ASTM D6304-00

(Test Method)Standard Test Method for Determination of Water in Petroleum Products, Lubricating Oils, and Additives by Coulometric Karl Fisher Titration

Standard Test Method for Determination of Water in Petroleum Products, Lubricating Oils, and Additives by Coulometric Karl Fisher Titration

SCOPE

1.1 This test method covers the direct determination of water in the range of 10 to 25 000 mg/kg entrained water in petroleum products and hydrocarbons using automated instrumentation. This test method also covers the indirect analysis of water thermally removed from samples and swept with dry inert gas into the Karl Fisher titration cell. Mercaptan, sulfide (S- or H2S), sulfur, and other compounds are known to interfere with this test method (see Section 5).

1.2 This test method is intended for use with commercially available coulometric Karl Fischer reagents and for the determination of water in additives, lube oils, base oils, automatic transmission fluids, hydrocarbon solvents, and other petroleum products. By proper choice of the sample size, this test method may be used for the determination of water from mg/kg to percent level concentrations.

1.3 Values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6304 – 00 An American National Standard

Standard Test Method for

Determination of Water in Petroleum Products, Lubricating

Oils, and Additives by Coulometric Karl Fischer Titration

This standard is issued under the fixed designation D 6304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5854 Practice for Mixing and Handling of Liquid

Samples of Petroleum and Petroleum Products

1.1 This test method covers the direct determination of

E 203 Test Method for Water Using Volumetric Karl Fischer

water in the range of 10 to 25 000 mg/kg entrained water in

Titration

petroleum products and hydrocarbons using automated instru-

mentation. This test method also covers the indirect analysis of

3. Summary of Test Method

water thermally removed from samples and swept with dry

3.1 An aliquot is injected into the titration vessel of a

inert gas into the Karl Fischer titration cell. Mercaptan, sulfide

−

coulometric Karl Fischer apparatus in which iodine for the Karl

(S or H S), sulfur, and other compounds are known to

Fisher reaction is generated coulometrically at the anode.

interfere with this test method (see Section 5).

When all of the water has been titrated, excess iodine is

1.2 This test method is intended for use with commercially

detected by an electrometric end point detector and the titration

available coulometric Karl Fischer reagents and for the deter-

is terminated. Based on the stoichiometry of the reaction, 1 mol

mination of water in additives, lube oils, base oils, automatic

of iodine reacts with 1 mol of water; thus, the quantity of water

transmission fluids, hydrocarbon solvents, and other petroleum

is proportional to the total integrated current according to

products. By proper choice of the sample size, this test method

Faraday’s Law.

may be used for the determination of water from mg/kg to

3.2 The sample injection can be done either by mass or

percent level concentrations.

volume.

1.3 Values stated in SI units are to be regarded as the

3.3 The viscous samples can be analyzed by using a water

standard.

vaporizer accessory that heats the sample in the evaporation

1.4 This standard does not purport to address all of the

chamber, and the vaporized water is carried into the Karl

safety concerns, if any, associated with its use. It is the

Fischer titration cell by a dry inert carrier gas.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 A knowledge of the water content of lubricating oils,

2. Referenced Documents additives, and similar products is important in the manufactur-

ing, purchase, sale, or transfer of such petroleum products to

2.1 ASTM Standards:

help in predicting their quality and performance characteristics.

D 1193 Specification for Reagent Water

4.2 For lubricating oils, the presence of moisture could lead

D 1298 Practice for Density, Relative Density (Specific

to premature corrosion and wear, an increase in the debris load

Gravity), or API Gravity of Crude Petroleum and Liquid

3 resulting in diminished lubrication and premature plugging of

Petroleum Products by Hydrometer Method

filters, an impedance in the effect of additives, and undesirable

D 4052 Test Method for Density and Relative Density of

4 support of deleterious bacterial growth.

Liquids by Digital Density Meter

D 4057 Practice for Manual Sampling of Petroleum and

5. Interferences

Petroleum Products

5.1 A number of substances and classes of compounds

D 4177 Practice for Automatic Sampling of Petroleum and

associated with condensation or oxidation-reduction reactions

Petroleum Products

interferes in the determination of water by Karl Fischer

titration. In petroleum products, the most common interfer-

ences are mercaptans and sulfides. At levels of less than 500

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee mg/kg as sulfur, the interference from these compounds is

D2.02 on Static Petroleum Measurement.

insignificant for water concentrations greater than 0.02 mass

Current edition approved Sept. 10, 2000. Published November 2000. Originally

published as D 6304 - 98. L:ast previous edition D 6304 - 98a.

Annual Book of ASTM Standards, Vol 11.01.

3 5

Annual Book of ASTM Standards, Vol 5.01. Annual Book of ASTM Standards, Vol 5.03.

4 6

Annual Book of ASTM Standards, Vol 5.02. Annual Book of ASTM Standards, Vol 15.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6304

%. For more information on substances that interfere in the defined by Type II of Specification D 1193.

determination of water by the Karl Fischer titration method, 7.3 Xylene, Reagent Grade, less than 100 to 200 mg/kg

see Test Method E 203. Some interferences, such as ketones, water, dried over a molecular sieve (Warning—Flammable.

may be overcome if the appropriate reagents are used. Vapor harmful).

5.2 The significance of the mercaptan and sulfide interfer- 7.4 Karl Fischer Reagent, standard commercially available

ence on the Karl Fischer titration for water in the 10 to 200 reagents for coulometric Karl Fischer titrations.

mg/kg range has not been determined experimentally. At these 7.4.1 Anode Solution— Mix six parts of commercial Karl

low water concentrations, however, the interference may be Fischer anode solution with four parts of reagent grade xylene

expected to be significant for mercaptan and sulfide concen- on a volume basis. Newly made Karl Fischer anode solution

trations of greater than 500 mg/kg as sulfur. shall be used. Other proportions of anode solution and xylene

5.3 Helpful hints in obtaining reliable results are given in may be used and determined for a particular reagent, apparatus,

Appendix X1. and sample tested. Some samples may not require and xylene,

whereas others will require the solvent effect of the xylene (

6. Apparatus

Warning—Flammable, toxic if inhaled, swallowed, or ab-

6.1 Coulometric Karl Fischer Apparatus (using electromet-

sorbed through skin).

ric end point)—A number of automatic coulometric Karl

NOTE 1—Toluene may be used in place of xylene. However, the

Fischer titration assemblies consisting of titration cell, plati-

precision data in Section 17 were obtained using xylene.

num electrodes, magnetic stirrer, and a control unit are avail-

7.4.2 Cathode Solution— Use standard commercially avail-

able on the market. Instructions for operation of these devices

able cathode Karl Fischer solution. Newly made solution shall

are provided by the manufacturers and are not described

be used (Warning—Flammable, may be fatal if inhaled,

herein.

swallowed, or absorbed through skin. Possible cancer hazard).

6.1.1 Water Vaporizer Accessory—A number of automatic

7.4.3 If the sample to be analyzed contains ketone, use

water vaporizer accessories are available on the market.

commercially available reagents that have been specially

Instructions for the operation of these devices are provided by

modified for use with ketones.

the manufacturers and are not described herein.

6.2 Syringes—Samples are most easily added to the titration

NOTE 2—Some laboratories add the ketone suppressing reagent as part

vessel by means of accurate glass or disposable plastic syringes

of their standard analytical procedure since often the laboratory does not

with luer fittings and hypodermic needles of suitable length to know whether the sample contains ketone.

dip below the surface of the anode solution in the cell when

7.5 Hexane, Reagent Grade, less than 100 to 200 mg/kg

inserted through the inlet port septum. The bores of the needles

water ( Warning—Flammable. Vapor harmful). Dried over

used shall be kept as small as possible, but large enough to

molecular sieve.

avoid problems arising from back pressure or blocking while

7.6 White Mineral Oil—Also called paraffin oil or mineral

sampling. Suggested syringe sizes are as follows:

oil. Reagent grade.

6.2.1 Ten microlitres, with a needle long enough to dip

7.7 Molecular Sieve 5Å—8 to 12 mesh.

below the surface of the anode solution in the cell when

inserted through the inlet port septum and graduated for

8. Sampling

readings to the nearest 0.01 μL or better. This syringe is used

8.1 Sampling is defined as all the steps required to obtain an

in the standardization step (see Section 10).

aliquot representative of the contents of any pipe, tank, or other

6.2.2 Two hundred fifty microlitres, 500 μL, and 1 mL

system and to place the sample into a container for analysis by

capacities and accurate to the nearest 1 μL, 1 μL, and 0.01 mL,

a laboratory or test facility.

respectively. A quality gas-tight glass syringe with a TFE-

8.2 Laboratory Sample—The sample of petroleum product

fluorocarbon plunger and luer fitting is recommended.

presented to the laboratory or test facility for analysis by this

test method. Only representative samples obtained as specified

7. Reagents and Materials

in Practices D 4057 and D 4177 and handled and mixed in

7.1 Purity of Reagents—Reagent grade chemicals shall be

accordance with Practice D 5854 shall be used to obtain the

used in all tests. Unless otherwise indicated, all reagents shall

laboratory sample.

conform to the specifications of the Committee on Analytical

Reagents of the American Chemical Society , where such

NOTE 3—Examples of laboratory samples include bottles from a

specifications are available. Use other grades, provided the manual sampling, receptacles from automatic samplers, and storage

containers holding a product from a previous analysis.

reagent is of sufficiently high purity to permit its use without

lessening the accuracy of the determination.

8.3 Test Specimen— The aliquot obtained from the labora-

7.2 Purity of Water— Unless otherwise indicated, refer-

tory sample for analysis by this test method. Once drawn, use

ences to water shall be understood to mean reagent water as

the entire portion of the test specimen in the analysis.

8.4 Select the test specimen size as indicated in Table 1

based in the expected water concentration.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

9. Preparation of Apparatus

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

9.1 Follow the manufacturer’s directions for preparation

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. and operation of the titration apparatus.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6304

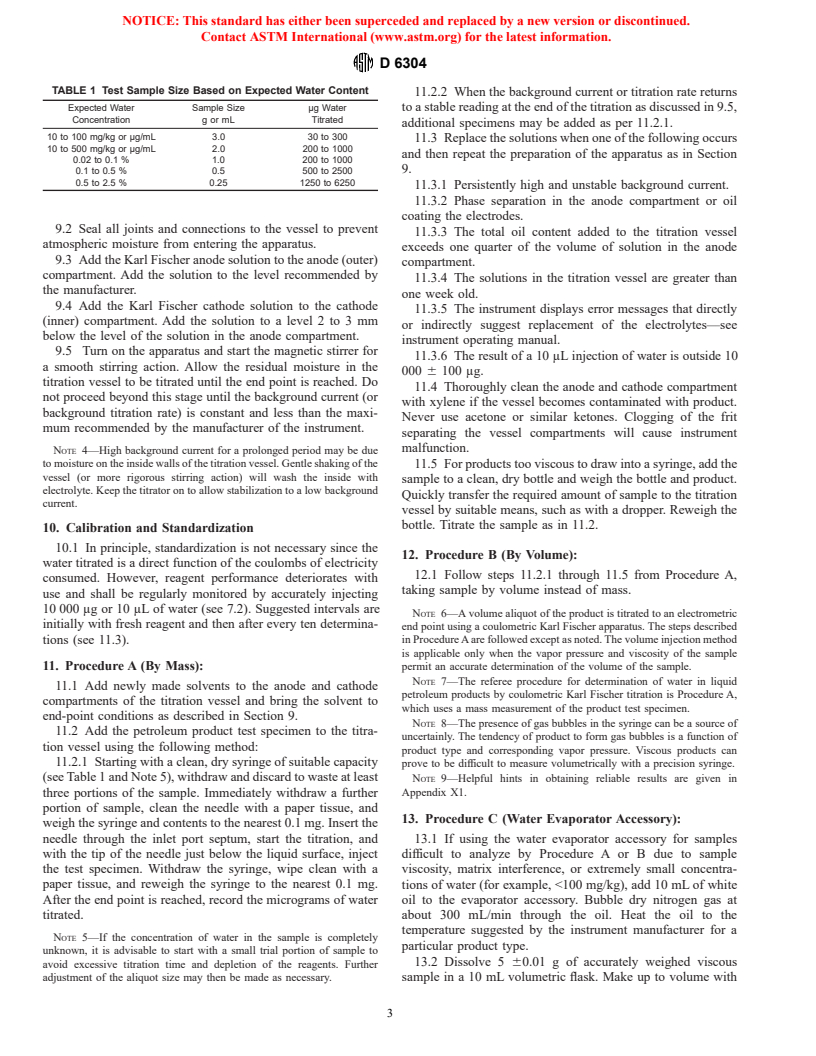

TABLE 1 Test Sample Size Based on Expected Water Content

11.2.2 When the background current or titration rate returns

Expected Water Sample Size μg Water to a stable reading at the end of the titration as discussed in 9.5,

Concentration g or mL Titrated

additional specimens may be added as per 11.2.1.

10 to 100 mg/kg or μg/mL 3.0 30 to 300

11.3 Replace the solutions when one of the following occurs

10 to 500 mg/kg or μg/mL 2.0 200 to 1000

and then repeat the preparation of the apparatus as in Section

0.02 to 0.1 % 1.0 200 to 1000

9.

0.1 to 0.5 % 0.5 500 to 2500

0.5 to 2.5 % 0.25 1250 to 6250

11.3.1 Persistently high and unstable background current.

11.3.2 Phase separation in the anode compartment or oil

coating the electrodes.

9.2 Seal all joints and connections to the vessel to prevent

11.3.3 The total oil content added to the titration vessel

atmospheric moisture from entering the apparatus.

exceeds one quarter of the volume of solution in the anode

9.3 Add the Karl Fischer anode solution to the anode (outer)

compartment.

compartment. Add the solution to the level recommended by

11.3.4 The solutions in the titration vessel are greater than

the manufacturer.

one week old.

9.4 Add the Karl Fischer cathode solution to the cathode

11.3.5 The instrument displays error messages that directly

(inner) compartment. Add the solution to a level 2 to 3 mm

or indirectly suggest replacement of the electrolytes—see

below the level of the solution in the anode compartment.

instrument operating manual.

9.5 Turn on the apparatus and start the magnetic stirrer for

11.3.6 The result of a 10 μL injection of water is outside 10

a smooth stirring action. Allow the residual moisture in the

000 6 100 μg.

titration vessel to be titrated until the end point is reached. Do

11.4 Thoroughly clean the anode and cathode compartment

not proceed beyond this stage until the background current (or

with xylene if the vessel becomes contaminated with product.

background titration rate) is constant and less than the maxi-

Never use acetone or similar ketones. Clogging of the frit

mum recommended by the manufacturer of the instrument.

separating the vessel compartments will cause instrument

malfunction.

NOTE 4—High background current for a prolonged period may be due

to moisture on the inside walls of the titration vessel. Gentle shaking of the 11.5 For products too viscous to draw into a syringe, add the

vessel (or more rigorous stirring action) will wash the inside with

sample to a clean, dry bottle and weigh the bottle and product.

electrolyte. Keep the titrator on to allow stabilization to a low background

Quickly transfer the required amount of sample to the titration

current.

vessel by suitable means, such as with a dropper. Reweigh the

bottle. Titrate the sample as in 11.2.

10. Calibration and Standardization

10.1 In principle, standardization is not necessary since the

12. Procedure B (By Volume):

water titrated is a direct function of the coulombs of electricity

12.1 Follow steps 11.2.1 through 11.5 from Procedure A,

consumed. However, reagent performance deteriorates with

taking sample by volume instead of mass.

use and shall be regularly monitored by accurately injecting

10 000 μg or 10 μL of water (see 7.2). Suggested intervals are

NOTE 6—A volume aliquot of the product is titrated to an electrometric

initially with fresh reagent and then after every ten determina-

end point using a coulometric K

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.