ASTM A1018/A1018M-01a

(Specification)Standard Specification for Steel, Sheet and Strip, Heavy Thickness Coils, Hot Rolled, Carbon, Structural, High-Strength Low-Alloy, Columbium or Vanadium, and High-Strength Low-Alloy with Improved Formability

Standard Specification for Steel, Sheet and Strip, Heavy Thickness Coils, Hot Rolled, Carbon, Structural, High-Strength Low-Alloy, Columbium or Vanadium, and High-Strength Low-Alloy with Improved Formability

SCOPE

1.1 This specification covers hot rolled, heavy thickness coils beyond the size limits of specification A1011.

1.2 The product is available in three designations; Structural Steel, and High-Strength Low-Alloy Steel, Columbium or Vanadium, and High-Strength Low-Alloy Steel with Improved Formability.

1.3 This material is available only in coils described as follows:ProductSize Limits, Coils Only Width, in [mm]Thickness, in [mm]Strip Over 8 to 12, incl

[Over 200 to 300] 0.230 to 1.000, incl

[Over 6.0 to 25]Sheet Over 12 to 48, incl

[Over 300 to 1200] 0.230 to 1.000, incl

[Over 6.0 to 25]Sheet Over 48

[Over 1200]0.180 to 1.000, incl

[Over 4.5 to 25]

1.4 Sheet and strip in coils of sizes noted in 1.3 are covered by this specification only with the following provisions:

1.4.1 The material is not to be converted into steel plates for structural or pressure vessel use unless tested in complete accordance with the appropriate sections of Specifications A6/A6M (plates provided from coils) or A20/A20M (plates produced from coils). Plate produced in this manner is no longer governed by this sheet steel specification and since this material is now plate, the appropriate plate standard must now apply.

1.4.2 This specification is not applicable to the steels covered by Specification A635/A635M.

1.4.3 The dimensional tolerances of Specification A635/A635M are applicable to material produced to this specification.

1.4.4 The material is to be fed directly from coils into a blanking press, drawing or forming operation, tube mill, rolling mill, or sheared or slit into blanks for subsequent drawing or forming.

1.4.5 Not all strength levels are available in all thicknesses. The user should consult the producer for appropriate size limitations.

1.5 The values stated in either inch-pound units or SI units [metric] are to be regarded separately as standard. Within the text the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 1018/A 1018M – 01a

Standard Specification for

Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled,

Carbon, Structural, High-Strength Low-Alloy, Columbium or

Vanadium, and High-Strength Low-Alloy with Improved

Formability

This standard is issued under the fixed designation A 1018/A 1018M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope mill, or sheared or slit into blanks for subsequent drawing or

forming.

1.1 This specification covers hot-rolled, heavy-thickness

1.4.5 Not all strength levels are available in all thicknesses.

coils beyond the size limits of specification A 1011.

The user should consult the producer for appropriate size

1.2 The product is available in three designations: Structural

limitations.

Steel; High-Strength Low-Alloy Steel, Columbium or Vana-

1.5 The values stated in either inch-pound units or SI units

dium; and High-Strength Low-Alloy Steel with Improved

[metric] are to be regarded separately as standard. Within the

Formability.

text the SI units are shown in brackets. The values stated in

1.3 This material is available only in coils described as

each system are not exact equivalents; therefore, each system

follows:

must be used independently of the other.

Product Size Limits, Coils Only

Width, in. [mm] Thickness, in. [mm]

2. Referenced Documents

Strip Over 8 to 12, incl 0.230 to 1.000, incl

2.1 ASTM Standards:

[Over 200 to 300] [Over 6.0 to 25]

A 6/A 6M Specification for General Requirements for

Sheet Over 12 to 48, incl 0.230 to 1.000, incl

[Over 300 to 1200] [Over 6.0 to 25]

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

Sheet Over 48 0.180 to 1.000, incl 2

Piling

[Over 1200] [Over 4.5 to 25]

A 20/A 20M Specification for General Requirements for

1.4 Sheet and strip in coils of sizes noted in 1.3 are covered

Steel Plates for Pressure Vessels

by this specification only with the following provisions:

A 370 Test Methods and Definitions for Mechanical Testing

1.4.1 The material is not to be converted into steel plates for

of Steel Products

structural or pressure vessel use unless tested in complete

A 1011 Specification for Steel, Sheet and Strip, Hot-Rolled,

accordance with the appropriate sections of Specifications

Carbon and Structural, and High-Strength Low-Alloy and

A 6/A 6M (plates provided from coils) or A 20/A 20M (plates 3

High-Strength Low-Alloy with Improved Formability

produced from coils). Plate produced in this manner is no

A 635/A 635M Specification for Steel, Sheet and Strip,

longer governed by this sheet steel specification and since this 3

Heavy-Thickness Coils, Carbon, Hot-Rolled

material is now plate, the appropriate plate standard must now

A 751 Test Methods, Practices, and Terminology for

apply. 3

Chemical Analysis of Steel Products

1.4.2 This specification is not applicable to the steels

E 29 Practice for Using Significant Digits in Test Data to

covered by Specification A 635/A 635M. 4

Determine Conformance with Specifications

1.4.3 The dimensional tolerances of Specification A 635/

G 101 Guide for Estimating the Atmospheric Corrosion

A 635M are applicable to material produced to this specifica- 5

Resistance of Low-Alloy Steels

tion.

1.4.4 The material is to be fed directly from coils into a 3. General Requirements for Delivery

blanking press, drawing or forming operation, tube mill, rolling

3.1 Material furnished under this specification shall con-

form to the applicable requirements of the current edition of

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloysand is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.04.

A01.19 on Steel Sheet and Strip. Annual Book of ASTM Standards, Vol 01.03.

Current edition approved Sept. 10, 2001. Published October 2001. Last previous Annual Book of ASTM Standards, Vol 14.02.

edition A 1018/A 1018M-01. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 1018/A 1018M

Specification A 635/A 635M, unless otherwise provided producer, material ordered to this specification will be supplied

herein. to meet the appropriate standard or restricted thickness toler-

ances shown in Specification A 635/A 635M,

4. Classification

NOTE 2—Not all producers are capable of meeting all the limitations of

4.1 Heavy thickness coils are available in the following

the thickness tolerance tables in Specification A 635/A 635M. The pur-

designations:

chaser should contact the producer regarding possible limitations prior to

4.1.1 Structural Steel—(SS grades 30[205], 33[230],

placing an order.

36[250] and 40[275]).

5.1.7 Coils size and weight requirements (must include

4.1.1.1 This material is intended for structural purposes

inside diameter (ID), outside diameter (OD), and maximum

where mechanical test values are required.

weight,

4.1.2 High-Strength Low-Alloy Steel—(HSLAS grades

5.1.8 Quantity (weight),

45[310], 50[340], 55[380], 60[410], 65[450], 70[480]) in

5.1.9 Application (part identification and description).

Classes 1 and 2.

5.1.10 Special requirements, if required, or supplementary

4.1.2.1 This material is intended for miscellaneous applica-

requirements S1 for HSLAS,

tions where greater strength and savings in weight are impor-

5.1.11 A report is required of heat analysis and mechanical

tant. The material is available in two classes. They are similar

properties as determined by the tension test.

in strength level, except that Class 2 offers improved weldabil-

ity and more formability than Class 1. Atmospheric corrosion

NOTE 3—A typical ordering description is as follows: (inch pound

resistance of these steels is equivalent to plain carbon steels.

units) ASTM A 1018/A 1018M: Grade 50, High-Strength, Low-Alloy,

Class 2, hot rolled sheet coils, pickled and oiled, cut edge, 0.500 by 40 in.

With copper specified, the atmospheric corrosion is somewhat

by coil; ID 24 in. , OD 72 in., maximum; coil weight 40 000 lb.,

enhanced.

maximum; 200 000 lb. for roll forming shapes; (SI units) ASTM A 1018/

4.1.3 High-Strength Low-Alloy with Improved

A 1018M: Grade 345, High-Strength Low-Alloy, Class 2, hot-rolled sheet

Formability—(HSLAS-F grades 50[340], 60[410], 70[480],

coils, pickled and oiled, cut edge; 10 mm by 900 mm by coil; ID 600 mm

80[550]).

, OD 1800 mm, maximum; coil weight 18 000 kg maximum; 90 000 kg

4.1.3.1 This material has improved formability when com-

for roll forming shapes.

pared with HSLAS. The steel is killed and made to a fine

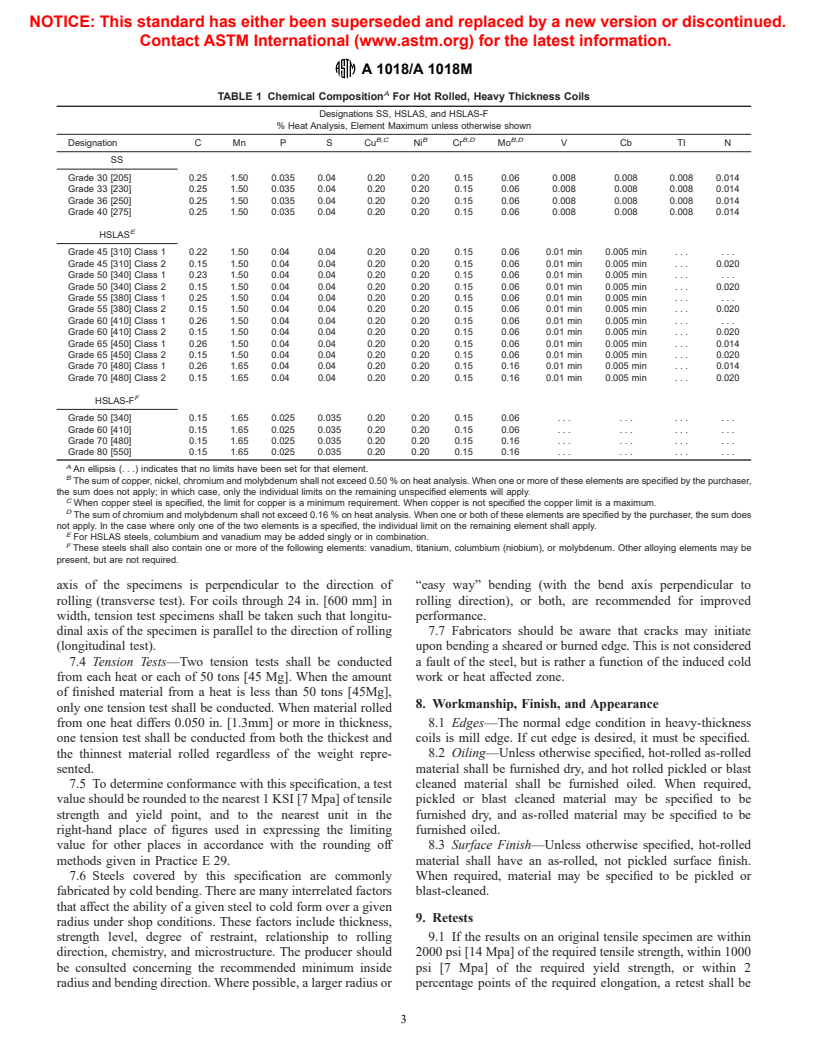

6. Chemical Composition

ferritic grain practice and includes microalloying elements

such as columbium, titanium, vanadium, zirconium, etc. The 6.1 The heat analysis of the steel shall conform to the

steel may be treated to achieve inclusion control. The material

requirements of Table 1.

is intended for miscellaneous applications where higher 6.1.1 Chemical analysis shall be conducted in accordance

strength, savings in weight, improved formability, and weld-

with Test Method A 751.

ability are important. Atmospheric corrosion resistance of these 6.1.2 Each of the elements listed in Table 1 shall be included

steels is equivalent to plain carbon steels. With copper speci-

in the report of the heat analysis. When the amount of copper,

fied, the atmospheric corrosion resistance is somewhat en-

nickel, chromium, or molybdenum is less than 0.02 %, the

hanced.

analysis may be reported as less than (<) 0.02 %, When the

amount of columbium, titanium, or vanadium is less than

NOTE 1—For methods of establishing the atmospheric corrosion resis-

0.008 %, the analysis may be reported as less than (<) 0.008 %.

tance of low-alloy steels, see Guide G 101.

6.1.3 For Structural Steel (SS) the addition of microalloying

5. Ordering Information

elements, including columbium, vanadium, or titanium, as well

as nitrogen, as strength enhancers is prohibited.

5.1 Orders for material under this specification shall include

6.1.4 When the steel is used in welded applications, the

the following information, as required, to describe adequately

welding procedure selected shall be compatible with the

the desired material.

chemical composition of the steel grade specified and the

5.1.1 ASTM specification number and year of issue.

intended service.

5.1.2 Name of material and designation (hot-rolled steel

sheet or hot-rolled strip) (include grade and, as appropriate,

7. Mechanical Properties

type and class for SS, HSLAS, and HSLAS-F) (see section

4.1). 7.1 Test specimen preparation and mechanical testing shall

be in accordance with Test Method A 370.

5.1.2.1 For HSLAS, when a class is not specified class 1

will be furnished) (see section 4.1), 7.2 Tensile Properties—The material as represented by the

test specimens shall conform to the mechanical property

5.1.3 Copper bearing, (if required),

5.1.4 Condition—Material in accordance with this specifi- requirements as stated in Table 2. These requirements do not

cation is furnished in the hot rolled condition. Pickled (or blast apply to the uncropped ends of unprocessed coils.

cleaned) must be specified if required. Material ordered as 7.3 Tension Test Specimen Location and Orientation—

pickled (or blast cleaned) will be oiled unless ordered dry, Tension test specimens shall be taken sufficiently far from the

5.1.5 Type of edge must be specified for hot rolled sheet as hot-rolled coil ends so that the sample is representative of

coils and strip coils, either mill edge or cut edge (sheet), mill material which received the designed processing. The test shall

edge or slit edge (strip), be taken approximately midway between the center and edge

5.1.6 Dimensions (decimal thickness and width of material), of the material as rolled. For coils wider than 24 in. [600 mm],

5.1.6.1 As agreed upon between the purchaser and the Tension test specimens shall be taken such that the longitudinal

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 1018/A 1018M

A

TABLE 1 Chemical Composition For Hot Rolled, Heavy Thickness Coils

Designations SS, HSLAS, and HSLAS-F

% Heat Analysis, Element Maximum unless otherwise sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.