ASTM D6667-04(2010)

(Test Method)Standard Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet Fluorescence

Standard Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet Fluorescence

SIGNIFICANCE AND USE

The sulfur content of LPG, used for fuel purposes, contributes to SOx emissions and can lead to corrosion in engine and exhaust systems. Some process catalysts used in petroleum and chemical refining can be poisoned by sulfur bearing materials in the feed stocks. This test method can be used to determine sulfur in process feeds, to measure sulfur in finished products, and can also be used for compliance determinations when acceptable to a regulatory authority.

SCOPE

1.1 This test method covers the determination of total volatile sulfur in gaseous hydrocarbons and liquefied petroleum (LP) gases. It is applicable to analysis of natural, processed, and final product materials containing sulfur in the range of 1 to 100 mg/kg (Note 1).

Note 1—An estimate of pooled limit of quantification (PLOQ), information regarding sample stability and other general information derived from the inter-laboratory study on precision can be referenced in the ASTM research report.

1.2 This test method may not detect sulfur compounds that do not vaporize under the conditions of the test.

1.3 This test method is applicable for total volatile sulfur determination in LP gases containing less than 0.35 % (mass/mass) halogen(s).

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 3.1 and Sections 6 and 7 for specific warning statements.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6667 – 04 (Reapproved 2010)

Standard Test Method for

Determination of Total Volatile Sulfur in Gaseous

Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet

Fluorescence

This standard is issued under the fixed designation D6667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3700 Practice for Obtaining LPG Samples Using a Float-

ing Piston Cylinder

1.1 This test method covers the determination of total

D5287 Practice for Automatic Sampling of Gaseous Fuels

volatile sulfur in gaseous hydrocarbons and liquefied petro-

D6299 Practice for Applying Statistical Quality Assurance

leum (LP) gases. It is applicable to analysis of natural,

and Control Charting Techniques to Evaluate Analytical

processed, and final product materials containing sulfur in the

Measurement System Performance

range of 1 to 100 mg/kg (Note 1).

F307 Practice for Sampling Pressurized Gas for GasAnaly-

NOTE 1—An estimate of pooled limit of quantification (PLOQ), infor-

sis

mation regarding sample stability and other general information derived

2.2 Gas Processor Association (GPA) Standards:

from the inter-laboratory study on precision can be referenced in the

GPA2166 Obtaining Natural Gas Samples forAnalysis by

ASTM research report.

Gas Chromatography

1.2 This test method may not detect sulfur compounds that

GPA 2174 Obtaining Liquid Hydrocarbon Samples for

do not vaporize under the conditions of the test.

Analysis by Gas Chromatography

1.3 This test method is applicable for total volatile sulfur

determination in LP gases containing less than 0.35 % (mass/

3. Summary of Test Method

mass) halogen(s).

3.1 Aheatedsamplevalveisusedtoinjectgaseoussamples.

1.4 The values stated in SI units are to be regarded as

Liquefied petroleum gas (LPG) samples are injected by a

standard.

sample valve connected to a heated expansion chamber. The

1.5 This standard does not purport to address all of the

gaseous sample then enters a high temperature combustion

safety concerns, if any, associated with its use. It is the

tube where sulfur is oxidized to sulfur dioxide (SO)inan

responsibility of the user of this standard to establish appro-

oxygen rich atmosphere. Water produced during the sample

priate safety and health practices and determine the applica-

combustion is removed and the sample combustion gases are

bility of regulatory limitations prior to use. See 3.1 and

next exposed to ultraviolet (UV) light. The SO absorbs the

Sections 6 and 7 for specific warning statements.

energy from the UV light and is converted to an excited sulfur

*

dioxide (SO ). Fluorescence emitted from the excited SO as

2 2

2. Referenced Documents

*

it returns to a stable state SO is detected by a photomultiplier

2.1 ASTM Standards:

tube,theresultingsignalisameasureofthesulfurcontainedin

D1070 Test Methods for Relative Density of Gaseous Fuels

the sample. (Warning—Exposure to excessive quantities of

D1265 Practice for Sampling Liquefied Petroleum (LP)

ultraviolet light is injurious to health. The operator shall avoid

Gases, Manual Method

exposing their person, especially their eyes, not only to direct

UV light but also to secondary or scattered radiation that is

present.)

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

4. Significance and Use

D02.03 on Elemental Analysis.

Current edition approved May 1, 2010. Published May 2010. Originally

4.1 The sulfur content of LPG, used for fuel purposes,

approved in 2001. Last previous edition approved in 2004 as D6667–04. DOI:

contributes to SOx emissions and can lead to corrosion in

10.1520/D6667-10.

engine and exhaust systems. Some process catalysts used in

Supporting data have been filed at ASTM International Headquarters and may

be obtained by requesting Research Report RR:D02-1506.

petroleum and chemical refining can be poisoned by sulfur

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Gas ProcessorsAssociation (GPA), 6526 E. 60th St.,Tulsa, OK

the ASTM website. 74145.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6667 – 04 (2010)

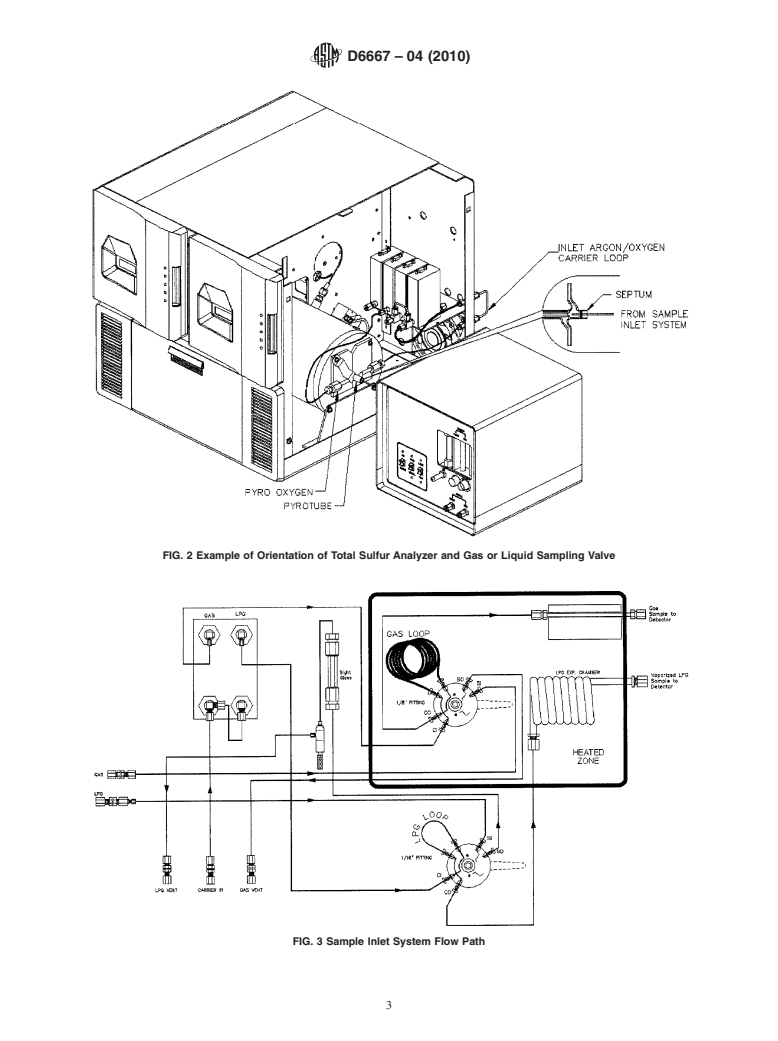

FIG. 1 Example of a Typical Direct Inject Quartz Pyrolysis Tube

bearing materials in the feed stocks. This test method can be 5.7 Strip Chart Recorder, equivalent electronic data logger,

used to determine sulfur in process feeds, to measure sulfur in integrator or, recorder (optional).

finished products, and can also be used for compliance deter-

minations when acceptable to a regulatory authority.

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be

5. Apparatus

used in tests. Unless otherwise indicated, it is intended that all

5.1 Furnace—An electric furnace held at a temperature

reagents shall conform to the specifications of the Committee

(1075 6 25°C) sufficient to pyrolyze the entire sample and 5

on Analytical Reagents of the American Chemical Society,

oxidize sulfur to SO .

where such specifications are available. Other grades may be

5.2 Combustion Tube—A quartz combustion tube con-

used, provided it is first ascertained that the reagent is of

structed to allow the direct injection of the sample into the

sufficiently high purity to permit its use without lessening the

heated oxidation zone of the furnace. The combustion tube

accuracy of the determination.

shall have side arms for the introduction of oxygen and carrier

6.2 Inert Gas—Argon or helium only, high purity grade

gas. The oxidation section shall be large enough (see Fig. 1)to

(that is, chromatography or zero grade), 99.998 % min purity,

ensure complete combustion of the sample (see 11.3). Fig. 1

moisture 5 mg/kg max. (Warning—Argon or helium may be a

depicts a typical combustion tube. Other configurations are

compressed gas under high pressure (7.1)).

acceptable when precision is not degraded.

6.3 Oxygen—High purity (that is chromatography or zero

5.3 Flow Control—The apparatus shall be equipped with

grade), 99.75 % min purity, moisture 5 mg/kg max, dried over

flow controllers capable of maintaining a constant supply of

molecular sieves. (Warning—Oxygen vigorously accelerates

oxygen and carrier gas at the specified rates.

combustion and may be compressed gas under high pressure

5.4 Drier Tube—The apparatus shall be equipped with a

(7.1)).

mechanism for the removal of water vapor formed during

6.4 Calibration Standards—Certified calibration standards

sample combustion. This can be accomplished with a mem-

from commercial sources or calibration gases prepared using

brane drying tube, or a permeation dryer that utilizes a

certified permeation tube devices are required. Table 1 lists the

selective capillary action for water removal.

sulfur source material and diluent matrices used during the

5.5 UV Fluorescence Detector—A quantitative detector ca-

inter-laboratory study (Notes 2 and 3).

pable of measuring light emitted from the fluorescence of

NOTE 2—Other sulfur sources and diluent materials may be used if

sulfur dioxide by UV light.

precision and accuracy are not degraded.

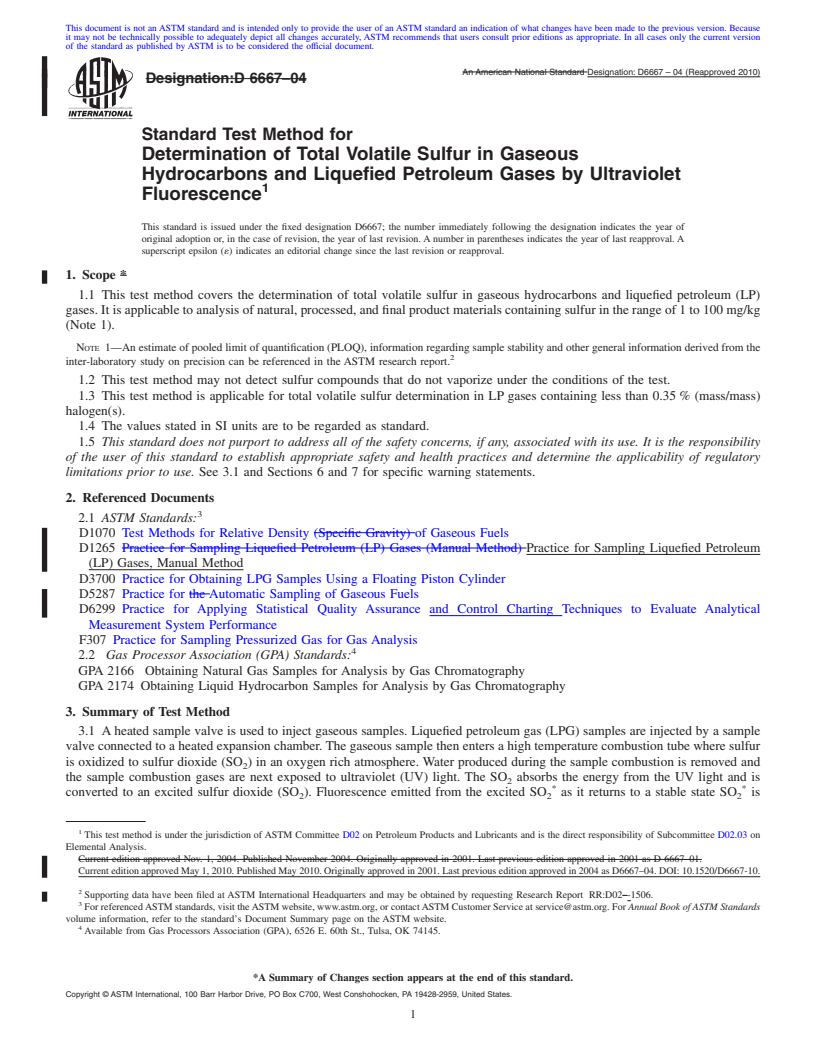

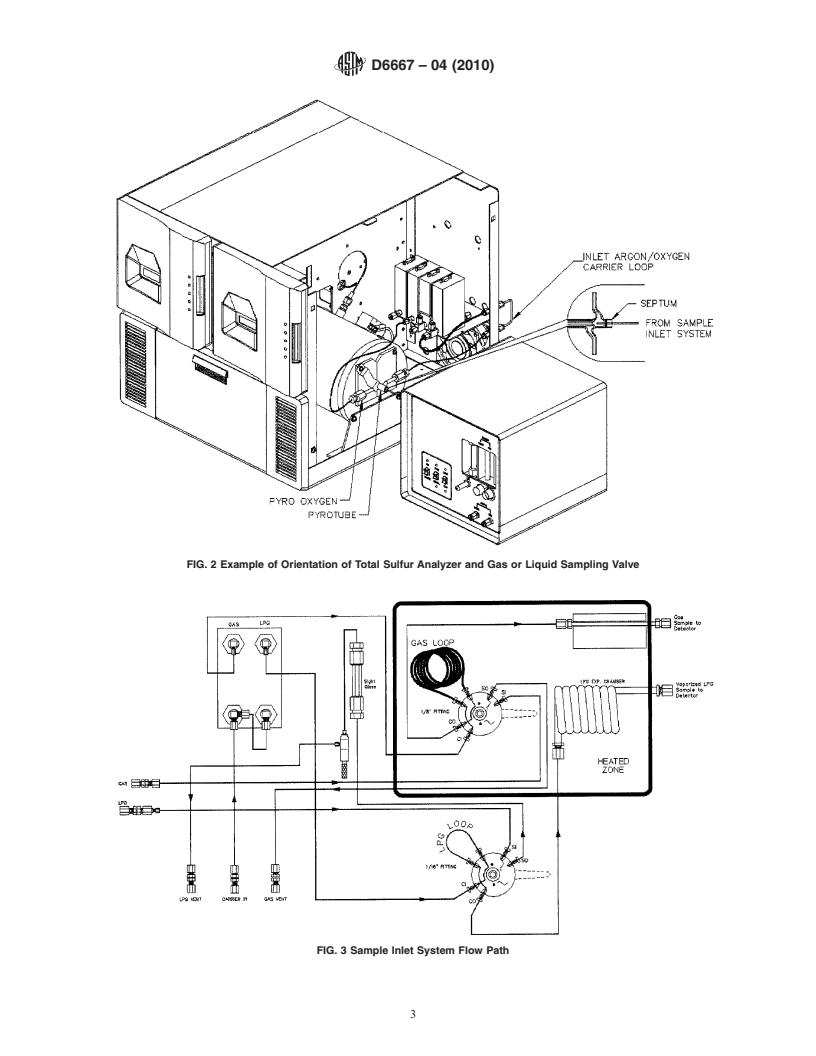

5.6 Sample Inlet System—The system provides a heated

gas-sampling valve, or a LP gas-sampling valve, or both, with

a heated expansion chamber, connected to the inlet of the

oxidation area, Fig. 2. The system is swept by an inert carrier

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

gas and shall be capable of allowing the quantitative delivery

listed by the American Chemical Society, see Analar Standards for Laboratory

of the material to be analyzed into the oxidation zone at a

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

controlled and repeatable rate of approximately 30 mL/min.

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

Fig. 3 provides an example. MD.

D6667 – 04 (2010)

FIG. 2 Example of Orientation of Total Sulfur Analyzer and Gas or Liquid Sampling Valve

FIG. 3 Sample Inlet System Flow Path

D6667 – 04 (2010)

TABLE 1 Typical Standard Materials TABLE 3 Typical Sulfur Calibration Ranges and Standard

Concentrations

Sulfur Source Diluent

Curve I Curve II

Dimethyl sulfide n, butane

Sulfur mg/kg Sulfur mg/kg

iso-butane

propylene

Blank Blank

propane

5.00 10.00

10.00 50.00

100.00

NOTE 3—Calibration standards are typically re-mixed and re-certified

on a regular basis depending upon frequency of use and age. These

than those indicated may be used if desired. However, the

calibration standards may have a useful life of about 6 to 12 months.

method precision using narrower ranges than those indicated

6.5 Quality Control (QC) Samples, preferably are portions

has not been determined. Ensure the standards used for

of one or more gas or LP gas materials that are stable and

calibration bracket the concentrations of the samples being

representative of the samples of interest.

analyzed.

7. Hazards

NOTE 4—The number of standards used per curve may vary.

7.1 High temperature, flammable hydrocarbons, and gases

10.2 With the sample valve in the load position, connect the

under high pressures occur in the test method. Use materials

pressurized sample container to the sample valve of the sample

that are rated for containing these pressurized hydrocarbons in

inlet system.

all sample containers and sample transfer apparatus. Exercise

10.3 Obtain a quantitative measurement of the injected

extra care when using flammable materials near the oxidative

material by filling the sample loop of the sample valve system

furnace.

for the matrix being analyzed (see Table 2) (Notes 5 and 6).

NOTE 5—Injection of a constant or similar sample size for all materials

8. Sampling

analyzed in a selected operating range promotes consistent combustion

8.1 Obtain a sample in accordance with Practices F307,

conditions and may simplify result calculations.

D1265, D3700, D5287,or GPA 2174 or GPA 2166. Analyze

NOTE 6—An automatic sample transfer and injection device may be

samples as soon as possible after taking from bulk supplies to

used.

prevent loss of sulfur or contamination due to exposure or

10.3.1 Flush the sample loop with sufficient calibrant to

contact with sample containers.

assure that the material to be injected is representative.

8.2 If the sample is not used immediately, then thoroughly

10.3.2 For LPG samples, if bubbles are present in the

mix it in its container prior to taking a test specimen. The use

viewable portion of the liquid column, flush the sample loop to

of segregated or specially treated sample containers can help

introduce a new liquid-full sample portion.

reduce sample cross-contamination and improve sample sta-

10.4 Start the analyzer and inject the calibration material

bility.

according to the manufacturer’s instructions.

10.5 Calibrate the instrument using one of the following

9. Preparation of Apparatus

techniques.

9.1 Assembleandchecktheapparatusforleaksaccordingto

10.5.1 Multi-point Calibration:

manufacturer’s instructions.

10.5.1.1 When the apparatus features an internal self-

9.2 Typical apparatus adjustments and conditions are listed

calibration routine, analyze the calibration standards and blank

in Table 2.

three times using the procedures described in 10.2-10.4.

9.3 Adjust instrument sensitivity and baseline stability and

10.5.1.2 Calibrate the analyzer according to the manufac-

perform instrument-blanking procedures following manufac-

turer’s instructions to yield sulfur concentration (see Section

turer’s guidelines.

13).Thiscurveistypicallylinearandsystemperformanceshall

be checked at least once per day, each day of use. (Note 7).

10. Calibration and Standardization

NOTE 7—Other calibration curve techniques may be used when accu-

10.1 ConsultTable 3 and select a calibration range based on

racy and precision are not degraded. The frequency of calibration may be

the anticipated sulfur concentrations present in samples to be

determined by the use of quality control charts or other quality assurance/

analyzed, preferably using a sulfur compound and a diluent

quality control techniques.

type representative of the samples to be analyzed (Note 4).

10.5.2 One-point Calibration:

Table 3 is representative of typical ranges, but narrower ranges

TABLE 4 Repeatability (r) and Reproducibility (R)

TABLE 2 Typical Operating Conditions

Concentration

Sample inlet system temperature 85 6 20°C rR

(mg/kg S)

Sample injection system carrier gas 25–30 mL/min

Furnace temperature 1075 6 25°C 1 0.1 0.3

Furnace oxygen flow meter setting 375–450 mL/min 5 0.6 1.6

Inlet oxygen flow meter setting 10–30 mL/min 10 1.2 3.1

Inlet carrier flow meter setting 130–160 mL/min 25 2.9 7.8

Gas sample size 10–20 mL 50 5.8 15.6

LPG sample size 15 µL 100 11.5 31.3

D6667 – 04 (2010)

Ac

10.5.2.1 Utilize a calibration standard (6.4) with a sulfur

K 5 (3)

Vc 3 Scv

content close to that of the samples to be analyzed (625 %

max.).

where:

10.5.2.2 Follow the instrument manufacturer’s instructions

Ac = integrated detector response for calibration standard,

to establish an instrument zero (instrument blank) by conduct-

in counts, and

ing an analysis run without injection of the calibration stan-

Mc = mass of calibration standard injected, in milligrams,

dard.

either measured directly or calculated from measured

10.5.2.3 Performmeasurementsofthecalibrationstandarda

volume injected and density.

minimum of three times.

Mc 5 V 3 Dc (4)

10.5.2.4 Calculate a calibration factor K, in counts per

nanogram of sulfur (counts/ng S) as described in 12.2.

where:

Dc = density of calibration standard at measurement tem-

11. Procedure

perature, g/mL,

11.1 Obtain a test specimen using the procedure described

Vc = volume of calibration standard injected, µL,

in Section 8. Typically the sulfur concentration in the test

Scg = sulfur content of calibration standard, mL/kg, and

specimen is less than the concentration of the highest standard

Scv = sulfur content of calibration standard, mg/L.

and greater than the concentration of the lowest standard used

12.2.1 Calculate the average of the calibration factor (K)

in the calibration.

and check that the standard de

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: D6667 – 04 (Reapproved 2010)

Designation:D 6667–04

Standard Test Method for

Determination of Total Volatile Sulfur in Gaseous

Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet

Fluorescence

This standard is issued under the fixed designation D6667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope *

1.1 This test method covers the determination of total volatile sulfur in gaseous hydrocarbons and liquefied petroleum (LP)

gases. It is applicable to analysis of natural, processed, and final product materials containing sulfur in the range of 1 to 100 mg/kg

(Note 1).

NOTE 1—An estimate of pooled limit of quantification (PLOQ), information regarding sample stability and other general information derived from the

inter-laboratory study on precision can be referenced in the ASTM research report.

1.2 This test method may not detect sulfur compounds that do not vaporize under the conditions of the test.

1.3 This test method is applicable for total volatile sulfur determination in LP gases containing less than 0.35 % (mass/mass)

halogen(s).

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. See 3.1 and Sections 6 and 7 for specific warning statements.

2. Referenced Documents

2.1 ASTM Standards:

D1070 Test Methods for Relative Density (Specific Gravity) of Gaseous Fuels

D1265 Practice for Sampling Liquefied Petroleum (LP) Gases (Manual Method) Practice for Sampling Liquefied Petroleum

(LP) Gases, Manual Method

D3700 Practice for Obtaining LPG Samples Using a Floating Piston Cylinder

D5287 Practice for the Automatic Sampling of Gaseous Fuels

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

F307 Practice for Sampling Pressurized Gas for Gas Analysis

2.2 Gas Processor Association (GPA) Standards:

GPA 2166 Obtaining Natural Gas Samples for Analysis by Gas Chromatography

GPA 2174 Obtaining Liquid Hydrocarbon Samples for Analysis by Gas Chromatography

3. Summary of Test Method

3.1 Aheated sample valve is used to inject gaseous samples. Liquefied petroleum gas (LPG) samples are injected by a sample

valve connected to a heated expansion chamber.The gaseous sample then enters a high temperature combustion tube where sulfur

is oxidized to sulfur dioxide (SO ) in an oxygen rich atmosphere. Water produced during the sample combustion is removed and

the sample combustion gases are next exposed to ultraviolet (UV) light. The SO absorbs the energy from the UV light and is

* *

converted to an excited sulfur dioxide (SO ). Fluorescence emitted from the excited SO as it returns to a stable state SO is

2 2 2

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved Nov. 1, 2004. Published November 2004. Originally approved in 2001. Last previous edition approved in 2001 as D 6667–01.

Current edition approved May 1, 2010. Published May 2010. Originally approved in 2001. Last previous edition approved in 2004 as D6667–04. DOI: 10.1520/D6667-10.

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02–-1506.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Gas Processors Association (GPA), 6526 E. 60th St., Tulsa, OK 74145.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6667 – 04 (2010)

detected by a photomultiplier tube, the resulting signal is a measure of the sulfur contained in the sample. (Warning—Exposure

to excessive quantities of ultraviolet light is injurious to health. The operator shall avoid exposing their person, especially their

eyes, not only to direct UV light but also to secondary or scattered radiation that is present.)

4. Significance and Use

4.1 The sulfur content of LPG, used for fuel purposes, contributes to SOx emissions and can lead to corrosion in engine and

exhaust systems. Some process catalysts used in petroleum and chemical refining can be poisoned by sulfur bearing materials in

the feed stocks. This test method can be used to determine sulfur in process feeds, to measure sulfur in finished products, and can

also be used for compliance determinations when acceptable to a regulatory authority.

5. Apparatus

5.1 Furnace—An electric furnace held at a temperature (1075 6 25°C) sufficient to pyrolyze the entire sample and oxidize

sulfur to SO .

5.2 Combustion Tube—A quartz combustion tube constructed to allow the direct injection of the sample into the heated

oxidation zone of the furnace. The combustion tube shall have side arms for the introduction of oxygen and carrier gas. The

oxidationsectionshallbelargeenough(seeFig.1)toensurecompletecombustionofthesample(see11.3).Fig.1depictsatypical

combustion tube. Other configurations are acceptable when precision is not degraded.

5.3 Flow Control—The apparatus shall be equipped with flow controllers capable of maintaining a constant supply of oxygen

and carrier gas at the specified rates.

5.4 Drier Tube—The apparatus shall be equipped with a mechanism for the removal of water vapor formed during sample

combustion.Thiscanbeaccomplishedwithamembranedryingtube,orapermeationdryerthatutilizesaselectivecapillaryaction

for water removal.

5.5 UV Fluorescence Detector—A quantitative detector capable of measuring light emitted from the fluorescence of sulfur

dioxide by UV light.

5.6 Sample Inlet System—The system provides a heated gas-sampling valve, or a LPgas-sampling valve, or both, with a heated

expansion chamber, connected to the inlet of the oxidation area, Fig. 2. The system is swept by an inert carrier gas and shall be

capable of allowing the quantitative delivery of the material to be analyzed into the oxidation zone at a controlled and repeatable

rate of approximately 30 mL/min. Fig. 3 provides an example.

5.7 Strip Chart Recorder, equivalent electronic data logger, integrator or, recorder (optional).

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in tests. Unless otherwise indicated, it is intended that all

FIG. 1 Example of a Typical Direct Inject Quartz Pyrolysis Tube

D6667 – 04 (2010)

FIG. 2 Example of Orientation of Total Sulfur Analyzer and Gas or Liquid Sampling Valve

FIG. 3 Sample Inlet System Flow Path

D6667 – 04 (2010)

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

6.2 Inert Gas—Argon or helium only, high purity grade (that is, chromatography or zero grade), 99.998 % min purity, moisture

5 mg/kg max. (Warning —Argon or helium may be a compressed gas under high pressure (7.1)).

6.3 Oxygen—High purity (that is chromatography or zero grade), 99.75 % min purity, moisture 5 mg/kg max, dried over

molecular sieves. (Warning—Oxygen vigorously accelerates combustion and may be compressed gas under high pressure (7.1)).

6.4 Calibration Standards—Certified calibration standards from commercial sources or calibration gases prepared using

certified permeation tube devices are required. Table 1 lists the sulfur source material and diluent matrices used during the

inter-laboratory study (Notes 2 and 3).

NOTE 2—Other sulfur sources and diluent materials may be used if precision and accuracy are not degraded.

NOTE 3—Calibration standards are typically re-mixed and re-certified on a regular basis depending upon frequency of use and age. These calibration

standards may have a useful life of about 6 to 12 months.

6.5 Quality Control (QC) Samples, preferably are portions of one or more gas or LP gas materials that are stable and

representative of the samples of interest.

7. Hazards

7.1 High temperature, flammable hydrocarbons, and gases under high pressures occur in the test method. Use materials that are

rated for containing these pressurized hydrocarbons in all sample containers and sample transfer apparatus. Exercise extra care

when using flammable materials near the oxidative furnace.

8. Sampling

8.1Obtain a sample in accordance with Practices F 307F 307, D 1265D 1265, D 3700D 3700, D 5287D 5287, or GPA-2174 or

GPA-2166

8.1 Obtain a sample in accordance with Practices F307, D1265, D3700, D5287, or GPA 2174 or GPA 2166. Analyze samples

as soon as possible after taking from bulk supplies to prevent loss of sulfur or contamination due to exposure or contact with

sample containers.

8.2 If the sample is not used immediately, then thoroughly mix it in its container prior to taking a test specimen. The use of

segregated or specially treated sample containers can help reduce sample cross-contamination and improve sample stability.

9. Preparation of Apparatus

9.1 Assemble and check the apparatus for leaks according to manufacturer’s instructions.

9.2 Typical apparatus adjustments and conditions are listed in Table 2.

9.3 Adjust instrument sensitivity and baseline stability and perform instrument-blanking procedures following manufacturer’s

guidelines.

10. Calibration and Standardization

10.1Consult

10.1 Consult Table 3 and select a calibration range based on the anticipated sulfur concentrations present in samples to be

analyzed, preferably using a sulfur compound and a diluent type representative of the samples to be analyzed (Note 4). Table 3

isrepresentativeoftypicalranges,butnarrowerrangesthanthoseindicatedmaybeusedifdesired.However,themethodprecision

using narrower ranges than those indicated has not been determined. Ensure the standards used for calibration bracket the

concentrations of the samples being analyzed.

NOTE 4—The number of standards used per curve may vary.

10.2 With the sample valve in the load position, connect the pressurized sample container to the sample valve of the sample

inlet system.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

TABLE 1 Typical Standard Materials

Sulfur Source Diluent

Dimethyl sulfide n, butane

iso-butane

propylene

propane

D6667 – 04 (2010)

TABLE 2 Typical Operating Conditions

Sample inlet system temperature 85 6 20°C

Sample injection system carrier gas 25–30 mL/min

Furnace temperature 1075 6 25°C

Furnace oxygen flow meter setting 375–450 mL/min

Inlet oxygen flow meter setting 10–30 mL/min

Inlet carrier flow meter setting 130–160 mL/min

Gas sample size 10–20 mL

LPG sample size 15 µL

TABLE 3 Typical Sulfur Calibration Ranges and Standard

Concentrations

Curve I Curve II

Sulfur mg/kg Sulfur mg/kg

Blank Blank

5.00 10.00

10.00 50.00

100.00

TABLE 4 Repeatability (r) and Reproducibility (R)

Concentration

rR

(mg/kg S)

1 0.1 0.3

5 0.6 1.6

10 1.2 3.1

25 2.9 7.8

50 5.8 15.6

100 11.5 31.3

10.3 Obtain a quantitative measurement of the injected material by filling the sample loop of the sample valve system for the

matrix being analyzed (see Table 2) (Notes 5 and 6).

NOTE 5—Injection of a constant or similar sample size for all materials analyzed in a selected operating range promotes consistent combustion

conditions and may simplify result calculations.

NOTE 6—An automatic sample transfer and injection device may be used.

10.3.1 Flush the sample loop with sufficient calibrant to assure that the material to be injected is representative.

10.3.2 For LPG samples, if bubbles are present in the viewable portion of the liquid column, flush the sample loop to introduce

a new liquid-full sample portion.

10.4 Start the analyzer and inject the calibration material according to the manufacturer’s instructions.

10.5 Calibrate the instrument using one of the following techniques.

10.5.1 Multi-point Calibration:

10.5.1.1 Whentheapparatusfeaturesaninternalself-calibrationroutine,analyzethecalibrationstandardsandblankthreetimes

using the procedures described in 10.2-10.4.

10.5.1.2 Calibrate the analyzer according to the manufacturer’s instructions to yield sulfur concentration (see Section 13). This

curve is typically linear and system performance shall be checked at least once per day, each day of use. (Note 7).

NOTE 7—Other calibration curve techniques may be used when accuracy and precision are not degraded. The frequency of calibration may be

determined by the use of quality control charts or other quality assurance/quality control techniques.

10.5.2 One-point Calibration:

10.5.2.1 Utilize a calibration standard (6.4) with a sulfur content close to that of the samples to be analyzed (625 % max.).

10.5.2.2 Follow the instrument manufacturer’s instructions to establish an instrument zero (instrument blank) by conducting an

analysis run without injection of the calibration standard.

10.5.2.3 Perform measurements of the calibration standard a minimum of three times.

10.5.2.4 Calculate a calibration factor K, in counts per nanogram of sulfur (counts/ng S) as described in 12.2.

11. Procedure

11.1 Obtain a test specimen using the procedure described in Section 8. Typically the sulfur concentration in the test specimen

is less than

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.