ASTM E2001-13

(Guide)Standard Guide for Resonant Ultrasound Spectroscopy for Defect Detection in Both Metallic and Non-metallic Parts

Standard Guide for Resonant Ultrasound Spectroscopy for Defect Detection in Both Metallic and Non-metallic Parts

SIGNIFICANCE AND USE

5.1 The primary advantage of RUS is its ability of making numerous measurements in a single test. In addition, it can examine rough ground parts. It requires little sample preparation, no couplants, and generally will work with soiled items; however, it has no capability with soft materials. Soft metals, polymers, rubbers, and wood parts are not viable candidates for this technology.

SCOPE

1.1 This guide describes a procedure for detecting defects in metallic and non-metallic parts using the resonant ultrasound spectroscopy method. The procedure is intended for use with instruments capable of exciting and recording whole body resonant states within parts which exhibit acoustical or ultrasonic ringing. It is used to distinguish acceptable parts from those containing defects, such as cracks, voids, chips, density defects, tempering changes, and dimensional variations that are closely correlated with the parts' mechanical system dynamic response.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2001 − 13

Standard Guide for

Resonant Ultrasound Spectroscopy for Defect Detection in

1

Both Metallic and Non-metallic Parts

This standard is issued under the fixed designation E2001; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.2 Definitions of Terms Specific to This Standard:

3.2.1 resonant ultrasonic spectroscopy (RUS), n—a nonde-

1.1 Thisguidedescribesaprocedurefordetectingdefectsin

structive examination method, which employs resonant ultra-

metallic and non-metallic parts using the resonant ultrasound

sound methodology for the detection and assessment of varia-

spectroscopy method. The procedure is intended for use with

tions and mechanical properties of a test object. In this

instruments capable of exciting and recording whole body

procedure, whereby a rigid part is caused to resonate, the

resonant states within parts which exhibit acoustical or ultra-

resonances are compared to a previously defined resonance

sonic ringing. It is used to distinguish acceptable parts from

pattern.Basedonthiscomparisonthepartisjudgedtobeeither

those containing defects, such as cracks, voids, chips, density

acceptable or unacceptable.

defects,temperingchanges,anddimensionalvariationsthatare

3.2.2 swept sine method, n—the use of an excitation source

closely correlated with the parts’ mechanical system dynamic

to create a transient vibration in a test object over a range of

response.

frequencies. Specifically, the input frequency is swept over a

1.2 The values stated in SI units are to be regarded as

range of frequencies and the output is characterized by a

standard. No other units of measurement are included in this

resonant amplitude response spectrum.

standard.

3.2.3 impulse excitation method, n—striking an object with

1.3 This standard does not purport to address all of the

a mechanical impact, or electromagnetic field (laser and/or

safety concerns, if any, associated with its use. It is the

EMAT) causing multiple resonances to be simultaneously

responsibility of the user of this standard to establish appro-

stimulated.

priate safety and health practices and determine the applica-

3.2.4 resonant inspection (RI), n—any induced resonant

bility of regulatory limitations prior to use.

nondestructive examination method employing an excitation

2. Referenced Documents force to create mechanical resonances for the purpose of

2

identifying a test object’s conformity to an established accept-

2.1 ASTM Standards:

able pattern.

E1316Terminology for Nondestructive Examinations

E1876Test Method for Dynamic Young’s Modulus, Shear

3

4. Summary of the Technology (1)

Modulus, and Poisson’s Ratio by Impulse Excitation of

4.1 Introduction:

Vibration

4.1.1 In addition to its basic research applications in

E2534PracticeforProcessCompensatedResonanceTesting

physics, materials science, and geophysics, Resonant Ultra-

Via Swept Sine Input for Metallic and Non-Metallic Parts

sound Spectroscopy (RUS) has been used successfully as an

applied nondestructive testing tool. Resonant ultrasound spec-

3. Terminology

troscopy in commercial, nondestructive testing has a few

3.1 Definitions—Thedefinitionsoftermsrelatingtoconven-

recognizable names including, RUS Nondestructive Testing,

tional ultrasonics can be found in Terminology E1316.

Acoustic Resonance Spectroscopy (ARS), and Resonant In-

spection. Early references to this body of science often are

1

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc- termed the “swept sine method.” It was not until 1990 (2) that

tive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic

the name Resonant Ultrasound Spectroscopy appeared, but the

Method.

two techniques are synonymous. Additionally, impulse

Current edition approved Dec. 1, 2013. Published January 2014. Originally

methods, like the striking of a rail car wheel with a hammer,

approved in 1998. Last previous edition approved in 2008 as E2001-08. DOI:

10.1520/E2001-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the ASTM website. this guide.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

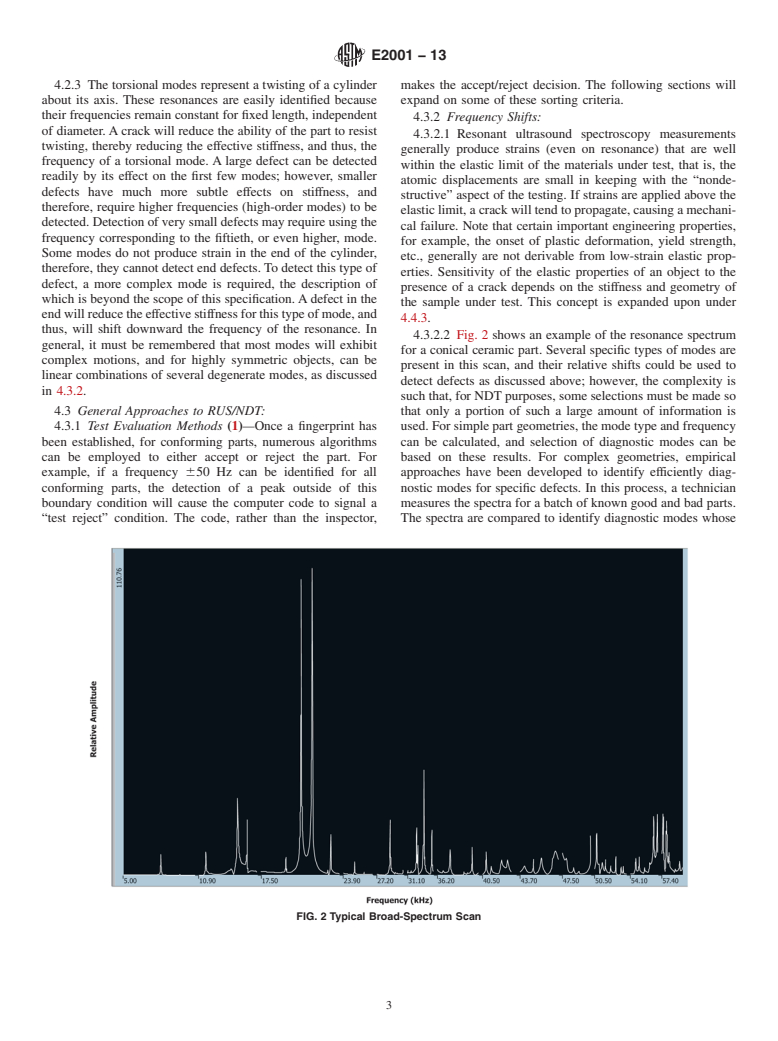

E2001 − 13

and listening for the responses, have been u

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2001 − 08 E2001 − 13

Standard Guide for

Resonant Ultrasound Spectroscopy for Defect Detection in

1

Both Metallic and Non-metallic Parts

This standard is issued under the fixed designation E2001; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This guide describes a procedure for detecting defects in metallic and non-metallic parts using the resonant ultrasound

spectroscopy method. The procedure is intended for use with instruments capable of exciting and recording whole body resonant

states within parts which exhibit acoustical or ultrasonic ringing. It is used to distinguish acceptable parts from those containing

defects, such as cracks, voids, chips, density defects, tempering changes, and dimensional variations that are closely correlated with

the parts’ mechanical system dynamic response.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E1316 Terminology for Nondestructive Examinations

E1876 Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration

E2534 Practice for Process Compensated Resonance Testing Via Swept Sine Input for Metallic and Non-Metallic Parts

3. Terminology

3.1 Definitions—The definitions of terms relating to conventional ultrasonics can be found in Terminology E1316.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 resonant ultrasonic spectroscopy (RUS), n—a nondestructive examination method, which employs resonant ultrasound

methodology for the detection and assessment of variations and mechanical properties of a test object. In this procedure, whereby

a rigid part is caused to resonate, the resonances are compared to a previously defined resonance pattern. Based on this comparison

the part is judged to be either acceptable or unacceptable.

3.2.2 swept sine method, n—the use of an excitation source to create a transient vibration in a test object over a range of

frequencies. Specifically, the input frequency is swept over a range of frequencies and the output is characterized by a resonant

amplitude response spectrum.

3.2.3 impulse excitation method, n—striking an object with a mechanical impact, or electromagnetic field (laser and/or EMAT)

causing multiple resonances to be simultaneously stimulated.

3.2.4 resonant inspection (RI), n—any induced resonant nondestructive examination method employing an excitation force to

create mechanical resonances for the purpose of identifying a test object’s conformity to an established acceptable pattern.

3

4. Summary of the Technology (1)

4.1 Introduction:

1

This guide is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic Method.

Current edition approved July 1, 2008Dec. 1, 2013. Published July 2008January 2014. Originally approved in 1998. Last previous edition approved in 20032008 as

E2001 - 98E2001 - 08.(2003). DOI: 10.1520/E2001-08.10.1520/E2001-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The boldface numbers in parentheses refer to the list of references at the end of this guide.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

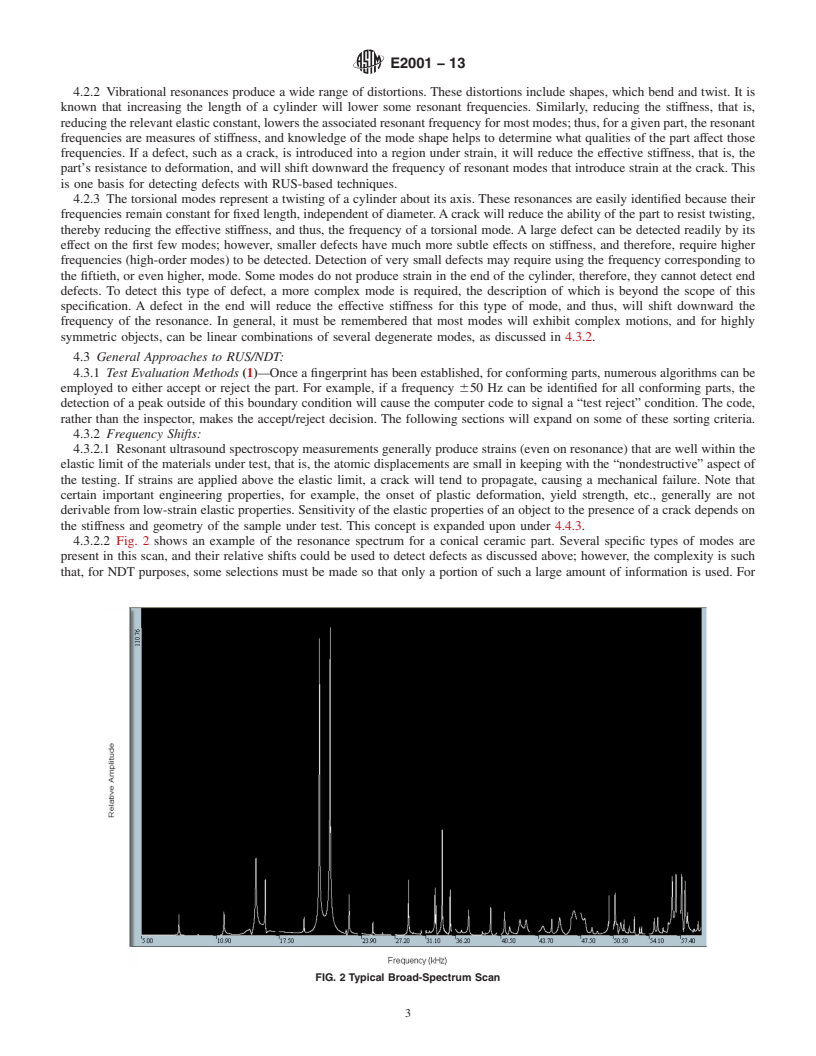

E2001 − 13

4.1.1 In addition to its basic research applications in physics, materials science, and geophysics, Resonant Ultrasound

Spectroscopy (RUS) has been used successfully as an applied nondestructive testing tool. Resonant ultrasound spectroscopy in

commercial, nondestructive testing has a few recognizable names including, RUS Nondestructive Testing, Acousti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.