ASTM E2515-11(2017)

(Test Method)Standard Test Method for Determination of Particulate Matter Emissions Collected by a Dilution Tunnel

Standard Test Method for Determination of Particulate Matter Emissions Collected by a Dilution Tunnel

SCOPE

1.1 This test method is applicable for the determination of particulate matter emissions from solid-fuel-burning appliances including woodstoves, pellet-burning appliances, factory-built fireplaces, masonry fireplaces, masonry heaters, indoor furnaces, and indoor and outdoor hydronic heaters within a laboratory environment.

1.2 Analytes will be a particulate matter (PM) with no CAS number assigned. For data quality objectives, see Appendix X1.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This test method does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2515 − 11 (Reapproved 2017)

Standard Test Method for

Determination of Particulate Matter Emissions Collected by

a Dilution Tunnel

This standard is issued under the fixed designation E2515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2986 Practice for Evaluation of Air Assay Media by the

Monodisperse DOP (Dioctyl Phthalate) Smoke Test

1.1 This test method is applicable for the determination of

(Withdrawn 2004)

particulate matter emissions from solid-fuel-burning appli-

E2558 Test Method for Determining Particulate Matter

ances including woodstoves, pellet-burning appliances,

Emissions from Fires in Wood-Burning Fireplaces

factory-built fireplaces, masonry fireplaces, masonry heaters,

E2618 Test Method for Measurement of Particulate Emis-

indoor furnaces, and indoor and outdoor hydronic heaters

sionsandHeatingEfficiencyofSolidFuel-FiredHydronic

within a laboratory environment.

Heating Appliances

1.2 Analytes will be a particulate matter (PM) with no CAS

E2779 Test Method for Determining Particulate Matter

number assigned. For data quality objectives, see Appendix

Emissions from Pellet Heaters

X1.

E2780 Test Method for Determining Particulate Matter

Emissions from Wood Heaters

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses are mathematical E2817 Test Method for Test Fueling Masonry Heaters

conversions to inch-pound units that are provided for informa-

2.2 AISI Document:

tion only and are not considered standard.

AISI 316 Stainless Steel

2.3 NIST Document:

1.4 This test method does not purport to address all of the

safety concerns, if any, associated with its use. It is the NIST Monograph 175 Standard Limits of Error

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1 Definitions of Terms Specific to This Standard:

1.5 This international standard was developed in accor-

3.1.1 laboratory environment—the area or room that is used

dance with internationally recognized principles on standard-

for the storage, weighing, assembly, disassembly, and desicca-

ization established in the Decision on Principles for the

tion of filters and related equipment (sample recovery and

Development of International Standards, Guides and Recom-

analysis).

mendations issued by the World Trade Organization Technical

3.1.2 particulate matter (PM)—all gas-borne matter result-

Barriers to Trade (TBT) Committee.

ing from combustion of solid fuel, as specified in the appliance

operation test method, that is collected and retained by the

2. Referenced Documents

specified filter and probe system under the conditions of the

2.1 ASTM Standards:

test.

3.1.3 test facility—the area in which the tested appliance is

This test method is under the jurisdiction of ASTM Committee E06 on

installed, operated, and sampled for emissions.

Performance of Buildings and is the direct responsibility of Subcommittee E06.54

on Solid Fuel Burning Appliances.

Current edition approved Sept. 1, 2017. Published September 2017. Originally

approved in 2007. Last previous edition approved in 2011 as E2515 – 11. DOI: The last approved version of this historical standard is referenced on

10.1520/E2515-11R17. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Iron and Steel Institute (AISI), 25 Massachusetts

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Ave., NW, Suite 800, Washington, DC 20001, http://www.steel.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2515 − 11 (2017)

4. Summary of Test Method 5. Safety

4.1 The total flue-gas exhaust from a solid fuel burning 5.1 Disclaimer—This test method may involve hazardous

appliance is collected along with ambient dilution air with a materials,operations,andequipment.Thistestmethodmaynot

collection hood. Duplicate sampling trains are used to extract address all of the safety problems associated with its use. It is

gas samples from the dilution tunnel for determination of the responsibility of the user of this test method to establish

particulate matter concentrations. Each sample train has two appropriate safety and health practices and to determine the

glass fiber filters in series. The samples are withdrawn at a applicability of regulatory limitations prior to performing this

consistently proportional rate from sampling points located at test method.

the centroid of a sampling tunnel. During sampling, the filters

6. Equipment and Supplies

are maintained at a temperature less than 32 °C (90 °F). The

mass of the sampled particulate matter is determined gravi-

6.1 Sample Collection—The following equipment is re-

metrically after the removal of uncombined water. The total

quired for sample collection:

particulate matter mass collected on the filters and in the probe

6.1.1 Particulate Sampling Train—Two separate, complete

and front filter housing are multiplied by the ratio of the particulate sampling trains (also referred to as “sampling

dilution tunnel flow to sample flow to determine the total

trains”) are required for each test run. The filter face velocity

particulate emissions during a test.

shall not exceed 150 mm/sec (30 ft/min) during the test run.

The dry gas meter shall be calibrated for the same flow rate

4.2 The sampling system for this test method consists of

range as encountered during the test runs. The sampling train

duplicatedual-filterdrysamplingtrains.Bothoftheparticulate

configuration is shown in Fig. 1 and consists of the following

sampling trains are operated simultaneously at a sample flow

components.

rate not to exceed 0.007 m /min (0.25 cfm⁄min). The total

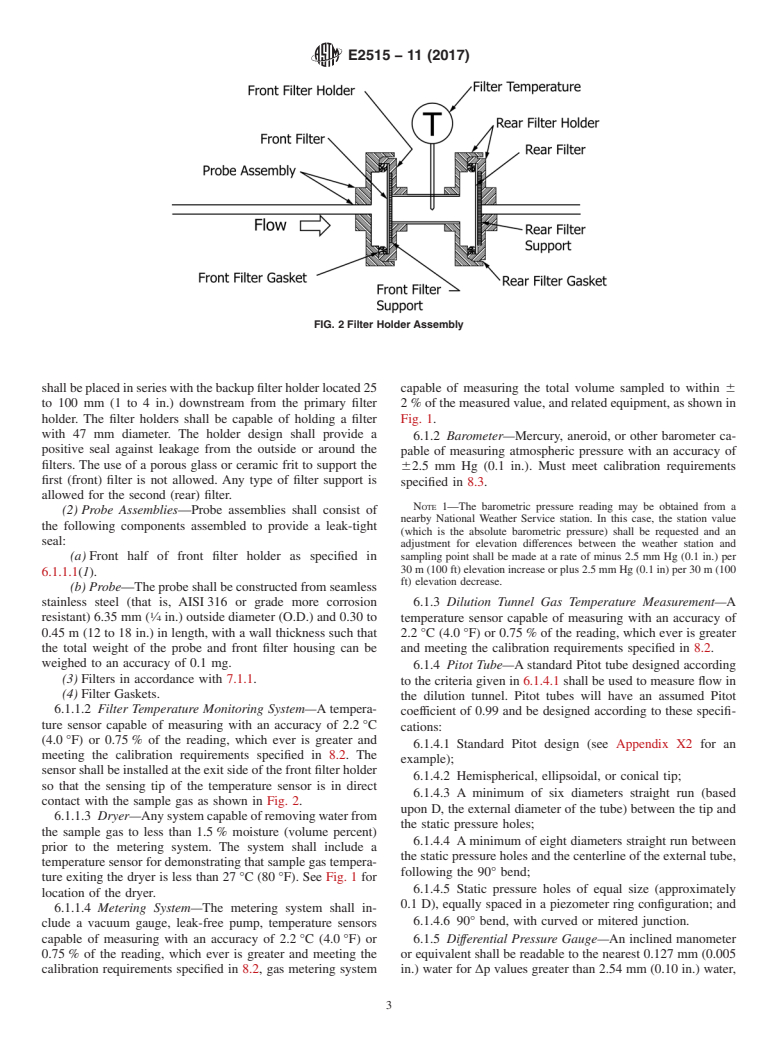

6.1.1.1 Filter Holder Assembly—The filter holder assembly

particulate results obtained from the two sampling trains are

is shown in Fig. 2 and consists of the following components:

averaged to determine the particulate emissions and are com-

(1) Filter Holders—The primary (front) filter holder shall

pared as a quality control check on the data validity.

be aluminum or PTFE. The backup (rear) filter holder may be

4.3 The particulate concentration results for each sampling 7

made of materials such as polycarbonate. With such plastic

train is adjusted by the particulate concentration result from a

materials, it is recommended not to use solvents when cleaning

single room air sample blank collected and processed the same

thefilterholderparts.Mildsoapanddistilledwatercanbeused

as the dilution tunnel particulate sampling trains described in

for cleaning plastic filter holder parts. The two filter holders

4.2, except that only one filter is used in the sampling train. A

metering system as described in 6.1.1.4 shall be used to

The Pall (Gelman) 1235 filter holder has been found suitable for this purpose.

determine the volume of room air collected. The sample flow

If you are aware of alternative suppliers, please provide this information to ASTM

rate shall not exceed 0.007 m /min (0.25 cfm).

International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend.

4.4 Appliances tested by this test method are to be fueled

The Pall (Gelman) 1119 filter holder has been found suitable for this purpose.

and operated as specified in appliance-specific test methods

If you are aware of alternative suppliers, please provide this information to ASTM

such as, but not limited to, Test Methods E2558, E2618,

International Headquarters. Your comments will receive careful consideration at a

E2779, E2780,or E2817. meeting of the responsible technical committee, which you may attend.

FIG. 1 Particulate Sampling Train

E2515 − 11 (2017)

FIG. 2 Filter Holder Assembly

shallbeplacedinserieswiththebackupfilterholderlocated25 capable of measuring the total volume sampled to within 6

to 100 mm (1 to 4 in.) downstream from the primary filter 2 % of the measured value, and related equipment, as shown in

holder. The filter holders shall be capable of holding a filter Fig. 1.

with 47 mm diameter. The holder design shall provide a

6.1.2 Barometer—Mercury, aneroid, or other barometer ca-

positive seal against leakage from the outside or around the

pable of measuring atmospheric pressure with an accuracy of

filters. The use of a porous glass or ceramic frit to support the

62.5 mm Hg (0.1 in.). Must meet calibration requirements

first (front) filter is not allowed. Any type of filter support is

specified in 8.3.

allowed for the second (rear) filter.

NOTE 1—The barometric pressure reading may be obtained from a

(2) Probe Assemblies—Probe assemblies shall consist of

nearby National Weather Service station. In this case, the station value

the following components assembled to provide a leak-tight

(which is the absolute barometric pressure) shall be requested and an

seal:

adjustment for elevation differences between the weather station and

(a) Front half of front filter holder as specified in sampling point shall be made at a rate of minus 2.5 mm Hg (0.1 in.) per

30 m (100 ft) elevation increase or plus 2.5 mm Hg (0.1 in) per 30 m (100

6.1.1.1(1).

ft) elevation decrease.

(b) Probe—The probe shall be constructed from seamless

stainless steel (that is, AISI 316 or grade more corrosion 6.1.3 Dilution Tunnel Gas Temperature Measurement—A

resistant) 6.35 mm ( ⁄4 in.) outside diameter (O.D.) and 0.30 to temperature sensor capable of measuring with an accuracy of

0.45 m (12 to 18 in.) in length, with a wall thickness such that 2.2 °C (4.0 °F) or 0.75 % of the reading, which ever is greater

the total weight of the probe and front filter housing can be and meeting the calibration requirements specified in 8.2.

weighed to an accuracy of 0.1 mg.

6.1.4 Pitot Tube—A standard Pitot tube designed according

(3) Filters in accordance with 7.1.1.

to the criteria given in 6.1.4.1 shall be used to measure flow in

(4) Filter Gaskets.

the dilution tunnel. Pitot tubes will have an assumed Pitot

6.1.1.2 Filter Temperature Monitoring System—A tempera-

coefficient of 0.99 and be designed according to these specifi-

ture sensor capable of measuring with an accuracy of 2.2 °C

cations:

(4.0 °F) or 0.75 % of the reading, which ever is greater and

6.1.4.1 Standard Pitot design (see Appendix X2 for an

meeting the calibration requirements specified in 8.2. The

example);

sensor shall be installed at the exit side of the front filter holder

6.1.4.2 Hemispherical, ellipsoidal, or conical tip;

so that the sensing tip of the temperature sensor is in direct

6.1.4.3 A minimum of six diameters straight run (based

contact with the sample gas as shown in Fig. 2.

upon D, the external diameter of the tube) between the tip and

6.1.1.3 Dryer—Anysystemcapableofremovingwaterfrom

the static pressure holes;

the sample gas to less than 1.5 % moisture (volume percent)

6.1.4.4 Aminimum of eight diameters straight run between

prior to the metering system. The system shall include a

the static pressure holes and the centerline of the external tube,

temperature sensor for demonstrating that sample gas tempera-

following the 90° bend;

ture exiting the dryer is less than 27 °C (80 °F). See Fig. 1 for

6.1.4.5 Static pressure holes of equal size (approximately

location of the dryer.

0.1 D), equally spaced in a piezometer ring configuration; and

6.1.1.4 Metering System—The metering system shall in-

6.1.4.6 90° bend, with curved or mitered junction.

clude a vacuum gauge, leak-free pump, temperature sensors

capable of measuring with an accuracy of 2.2 °C (4.0 °F) or 6.1.5 Differential Pressure Gauge—An inclined manometer

0.75 % of the reading, which ever is greater and meeting the or equivalent shall be readable to the nearest 0.127 mm (0.005

calibration requirements specified in 8.2, gas metering system in.) water for ∆p values greater than 2.54 mm (0.10 in.) water,

E2515 − 11 (2017)

and to the nearest 0.025 mm (0.001 in.) water for ∆p values each other in the dilution tunnel sampling section. These

less than 2.54 mm (0.10 in.) water. velocity traverse points shall be of sufficient size to allow entry

6.1.6 Dilution Tunnel—The dilution tunnel apparatus is ofthestandardPitottubebutshallnotexceed12.7mm(0.5in.)

shown in Fig. 3 and Fig. 4 and consists of the following diameter. Two particulate sample extraction ports shall be

components: located at least four tunnel diameters downstream of the

6.1.6.1 Hood—Constructed of steel. Hood shall be large velocity traverse ports and at least two tunnel diameters

enough to capture all of the flue-gas flow exiting the top of the upstream from the next downstream flow disturbance. These

appliance chimney. The dilution tunnel hood shall be conical sample extraction ports shall be of sufficient size to allow entry

with a minimum diameter at the entrance of at least four times ofthesamplingprobes.Thetotallengthofductfromthecenter

the tunnel diameter. The height of the conical section shall be of the outlet of the hood to the sampling ports shall not exceed

at least three tunnel diameters. A skirt can be used around the 9.1 m (30 ft). (See Fig. 3.)

inlet to the conical section to insure capture of the flue-gas

6.1.6.4 Blower—Squirrel cage or other type of fan capable

exhaust as shown in 9.2.4 as long as the requirements of 9.2.3

of gathering and moving all flue-gases and entrained dilution

are met.The outlet of the conical section shall be sized to mate

air from the dilution tunnel extraction hood to the dilution

with the mixing section of the dilution tunnel. (See Fig. 3 and

tunnel exhaust having sufficient flow to maintain dilution rate

Fig. 4.)

specifications in Section 9. (See 9.2.)

6.1.6.2 90° Elbows—Steel 90° elbows should be used for

6.1.7 Test Facility Temperature Monitor—A thermocouple

connecting mixing section, the sampling section, and the

capable of measuring with an accuracy of 2.2 °C (4.0 °F) or

op

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.