ASTM E2192-13(2022)

(Guide)Standard Guide for Planar Flaw Height Sizing by Ultrasonics

Standard Guide for Planar Flaw Height Sizing by Ultrasonics

SIGNIFICANCE AND USE

5.1 The practices referenced in this document are applicable to measuring the height of planar flaws open to the surface that originate on the far-surface or near-surface of the component. These practices are applicable to through-wall sizing of mechanical or thermal fatigue flaws, stress corrosion flaws, or any other surface-connected planar flaws.

5.2 The techniques outlined describe proven ultrasonic flaw sizing practices and their associated limitations, using refracted longitudinal wave and shear wave techniques as applied to ferritic or austenitic components. Other materials may be examined using this guide with appropriate standardization reference blocks. The practices described are applicable to both manual and automated examinations.

5.3 The techniques recommended in this standard guide use Time of Flight (TOF) or Delta Time of Flight (ΔTOF) methods to accurately measure the flaw size. This guide does not include the use of signal amplitude methods to determine flaw size.

5.4 Generally, with these sizing methods the volume of material (or component thickness) to be sized is divided into thirds; the inner 1/3 , the middle 1/3 and the near 1/3. Using the far-surface Creeping Wave Method the user can qualitatively segregate the flaw into the approximate 1/3 zone.

5.5 The sizing methods are used in 1/3 zones to quantitatively size the crack, that is, Tip-diffraction for the far 1/3 , Bi-Modal method for the middle 1/3 , and the Focused Longitudinal Wave or Focused Shear Wave Methods for the near 1/3 . These 1/3 zones are generally applicable to most sizing applications, however, the various sizing methods have applications outside these 1/3 zones provided a proper reference block and technique is demonstrated.

SCOPE

1.1 This guide provides tutorial information and a description of the principles and ultrasonic examination techniques for measuring the height of planar flaws which are open to the surface. The practices and technology described in this standard guide are intended as a reference to be used when selecting a specific ultrasonic flaw sizing technique as well as establishing a means for instrument standardization.2

1.2 This standard guide does not provide or suggest accuracy or tolerances of the techniques described. Parameters such as search units, examination surface conditions, material composition, etc. can all have a bearing on the accuracy of results. It is recommended that users assess accuracy and tolerances applicable for each application.

1.3 This guide does not purport to provide instruction to measure flaw length.

1.4 This standard guide does not provide, suggest, or specify acceptance standards. After flaw-sizing evaluation has been made, the results should be applied to an appropriate code or standard that specifies acceptance criteria.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory requirements prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2192 − 13 (Reapproved 2022)

Standard Guide for

Planar Flaw Height Sizing by Ultrasonics

This standard is issued under the fixed designation E2192; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide provides tutorial information and a descrip- 2.1 ASTM Standards:

tionoftheprinciplesandultrasonicexaminationtechniquesfor E1316 Terminology for Nondestructive Examinations

measuring the height of planar flaws which are open to the E543 Specification forAgencies Performing Nondestructive

surface. The practices and technology described in this stan- Testing

dard guide are intended as a reference to be used when

2.2 ASNT Standards

selecting a specific ultrasonic flaw sizing technique as well as

SNT-TC-1A Personnel Qualification and Certification in

establishing a means for instrument standardization.

Nondestructive Testing

ANSI/ASNT-CP-189 Standard for Qualification and Certifi-

1.2 This standard guide does not provide or suggest accu-

cation of Nondestructive Testing Personnel

racyortolerancesofthetechniquesdescribed.Parameterssuch

2.3 AIA Standards

as search units, examination surface conditions, material

composition, etc. can all have a bearing on the accuracy of NAS-410 Nondestructive Testing Personnel Qualification

and Certification

results. It is recommended that users assess accuracy and

tolerances applicable for each application.

3. Terminology

1.3 This guide does not purport to provide instruction to

3.1 Definitions—Related terminology is defined in Termi-

measure flaw length.

nology E1316.

1.4 This standard guide does not provide, suggest, or

3.2 Definitions of Terms Specific to This Standard:

specify acceptance standards. After flaw-sizing evaluation has

3.2.1 corner reflection—the reflected ultrasonic energy re-

beenmade,theresultsshouldbeappliedtoanappropriatecode

sulting from the interaction of ultrasound with the intersection

or standard that specifies acceptance criteria.

of a flaw and the component surface at essentially 90 degrees.

1.5 The values stated in SI units are to be regarded as the

3.2.2 doublet—two ultrasonic signals that appear on the

standard. The values given in parentheses are for information

screen simultaneously and move in unison as search unit is

only.

manipulated toward and away from the flaw. During tip-

1.6 This standard does not purport to address all of the

diffraction flaw sizing, the flaw tip signal and flaw base signal

safety concerns, if any, associated with its use. It is the

(corner reflector) will appear as a doublet.

responsibility of the user of this standard to establish appro-

3.2.3 far-surface—the surface of the examination piece

priate safety, health, and environmental practices and deter-

opposite the surface on which the search unit is placed. (For

mine the applicability of regulatory requirements prior to use.

example, when examining pipe from the outside surface the

1.7 This international standard was developed in accor-

far-surface would be the inside pipe surface).

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.2.4 focus—the term as used in this document applies to

Development of International Standards, Guides and Recom- dualcrossed-beamsearchunitsthathavebeenmanufacturedso

mendations issued by the World Trade Organization Technical that they have a maximum sensitivity at a predetermined depth

Barriers to Trade (TBT) Committee. or sound path in the component. Focusing effect may be

1 3

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Method. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2022. Published December 2022. Originally the ASTM website.

approved in 2002. Last previous edition approved in 2018 as E2192 – 13(2018). AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

DOI: 10.1520/E2192-13R22. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org

2 5

ThisStandardGuideisadaptedfrommaterialsuppliedtoASTMSubcommittee Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

E07.06 by the Electric Power Research Institute (EPRI). Wilson Blvd., Suite 1700,Arlington,VA22209-3928, http://www.aia-aerospace.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2192 − 13 (2022)

obtained with the use of dual-element search units having both 5.5 The sizing methods are used in ⁄3 zones to quantita-

refracted and roof angles applied to each element. tively size the crack, that is, Tip-diffraction for the far ⁄3,

Bi-Modal method for the middle ⁄3, and the Focused Longi-

3.2.5 near-surface—the surface of the examination piece on

tudinal Wave or Focused Shear Wave Methods for the near ⁄3

whichthesearchunitisplaced.(Forexample,whenexamining

. These ⁄3 zones are generally applicable to most sizing

pipe from the outside surface the near-surface would be the

applications, however, the various sizing methods have appli-

outside pipe surface).

cations outside these ⁄3 zones provided a proper reference

3.2.6 sizing—measurement of the through-wall height or

block and technique is demonstrated.

depth dimension of a discontinuity or flaw.

6. Basis of Application

3.2.7 30-70-70—term that is applied to the technique (and

sometimes the search unit) using an incident angle that

6.1 The following items are subject to contractual agree-

produces a nominal 70° L wave in the examination piece.

ment between the parties using or referencing this standard.

Provided that a parallel far-surface exists, the 30° shear wave,

6.2 Personnel Qualification

produced simultaneously at the near surface, reflects as a 30°

6.2.1 If specified in the contractual agreement, personnel

shear wave and generates a nominal 70° L wave as a result of

performing examinations to this standard shall be qualified in

mode conversion off the far-surface. The 70° L wave reflects

accordance with a nationally or internationally recognized

off a planar flaw and is received by the search unit as a 70° L

NDT personnel qualification practice or standard such as

wave.

ANSI/ASNT-CP-189, SNT-TC-1A, NAS-410, or a similar

document and certified by the employer or certifying agency,

4. Summary of Guide

as applicable. The practice or standard used and its applicable

4.1 This guide describes methods for the following flaw

revision shall be identified in the contractual agreement be-

sizing techniques.

tween the using parties.

4.1.1 Far-surface creeping wave or mode conversion

6.3 Qualification of Nondestructive Agencies—If specified

method,

in the contractual agreement, NDT agencies shall be qualified

4.1.2 Flaw-tip-diffraction method,

and evaluated as described in Specification E543. The appli-

4.1.3 Dual element bi-modal method, and

cable edition of Specification E543 shall be specified in the

4.1.4 Dual element, (focused) longitudinal wave or dual

contractual agreement.

element, (focused) shear wave methods.

6.4 Procedures and Techniques—The procedures and tech-

4.2 In this guide, ultrasonic sound paths are generally

niques to be utilized shall be as specified in the contractual

shown diagrammatically by single lines in one plane that

agreement.

represent the center of the ultrasonic energy.

6.5 Reporting Criteria/Acceptance Criteria—Reporting cri-

4.3 Additional information on flaw sizing techniques may

teria for the examination results are not specified in this

be found in the references listed in the Bibliography section.

standard, they shall be specified in the contractual agreement.

5. Significance and Use

6.6 Reexamination of Repaired/Reworked Items—

5.1 Thepracticesreferencedinthisdocumentareapplicable Reexamination of repaired/reworked items is not addressed in

to measuring the height of planar flaws open to the surface that this standard and if required shall be specified in the contrac-

originate on the far-surface or near-surface of the component. tual agreement.

These practices are applicable to through-wall sizing of me-

7. Ultrasonic Flaw Sizing Methods

chanical or thermal fatigue flaws, stress corrosion flaws, or any

other surface-connected planar flaws.

7.1 30-70-70 Mode Conversion or Far-surface Creeping

Wave Method—The far-surface Creeping Wave or 30-70-70

5.2 The techniques outlined describe proven ultrasonic flaw

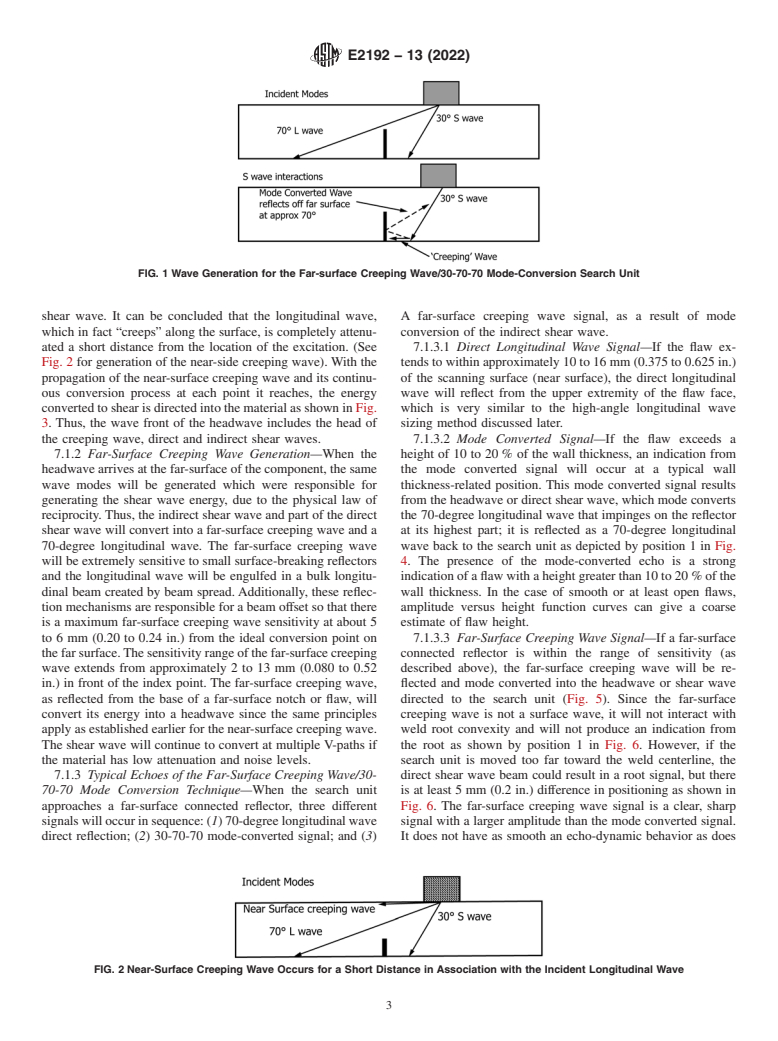

Mode Conversion method (as illustrated in Fig. 1) provides

sizingpracticesandtheirassociatedlimitations,usingrefracted

qualitative additional depth sizing information. This method

longitudinal wave and shear wave techniques as applied to

has considerable potential for use when approximating flaw

ferritic or austenitic components. Other materials may be

size, or, determining that the flaw is far-surface connected.

examined using this guide with appropriate standardization

7.1.1 Excitation of Creeping Waves—The excitation of re-

referenceblocks.Thepracticesdescribedareapplicabletoboth

fracted longitudinal waves is always accompanied by refracted

manual and automated examinations.

shear waves. In the vicinity of the excitation, the separation

5.3 The techniques recommended in this standard guide use

between these two wave modes is not significantly distinct.At

Time of Flight (TOF) or DeltaTime of Flight (∆TOF) methods

the surface, a longitudinal wave cannot exist independently of

toaccuratelymeasuretheflawsize.Thisguidedoesnotinclude

a shear wave because neither mode can comply with the

the use of signal amplitude methods to determine flaw size.

boundaryconditionsforthehomogeneouswaveequationatthe

5.4 Generally, with these sizing methods the volume of free surface alone; consequently, the so-called headwave is

material (or component thickness) to be sized is divided into formed. The headwave is always generated if a wave mode

1 1 1

thirds; the inner ⁄3, the middle ⁄3 and the near ⁄3. Using the with higher velocity (the longitudinal wave) is coupled to a

far-surface Creeping Wave Method the user can qualitatively wave mode with lower velocity (the direct shear wave) at an

segregate the flaw into the approximate ⁄3 zone. interface. The longitudinal wave continuously energizes the

E2192 − 13 (2022)

FIG. 1 Wave Generation for the Far-surface Creeping Wave/30-70-70 Mode-Conversion Search Unit

shear wave. It can be concluded that the longitudinal wave, A far-surface creeping wave signal, as a result of mode

which in fact “creeps” along the surface, is completely attenu- conversion of the indirect shear wave.

ated a short distance from the location of the excitation. (See 7.1.3.1 Direct Longitudinal Wave Signal—If the flaw ex-

Fig. 2 for generation of the near-side creeping wave). With the tends to within approximately 10 to 16 mm (0.375 to 0.625 in.)

propagation of the near-surface creeping wave and its continu- of the scanning surface (near surface), the direct longitudinal

ous conversion process at each point it reaches, the energy wave will reflect from the upper extremity of the flaw face,

convertedtoshearisdirectedintothematerialasshowninFig. which is very similar to the high-angle longitudinal wave

3. Thus, the wave front of the headwave includes the head of sizing method discussed later.

the creeping wave, direct and indirect shear waves. 7.1.3.2 Mode Converted Signal—If the flaw exceeds a

7.1.2 Far-Surface Creeping Wave Generation—When the height of 10 to 20 % of the wall thickness, an indication from

headwave arrives at the far-surface of the component, the same the mode converted signal will occur at a typical wall

wave modes will be generated which were responsible for thickness-related position. This mode converted signal results

generating the shear wave energy, due to the physical law of from the headwave or direct shear wave, which mode converts

reciprocity. Thus, the indirect shear wave and part of the direct the 70-degree longitudinal wave that impinges on the reflector

shear wave will convert into a far-surface creeping wave and a at its highest part; it is reflected as a 70-degree longitudinal

70-degree longitudinal wave. The far-surface creeping wave wave back to the search unit as depicted by position 1 in Fig.

will be extremely sensitive to small surface-breaking reflectors 4. The presence of the mode-converted echo is a strong

and the longitudinal wave will be engulfed in a bulk longitu- indicationofaflawwithaheightgreaterthan10to20 %ofthe

dinal beam created by beam spread.Additionally, these reflec- wall thickness. In the case of smooth or at least open flaws,

tion mechanisms are responsible for a beam offset so that there amplitude versus height function curves can give a coarse

is a maximum far-surface creeping wave sensitivity at about 5 estimate of flaw height.

to 6 mm (0.20 to 0.24 in.) from the ideal conversion point on 7.1.3.3 Far-Surface Creeping Wave Signal—If a far-surface

thefarsurface.Thesensitivityrangeofthefar-surfacecreeping connected reflector is within the range of sensitivity (as

wave extends from approximately 2 to 13 mm (0.080 to 0.52 described above), the far-surface creeping wave will be re-

in.) in front of the index point. The far-surface creeping wave, flected and mode converted into the headwave or shear wave

as reflected from the base of a far-surface notch or flaw, will directed to the search unit (Fig. 5). Since the far-surface

convert its energy into a headwave since the same principles creeping wave is not a surface wave, it will not interact with

apply as established earlier for the near-surface creeping wave. weld root convexity and will not produce an indication from

The shear wave will continue to convert at multiple V-paths if the root as shown by position 1 in Fig. 6. However, if the

the material has low attenuation and noise levels. search unit is moved too far toward the weld centerline, the

7.1.3 Typical Echoes of the Far-Surface Creeping Wave/30- direct shear wave beam could result in a root signal, but there

70-70 Mode Conversion Technique—When the search unit is at least 5 mm (0.2 in.) difference in positioning as shown in

approaches a far-surface connec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.