ASTM C1399/C1399M-10(2015)

(Test Method)Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete (Withdrawn 2024)

Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete (Withdrawn 2024)

SIGNIFICANCE AND USE

5.1 This test method provides a quantitative measure useful in the evaluation of the performance of fiber–reinforced concrete. It allows for comparative analysis among beams containing different fiber types, including materials, dimension and shape, and different fiber contents. Results can be used to optimize the proportions of fiber–reinforced concrete mixtures, to determine compliance with construction specifications, to evaluate fiber–reinforced concrete which has been in service, and as a tool for research and development of fiber–reinforced concrete (See Note 2).

Note 2: Banthia and Dubey3 compared results using this test method with residual strengths at the same net deflections using a test protocol that is similar to that described in Test Method C1609/C1609M on 45 beams with a single fiber configuration at proportions of 0.1, 0.3, and 0.5 % by volume. The results by this test method were on average 6.4 % lower than by the procedure of Test Method C1609/C1609M.

5.2 Test results are intended to reflect either consistency or differences among variables used in proportioning the fiber–reinforced concrete to be tested, including fiber type (material), fiber size and shape, fiber amount, beam preparation (sawed or molded), and beam conditioning.

5.3 In molded beams fiber orientation near molded surfaces will be affected by the process of molding. For tests of fiber-reinforced concrete containing relatively rigid or stiff fibers of length greater than 35 mm [1.4 in.], the use of sawed beams cut from samples with an initial width and depth of at least 3 times the length of the fiber is required to minimize effects of fiber orientation. When sawed beams are employed, and to avoid the effects of fiber orientation, care shall be applied to ensure that the flexural tensile surface of the beam is a sawed surface.

SCOPE

1.1 This test method covers the determination of residual strength of a fiber–reinforced concrete test beam. The average residual strength is computed using specified beam deflections that are obtained from a beam that has been cracked in a standard manner. The test provides data needed to obtain that portion of the load–deflection curve beyond which a significant amount of cracking damage has occurred and it provides a measure of post–cracking strength, as such strength is affected by the use of fiber–reinforcement.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of residual strength of a fiber–reinforced concrete test beam. The average residual strength is computed using specified beam deflections that are obtained from a beam that has been cracked in a standard manner. The test provides data needed to obtain that portion of the load–deflection curve beyond which a significant amount of cracking damage has occurred and it provides a measure of post–cracking strength, as such strength is affected by the use of fiber–reinforcement.

Formerly under the jurisdiction of Committee C09 on Temperature Measurement, this test method was withdrawn in January 2024 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1399/C1399M −10 (Reapproved 2015)

Standard Test Method for

Obtaining Average Residual-Strength of Fiber-Reinforced

Concrete

This standard is issued under the fixed designation C1399/C1399M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Specimens in the Laboratory

C823 Practice for Examination and Sampling of Hardened

1.1 This test method covers the determination of residual

Concrete in Constructions

strength of a fiber–reinforced concrete test beam. The average

C1609/C1609M Test Method for Flexural Performance of

residual strength is computed using specified beam deflections

Fiber-ReinforcedConcrete(UsingBeamWithThird-Point

that are obtained from a beam that has been cracked in a

Loading)

standard manner. The test provides data needed to obtain that

portionoftheload–deflectioncurvebeyondwhichasignificant

3. Terminology

amount of cracking damage has occurred and it provides a

3.1 Definitions of Terms Specific to This Standard:

measure of post–cracking strength, as such strength is affected

by the use of fiber–reinforcement. 3.1.1 deflection—mid–span deflection of the test beam ob-

tained in a manner that excludes deflection caused by the

1.2 The values stated in either SI units or inch-pound units

following: (1) the flexural test apparatus, (2) crushing and

are to be regarded separately as standard. The values stated in

seating of the beam at support contact points, and (3) torsion of

each system may not be exact equivalents; therefore, each

the beam; sometimes termed net deflection.

system shall be used independently of the other. Combining

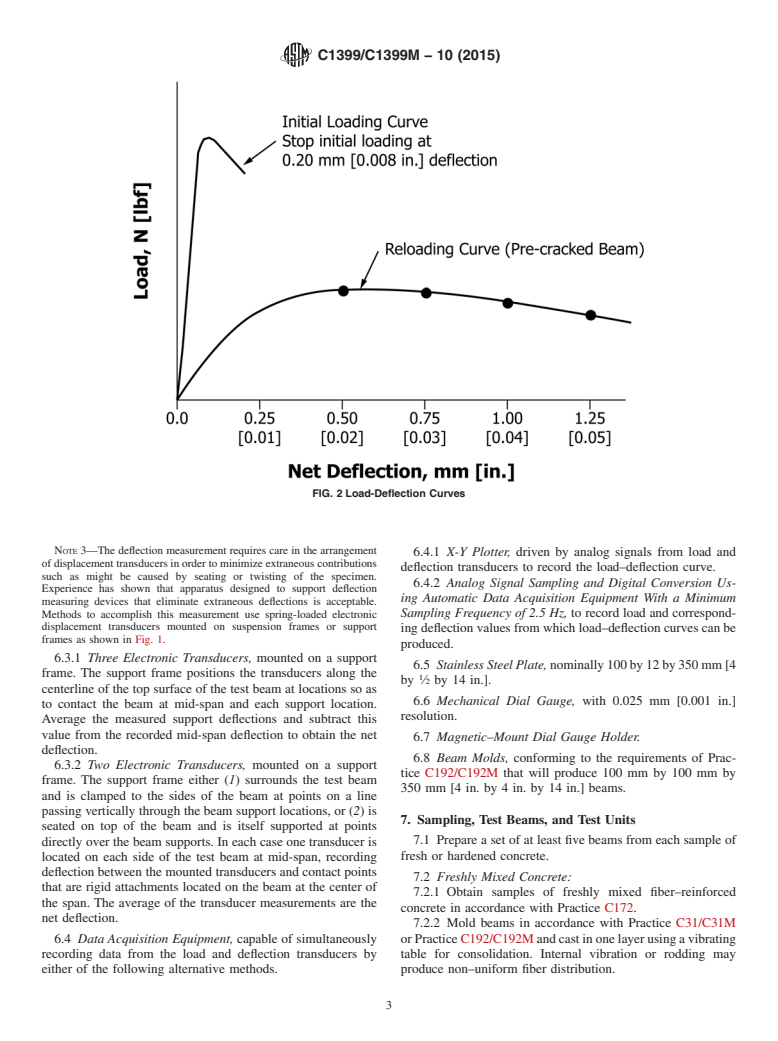

3.1.2 initial loading curve—the load–deflection curve ob-

values from the two systems may result in non-conformance

tained by testing an assembly that includes both the test beam

with the standard.

and a specified steel plate (Fig. 1); plotted to a deflection of at

1.3 This standard does not purport to address all of the

least 0.20 mm [0.008 in.] (Fig. 2).

safety concerns, if any, associated with its use. It is the

3.1.3 reloading curve—the load–deflection curve obtained

responsibility of the user of this standard to establish appro-

by reloading and retesting the pre-cracked beam, that is, after

priate safety and health practices and determine the applica-

the initial loading but without the steel plate. (Fig. 2)

bility of regulatory limitations prior to use.

3.1.4 reloading deflection—deflection measured during the

2. Referenced Documents

reloading of the cracked beam and with zero deflection

referenced to the start of the reloading.

2.1 ASTM Standards:

C31/C31M Practice for Making and Curing Concrete Test

3.1.5 residual strength—the flexural stress on the cracked

Specimens in the Field

beam section obtained by calculation using loads obtained

C42/C42M Test Method for Obtaining and Testing Drilled

from the reloading curve at specified deflection values (See

Cores and Sawed Beams of Concrete

Note 1).

C78 Test Method for Flexural Strength of Concrete (Using

NOTE 1—Residual strength is not a true stress but an engineering stress

Simple Beam with Third-Point Loading)

computed using the flexure formula for linear elastic materials and gross

C172 Practice for Sampling Freshly Mixed Concrete

(uncracked) section properties.

C192/C192M Practice for Making and Curing Concrete Test

3.1.6 average residual strength—the average stress–carry-

ing ability of the cracked beam that is obtained by calculation

using the residual strength at four specified deflections.

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

C09.42 on Fiber-Reinforced Concrete.

4. Summary of Test Method

Current edition approved July 1, 2015. Published September 2015. Originally

4.1 Cast or sawed beams of fiber–reinforced concrete are

approved in 1998. Last previous edition approved in 2010 as C1399–10. DOI:

10.1520/C1399_C1399M-10R15.

cracked using the third–point loading apparatus specified in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Test Method C78 modified by a steel plate used to assist in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

support of the concrete beam during an initial loading cycle

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (Fig. 1). The steel plate is used to help control the rate of

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1399/C1399M−10 (2015)

FIG. 1Schematic of a Suitable Apparatus Where the Deflection Gauge Support Frame is Seated on the Beam

deflection when the beam cracks. After the beam has been (material),fibersizeandshape,fiberamount,beampreparation

cracked in the specified manner, the steel plate is removed and (sawed or molded), and beam conditioning.

the cracked beam is reloaded to obtain data to plot a reloading

5.3 In molded beams fiber orientation near molded surfaces

load–deflection curve. Load values at specified deflection

will be affected by the process of molding. For tests of

values on the reloading curve are averaged and used to

fiber-reinforced concrete containing relatively rigid or stiff

calculate the average residual strength of the beam.

fibers of length greater than 35 mm [1.4 in.], the use of sawed

beams cut from samples with an initial width and depth of at

5. Significance and Use

least 3 times the length of the fiber is required to minimize

5.1 This test method provides a quantitative measure useful

effects of fiber orientation. When sawed beams are employed,

in the evaluation of the performance of fiber–reinforced

and to avoid the effects of fiber orientation, care shall be

concrete. It allows for comparative analysis among beams

applied to ensure that the flexural tensile surface of the beam is

containing different fiber types, including materials, dimension

a sawed surface.

and shape, and different fiber contents. Results can be used to

6. Apparatus

optimize the proportions of fiber–reinforced concrete mixtures,

to determine compliance with construction specifications, to

6.1 EitherScrewGearorHydraulicTestingApparatus,with

evaluate fiber–reinforced concrete which has been in service,

the ability to control the rate of motion of the loading head and

and as a tool for research and development of fiber–reinforced

meeting the requirements ofTest Method C78.Aload cell with

concrete (See Note 2).

a 44.5 kN capacity [10,000 lbf] will generally be required.

3 Closed-loop feed-back controlled deflection apparatus is not

NOTE 2—Banthia and Dubey compared results using this test method

required.

withresidualstrengthsatthesamenetdeflectionsusingatestprotocolthat

is similar to that described in Test Method C1609/C1609M on 45 beams

6.2 Flexural-Loading Beam-Support Apparatus, conform-

with a single fiber configuration at proportions of 0.1, 0.3, and 0.5 % by

ing to the requirements of Test Method C78.

volume.The results by this test method were on average 6.4 % lower than

by the procedure of Test Method C1609/C1609M.

6.3 Load and Deflection–Measuring Devices, such as load

cells and electronic transducers, capable of producing elec-

5.2 Test results are intended to reflect either consistency or

tronic analog signals and having support apparatus located and

differences among variables used in proportioning the fiber-

arranged in a manner that provides determination of applied

–reinforced concrete to be tested, including fiber type

load and mid-span deflection (See 3.1.5) of the beam. Measure

deflectionusingadevicecapableofmeasuringnetdeflectionat

Banthia, N. and Dubey, A., “Measurement of Flexural Toughness of Fiber

the beam mid–span with a minimum resolution of 0.025 mm

ReinforcedConcreteUsingaNovelTechnique,PartI:AssessmentandCalibration,”

In Press, Materials Journal, American Concrete Institute. [0.001 in.] by one of the following alternative methods.

C1399/C1399M−10 (2015)

FIG. 2Load-Deflection Curves

NOTE 3—The deflection measurement requires care in the arrangement

6.4.1 X-Y Plotter, driven by analog signals from load and

of displacement transducers in order to minimize extraneous contributions

deflection transducers to record the load–deflection curve.

such as might be caused by seating or twisting of the specimen.

6.4.2 Analog Signal Sampling and Digital Conversion Us-

Experience has shown that apparatus designed to support deflection

ing Automatic Data Acquisition Equipment With a Minimum

measuring devices that eliminate extraneous deflections is acceptable.

Methods to accomplish this measurement use spring-loaded electronic Sampling Frequency of 2.5 Hz, to record load and correspond-

displacement transducers mounted on suspension frames or support

ing deflection values from which load–deflection curves can be

frames as shown in Fig. 1.

produced.

6.3.1 Three Electronic Transducers, mounted on a support

6.5 StainlessSteelPlate,nominally100by12by350mm[4

frame. The support frame positions the transducers along the

by ⁄2 by 14 in.].

centerline of the top surface of the test beam at locations so as

6.6 Mechanical Dial Gauge, with 0.025 mm [0.001 in.]

to contact the beam

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1399/C1399M − 10 (Reapproved 2015)

Standard Test Method for

Obtaining Average Residual-Strength of Fiber-Reinforced

Concrete

This standard is issued under the fixed designation C1399/C1399M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Specimens in the Laboratory

C823 Practice for Examination and Sampling of Hardened

1.1 This test method covers the determination of residual

Concrete in Constructions

strength of a fiber–reinforced concrete test beam. The average

C1609/C1609M Test Method for Flexural Performance of

residual strength is computed using specified beam deflections

Fiber-Reinforced Concrete (Using Beam With Third-Point

that are obtained from a beam that has been cracked in a

Loading)

standard manner. The test provides data needed to obtain that

portion of the load–deflection curve beyond which a significant

3. Terminology

amount of cracking damage has occurred and it provides a

measure of post–cracking strength, as such strength is affected 3.1 Definitions of Terms Specific to This Standard:

3.1.1 deflection—mid–span deflection of the test beam ob-

by the use of fiber–reinforcement.

tained in a manner that excludes deflection caused by the

1.2 The values stated in either SI units or inch-pound units

following: (1) the flexural test apparatus, (2) crushing and

are to be regarded separately as standard. The values stated in

seating of the beam at support contact points, and (3) torsion of

each system may not be exact equivalents; therefore, each

the beam; sometimes termed net deflection.

system shall be used independently of the other. Combining

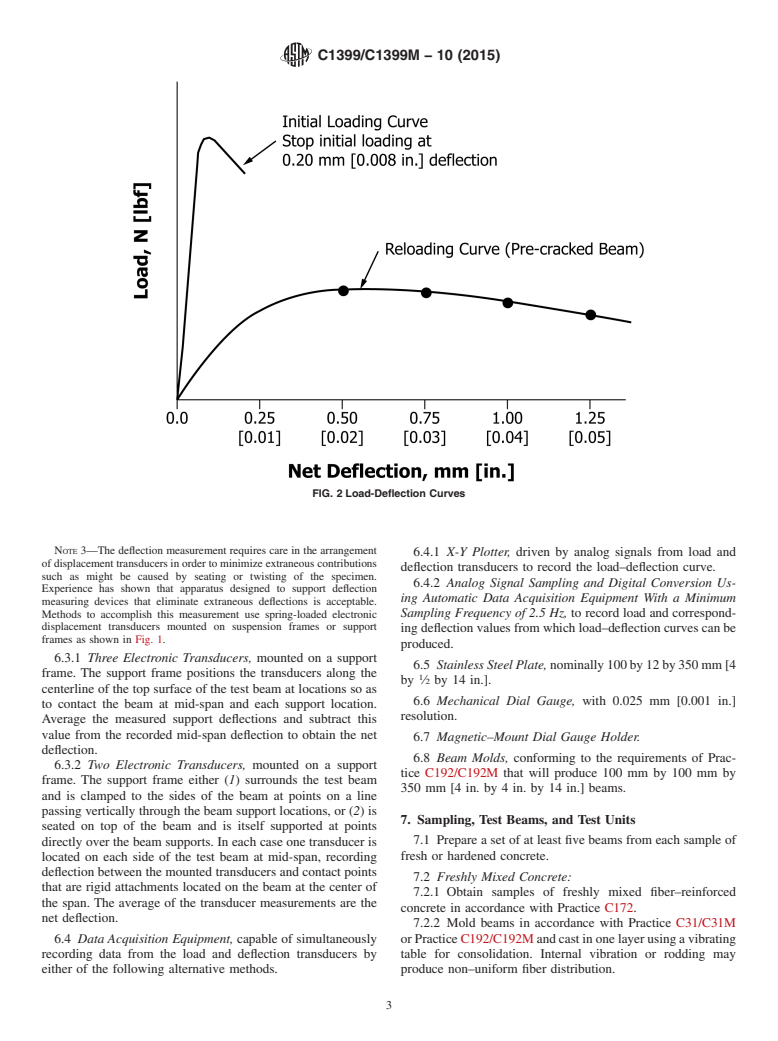

3.1.2 initial loading curve—the load–deflection curve ob-

values from the two systems may result in non-conformance

tained by testing an assembly that includes both the test beam

with the standard.

and a specified steel plate (Fig. 1); plotted to a deflection of at

1.3 This standard does not purport to address all of the

least 0.20 mm [0.008 in.] (Fig. 2).

safety concerns, if any, associated with its use. It is the

3.1.3 reloading curve—the load–deflection curve obtained

responsibility of the user of this standard to establish appro-

by reloading and retesting the pre-cracked beam, that is, after

priate safety and health practices and determine the applica-

the initial loading but without the steel plate. (Fig. 2)

bility of regulatory limitations prior to use.

3.1.4 reloading deflection—deflection measured during the

2. Referenced Documents

reloading of the cracked beam and with zero deflection

2.1 ASTM Standards: referenced to the start of the reloading.

C31/C31M Practice for Making and Curing Concrete Test

3.1.5 residual strength—the flexural stress on the cracked

Specimens in the Field

beam section obtained by calculation using loads obtained

C42/C42M Test Method for Obtaining and Testing Drilled

from the reloading curve at specified deflection values (See

Cores and Sawed Beams of Concrete

Note 1).

C78 Test Method for Flexural Strength of Concrete (Using

NOTE 1—Residual strength is not a true stress but an engineering stress

Simple Beam with Third-Point Loading)

computed using the flexure formula for linear elastic materials and gross

C172 Practice for Sampling Freshly Mixed Concrete

(uncracked) section properties.

C192/C192M Practice for Making and Curing Concrete Test

3.1.6 average residual strength—the average stress–carry-

ing ability of the cracked beam that is obtained by calculation

1 using the residual strength at four specified deflections.

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

C09.42 on Fiber-Reinforced Concrete.

4. Summary of Test Method

Current edition approved July 1, 2015. Published September 2015. Originally

4.1 Cast or sawed beams of fiber–reinforced concrete are

approved in 1998. Last previous edition approved in 2010 as C1399–10. DOI:

10.1520/C1399_C1399M-10R15.

cracked using the third–point loading apparatus specified in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Test Method C78 modified by a steel plate used to assist in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

support of the concrete beam during an initial loading cycle

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (Fig. 1). The steel plate is used to help control the rate of

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1399/C1399M − 10 (2015)

FIG. 1 Schematic of a Suitable Apparatus Where the Deflection Gauge Support Frame is Seated on the Beam

deflection when the beam cracks. After the beam has been (material), fiber size and shape, fiber amount, beam preparation

cracked in the specified manner, the steel plate is removed and (sawed or molded), and beam conditioning.

the cracked beam is reloaded to obtain data to plot a reloading

5.3 In molded beams fiber orientation near molded surfaces

load–deflection curve. Load values at specified deflection

will be affected by the process of molding. For tests of

values on the reloading curve are averaged and used to

fiber-reinforced concrete containing relatively rigid or stiff

calculate the average residual strength of the beam.

fibers of length greater than 35 mm [1.4 in.], the use of sawed

beams cut from samples with an initial width and depth of at

5. Significance and Use

least 3 times the length of the fiber is required to minimize

5.1 This test method provides a quantitative measure useful

effects of fiber orientation. When sawed beams are employed,

in the evaluation of the performance of fiber–reinforced

and to avoid the effects of fiber orientation, care shall be

concrete. It allows for comparative analysis among beams

applied to ensure that the flexural tensile surface of the beam is

containing different fiber types, including materials, dimension

a sawed surface.

and shape, and different fiber contents. Results can be used to

6. Apparatus

optimize the proportions of fiber–reinforced concrete mixtures,

to determine compliance with construction specifications, to

6.1 Either Screw Gear or Hydraulic Testing Apparatus, with

evaluate fiber–reinforced concrete which has been in service,

the ability to control the rate of motion of the loading head and

and as a tool for research and development of fiber–reinforced

meeting the requirements of Test Method C78. A load cell with

concrete (See Note 2).

a 44.5 kN capacity [10,000 lbf] will generally be required.

3 Closed-loop feed-back controlled deflection apparatus is not

NOTE 2—Banthia and Dubey compared results using this test method

required.

with residual strengths at the same net deflections using a test protocol that

is similar to that described in Test Method C1609/C1609M on 45 beams

6.2 Flexural-Loading Beam-Support Apparatus, conform-

with a single fiber configuration at proportions of 0.1, 0.3, and 0.5 % by

ing to the requirements of Test Method C78.

volume. The results by this test method were on average 6.4 % lower than

by the procedure of Test Method C1609/C1609M.

6.3 Load and Deflection–Measuring Devices, such as load

cells and electronic transducers, capable of producing elec-

5.2 Test results are intended to reflect either consistency or

tronic analog signals and having support apparatus located and

differences among variables used in proportioning the fiber-

arranged in a manner that provides determination of applied

–reinforced concrete to be tested, including fiber type

load and mid-span deflection (See 3.1.5) of the beam. Measure

deflection using a device capable of measuring net deflection at

Banthia, N. and Dubey, A., “Measurement of Flexural Toughness of Fiber

the beam mid–span with a minimum resolution of 0.025 mm

Reinforced Concrete Using a Novel Technique, Part I: Assessment and Calibration,”

In Press, Materials Journal, American Concrete Institute. [0.001 in.] by one of the following alternative methods.

C1399/C1399M − 10 (2015)

FIG. 2 Load-Deflection Curves

NOTE 3—The deflection measurement requires care in the arrangement

6.4.1 X-Y Plotter, driven by analog signals from load and

of displacement transducers in order to minimize extraneous contributions

deflection transducers to record the load–deflection curve.

such as might be caused by seating or twisting of the specimen.

6.4.2 Analog Signal Sampling and Digital Conversion Us-

Experience has shown that apparatus designed to support deflection

ing Automatic Data Acquisition Equipment With a Minimum

measuring devices that eliminate extraneous deflections is acceptable.

Sampling Frequency of 2.5 Hz, to record load and correspond-

Methods to accomplish this measurement use spring-loaded electronic

displacement transducers mounted on suspension frames or support

ing deflection values from which load–deflection curves can be

frames as shown in Fig. 1.

produced.

6.3.1 Three Electronic Transducers, mounted on a support

6.5 Stainless Steel Plate, nominally 100 by 12 by 350 mm [4

frame. The support frame positions the transducers along the

by ⁄2 by 14 in.].

centerline of the top surface of the test beam at locations so as

6.6 Mechanical Dial Gauge, with 0.025 mm [0.001 in.]

to contact the beam at mid-span and each support location.

resolution.

Average the mea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.