provided

D1265 Practice for Sampling Liquefied Petroleum (LP)

thatallsafetyprecautionsspecifictothesechemicalsarestrictlyfollowed.

Gases—Manual Method

NOTE 2—The procedure for sampling liquified petroleum gases is

D1856 TestMethodforRecoveryofAsphaltfromSolution

described in Practice D1265; the procedure for sampling fluid power

hydraulicfluidsiscoveredinANSIB93.19andB93.44;theprocedurefor by Abson Method

sampling insulating oils is described in Practice D923; and the procedure

D2172 Test Methods for Quantitative Extraction of Bitu-

for sampling natural gas is described in Test Method D1145.

men from Bituminous Paving Mixtures

NOTE 3—The procedure for special fuel samples for trace metal 8

D2880 Specification for Gas Turbine Fuel Oils

analysis is described in an appendix to Specification D2880.

D4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

2. Referenced Documents

D4306 Practice for Aviation Fuel Sample Containers for

2.1 ASTM Standards:

Tests Affected by Trace Contamination

D86 Test Method for Distillation of Petroleum Products at

D5842 Practice for Mixing and Handling of Liquids of

Atmospheric Pressure

Petroleum and Petroleum Products

D217 Test Methods for Cone Penetration of Lubricating

D5854 Practice for Mixing and Handling of Fuels for

Grease

Volatility Measurements

D244 Test Methods for Emulsified Asphalts

2.2 American National Standards:

D268 Guide for Sampling and Testing Volatile Solvents

B93.19 StandardMethodforExtractionFluidSamplesfrom

and Chemical Intermediates for Use in Paint and Related

the Lines of an Operating Hydraulic Fluid Power System

Annual Book of ASTM Standards, Vol 06.04.

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

Annual Book of ASTM Standards, Vol 05.06.

Products and Lubricantsand is the direct responsibility of Subcommittee D02.02on

Annual Book of ASTM Standards, Vol 10.03.

Static Petroleum Measurement (Joint ASTM-API). Discontinued; see 1987 Annual Book of ASTM Standards, Vol 05.05.

Current edition approved Nov. 10, 1995. Published January 1996. Originally Annual Book of ASTM Standards, Vol 05.02.

published as D4057–81. Last previous edition D4057–88. Annual Book of ASTM Standards, Vol 05.03.

2 10

Annual Book of ASTM Standards, Vol 05.01. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 04.03. Floor, New York, NY 10036.

Copyright ©ASTM, 100 Barr Harbor Drive, West Conshohocken, PA19428-2959, United States.

D4057

TABLE 1 Typical Sampling Procedures and Applicability

Application Type of Container Procedure

Liquids of more than (13.8 kPa) and not more than 101 kPa storage tanks, ship and barge tanks, tank cars, tank trucks bottle sampling

(14.7 psia) RVP

thief sampling

Liquids of 101 kPa (14.7 psia) RVP or less storage tanks with taps tap sampling

Bottom sampling of liquids of 13.8 kPa (2 psia) RVP or less storage tanks with taps tap sampling

Liquids of 101 kPa (14.7 psia) RVP or less pipes or lines pipeline sampling

Liquids of 13.8 kPa (2 psia) RVP or less storage tanks, ships, barges bottle sampling

Liquids of 13.8 kPa (2 psia) RVP or less free or open-discharge streams dipper sampling

Liquids of 13.8 kPa (2 psia) RVP or less drums, barrels, cans tube sampling

Bottom or thief sampling of liquids of 13.8 kPa (2 psia) RVP or less tank cars, storage tanks thief sampling

Liquids and semi-liquids of 13.8 kPa (2 psia) RVP or less free or open-discharge streams; open tanks or kettles with open dipper sampling

heads; tank cars, tank trucks, drums

Crude petroleum storage tanks, ship and barge, tanks, tank cars, tank trucks, automatic sampling

pipelines

thief sampling

bottle sampling

tap sampling

Industrial aromatic hydrocarbons storage tanks, ship and barge tanks bottle sampling

Waxes, solids bitumens, other soft solids barrels, cases, bags, cakes boring sampling

Petroleum coke; lumpy solids freight cars, conveyors, bags, barrels, boxes grab sampling

Greases, soft waxes, asphalts kettles, drums, cans, tubes grease sampling

Asphaltic materials storage tanks, tank cars, lines, packages .

Emulsified asphalts storage tanks, tank cars, lines, packages .

(for Particulate Contamination Analysis) 3.1.1.3 bottom sample— a spot sample collected from the

material at the bottom of the tank, container, or line at its

B93.44 Method for Extracting Fluid Samples from the

lowest point.

Reservoir of an Operating Hydraulic Fluid Power System

2.3 API Manual of Petroleum Measurement Standards: (a) Discussion—In practice, the term bottom sample has a

variety of meanings. As a result, it is recommended that the

Chapter 8.2 Automatic Sampling of Petroleum and Petro-

exact sampling location (for example, 15 cm from the bottom)

leum Products

should be specified when using this term.

Chapter 8.3 Standard Practice for Mixing and Handling of

Liquid Samples of Petroleum and Petroleum Products 3.1.1.4 bottom water sample—a spot sample of free water

taken from beneath the petroleum contained in a ship or barge

Chapter 8.4 Standard Practice for the Sampling and Han-

compartment or a storage tank.

dling of Fuels for Volatility Measurements

3.1.1.5 clearance sample— a spot sample taken with the

Chapter 9.3 Thermohydrometer Test Method for Density

inlet opening of the sampling apparatus 10 cm (4 in.) (some

and API Gravity of Crude Petroleum and Liquid Petro-

regulatory agencies require 15 cm (6 in.)) below the bottom of

leum Products

the tank outlet.

Chapter 17.1 Guidelines for Marine Cargo Inspection

(a) Discussion—Thistermisnormallyassociatedwithsmall

Chapter17.2 MeasurementofCargoesAboardMarineTank

(159 m or 1000 Bbls or less) tanks, commonly referred to as

Vessels

lease tanks.

Chapter 18.1 Measurement Procedures for Crude Oil Gath-

3.1.1.6 composite sample— a blend of spot samples mixed

ered from Small Tanks By Truck

in proportion to the volumes of material from which the spot

Chapter 10, various sections, Sediment and Water Determi-

samples were obtained.

nation

3.1.1.7 core sample— a sample of uniform cross sectional

area taken at a given height in a tank.

3. Terminology

3.1.1.8 dipper sample— a sample obtained by placing a

3.1 Definitions of Terms Specific to This Standard:

dipper or other collecting vessel in the path of a free-flowing

3.1.1 Samples:

stream to collect a definite volume from the full cross section

3.1.1.1 all-levels sample—a sample obtained by submerg-

of the stream at regular time intervals for a constant time rate

ing a stoppered beaker or bottle to a point as near as possible

offloworattimeintervalsvariedinproportiontotheflowrate.

tothedraw-offlevel,thenopeningthesamplerandraisingitat

3.1.1.9 drain sample— a sample obtained from the water

a rate such that it is approximately three-fourths full as it

draw-off valve on a storage tank.

emerges from the liquid.

(a) Discussion—Occasionally, a drain sample may be the

3.1.1.2 boring sample— a sample of the material contained

same as a bottom sample (for example, in the case of a tank

in a barrel, case, bag, or cake that is obtained from the chips

car).

created by boring holes into the material with a ship auger.

3.1.1.10 floating roof sample—a spot sample taken just

below the surface to determine the density of the liquid on

11 which the roof is floating.

Available from American Petroleum Institute, 1220 L St., NW, Washington,

DC 20005. 3.1.1.11 flow proportional sample—a sample taken from a

D4057

pipe such that the rate of sampling is proportional throughout 3.1.1.21 sampling—allthestepsrequiredtoobtainasample

the sampling period to the flow rate of the fluid in the pipe. that is representative of the contents of any pipe, tank, or other

3.1.1.12 grab sample— a sample obtained by collecting vessel and to place that sample in a container from which a

equal quantities from parts or packages of a shipment of loose representative test specimen can be taken for analysis.

solids such that the sample is representative of the entire 3.1.1.22 spot sample— a sample taken at a specific location

shipment. in a tank or from a flowing stream in a pipe at a specific time.

3.1.1.13 grease sample— a sample obtained by scooping or 3.1.1.23 surface sample— a spot sample skimmed from the

dipping a quantity of soft or semi-liquid material contained surface of a liquid in a tank.

from a package in a representative manner. 3.1.1.24 tank composite sample—a blend created from the

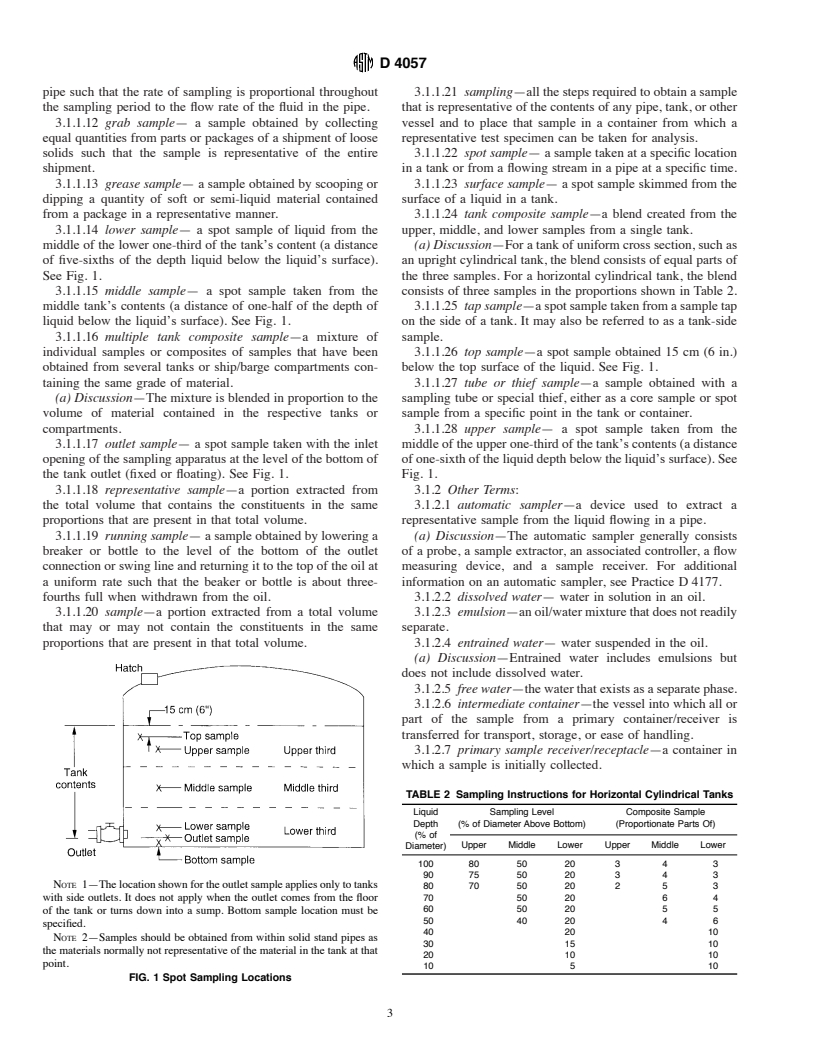

3.1.1.14 lower sample— a spot sample of liquid from the upper, middle, and lower samples from a single tank.

middle of the lower one-third of the tank’s content (a distance (a) Discussion—Foratankofuniformcrosssection,suchas

of five-sixths of the depth liquid below the liquid’s surface). an upright cylindrical tank, the blend consists of equal parts of

See Fig. 1. the three samples. For a horizontal cylindrical tank, the blend

3.1.1.15 middle sample— a spot sample taken from the consists of three samples in the proportions shown in Table 2.

middle tank’s contents (a distance of one-half of the depth of 3.1.1.25 tapsample—aspotsampletakenfromasampletap

liquid below the liquid’s surface). See Fig. 1. on the side of a tank. It may also be referred to as a tank-side

3.1.1.16 multiple tank composite sample—a mixture of sample.

individual samples or composites of samples that have been 3.1.1.26 top sample—a spot sample obtained 15 cm (6 in.)

obtained from several tanks or ship/barge compartments con- below the top surface of the liquid. See Fig. 1.

taining the same grade of material. 3.1.1.27 tube or thief sample—a sample obtained with a

(a) Discussion—The mixture is blended in proportion to the sampling tube or special thief, either as a core sample or spot

volume of material contained in the respective tanks or sample from a specific point in the tank or container.

compartments. 3.1.1.28 upper sample— a spot sample taken from the

3.1.1.17 outlet sample— a spot sample taken with the inlet middleoftheupperone-thirdofthetank’scontents(adistance

openingofthesamplingapparatusatthelevelofthebottomof ofone-sixthoftheliquiddepthbelowtheliquid’ssurface).See

the tank outlet (fixed or floating). See Fig. 1. Fig. 1.

3.1.1.18 representative sample—a portion extracted from 3.1.2 Other Terms:

the total volume that contains the constituents in the same 3.1.2.1 automatic sampler—a device used to extract a

proportions that are present in that total volume. representative sample from the liquid flowing in a pipe.

3.1.1.19 running sample—asampleobtainedbyloweringa (a) Discussion—The automatic sampler generally consists

breaker or bottle to the level of the bottom of the outlet of a probe, a sample extractor, an associated controller, a flow

connectionorswinglineandreturningittothetopoftheoilat measuring device, and a sample receiver. For additional

a uniform rate such that the beaker or bottle is about three- information on an automatic sampler, see Practice D4177.

fourths full when withdrawn from the oil. 3.1.2.2 dissolved water— water in solution in an oil.

3.1.1.20 sample—a portion extracted from a total volume 3.1.2.3 emulsion—anoil/watermixturethatdoesnotreadily

that may or may not contain the constituents in the same separate.

proportions that are present in that total volume. 3.1.2.4 entrained water— water suspended in the oil.

(a) Discussion—Entrained water includes emulsions but

does not include dissolved water.

3.1.2.5 freewater—thewaterthatexistsasaseparatephase.

3.1.2.6 intermediate container—the vessel into which all or

part of the sample from a primary container/receiver is

transferred for transport, storage, or ease of handling.

3.1.2.7 primary sample receiver/receptacle—a container in

which a sample is initially collected.

TABLE 2 Sampling Instructions for Horizontal Cylindrical Tanks

Liquid Sampling Level Composite Sample

Depth (% of DiameterAbove Bottom) (Proportionate Parts Of)

(% of

Upper Middle Lower Upper Middle Lower

Diameter)

100 80 50 20 3 4 3

90 75 50 20 3 4 3

NOTE 1—Thelocationshownfortheoutletsampleappliesonlytotanks

80 70 50 20 2 5 3

with side outlets. It does not apply when the outlet comes from the floor 70 50 20 6 4

60 50 20 5 5

of the tank or turns down into a sump. Bottom sample location must be

50 40 20 4 6

specified.

40 20 10

NOTE 2—Samples should be obtained from within solid stand pipes as

30 15 10

thematerialsnormallynotrepresentativeofthematerialinthetankatthat

20 10 10

point.

10 5 10

FIG. 1 Spot Sampling Locations

D4057

(a) Discussion—Examples of primary sampler containers 6. Apparatus

include glass and plastic bottles, cans, core-type thief, and

6.1 Sample containers come in a variety of shapes, sizes,

fixed and portable sample receivers.

and materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.