ASTM F1000-13

(Practice)Standard Practice for Piping System Drawing Symbols

Standard Practice for Piping System Drawing Symbols

SIGNIFICANCE AND USE

2.1 Figure 1 provides symbols for strainers, separators, and filters.

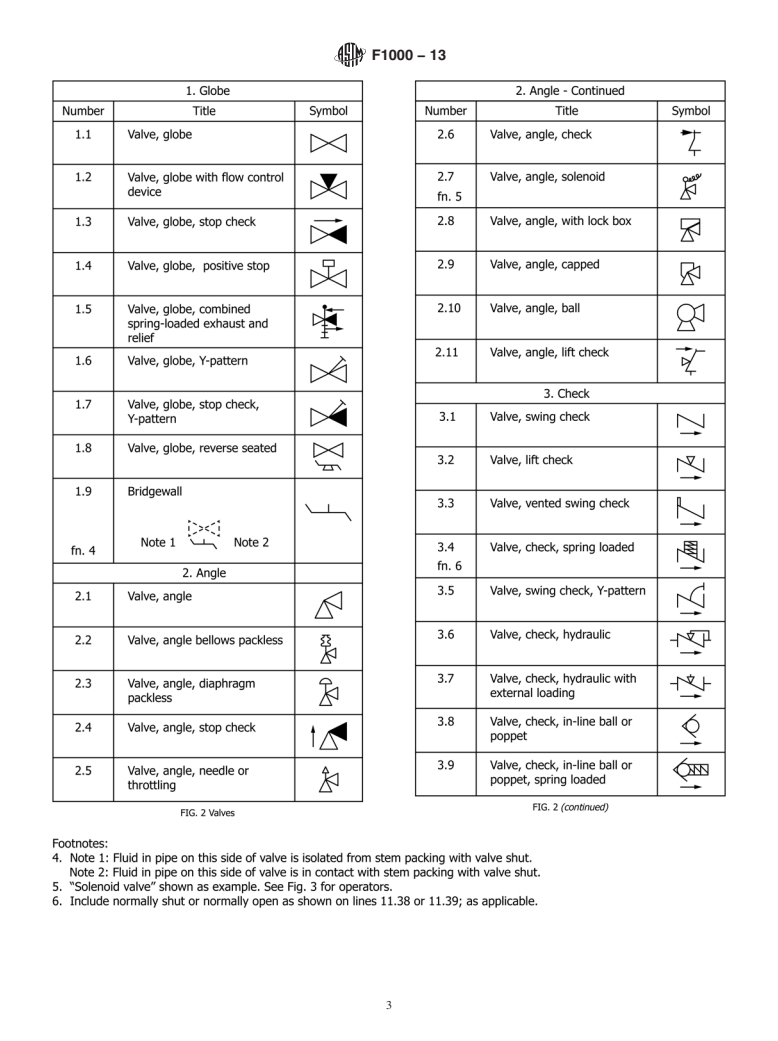

2.2 Figure 2 provides symbols for valves. Valves are categorized under the following headings: globe, angle, check, ball, butterfly, gate, relief, manifolds, control, noise control, and miscellaneous.

2.3 Figure 3 provides symbols for valve appendages such as actuators and locking devices. Symbols shown on Fig. 3 are to be combined with the appropriate symbol from Fig. 2.

2.4 Figure 4 provides symbols for piping system–related instrumentation. These symbols are categorized under the following headings: pressure, temperature, flow, level, switches, alarms, and miscellaneous.

2.5 Figure 5 provides symbols for fans, pumps, and turbines.

2.6 Figure 6 provides symbols for plumbing components.

2.7 Figure 7 provides symbols for pipe and pipe fittings.

2.8 Figure 8 provides symbols for noise control components and designations. These symbols are generally used for submarine design.

2.9 Figure 9 provides symbols for transitions. These symbols identify transitions such as pipe material or pipe schedule changes.

2.10 Figure 10 provides symbols for miscellaneous components. These are components which could not be classified under the above categories. Examples include heat exchangers, flasks, and sea chests.

2.11 Figure 11 provides symbols for grooved piping.

SCOPE

1.1 This practice establishes piping system drawing symbols for marine use.

1.2 This set of standard symbols is intended for use on piping system diagrammatics and arrangements for ships.

1.3 Where graphical symbols are required for an item or equipment not covered by this practice, the form and character of the symbol will be left to the discretion of the activity concerned, provided that the symbol used does not duplicate any of those contained herein, and is clearly understandable, subject to one interpretation only, or explained by a suitable note on the drawing when necessary.

1.4 Since symbolic representation does not usually involve exact or scale layout or the actual run or leads of piping, the same symbol may be used for all projections of the system (plan, elevations, and sections).

1.5 Symbols for fluid power, heating, ventilation, and air conditioning (HVAC), and Navy damage control diagrams are not included in this practice.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1000 − 13 An American National Standard

Standard Practice for

1

Piping System Drawing Symbols

This standard is issued under the fixed designation F1000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Significance and Use

2.1 Figure 1 provides symbols for strainers, separators, and

1.1 This practice establishes piping system drawing sym-

filters.

bols for marine use.

2.2 Figure 2 provides symbols for valves. Valves are cat-

1.2 This set of standard symbols is intended for use on

egorized under the following headings: globe, angle, check,

piping system diagrammatics and arrangements for ships.

ball, butterfly, gate, relief, manifolds, control, noise control,

and miscellaneous.

1.3 Where graphical symbols are required for an item or

equipment not covered by this practice, the form and character

2.3 Figure 3 provides symbols for valve appendages such as

of the symbol will be left to the discretion of the activity

actuators and locking devices. Symbols shown on Fig. 3 are to

concerned, provided that the symbol used does not duplicate

be combined with the appropriate symbol from Fig. 2.

any of those contained herein, and is clearly understandable,

2.4 Figure 4 provides symbols for piping system–related

subject to one interpretation only, or explained by a suitable

instrumentation. These symbols are categorized under the

note on the drawing when necessary.

following headings: pressure, temperature, flow, level,

switches, alarms, and miscellaneous.

1.4 Since symbolic representation does not usually involve

exact or scale layout or the actual run or leads of piping, the 2.5 Figure 5 provides symbols for fans, pumps, and tur-

bines.

same symbol may be used for all projections of the system

(plan, elevations, and sections).

2.6 Figure 6 provides symbols for plumbing components.

2.7 Figure 7 provides symbols for pipe and pipe fittings.

1.5 Symbols for fluid power, heating, ventilation, and air

conditioning (HVAC), and Navy damage control diagrams are

2.8 Figure 8 provides symbols for noise control components

not included in this practice.

and designations. These symbols are generally used for sub-

marine design.

1.6 This international standard was developed in accor-

2.9 Figure 9 provides symbols for transitions. These sym-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the bols identify transitions such as pipe material or pipe schedule

changes.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

2.10 Figure 10 provides symbols for miscellaneous compo-

Barriers to Trade (TBT) Committee.

nents. These are components which could not be classified

under the above categories. Examples include heat exchangers,

flasks, and sea chests.

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

2.11 Figure 11 provides symbols for grooved piping.

Marine Technology and is the direct responsibility of Subcommittee F25.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.