ASTM D1189-61(1973)

(Test Method)Method of Test for Vacuum Distillation of Liquid and Semi-Solid Asphaltic Materials to Obtain a Residue of Specified Penetration (Withdrawn 1979)

Method of Test for Vacuum Distillation of Liquid and Semi-Solid Asphaltic Materials to Obtain a Residue of Specified Penetration (Withdrawn 1979)

General Information

Standards Content (Sample)

~~r~ Designation: D 1189 - 61 (Reapproved 1973)

Standard Test Method for

VACUUM DISTILLATION OF LIQUID AND SEMI

SOLID ASPHALTIC MATERIALS TO OBTAIN A

RESIDUE OF SPECIFIED PENETRATION 1

This Standard is issued under the fixed designation D 1189; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of

last reapproval.

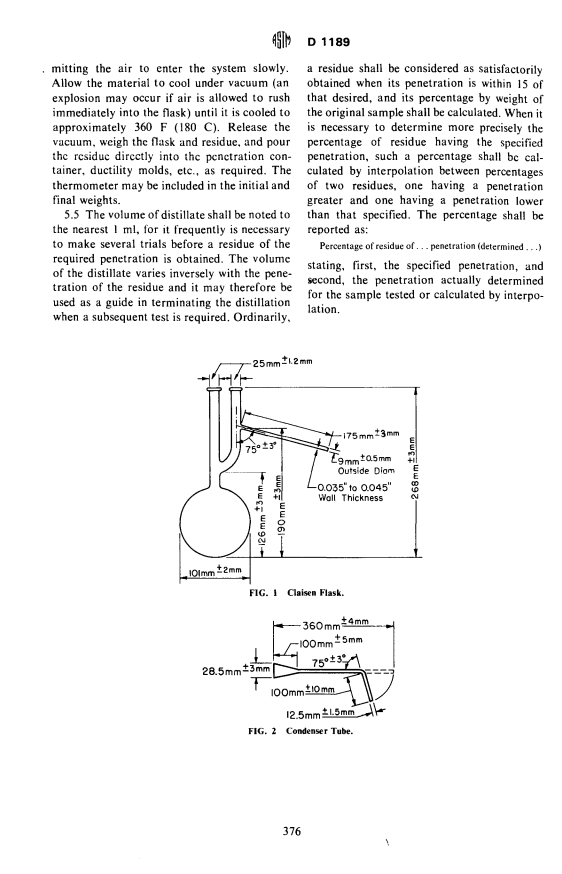

1. Scope Outside diameter of small end 12.5 ± 1.5 mm

28.5 ± 3.0 mm

Outside diameter of large end

1.1 This method of test covers the determi

Length 360.0 ± 4.0 mm

Length of tapered part 100.0 ± 5.0 mm

nation, by vacuum <;Iistillation and with the

elimination of oxidation effects, ofthe quantity

The condenser tube shall be as shown in Fig. 2,

of asphaltic residue of specified penetration.

with a 75-deg angle smooth bend toward the

When the penetration of the residue is not

and with approximately a 100-mm

outlet,

otherwise stated, it shall be understood to be

straight section at the outlet.

100. The residue obtained is available for tests

2.3 Shield-A galvanized il'Qn shield, lined

as desired.

with VB-in. (3.2-mm) asbestos, fitted with

N OTE I-The test results on the residue may be

transparent covered windows, of the form and

affected by nonasphaltic materials present in the

dimensions shown in Fig. 3, to protect the flask

asphalt.

from air currents and to prevent radiation. The

NOTE 2-This method is not intended to replace

ASTM Method D 243, Test for Residue of Specified

cover (top) may be of Transite board made in

Penetration', which introduces oxidation effects.

two parts, or it may be of galvanized iron lined

with VB-in. asbestos.

2. Apparatus

2.4 Receiver-Graduated cylinder, of uni

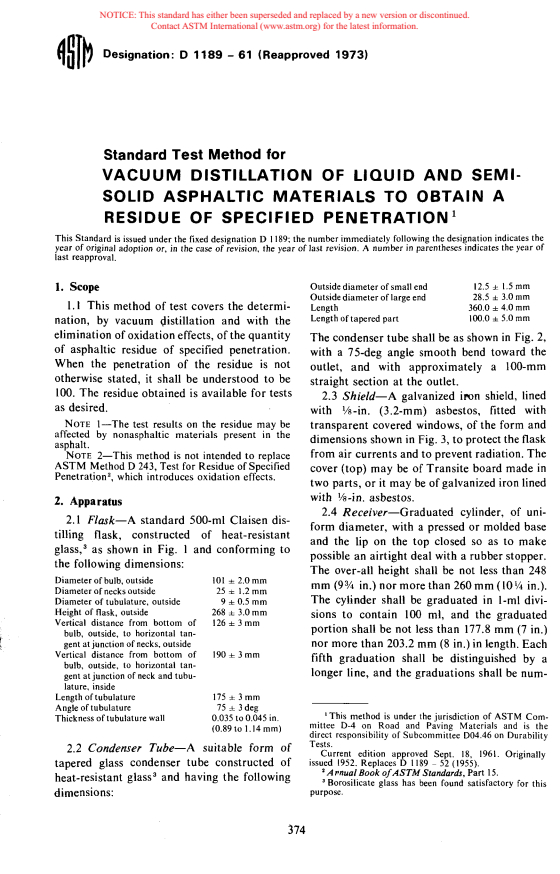

2.1 Flask-A standard 500-ml Claisen dis

form diameter, with a pressed or molded base

tilling flask, constructed of heat-resistant

and the lip on the top closed so as to make

glass,' as shown in Fig. I and conforming to

possible an airtight deal with a rubber stopper.

the following dimensions:

The over-all height shall be not less than 248

Diameter of bulb, outside lOl ± 2.0mm

mm (9% in.) nor more than 260 mm (10 V4 in.).

Diameter of necks outside 25 ± 1.2mm

Diameter of tubulature, outside 9 ± 0.5 mm The cylinder shall be graduated in I-ml divi

Height of flask, outside 268 ± 3.0mm

sions to contain 100 ml, and the graduated

Vertical distance from bottom of 126±3mm

portion shall be not less than 177.8 mm (7 in.)

bulb, outside, to horizontal tan

gent at junction of necks, outside nor more than 203.2 mm (8 in.) in length. Each

Vertical distance from bottom of 190±3mm

fifth graduation shall be distinguished by a

bulb, outside, to horizontal tan

longer line, and the graduations shall be num-

gent at junction of neck and tubu

lature, inside

Length of tubulature 175 ± 3 mm

Angle oftubulature 75 ± 3 deg

I This method is under the jurisdiction of ASTM Com

Thickness of tubulature wall 0.035 to 0.045 in.

mittee D-4 on Road and Paving Materials and is the

(0.89 to 1.14 mm)

direct responsibility of Subcommittee D04.46 on Durability

Tests.

2.2 Condenser Tube-A suitable form of

Current edition approved Sept. 18. 1961. Originally

issued 1952. Replaces D 1189 - 52 (1955).

tapered glass condenser tube constructed of

2 Apnual Book of ASTM Standards, Part 15.

heat-resistant glass' and having the following

, Borosilicate glass has been found satisfactory for this

purpose.

dimensions:

374

---------------------- Page: 1 ----------------------

01189

bered from the bottom up at intervals of 10 ml. eter, vacuum source, etc. shall be connected

The graduations shall not be in error by more into the system as shown in Fig. 4. To prevent

than I ml at any point on the scale. Immedi air leakage into the system, %-in. hose clamps

may be used at all the rubber tubing glass

ately above the lOO-ml graduation line, ap

proximately 45 mm of chemically resistant connection points. All glass items should be

glass tubing, 7 mm in outside diameter, shall well annealed and of uniform and heavy wall

be sealed in to provide a vacuum connection. thickness in order to avoid danger of collapse

2.5 Thermometer-An ASTM High Distil under vacuum.

Thermometer having a range from 30 to

lation

5. Procedure

760 F (-2 to +400 C), as specified, and

conforming to the requirements for Thermom 5.1 Charge the tared flask with 200 ± 0.1 g

eter SF or SC, respectively, as prescribed in of the material to be tested and insert the

ASTM Specification E -I for ASTM thermometer. Place the flask in the assembly,

tighten the connections, and apply the vacuum.

Thermometers. •

2.6 Manometer-A suitable laboratory ma (If trouble is encountered in foaming, heating

nometer or gage for measuring the pressure ()f to 190 F (90 C) before applying the vacuum

the system at the receiver to within I mm Hg. will be of assistance.) Apply heat slowly. Care

2.7 Va

...

Disqus seems to be taking longer than usual. Reload?