ASTM F1398-93(1999)

(Test Method)Standard Test Method for Determination of Total Hydrocarbon Contribution by Gas Distribution System Components

Standard Test Method for Determination of Total Hydrocarbon Contribution by Gas Distribution System Components

SCOPE

1.1 This test method covers the testing of components for total hydrocarbons (THC) contribution to a gas distribution system at ambient temperature. In addition, this test method allows testing of the component at elevated ambient temperatures as high as 70°C.

1.2 This test method applies to in-line components containing electronics grade materials in the gaseous form, such as those used in semiconductor gas distribution systems.

1.3 Limitations:

1.3.1 This test method is limited by the sensitivity of current instrumentation, as well as by the response time of the instrumentation. This test method is not intended to be used for components larger than 12.7-mm ( 1/2-in.) outside diameter nominal size. This test method could be applied to larger components; however, the stated volumetric flow rate may not provide adequate mixing to ensure a representative sample. Higher flow rates may improve the mixing but excessively dilute the sample.

1.3.2 Different instrumental methods (such as flame ionization detector (FID), mass spectrometer (MS)) will yield total hydrocarbon (THC) levels that are not comparable due to different sensitivities to different molecular species. Hydrocarbon contaminants of high-purity gas distribution systems can be subdivided into two general categories: (1) noncondensable hydrocarbons (

1.3.3 Because of the tremendous disparity of hydrocarbon species, it is suggested that direct comparisons be made only among data gathered using the same detection method.

1.3.4 This test method is intended for use by operators who understand the use of the apparatus at a level equivalent to six months of experience.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 1398–93 (Reapproved 1999)

Standard Test Method for

Determination of Total Hydrocarbon Contribution by Gas

Distribution System Components

This standard is issued under the fixed designation F 1398; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This test method

presents a procedure that may be applied for the evaluation of one or more components considered for

use in such systems.

1. Scope surfaces as residues. Condensable hydrocarbons include pump

oils, degreasing agents, and polishing compound vehicles.

1.1 This test method covers the testing of components for

1.3.3 Because of the tremendous disparity of hydrocarbon

total hydrocarbons (THC) contribution to a gas distribution

species, it is suggested that direct comparisons be made only

system at ambient temperature. In addition, this test method

among data gathered using the same detection method.

allows testing of the component at elevated ambient tempera-

1.3.4 This test method is intended for use by operators who

tures as high as 70°C.

understand the use of the apparatus at a level equivalent to six

1.2 This test method applies to in-line components contain-

months of experience.

ing electronics grade materials in the gaseous form, such as

1.4 The values stated in SI units are to be regarded as the

those used in semiconductor gas distribution systems.

standard. The inch-pound units given in parentheses are for

1.3 Limitations:

information only.

1.3.1 Thistestmethodislimitedbythesensitivityofcurrent

1.5 This standard does not purport to address all of the

instrumentation, as well as by the response time of the

safety concerns, if any, associated with its use. It is the

instrumentation.This test method is not intended to be used for

responsibility of the user of this standard to establish appro-

components larger than 12.7-mm ( ⁄2-in.) outside diameter

priate safety and health practices and determine the applica-

nominal size. This test method could be applied to larger

bility of regulatory limitations prior to use. Specific hazard

components; however, the stated volumetric flow rate may not

statements are given in Section 5.

provide adequate mixing to ensure a representative sample.

Higher flow rates may improve the mixing but excessively

2. Terminology

dilute the sample.

2.1 Definitions:

1.3.2 Different instrumental methods (such as flame ioniza-

2.1.1 baseline—the instrument response under steady state

tion detector (FID), mass spectrometer (MS)) will yield total

conditions.

hydrocarbon (THC) levels that are not comparable due to

2.1.2 glove bag—an enclosure that contains a controlled

different sensitivities to different molecular species. Hydrocar-

atmosphere. A glove box could also be used for this test

bon contaminants of high-purity gas distribution systems can

method.

be subdivided into two general categories: ( 1) noncondensable

2.1.3 heat trace— heating of component, spool piece, or

hydrocarbons (

teststandbyauniformandcompletewrappingoftheitemwith

removal and relative atmospheric abundance, and (2) condens-

resistant heat tape.

able hydrocarbons, that are often left behind on component

2.1.4 methane (CH ) equivalent—that concentration of CH

4 4

that causes the same instrument response as the sample.

2.1.4.1 Discussion—The calibration gas contains a known

This test method is under the jurisdiction of ASTM Committee F-1 on

concentration of methane (CH ). Instrument response to zero

Electronics and is the direct responsibility of Subcommittee F01.10 on Processing

gas and span gas defines the calibration curve for the analyzer.

Environments.

Instrument response to the sample is the summation of the

Current edition approved April 15, 1993. Published June 1993. Originally

published as F 1398 – 92. Last previous edition F 1398 – 92. response for each hydrocarbon reaching the detector. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1398–93 (1999)

concentration reported is the methane concentration, from the 2.3.9 V-3, V-4 = inlet and outlet valves of test loop, respec-

calibrationcurvethatcorrespondstotheinstrumentresponseto tively.

the sample. The sample’s concentration is equivalent to the

3. Significance and Use

methaneconcentrationthatwouldproducethesameinstrument

3.1 The purpose of this test method is to define a procedure

response.

for testing components being considered for installation into a

2.1.5 minimum detection limit (MDL) of the instrument—

high-purity gas distribution system. Application of this test

the lowest instrument response above zero detectable that is

method is expected to yield comparable data among compo-

readable by the instrument and at least two times the amplitude

nents tested for purposes of qualification for this installation.

of the noise.

2.1.6 response time—the time required for the system to

4. Apparatus

reach steady state after a measurable change in concentration.

4.1 Materials:

2.1.7 spool piece—a null component, consisting of a

4.1.1 Test Gas, purified nitrogen or argon with a maximum

straightpieceofelectropolishedtubingandappropriatefittings,

THC concentration not exceeding the manufacturer’s stated

used in place of the test component to establish the baseline.

minimum detection limit of the instrument (MDL). Particulate

2.1.8 standard conditions—101.3 kPa, 0.0°C (14.73 psia,

filtration of the test gas to 0.02 µm or finer is required, using a

32°F).

typical electronics grade filter. The filter must be compatible

2.1.9 test component—any device being tested, such as a

with the 94°C (200°F) bake-out.

valve, regulator, or filter.

4.1.2 Spool Piece, that can be installed in place of the test

2.1.10 test stand—the physical test system used to measure

component is required. This piece is to be a straight section of

impurity levels.

316Lelectropolished stainless steel tubing with no restrictions.

2.1.11 zero gas—a gas that has a THC concentration below

Thelengthofthespoolpieceshallbe200mm.Thespoolpiece

the MDLof the analytical instrument. This purified gas is used

shall have the same end connections as the test component.

for both instrument calibration and component testing.

4.1.2.1 Components with Stub Ends—Use compression fit-

2.2 Abbreviations: Abbreviations:

tings with nylon or teflon ferrules to connect the spool piece

2.2.1 FID—flame ionization detector.

and test component to the test loop. Keep the purged glove bag

2.2.2 MFC—mass flow controller.

around each component for the duration of the test. In the case

2.2.3 MS—mass spectrometer.

of long pieces of electropolished tubing, use two glove bags,

2.2.4 ppbv—parts per billion by volume assuming ideal gas

one at each end.

behavior, equivalent to nmole/mole (such as nL/L).

4.1.3 Tubing, used downstream of the purifier shall be 316L

2.2.4.1 Discussion—The same as molar parts per billion

electropolishedstainlesssteelseamlesstubing.Thediameterof

(ppb).

the sample line to the analyzer shall not be larger than 6.4 mm

2.2.5 ppbw—parts per billion by weight (such as ng/g).

( ⁄4 in.). The length of the sample line from the tee (installed

2.2.6 ppmv—parts per million by volume assuming ideal

upstream of the pressure gage P ) to the analyzer shall not be

gas behavior, equivalent to µmole/mole (such as µL/L).

more than 600 mm to minimize the effect (adsorption/

2.2.6.1 Discussion—The same as molar parts per million

desorption) of the sample line on the result. The sample line

(ppm).

shall have no more than two mechanical joints.

2.2.7 ppmw—parts per million by weight (such as µg/g).

4.1.4 Valves, diaphragm or bellows type and must be ca-

2.2.8 slpm—standard liters per minute. The gas volumetric

pable of unimpaired operation at 94°C (200°F). The use of

flow rate measured in liters per minute at 0.0°C (32°F) and

all-welded, all-metal valves is preferred.

101.3 kPa (1 atm).

4.2 Instrumentation:

2.2.9 THC—total hydrocarbon.

4.2.1 THC Analyzer— The THC analyzer is to be placed

2.3 Symbols:

downstream of the test component.Accurate baseline readings

2.3.1 P —the inlet pressure measured upstream of the

must be obtained prior to and subsequent to each of the tests.

purifier and filter in the test apparatus.

The baseline must return to levels <100 ppbv, before and after

2.3.2 P —the outlet measured downstream of the analyzer

the tests. Deviations greater than this require that all results be

in the test apparatus.

rejectedandanewtestcomponentbetested.Theanalyzermust

2.3.3 Q = the bypass sample flow not going through the

1 be capable of accurately recording changes in THC concentra-

analytical system.

tions on a real-time basis, within the constraints of the data

2.3.4 Q = the total sample flow through the analytical

2 acquisition system.

system.

4.2.2 THC analyzer calibration—Two-point calibration,

2.3.5 Q = the flow through the spool piece or component.

s zero and span, is to be performed regularly. Zero gas is defined

2.3.6 T = the temperature of the air discharged by the

as below the manufacturer’s stated MDL of the instrument,

a

analyzer’s cooling exhaust.

supplied by purified gas, with the purifier in close proximity to

2.3.7 T = the temperature of the spool piece or component.

the analyzer. Span gas is analyzed at the lowest possible

s

2.3.7.1 Discussion—The thermocouple must be located in

detectionrange,whichmaynotbeatthelowestdetectionrange

contact with the outside wall of the component or spool piece. oftheinstrument.Spangasis5–10ppmvmethane, 620 %for

2.3.8 V-1, V-2 = inlet and outlet valves of bypass loop, FID. Calibration is based on traceable methane concentration

respectively. in the base gas (nitrogen or argon).

F 1398–93 (1999)

4.2.3 Flame Ionization Detector (FID)—The FID detects 5.1.3 Do not exceed ratings (such as pressure, temperature,

hydrocarbon species by ionizing the organic material in a and flow) of the component.

flame. Ions produced in the hydrogen flame yield a measurable 5.1.4 Gloves are to be worn for all steps.

current, directly related to the quantity of hydrocarbons intro- 5.1.5 Limit exposure of the instrument and test component

duced to the flame. Burner gases, hydrogen, and air are not to

to atmospheric and hydrocarbon contamination before and

containmeasurableamountsofTHC.Purifiersareavailablefor during the test.

this purpose (especially to remove methane). Burner gases

5.1.6 Precautions must be taken to insure that the tempera-

must be maintained at a temperature between 18 and 26°C (64 ture measured by the thermocouple is as close as possible to

and 78°F).

that of the spool piece or the test component. Use appropriate

4.2.3.1 The THC data are referred to as ppmv quantity of insulation and conductive shield to achieve as uniform a

CH equivalents, corresponding to the sum of the number of

temperature as possible.

equivalent carbons. Simple, low molecular weight hydrocar-

5.1.7 Ensure that adequate mixing of the test gas is attained.

bons are readily detected and quantified as total THC. Higher

molecular weight hydrocarbons and more substituted hydro-

6. Preparation of Apparatus

carbons may not be detected well. The FID is, therefore, a

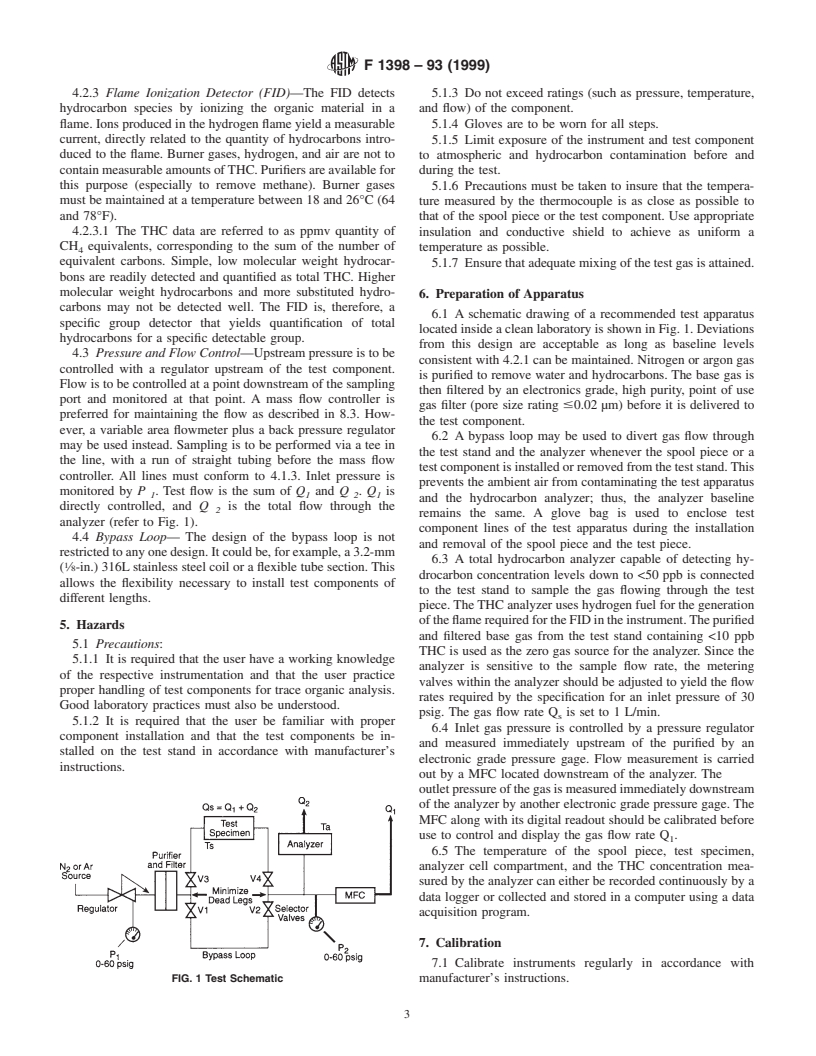

6.1 A schematic drawing of a recommended test apparatus

specific group detector that yields quantification of total

located inside a clean laboratory is shown in Fig. 1. Deviations

hydrocarbons for a specific detectable group.

from this design are acceptable as long as baseline levels

4.3 Pressure and Flow Control—Upstream pressure is to be

consistent with 4.2.1 can be maintained. Nitrogen or argon gas

controlled with a regulator upstream of the test component.

is purified to remove water and hydrocarbons. The base gas is

Flow is to be controlled at a point downstream of the sampling

then filtered by an electronics grade, high purity, point of use

port and monitored at that point. A mass flow controller is

gas filter (pore size rating#0.02 µm) before it is delivered to

preferred for maintaining the flow as described in 8.3. How-

the test component.

ever, a variable area flowmeter plus a back pressure regulator

6.2 A bypass loop may be used to divert gas flow through

may be used instead. Sampling is to be performed via a tee in

the test stand and the analyzer whenever the spool piece or a

the line, with a run of straight tubing before the mass flow

testcomponentisinstalledorremovedfromtheteststand.This

controller. All lines must conform to 4.1.3. Inlet pressure is

prevents the ambient air from contaminating the test apparatus

monitored by P . Test flow is the sum of Q and Q . Q is

1 1 2 1

and the hydrocarbon analyzer; thus, the analyzer baseline

directly controlled, and Q is the total flow through the

remains the same. A glove bag is used to enclose test

analyzer (refer to Fig. 1).

component lines of the test apparatus during the installation

4.4 Bypass Loop— The design of the bypass loop is not

and removal of the spool piece and the test piece.

restrictedtoanyonedesign.Itcouldbe,forexample,a3.2-mm

6.3 A total hydrocarbon analyzer capable of detecting hy-

( ⁄8-in.) 316Lstainless steel coil or a flexible tube section. This

drocarbon concentration levels down to <50 ppb is connected

allows the flexibility necessary to install test components of

to the test stand to sample the gas flowing through the test

different lengths.

piece.TheTHC analyzer uses hydrogen fuel for the generation

oftheflamerequiredfortheFIDintheinstrument.Thepurified

5. Hazards

and filtered base gas from the test stand containing <10 ppb

5.1 Precautions:

THC is used as the zero gas source for the analyzer. Since the

5.1.1 It is required that the user have a working knowledge

analyzer is sensitive to the sample flow rate, the metering

of the respective instrumentation and that the user practice

valves within the analyzer should be adjusted to yield the flow

proper handling of test components for trace organic analysis.

rates required by the specification for an inlet pressure of 30

Good laboratory practices must also be understood.

psig. The gas flow rate Q is set to 1 L/min.

s

5.1.2 It is required that the user be familiar with proper

6.4 Inlet gas pressure is controlled by a pressure regulator

component installation and that the test components be in-

and measured immediately upstream of the purified by an

stalled on the test stand in accordance with manufacturer’s

electronic grade pressure gage. Flow measurement is carried

instructions.

o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.