ASTM E2598/E2598M-13

(Practice)Standard Practice for Acoustic Emission Examination of Cast Iron Yankee and Steam Heated Paper Dryers

Standard Practice for Acoustic Emission Examination of Cast Iron Yankee and Steam Heated Paper Dryers

SIGNIFICANCE AND USE

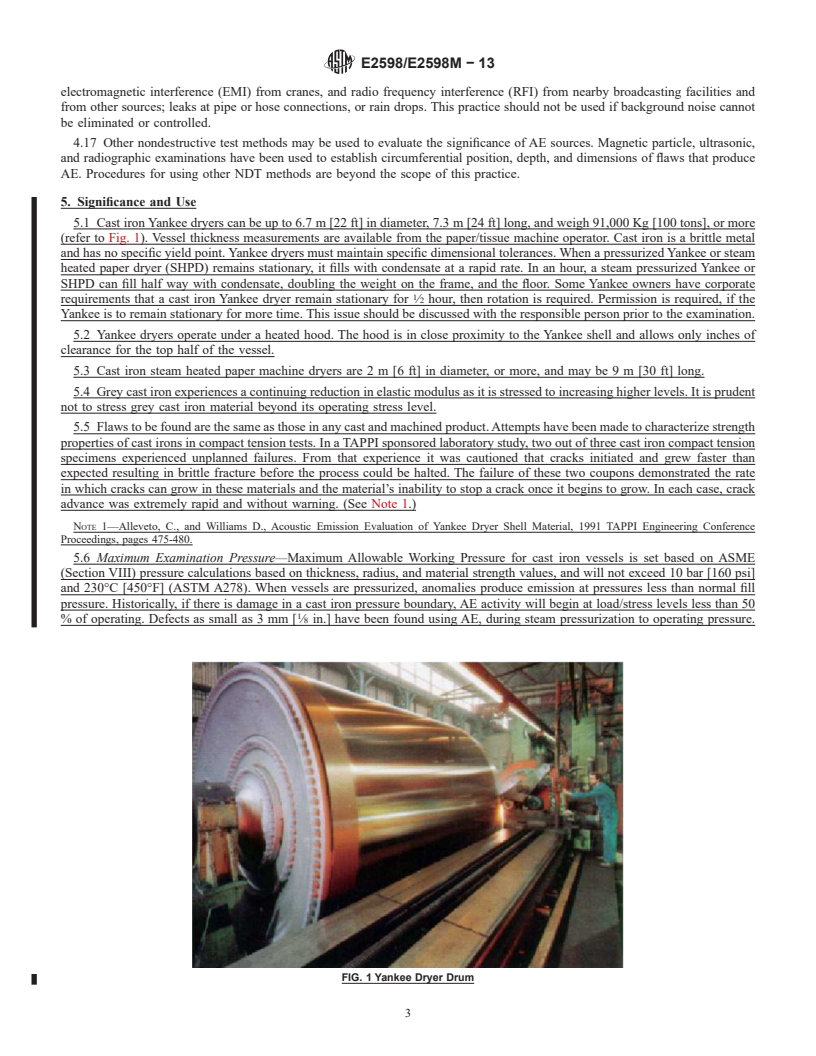

5.1 Cast iron Yankee dryers can be up to 6.7 m [22 ft] in diameter, 7.3 m [24 ft] long, and weigh 91,000 Kg [100 tons], or more (refer to Fig. 1

FIG. 1 Yankee Dryer Drum). Vessel thickness measurements are available from the paper/tissue machine operator. Cast iron is a brittle metal and has no specific yield point. Yankee dryers must maintain specific dimensional tolerances. When a pressurized Yankee or steam heated paper dryer (SHPD) remains stationary, it fills with condensate at a rapid rate. In an hour, a steam pressurized Yankee or SHPD can fill half way with condensate, doubling the weight on the frame, and the floor. Some Yankee owners have corporate requirements that a cast iron Yankee dryer remain stationary for 1/2 hour, then rotation is required. Permission is required, if the Yankee is to remain stationary for more time. This issue should be discussed with the responsible person prior to the examination.

5.2 Yankee dryers operate under a heated hood. The hood is in close proximity to the Yankee shell and allows only inches of clearance for the top half of the vessel.

5.3 Cast iron steam heated paper machine dryers are 2 m [6 ft] in diameter, or more, and may be 9 m [30 ft] long.

5.4 Grey cast iron experiences a continuing reduction in elastic modulus as it is stressed to increasing higher levels. It is prudent not to stress grey cast iron material beyond its operating stress level.

5.5 Flaws to be found are the same as those in any cast and machined product. Attempts have been made to characterize strength properties of cast irons in compact tension tests. In a TAPPI sponsored laboratory study, two out of three cast iron compact tension specimens experienced unplanned failures. From that experience it was cautioned that cracks initiated and grew faster than expected resulting in brittle fracture before the process could be halted. The failure of these two coupons demonstrated the rate in which cracks can grow in these materials and the mat...

SCOPE

1.1 This practice provides guidelines for carrying out acoustic emission (AE) examinations of Yankee and Steam Heated Paper Dryers (SHPD) of the type to make tissue, paper, and paperboard products.

1.2 This practice requires pressurization to levels used during normal operation. The pressurization medium may be high temperature steam, air, or gas. The dryer is also subjected to significant stresses during the heating up and cooling down periods of operation. Acoustic Emission data maybe collected during these time periods but this testing is beyond the scope of this document.

1.3 The AE measurements are used to detect, as well as, localize emission sources. Other methods of nondestructive testing (NDT) may be used to further evaluate the significance of acoustic emission sources.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standards.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2598/E2598M − 13

Standard Practice for

Acoustic Emission Examination of Cast Iron Yankee and

1

Steam Heated Paper Dryers

This standard is issued under the fixed designation E2598/E2598M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Pressure-Containing Parts for Temperatures Up to 650°F

(350°C)

1.1 This practice provides guidelines for carrying out acous-

E543 Specification for Agencies Performing Nondestructive

tic emission (AE) examinations of Yankee and Steam Heated

Testing

Paper Dryers (SHPD) of the type to make tissue, paper, and

E569 Practice for Acoustic Emission Monitoring of Struc-

paperboard products.

tures During Controlled Stimulation

1.2 This practice requires pressurization to levels used

E650 Guide for Mounting Piezoelectric Acoustic Emission

during normal operation. The pressurization medium may be

Sensors

high temperature steam, air, or gas. The dryer is also subjected

E976 Guide for Determining the Reproducibility of Acoustic

to significant stresses during the heating up and cooling down

Emission Sensor Response

periods of operation. Acoustic Emission data maybe collected

E1316 Terminology for Nondestructive Examinations

during these time periods but this testing is beyond the scope

E2374 Guide for Acoustic Emission System Performance

of this document.

Verification

3

1.3 The AE measurements are used to detect, as well as,

2.2 ASNT Standards:

localize emission sources. Other methods of nondestructive

SNT-TC-1A Recommended Practice for Nondestructive

testing (NDT) may be used to further evaluate the significance

Testing Personnel

of acoustic emission sources.

ANSI/ASNT CP-189 Standard for Qualification and Certifi-

cation of Nondestructive Testing Personnel

1.4 Units—The values stated in either SI units or inch-

pound units are to be regarded as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3.1 Definitions—See Terminology E1316 for general termi-

values from the two systems may result in non-conformance

nology applicable to this practice.

with the standards.

1.5 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 Each mounted sensor, on the cast iron vessel, monitors

responsibility of the user of this standard to establish appro-

while the vessel is stationary and pressurized to normal

priate safety and health practices and determine the applica-

operating pressure. The vessel may be at ambient, or operating

bility of regulatory limitations prior to use.

120°C-230°C [250°F-450°F] temperature.

4.2 Each mounted AE sensor is connected to an acoustic

2. Referenced Documents

emission signal processor. After a monitoring period (up to 10

2

2.1 ASTM Standards:

minutes) and pre-examination sensor sensitivity checks, pres-

A278/A278M Specification for Gray Iron Castings for

surization can begin.

4.3 Location

1

4.3.1 Zone Location—Each channel shall have the same

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

system examination threshold. A simulated AE source gener-

Acoustic Emission Method.

ated anywhere on the vessel shall be detected by at least one

Current edition approved Jan. 1, 2013. Published January 2013. Originally

sensor.

approved in 2007. Last previous edition approved in 2007 as E2598 - 07. DOI:

10.1520/E2598_E2598-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for Nondestructive Testing (ASNT), P.O. Box

the ASTM website. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2598/E2598M − 13

4.3.2 Source Location—All location data resulting from begins to grow. In each case, crack advance was extremely

4

analysis shall be presented in a manner consistent with the rapid and without warning.

previously established calibration accuracy. The simulated AE

4.12 Maximum Examination Pressure—Maximum Allow-

source generated in each structure mounted sensor array shall

able Working Pressure for cas

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2598 − 07 E2598/E2598M − 13

Standard Practice for

Acoustic Emission Examination of Cast Iron Yankee and

1

Steam Heated Paper Dryers

This standard is issued under the fixed designation E2598;E2598/E2598M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice provides guidelines for carrying out acoustic emission (AE) examinations of Yankee and Steam Heated Paper

Dryers (SHPD) of the type to make tissue, paper, and paperboard products.

1.2 This practice requires pressurization to levels used during normal operation. The pressurization medium may be high

temperature steam, air, or gas. The dryer is also subjected to significant stresses during the heating up and cooling down periods

of operation. Acoustic Emission data maybe collected during these time periods but this testing is beyond the scope of this

document.

1.3 The AE measurements are used to detect, as well as, localize emission sources. Other methods of nondestructive testing

(NDT) may be used to further evaluate the significance of acoustic emission sources.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standards.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A278/A278M Specification for Gray Iron Castings for Pressure-Containing Parts for Temperatures Up to 650°F (350°C)

E543 Specification for Agencies Performing Nondestructive Testing

E569 Practice for Acoustic Emission Monitoring of Structures During Controlled Stimulation

E650 Guide for Mounting Piezoelectric Acoustic Emission Sensors

E976 Guide for Determining the Reproducibility of Acoustic Emission Sensor Response

E1316 Terminology for Nondestructive Examinations

E2374 Guide for Acoustic Emission System Performance Verification

3

2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive Testing Personnel

ANSI/ASNT CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

3. Terminology

3.1 Definitions—See Terminology E1316 for general terminology applicable to this practice.

4. Summary of Practice

4.1 Each mounted sensor, on the cast iron vessel, monitors while the vessel is stationary and pressurized to normal operating

pressure. The vessel may be at ambient, or operating (250°F-450°F) 120°C-230°C [250°F-450°F] temperature.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.04 on Acoustic Emission

Method.

Current edition approved Dec. 1, 2007Jan. 1, 2013. Published January 2008January 2013. Originally approved in 2007. Last previous edition approved in 2007 as E2598

- 07. DOI: 10.1520/E2598-07.10.1520/E2598_E2598-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2598/E2598M − 13

4.2 Each mounted AE sensor is connected to an acoustic emission signal processor. After a monitoring period (up to 10 minutes)

and pre-examination sensor sensitivity checks, pressurization can begin.

4.3 Location

4.3.1 Zone Location—Each channel shall have the same system examination threshold. A simulated AE source generated

anywhere on the vessel shall be detected by at least one sensor.

4.3.2 Source Location—All location data resulting from analysis sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.