ASTM C779/C779M-00

(Test Method)Standard Test Method for Abrasion Resistance of Horizontal Concrete Surfaces

Standard Test Method for Abrasion Resistance of Horizontal Concrete Surfaces

SCOPE

1.1 This test method covers three procedures for determining the relative abrasion resistance of horizontal concrete surfaces. The procedures differ in the type and degree of abrasive force they impart, and are intended for use in determining variations in surface properties of concrete affected by mixture proportions, finishing, and surface treatment. They are not intended to provide a quantitative measurement of the length of service that may be expected from a specific surface.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-Other procedures are available for measuring the abrasion resistance of concrete surfaces in addition to the three procedures contained in this test method. Consideration should be given to Test Methods C944 and C418. The test method most closely representing service conditions should be used.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C779/C779M–00

Standard Test Method for

Abrasion Resistance of Horizontal Concrete Surfaces

This standard is issued under the fixed designation C 779/C 779M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope abrasion resistance of concrete, concrete materials, and curing

or finishing procedures. They may also be used for quality

1.1 This test method covers three procedures for determin-

acceptance of products and surface exposed to wear. They are

ing the relative abrasion resistance of horizontal concrete

notintendedtoprovideaquantitativemeasurementoflengthof

surfaces. The procedures differ in the type and degree of

service.

abrasive force they impart, and are intended for use in

3.2 The equipment used by each of these procedures is

determining variations in surface properties of concrete af-

portable and thus suitable for either laboratory or field testing.

fected by mixture proportions, finishing, and surface treatment.

The three procedures determine the relative wear of concrete

Theyarenotintendedtoprovideaquantitativemeasurementof

surfaces as follows:

the length of service that may be expected from a specific

3.2.1 Procedure A—The revolving-disk machine operates

surface.

by sliding and scuffing of steel disks in conjunction with

1.2 The values stated in SI units or inch-pound units are to

abrasive grit.

be regarded separately as standard. Within the text, the

3.2.2 Procedure B—The dressing-wheel machine operates

inch-pound units are shown in brackets. The values stated in

by impact and sliding friction of steel dressing wheels.

each system are not exact equivalents; therefore, each system

3.2.3 Procedure C—The ball-bearing machine operates by

shall be used independently of each other.

high-contact stresses, impact, and sliding friction from steel

1.3 This standard does not purport to address all of the

balls.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

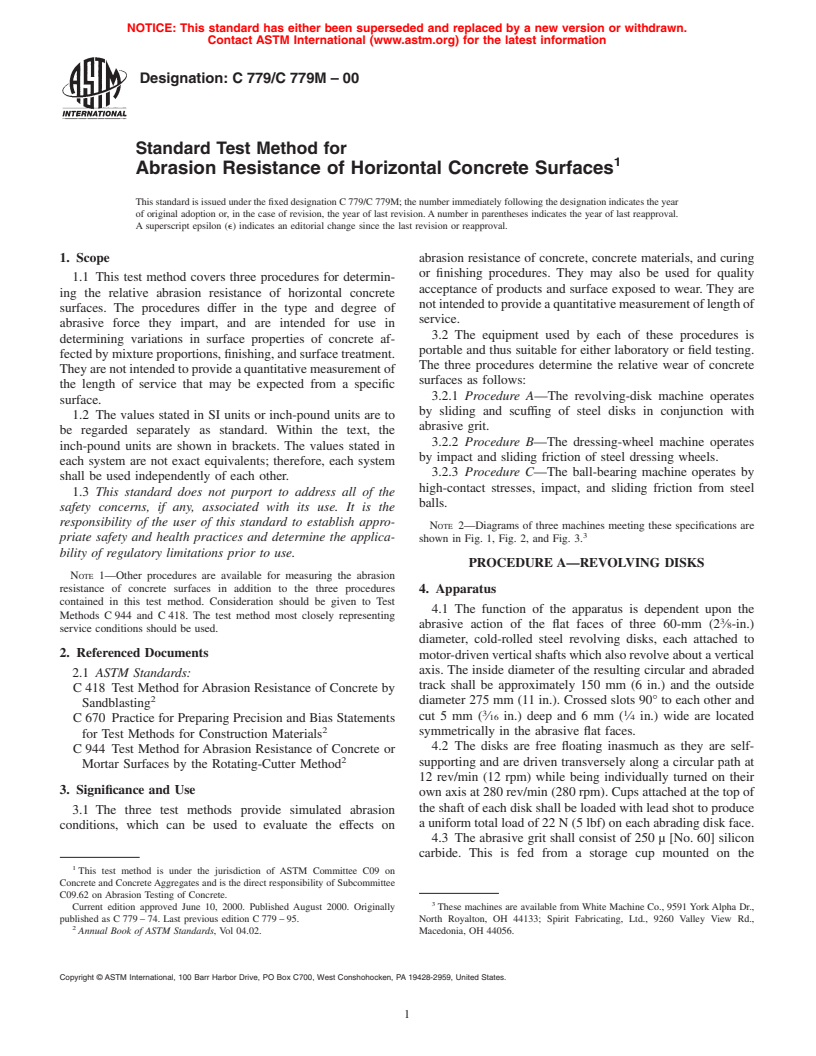

NOTE 2—Diagrams of three machines meeting these specifications are

priate safety and health practices and determine the applica- shown in Fig. 1, Fig. 2, and Fig. 3.

bility of regulatory limitations prior to use.

PROCEDURE A—REVOLVING DISKS

NOTE 1—Other procedures are available for measuring the abrasion

resistance of concrete surfaces in addition to the three procedures

4. Apparatus

contained in this test method. Consideration should be given to Test

4.1 The function of the apparatus is dependent upon the

Methods C 944 and C 418. The test method most closely representing

abrasive action of the flat faces of three 60-mm (2 ⁄8-in.)

service conditions should be used.

diameter, cold-rolled steel revolving disks, each attached to

2. Referenced Documents

motor-driven vertical shafts which also revolve about a vertical

axis. The inside diameter of the resulting circular and abraded

2.1 ASTM Standards:

track shall be approximately 150 mm (6 in.) and the outside

C 418 Test Method for Abrasion Resistance of Concrete by

diameter 275 mm (11 in.). Crossed slots 90° to each other and

Sandblasting

3 1

cut5mm( ⁄16 in.) deep and 6 mm ( ⁄4 in.) wide are located

C 670 Practice for Preparing Precision and Bias Statements

symmetrically in the abrasive flat faces.

for Test Methods for Construction Materials

4.2 The disks are free floating inasmuch as they are self-

C 944 Test Method for Abrasion Resistance of Concrete or

supporting and are driven transversely along a circular path at

Mortar Surfaces by the Rotating-Cutter Method

12 rev/min (12 rpm) while being individually turned on their

3. Significance and Use

own axis at 280 rev/min (280 rpm). Cups attached at the top of

the shaft of each disk shall be loaded with lead shot to produce

3.1 The three test methods provide simulated abrasion

a uniform total load of 22 N (5 lbf) on each abrading disk face.

conditions, which can be used to evaluate the effects on

4.3 The abrasive grit shall consist of 250 µ [No. 60] silicon

carbide. This is fed from a storage cup mounted on the

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.62 on Abrasion Testing of Concrete.

Current edition approved June 10, 2000. Published August 2000. Originally These machines are available from White Machine Co., 9591 York Alpha Dr.,

published as C 779 – 74. Last previous edition C 779 – 95. North Royalton, OH 44133; Spirit Fabricating, Ltd., 9260 Valley View Rd.,

Annual Book of ASTM Standards, Vol 04.02. Macedonia, OH 44056.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C779/C779M

FIG. 1 Revolving Disks Abrasion Test Machine

revolving circular plate through a 3-mm ( ⁄8-in.) orifice passing

through the plate. The flow of abrasive shall be controlled to a

rate of 4 to 6 g/min by an adjusting needle located in the

orifice. The abrasive falls at the midwidth of the circular

abraded track, and midway between two of the disks.

4.4 The micrometer bridge consists of a machine-finished

25-mm (1-in.) rectangular steel bar of at least 300-mm (12-in.),

clear span supported by a tripod and drilled along its centerline

1 1

with ten 3-mm ( ⁄8-in.) diameter holes spaced 6-mm ( ⁄4 in.) on

center. The measuring instrument is a depth micrometre with a

needle having an effective depth range of 25 to 50 mm (1 to 2

in.) and graduated to an accuracy of at least 0.025 mm (0.001

in.).

5. Test Specimen

5.1 For laboratory test purposes, the machine is designed to

accommodate approximately 300 by 300-mm (12 by 12-in.)

test specimens. The apparatus is equipped with an adjusting

handle linked by a sprocket and chain-drive assembly to the

four 25-mm (1-in.) diameter posts which support the entire

rotating abrasion element. This feature permits the abrasion of

test panels up to approximately 100-mm (4-in.) in thickness.A

zero adjustment in the height of the abrasion assembly also

permits the use of the apparatus as a portable device for

measuring the abrasion resistance on the surfaces in place as

FIG. 2 Dressing Wheel Abrasion Test Machine

well as on test specimens.

C779/C779M

depth of the slots to less than 1.5 mm ( ⁄16in.), they shall be

replaced.Newdiskfacesshallbesubjectedtoabreak-inperiod

of at least 15 min.

7. Interpretation of Results

7.1 The comparison of measurements of average depth of

wear of representative surfaces at 30 and 60-min exposure to

abrasion will indicate the relative abrasion resistance of these

surfaces.

8. Report

8.1 Report the depth of wear of each surface tested as well

as the average obtained on replicate surfaces.

8.2 Record mixture proportions (including cement content

and water-cement ratio), specific gravities, grading of fine and

coarse aggregates, Los Angeles abrasion test results, type and

amount of material added to freshly placed concrete surface,

typeandextentoftroweling,curingdetails,andageofconcrete

when tested.

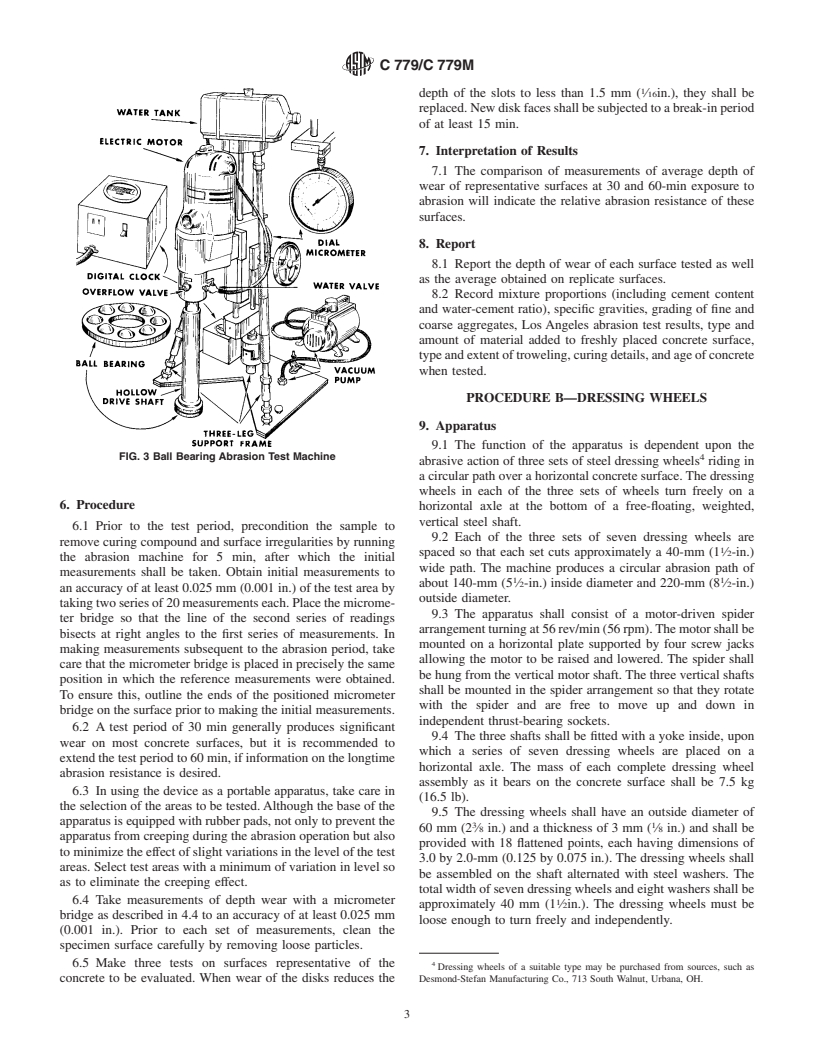

PROCEDURE B—DRESSING WHEELS

9. Apparatus

9.1 The function of the apparatus is dependent upon the

FIG. 3 Ball Bearing Abrasion Test Machine

abrasive action of three sets of steel dressing wheels riding in

a circular path over a horizontal concrete surface. The dressing

wheels in each of the three sets of wheels turn freely on a

6. Procedure

horizontal axle at the bottom of a free-floating, weighted,

vertical steel shaft.

6.1 Prior to the test period, precondition the sample to

9.2 Each of the three sets of seven dressing wheels are

remove curing compound and surface irregularities by running

spaced so that each set cuts approximately a 40-mm (1 ⁄2-in.)

the abrasion machine for 5 min, after which the initial

wide path. The machine produces a circular abrasion path of

measurements shall be taken. Obtain initial measurements to

1 1

about 140-mm (5 ⁄2-in.) inside diameter and 220-mm (8 ⁄2-in.)

an accuracy of at least 0.025 mm (0.001 in.) of the test area by

outside diameter.

takingtwoseriesof20measurementseach.Placethemicrome-

9.3 The apparatus shall consist of a motor-driven spider

ter bridge so that the line of the second series of readings

arrangementturningat56rev/min(56rpm).Themotorshallbe

bisects at right angles to the first series of measurements. In

mounted on a horizontal plate supported by four screw jacks

making measurements subsequent to the abrasion period, take

allowing the motor to be raised and lowered. The spider shall

care that the micrometer bridge is placed in precisely the same

be hung from the vertical motor shaft. The three vertical shafts

position in which the reference measurements were obtained.

shall be mounted in the spider arrangement so that they rotate

To ensure this, outline the ends of the positioned micrometer

with the spider and are free to move up and down in

bridge on the surface prior to making the initial measurements.

independent thrust-bearing sockets.

6.2 A test period of 30 min generally produces significant

9.4 The three shafts shall be fitted with a yoke inside, upon

wear on most concrete surfaces, but it is recommended to

which a series of seven dressing wheels are placed on a

extend the test period to 60 min, if information on the longtime

horizontal axle. The mass of each complete dressing wheel

abrasion resistance is desired.

assembly as it bears on the concrete surface shall be 7.5 kg

6.3 In using the device as a portable apparatus, take care in

(16.5 lb).

the selection of the areas to be tested.Although the base of the

9.5 The dressing wheels shall have an outside diameter of

apparatus is equipped with rubber pads, not only to prevent the

3 1

60 mm (2 ⁄8 in.) and a thickness of 3 mm ( ⁄8 in.) and shall be

apparatus from creeping during the abrasion operation but also

provided with 18 flattened points, each having dimensions of

to minimize the effect of slight variations in the level of the test

3.0 by 2.0-mm (0.125 by 0.075 in.). The dressing wheels shall

areas. Select test areas with a minimum of variation in level so

be assembled on the shaft alternated with steel washers. The

as to eliminate the creeping effect.

total width of seven dressing wheels and eight washers shall be

6.4 Take measurements of depth wear with a micrometer

approximately 40 mm (1 ⁄2in.). The dressing wheels must be

bridge as described in 4.4 to an accuracy of at least 0.025 mm

loose enough to turn freely and independently.

(0.001 in.). Prior to each set of measurements, clean the

specimen surface carefully by removing loose particles.

6.5 Make three tests on surfaces representative of the

Dressing wheels of a suitable type may be purchased from sources, such as

concrete to be evaluated. When wear of the disks reduces the Desmond-Stefan Manufacturing Co., 713 South Walnut, Urbana, OH.

C779/C779M

9.6 The measuring instrument shall be a dial micrometer, 13.2 Record the mixture proportions including cement con-

reading to an accuracy of at least 0.025 mm (0.001 in.) with a tent and water-cement ratio, specific gravities, grading of fine

range of at least 10 mm (0.4 in.). The contact end of the and coarse aggregates, Los Angeles abrasion test results, type

micrometer spindle shall have a spherical surface of 9.5-mm and amount of material added to freshly placed concrete

( ⁄8-in.) diameter. A jig located on the underside of the spider surface, type and extent of troweling, curing details, and age of

holdsthemicrometremagneticallyintheapproximatecenterof concrete when tested.

the path of the dressing wheels.

PROCEDURE C—BALL BEARINGS

10. Test Specimen

14. Apparatus

10.1 Place a sample approximately 300 by 300 by 100-mm

(12 by 12 by 4-in.) thick into the machine and lock it in place

14.1 The function of the apparatus is dependent upon the

with vises provided. Do not remove the sample until the test is

abrasive action of a rapidly rotating ball bearing under load on

completed. Test three identical samples.

a wet concrete test surface. Water is used to flush out loose

particles from the test path, bringing the ball bearing in contact

11. Procedure

with sand and stone particles still bonded to the concrete

11.1 Position the abrasion apparatus over surface to be

surface, thus providing impact as well as sliding friction.

tested. Rubber pads on the bottom of machine will hold the

14.2 The apparatus shall consist of a motordriven, hollow,

machine in place. Turn the screw crank until the full weight of

vertical shaft resting on and turning ball bearings which rest on

each dressing-wheel shaft is resting on the concrete surface.

the concrete surface. As the ball bearings cut into the concrete

Lower the spider as far as possible without exerting any

surface, depth-of-wear readings can be taken continuously

pressure from the spider itself onto these three shafts. Allow a

without stopping the test.

spacing of 15 mm (0.5 in.) for vertical travel of the dressing

14.3 A digital clock shall be electrically connected to the

wheels. Lock the screw crank to prevent any change in vertical

drive motor so that both the drive motor and the clock can be

movement of the spider during testing.

started simultaneously. The clock shall read in seconds up to

11.2 Take an initial measurement to the nearest 0.025 mm

9999 s.

(0.001 in.) on the test area with the dial micrometer in place

14.4 The abrasion tool shall be composed of eight 18-mm

while revolving the spider two revolutions by hand. Record

( ⁄32-in.) diameter steel balls equally spaced in a retainer ring.

this initial reading as a reference reading and then remove the

The diameter of the ball circle shall be 60 mm (2 ⁄2 in.). The

micrometer. Start the machine and let it run for 30 min, brush

abrasion tool shall be given a breaking-in period of 300 s. The

offtheloosematerial,insertthedialmicrometer,andrecordthe

abrasion tool shall be discarded when the diameter of the steel

average reading again. If the readings are not reasonably

ball has been reduced to 17.8 mm (0.7 in.).

uniform, record several readings taken around the circumfer-

NOTE 3—During this period the steel balls will become slightly

ence of the abraded surface from which the average reading

textured, leaving an apparent larger diameter.

may be computed. The difference between the reference

14.5 The hollow vertical drive shaft shall be provided with

reading and the 30-min reading is indicative of the depth of

a flanged bearing plate at its lower end, grooved to match the

wear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.