ASTM E2478-11

(Practice)Standard Practice for Determining Damage-Based Design Stress for Glass Fiber Reinforced Plastic (GFRP) Materials Using Acoustic Emission

Standard Practice for Determining Damage-Based Design Stress for Glass Fiber Reinforced Plastic (GFRP) Materials Using Acoustic Emission

SIGNIFICANCE AND USE

The damage-based design approach will permit an additional method of design for GFRP materials. This is a very useful technique to determine the performance of different types of resins and composition of GFRP materials in order to develop a damage tolerant and reliable design. This AE-based method is not unique, other damage-sensitive evaluation methods can also be used.

This practice involves the use of acoustic emission instrumentation and examination techniques as a means of damage detection to support a destructive test, in order to derive the damage-based design stress.

This practice is not intended as a definitive predictor of long-term performance of GFRP materials (such as those used in vessels). For this reason, codes and standards require cyclic proof testing of prototypes (for example, vessels) which are not a part of this practice.

Other design methods exist and are permitted.

SCOPE

1.1 This practice details procedures for establishing the direct stress and shear stress damage-based design values for use in the damage-based design criterion for materials to be used in GFRP vessels and other GFRP structures. The practice uses data derived from acoustic emission examination of four-point beam bending tests and in-plane shear tests (see ASME Section X, Article RT-8).

1.2 The onset of lamina damage is indicated by the presence of significant acoustic emission during the reload portion of load/reload cycles. “Significant emission” is defined with historic index.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2478 − 11

StandardPractice for

Determining Damage-Based Design Stress for Glass Fiber

Reinforced Plastic (GFRP) Materials Using Acoustic

1

Emission

This standard is issued under the fixed designation E2478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D3846 Test Method for In-Plane Shear Strength of Rein-

forced Plastics

1.1 This practice details procedures for establishing the

E543 Specification forAgencies Performing Nondestructive

direct stress and shear stress damage-based design values for

Testing

use in the damage-based design criterion for materials to be

E976 GuideforDeterminingtheReproducibilityofAcoustic

used in GFRPvessels and other GFRPstructures. The practice

Emission Sensor Response

uses data derived from acoustic emission examination of

E1316 Terminology for Nondestructive Examinations

four-point beam bending tests and in-plane shear tests (see

E2374 Guide for Acoustic Emission System Performance

ASME Section X, Article RT-8).

Verification

1.2 Theonsetoflaminadamageisindicatedbythepresence

3

2.2 ASME Documents:

of significant acoustic emission during the reload portion of

ASMESectionX,ArticleRT-8 TestMethodforDetermining

load/reload cycles. “Significant emission” is defined with

Damage-Based Design Criterion

historic index.

ASMESectionV,Article11 AcousticEmissionExamination

1.3 Units—The values stated in inch-pound units are to be

of Fiber-Reinforced Plastic Vessels

regarded as standard. The values given in parentheses are

2.3 Other Standards:

mathematical conversions to SI units which are provided for

ANSI/ASNT-CP-189 Qualification and Certification of

information only and are not considered standard.

4

Nondestructive Testing Personnel

1.4 This standard does not purport to address all of the

SNT-TC-1A Recommended Practice for Personnel Qualifi-

4

safety concerns, if any, associated with its use. It is the

cation and Certification in Nondestructive Testing

responsibility of the user of this standard to establish appro-

NAS-410 Certification and Qualification of Nondestructive

5

priate safety and health practices and determine the applica-

Test Personnel

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents

3.1 Definitions of terms related to conventional acoustic

2

2.1 ASTM Standards:

emission are in Terminology E1316, Section B.

D790 Test Methods for Flexural Properties of Unreinforced

3.2 Definitions of Terms Specific to This Standard:

and Reinforced Plastics and Electrical Insulating Materi-

3.2.1 historic index—a measure of the change in MARSE

als

(or other AE feature parameter such as AE Signal Strength)

D4255/D4255M Test Method for In-Plane Shear Properties

throughout an examination.

of Polymer Matrix Composite Materials by the Rail Shear

Method

3.2.2 knee in the curve—a dramatic change in the slope of

the cumulative AE (MARSE or Signal Strength) versus time

curve.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

Acoustic Emission Method.

3

Current edition approved Dec. 1, 2011. Published January 2012. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 2006. Last previous edition approved in 2006 as E2478 - 06a. DOI: International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

10.1520/E2478-11. www.asme.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

the ASTM website. WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

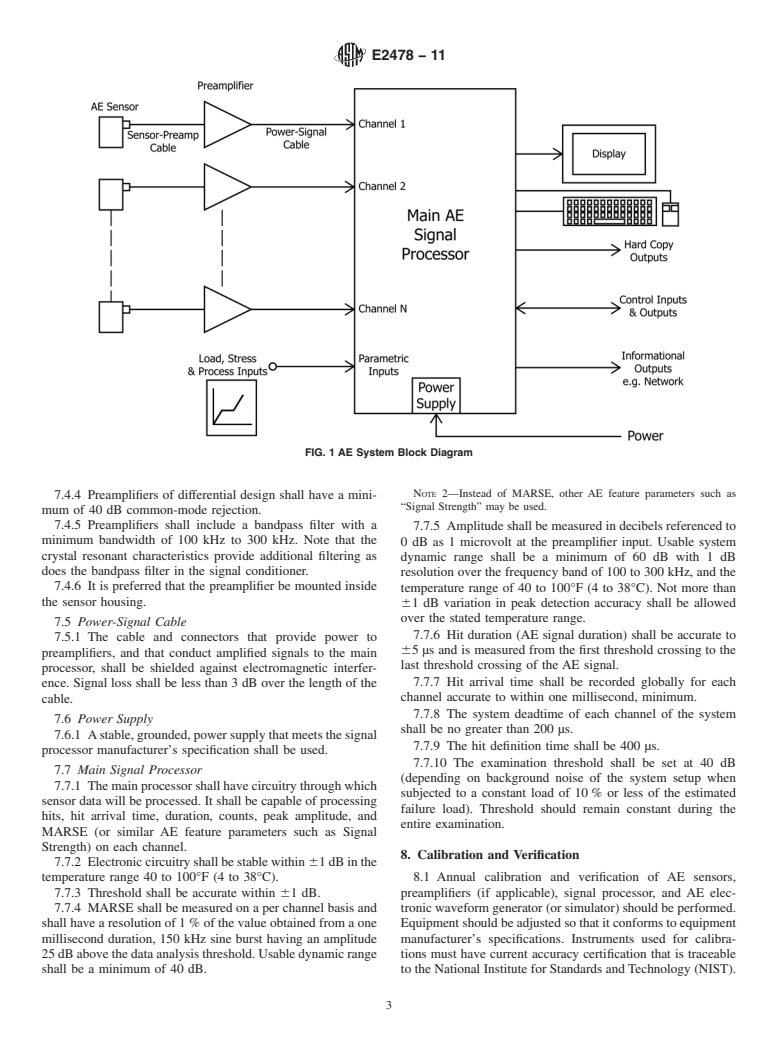

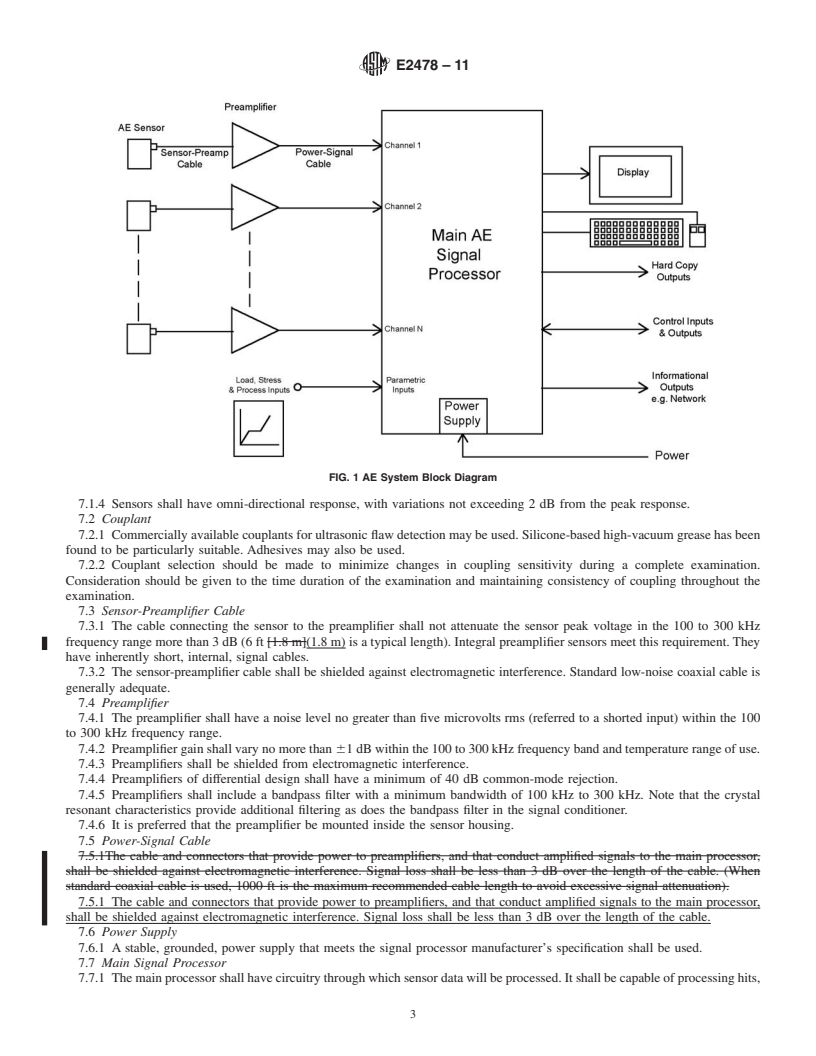

E2478 − 11

3.2.3 measured area of the rectified signal envelope 6.1.3 Procedure and Techniques—The procedures and tech-

(MARSE)—a measure of the area under the envelope of the niques to be utilized shall be as specified in the contractual

rectified linear voltage time signal from the sensor. (seeASME agreement.

Section V, Article 11) 6.1.4 Timing of Examination—The timing of examination

shall be in accordance

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2478–06a Designation:E2478–11

Standard Practice for

Determining Damage-Based Design Stress for Fiberglass

Glass Fiber Reinforced Plastic (GFRP) Materials Using

1

Acoustic Emission

This standard is issued under the fixed designation E2478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice details procedures for establishing the direct stress and shear stress damage-based design values for use in the

damage-based design criterion for materials to be used in GFRP vessels and other compositeGFRP structures. The practice uses

data derived from acoustic emission examination of four-point beam bending tests and in-plane shear tests (seeASME Section X,

Article RT-8).

1.2 The onset of lamina damage is indicated by the presence of significant acoustic emission during the reload portion of

load/reload cycles. “Significant emission” is defined with historic index.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in bracketsparentheses are

mathematical conversions to SI units which are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D4255/D4255M Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

D3846 Test Method for In-Plane Shear Strength of Reinforced Plastics

E543 Specification for Agencies Performing Nondestructive Testing

E976 Guide for Determining the Reproducibility of Acoustic Emission Sensor Response

E1316 Terminology for Nondestructive Examinations

E2374 Guide for Acoustic Emission System Performance Verification

3

2.2 ASME Documents:

ASME Section X, Article RT-8 Test Method for Determining Damage-Based Design Criterion

ASME Section V, Article 11 Acoustic Emission Examination of Fiber-Reinforced Plastic Vessels

2.3 Other Standards:

4

ANSI/ASNT-CP-189 Qualification and Certification of Nondestructive Testing Personnel

4

SNT-TC-1A Recommended Practice for Personnel Qualification and Certification in Nondestructive Testing

5

NAS-410 Certification and Qualification of Nondestructive Test Personnel

3. Terminology

3.1 Definitions of terms related to conventional acoustic emission are in Terminology E1316, Section B.

3.2 Definitions of Terms Specific to This Standard:

1

This practice is under the jurisdiction ofASTM Committee E07 on NondestructiveTesting and is the direct responsibility of Subcommittee E07.04 onAcoustic Emission

Method.

Current edition approved Dec. 1, 2006.2011. Published January 2007.2012. Originally approved in 2006. Last previous edition approved in 2006 as E2478 - 06a. DOI:

10.1520/E2478-06A.10.1520/E2478-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

4

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

5

Available from Aerospace Industries Association of America, Inc. (AIA), 1250 Eye St., NW, Washington, DC 20005.

5

Available from Aerospace Industries Association of America, Inc. (AIA), 1000 Wilson Blvd., Suite 1700, Arlington, VA 22209-3928, http://www.aia-aerospace.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2478–11

3.2.1 historic index—a measure of the change in MARSE (or other AE feature parameter such as AE Signal Strength or AE

Energy)Strength) throughout an examination.

3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.