ASTM E2092-04

(Test Method)Standard Test Method for Distortion Temperature in Three-Point Bending by Thermomechanical Analysis

Standard Test Method for Distortion Temperature in Three-Point Bending by Thermomechanical Analysis

SIGNIFICANCE AND USE

Data obtained by this test method shall not be used to predict the behavior of materials at elevated temperatures except in applications in which the conditions of time, temperature, method of loading, and stress are similar to those specified in the test.

This standard is particularly suited for quality control and development work. The data are not intended for use in design or predicting endurance at elevated temperatures.

SCOPE

1.1 This test method describes the determination of the temperature at which the specific modulus of a test specimen is realized by deflection in three-point bending. This temperature is identified as the distortion temperature measured. The distortion temperature is that temperature at which a test specimen of defined geometry deforms to a level of strain under applied stress of 0.455 and 1.82 MPa (66 and 264 psi) equivalent to those used in Test Method D 648. The test may be performed over the range of temperature from ambient to 300C.Note 1

Results may or may not agree with those obtained by Test Method D 648.

1.2 Electronic instrumentation or automated data analysis and reduction systems or treatments equivalent to this test method may be used.Note 2

Since all electronic data treatments are not equivalent, the user shall verify equivalency to this test method.

1.3 SI values are to be regarded as the standard. Inch-pound units in parentheses are for information only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

1.5 There is no ISO standard equivalent to this test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2092–04

Standard Test Method for

Distortion Temperature in Three-Point Bending by

1

Thermomechanical Analysis

This standard is issued under the fixed designation E 2092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D 648 Test Method for Deflection Temperature of Plastics

Under Flexural Load

1.1 This test method describes the determination of the

E 473 Terminology Relating to Thermal Analysis

temperature at which the specific modulus of a test specimen is

E 1142 Terminology Relating to Thermophysical Properties

realized by deflection in three-point bending. This temperature

E 1363 Test Method for Temperature Calibration of Ther-

is identified as the distortion temperature measured. The

momechanical Analyzers

distortion temperature is that temperature at which a test

specimen of defined geometry deforms to a level of strain

3. Terminology

under applied stress of 0.455 (Method A) and 1.82 MPa

3.1 Definitions—Specific technical terms used in this stan-

(Method B) (66 and 264 psi) equivalent to those used in Test

dard are defined in Terminologies E 473 and E 1142.

Method D 648. The test may be performed over the range of

3.1.1 distortion temperature [°C], n—the temperature at

temperature from ambient to 300°C.

which an arbitrary strain level is obtained in three-point

NOTE 1—Thistestmethodisintendedtoprovideresultssimilartothose

bending under an arbitrary load.

of Test Method D 648 but are performed on a thermomechanical analyzer

3.1.2 strain, r [mm/m], n—thedimensionchangeinnormal-

using a smaller test specimen. Equivalence of results to those obtained by

izing dimension due to an applied force.

Test Method D 648 has been demonstrated on a limited number of

2

3.1.3 stress, S [Pa = N/m ], n—force per unit area.

materials. Until the user demonstrates equivalence, the results of this test

method shall be considered to be independent and unrelated to those of

4. Summary of Test Method

Test Method D 648.

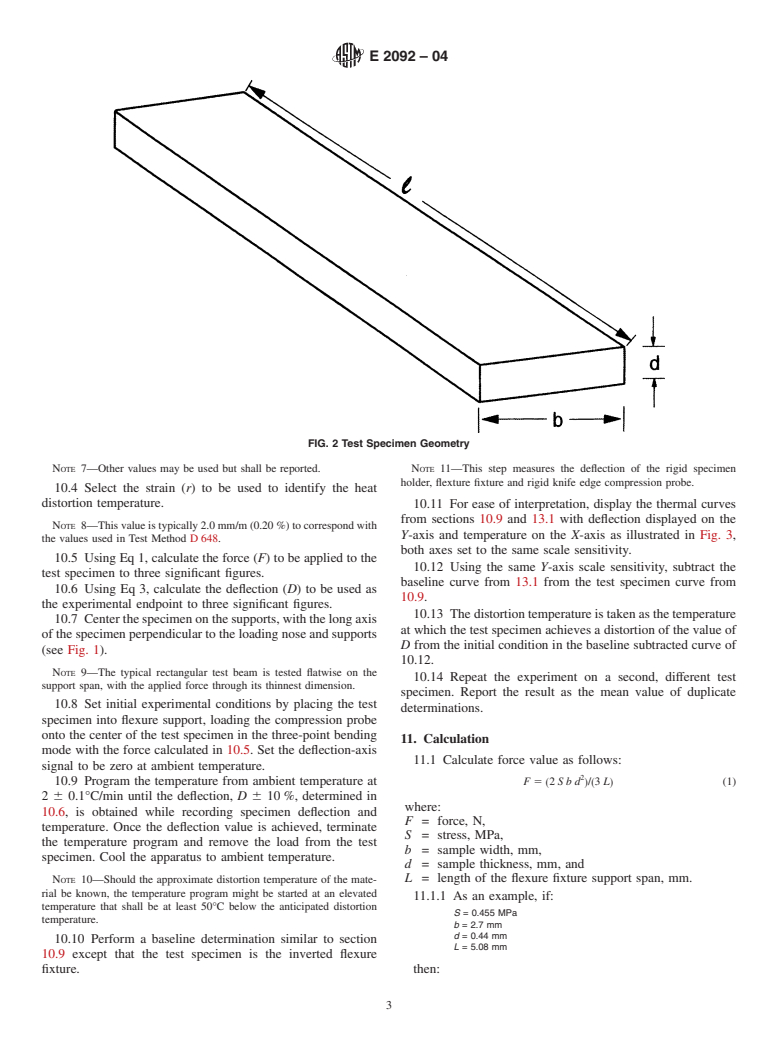

4.1 A test specimen of known dimensions is tested in

1.2 Electronic instrumentation or automated data analysis

three-point bending mode. A known stress is applied to the

and reduction systems or treatments equivalent to this test

center of a test specimen supported near its ends, as it is heated

method may be used.

at a constant rate from ambient temperature to the upper

NOTE 2—Since all electronic data treatments are not equivalent, the

temperature limit for the material. The deflection of the test

user shall verify equivalency to this test method.

specimen is recorded as a function of temperature. The

1.3 SI values are the standard.

temperature at which a predetermined level of strain is ob-

1.4 This standard does not purport to address all of the

served in the test specimen is analyzed as the distortion

safety problems, if any, associated with its use. It is the

temperature.

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and to determine the

applicability of regulatory limitations prior to use. 5.1 Data obtained by this test method shall not be used to

1.5 There is no ISO standard equivalent to this test method.

predict the behavior of materials at elevated temperatures

except in applications in which the conditions of time, tem-

2. Referenced Documents

perature, method of loading, and stress are similar to those

2

2.1 ASTM Standards:

specified in the test.

5.2 This standard is particularly suited for quality control

and development work. The data are not intended for use in

1

This test method is under the jurisdiction of Committee E37 on Thermal

design or predicting endurance at elevated temperatures.

Measurements and is the direct responsibility of Subcommittee E37.10 on Funda-

mental, Statistical and Mechanical Properties.

6. Apparatus

Current edition approved March 1, 2004. Published April 2004. Originally

approved in 2000. Last previous edition approved in 2003 as E2092–03.

6.1 A thermomechanical analyzer consisting of:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer tot he standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2092–04

6.1.1 Rigid Specimen Holder, of inert, low expansivity 6.1.10 While not required, it is convenient to have a data

-1 -1

material<20µmm ·°C tocenterthespecimeninthefurnace

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.