ASTM C1383-04(2010)

(Test Method)Standard Test Method for Measuring the P-Wave Speed and the Thickness of Concrete Plates Using the Impact-Echo Method

Standard Test Method for Measuring the P-Wave Speed and the Thickness of Concrete Plates Using the Impact-Echo Method

SIGNIFICANCE AND USE

This test method may be used as a substitute for, or in conjunction with, coring to determine the thickness of slabs, pavements, decks, walls, or other plate structures. There is a certain level of systematic error in the calculated thickness due to the discrete nature of the digital records that are used. The absolute systematic error depends on the plate thickness, the sampling interval, and the sampling period.

Because the wave speed can vary from point-to-point in the structure due to differences in concrete age or batch-to-batch variability, the wave speed is measured (Procedure A) at each point where a thickness determination (Procedure B) is required.

The maximum and minimum thickness that can be measured is limited by the details of the testing apparatus (transducer response characteristics and the specific impactor). The limits shall be specified by manufacturer of the apparatus, and the apparatus shall not be used beyond these limits. If test equipment is assembled by the user, thickness limitations shall be established and documented.

This test method is not applicable to plate structures with overlays, such as a concrete bridge deck with an asphalt or portland cement concrete overlay. The method is based on the assumption that the concrete plate has the same P-wave speed throughout its depth.

Procedure A is performed on concrete that is air dry as high surface moisture content may affect the results.

Procedure B is applicable to a concrete plate resting on a subgrade of soil, gravel, permeable asphalt concrete, or lean portland cement concrete provided there is sufficient difference in acoustic impedance between the concrete and subgrade or there are enough air voids at the interface to produce measurable reflections. If these conditions are not satisfied, the waveform will be of low amplitude and the amplitude spectrum will not include a dominant peak at the frequency corresponding to the thickness (Eq 2). If the interface between the concrete...

SCOPE

1.1 This test method covers procedures for determining the thickness of concrete slabs, pavements, bridge decks, walls, or other plate-like structure using the impact-echo method.

1.2 The following two procedures are covered in this test method:

1.2.1 Procedure A: P-Wave Speed Measurement—This procedure measures the time it takes for the P-wave generated by a short-duration, point impact to travel between two transducers positioned a known distance apart along the surface of a structure. The P-wave speed is calculated by dividing the distance between the two transducers by the travel time.

1.2.2 Procedure B: Impact-Echo Test—This procedure measures the frequency at which the P-wave generated by a short-duration, point impact is reflected between the parallel (opposite) surfaces of a plate. The thickness is calculated from this measured frequency and the P-wave speed obtained from Procedure A.

1.2.3 Unless specified otherwise, both Procedure A and Procedure B must be performed at each point where a thickness determination is made.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1383 − 04(Reapproved 2010)

Standard Test Method for

Measuring the P-Wave Speed and the Thickness of

Concrete Plates Using the Impact-Echo Method

This standard is issued under the fixed designation C1383; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers procedures for determining the

C597 Test Method for Pulse Velocity Through Concrete

thickness of concrete slabs, pavements, bridge decks, walls, or

E1316 Terminology for Nondestructive Examinations

other plate-like structure using the impact-echo method.

1.2 The following two procedures are covered in this test

3. Terminology

method:

3.1 Definitions:

1.2.1 Procedure A: P-Wave Speed Measurement—This pro-

3.1.1 acoustic impedance, n—the product of P-wave speed

cedure measures the time it takes for the P-wave generated by

and density that is used in computations of characteristics of

a short-duration, point impact to travel between two transduc-

stress wave reflection at boundaries.

ers positioned a known distance apart along the surface of a

3.1.2 amplitude spectrum, n—a plot of relative amplitude

structure. The P-wave speed is calculated by dividing the

versus frequency that is obtained from the waveform using a

distance between the two transducers by the travel time.

Fourier transform technique.

1.2.2 Procedure B: Impact-Echo Test—This procedure mea-

3.1.3 Fourier transform, n—a numerical technique used to

sures the frequency at which the P-wave generated by a

convert digital waveforms from the time domain to the

short-duration, point impact is reflected between the parallel

frequency domain.

(opposite) surfaces of a plate. The thickness is calculated from

3.1.3.1 Discussion—The peaks in the amplitude spectrum

this measured frequency and the P-wave speed obtained from

correspond to the dominant frequencies in the waveform.

Procedure A.

1.2.3 Unless specified otherwise, both Procedure A and

3.1.4 impact-echo method, n—a send-receive nondestruc-

ProcedureBmustbeperformedateachpointwhereathickness

tive test method based on the use of a short-duration mechani-

determination is made.

cal impact to generate transient stress waves and the use of a

broadband receiving transducer placed adjacent to the impact

1.3 The values stated in SI units are to be regarded as

point.

standard. No other units of measurement are included in this

3.1.4.1 Discussion—Waveforms are converted to the fre-

standard.

quency domain and the resulting amplitude spectra are ana-

1.4 The text of this standard references notes and footnotes

lyzed to obtain the dominant frequencies in the structure’s

that provide explanatory material. These notes and footnotes

response to the impact. These frequencies are used to deter-

(excluding those in tables and figures) shall not be considered

mine the thickness of the structure or the presence of flaws.

as requirements of the standard.

3.1.5 impact duration, n—the time that the impactor used to

1.5 This standard does not purport to address all of the

generate stress waves is in contact with the test surface. Also

safety concerns, if any, associated with its use. It is the referred to as contact time.

responsibility of the user of this standard to establish appro- 3.1.5.1 Discussion—The impact duration is a critical aspect

priate safety and health practices and determine the applica- in the success of the two procedures covered by this method.

bility of regulatory limitations prior to use. Recommended impact durations are given. In practice, the

impact duration will depend on the type of impactor and the

condition of the concrete at the point of impact. Smooth, hard

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.64 on Nondestructive and In-Place Testing. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 15, 2010. Published March 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2004 as C1383–04. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1383-04R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1383 − 04 (2010)

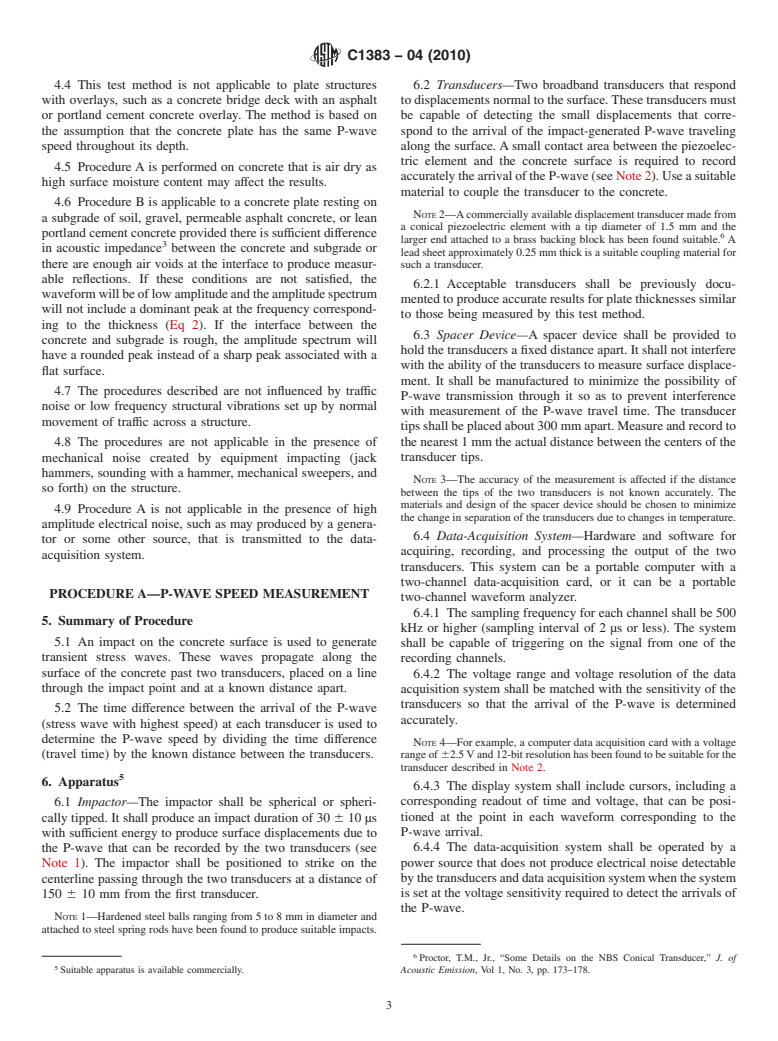

surfaces will result in shorter impact durations than rough, soft 3.1.13 Refer to Terminology E1316 for additional

surfaces. The user should verify that the impact durations are definitions, related to nondestructive ultrasonic examination,

within the recommended ranges. An approximate measure of that are applicable to this test method.

the impact duration can be obtained from the portion of the 3.2 Definitions of Terms Specific to This Standard:

3 3,4

waveform corresponding to the surface wave arrival. Fig. 1 3.2.1 apparent P-wave speed in a plate ,n—a parameter

that is 0.96 of the P-wave speed:

C 5 0.96 C (1)

p, plate p

where:

C = the apparent P-wave speed in a plate, m/s, and

p, plate

C = the P-wave speed in concrete that is obtained from

p

Procedure A, m/s.

3.2.1.1 Discussion—This parameter is used in thickness

calculations in impact-echo measurements on plates. The

P-wave speed in a material (concrete) is converted to the

apparent P-wave speed in a plate that is used to calculate the

plate thickness by the following equation:

C

p, plate

T 5 (2)

2f

where:

T = the thickness of the plate, m, and

f = the frequency of the P-wave thickness mode of the plate

obtained from the amplitude spectrum, Hz.

FIG. 1 Expanded View of Surface-Wave Portion of Waveform

Showing the Width of the Surface Wave Signal as an Approxima-

3.2.2 plate, n—any prismatic structure where the lateral

tion of the Contact Time of the Impact

dimensions are at least six times the thickness.

3.2.2.1 Discussion—Minimum lateral dimensions are nec-

shows an example of the surface-wave portion of a waveform

essary to prevent plate modes of vibration from interfering

and the approximate contact time is indicated.

with the identification of the thickness mode frequency in the

amplitude spectrum. The minimum lateral dimensions and

3.1.6 P-wave, n—the dilatational (longitudinal or primary)

acceptable sampling period are related, as explained in Note

stress wave that causes particle displacement parallel to the

11.

direction of wave propagation. This wave produces normal

stresses (tensile or compressive) as it propagates.

4. Significance and Use

3.1.7 P-wave speed, n—the speed with which the P-wave

4.1 This test method may be used as a substitute for, or in

propagates through a semi-infinite solid.

conjunction with, coring to determine the thickness of slabs,

3.1.7.1 Discussion—The P-wave speed is the same as the

pavements, decks, walls, or other plate structures. There is a

compressional pulse velocity measured according to Test

certain level of systematic error in the calculated thickness due

Method C597.

to the discrete nature of the digital records that are used. The

3.1.8 sampling frequency, n—the rate at which the points

absolute systematic error depends on the plate thickness, the

that comprise the waveform are recorded; the inverse of the

sampling interval, and the sampling period.

sampling interval, expressed in Hz or samples/s (also referred

4.2 Because the wave speed can vary from point-to-point in

to as sampling rate).

the structure due to differences in concrete age or batch-to-

3.1.9 sampling period, n—the duration of the waveform,

batch variability, the wave speed is measured (ProcedureA) at

which equals the number of points in the waveform multiplied

each point where a thickness determination (Procedure B) is

by the sampling interval.

required.

3.1.10 sampling interval, n—the time difference between

4.3 The maximum and minimum thickness that can be

any two adjacent points in the waveform.

measured is limited by the details of the testing apparatus

3.1.11 surface wave, n—a stress wave in which the particle

(transducer response characteristics and the specific impactor).

motion is elliptical and the amplitude of particle motion

The limits shall be specified by manufacturer of the apparatus,

decreasesrapidlywithdepth.Alsoknownas Rayleigh wave(or

and the apparatus shall not be used beyond these limits. If test

R-wave).

equipment is assembled by the user, thickness limitations shall

be established and documented.

3.1.12 waveform, n—a recorded signal from a transducer

that is a plot of voltage versus time.

Sansalone, M., Lin, J. M., and Streett, W. B., “A Procedure for Determining

P-wave Speed in Concrete for Use in Impact-Echo Testing Using P-wave Speed

Sansalone, M. and Streett, W.B., Impact-Echo: Nondestructive Evaluation of MeasurementTechnique,” ACI Journal,Vol. 94, No. 6, November–December 1997,

Concrete and Masonry, Bullbrier Press, Ithaca, NY and Jersey Shore, PA, 1997. pp. 531–539.

C1383 − 04 (2010)

4.4 This test method is not applicable to plate structures 6.2 Transducers—Two broadband transducers that respond

with overlays, such as a concrete bridge deck with an asphalt to displacements normal to the surface.These transducers must

or portland cement concrete overlay. The method is based on be capable of detecting the small displacements that corre-

the assumption that the concrete plate has the same P-wave spond to the arrival of the impact-generated P-wave traveling

speed throughout its depth. along the surface.Asmall contact area between the piezoelec-

tric element and the concrete surface is required to record

4.5 Procedure A is performed on concrete that is air dry as

accuratelythearrivaloftheP-wave(seeNote2).Useasuitable

high surface moisture content may affect the results.

material to couple the transducer to the concrete.

4.6 Procedure B is applicable to a concrete plate resting on

NOTE2—Acommerciallyavailabledisplacementtransducermadefrom

a subgrade of soil, gravel, permeable asphalt concrete, or lean

a conical piezoelectric element with a tip diameter of 1.5 mm and the

portland cement concrete provided there is sufficient difference

larger end attached to a brass backing block has been found suitable. A

in acoustic impedance between the concrete and subgrade or

lead sheet approximately 0.25 mm thick is a suitable coupling material for

there are enough air voids at the interface to produce measur- such a transducer.

able reflections. If these conditions are not satisfied, the

6.2.1 Acceptable transducers shall be previously docu-

waveformwillbeoflowamplitudeandtheamplitudespectrum

mentedtoproduceaccurateresultsforplatethicknessessimilar

will not include a dominant peak at the frequency correspond-

to those being measured by this test method.

ing to the thickness (Eq 2). If the interface between the

6.3 Spacer Device—A spacer device shall be provided to

concrete and subgrade is rough, the amplitude spectrum will

hold the transducers a fixed distance apart. It shall not interfere

have a rounded peak instead of a sharp peak associated with a

with the ability of the transducers to measure surface displace-

flat surface.

ment. It shall be manufactured to minimize the possibility of

4.7 The procedures described are not influenced by traffic

P-wave transmission through it so as to prevent interference

noise or low frequency structural vibrations set up by normal

with measurement of the P-wave travel time. The transducer

movement of traffic across a structure.

tipsshallbeplacedabout300mmapart.Measureandrecordto

the nearest 1 mm the actual distance between the centers of the

4.8 The procedures are not applicable in the presence of

mechanical noise created by equipment impacting (jack transducer tips.

hammers, sounding with a hammer, mechanical sweepers, and

NOTE 3—The accuracy of the measurement is affected if the distance

so forth) on the structure.

between the tips of the two transducers is not known accurately. The

materials and design of the spacer device should be chosen to minimize

4.9 Procedure A is not applicable in the presence of high

the change in separation of the transducers due to changes in temperature.

amplitude electrical noise, such as may produced by a genera-

6.4 Data-Acquisition System—Hardware and software for

tor or some other source, that is transmitted to the data-

acquiring, recording, and processing the output of the two

acquisition system.

transducers. This system can be a portable computer with a

two-channel data-acquisition card, or it can be a portable

PROCEDURE A—P-WAVE SPEED MEASUREMENT

two-channel waveform analyzer.

6.4.1 The sampling frequency for each channel shall be 500

5. Summary of Procedure

kHz or higher (sampling interval of 2 µs or less). The system

5.1 An impact on the concrete surface is used to generate shall be capable of triggering on the signal from one of the

transient stress waves. These waves propagate along the

recording channels.

surface of the concrete past two transducers, placed on a line

6.4.2 The voltage range and voltage resolution of the data

through the impact point and at a known distance apart.

acquisition system shall be matched with the sensitivity of the

transducers so that the arrival of the P-wave is determined

5.2 The time difference between the arrival of the P-wave

accurately.

(stress wave with highest speed) at each transducer is used to

determine the P-wave speed by dividing the time difference

NOTE 4—For example, a computer data acquisition card with a voltage

(travel time) by the known distance between the transducers. rangeof 62.5Vand12-bitresolutionhasbeenfoundtobesuitableforthe

transducer described in Note 2.

6. Apparatus

6.4.3 The display system shall include cursors, including a

corresponding readout of time and voltage, that can be posi-

6.1 Impactor—The impactor shall be spherical or spheri-

cally tipped. It shall produce an impact duration of 30 6 10 µs tioned at the point in each waveform corresponding to the

P-wave arrival.

with sufficient energy to produce surface displacements due to

the P-wave that can be recorded by the two transducers (see 6.4.4 The data-acquisition system shall be operated by a

power source that does not produce electrical noise detectable

Note 1). The impactor shall be positioned to strike on the

centerline passing through the two transducers at a distance of bythetransducersanddataacquisitionsystemwhenthesystem

is set at the voltage sensitivity required to detect the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.