ASTM F1469-99

(Guide)Standard Guide for Conducting a Repeatability and Reproducibility Study on Test Equipment for Nondestructive Testing

Standard Guide for Conducting a Repeatability and Reproducibility Study on Test Equipment for Nondestructive Testing

SCOPE

1.1 This guide describes the steps required to conduct a complete repeatability and reproducibility (RR) study on nondestructive test equipment. This guide is a manual (use of calculator) method. Other methods may utilize the application of computer driven software.

1.2 This guide can be used to evaluate all test equipment that provides variable measuring data.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 1469–99

Standard Guide for

Conducting a Repeatability and Reproducibility Study on

1

Test Equipment for Nondestructive Testing

This standard is issued under the fixed designation F 1469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Equipment Certification

1.1 This guide describes the steps required to conduct a 4.1 Test equipment shall be certified through use of certified

complete repeatability and reproducibility (RR) study on standards as accurate to the manufacturer’s / user’s calibration

nondestructive test equipment. This guide is a manual (use of systems with certified standards before a repeatability and

calculator) method. Other methods may utilize the application reproducibility study is performed.

of computer driven software. 4.2 Certifications must be traceable to the National Institute

1.2 This guide can be used to evaluate all test equipment of Standards and Technology (NIST), or recognized equiva-

that provides variable measuring data. lent, and shall be current to the test equipment’s calibration

schedule.

2. Terminology

5. Procedure

2.1 Definitions:

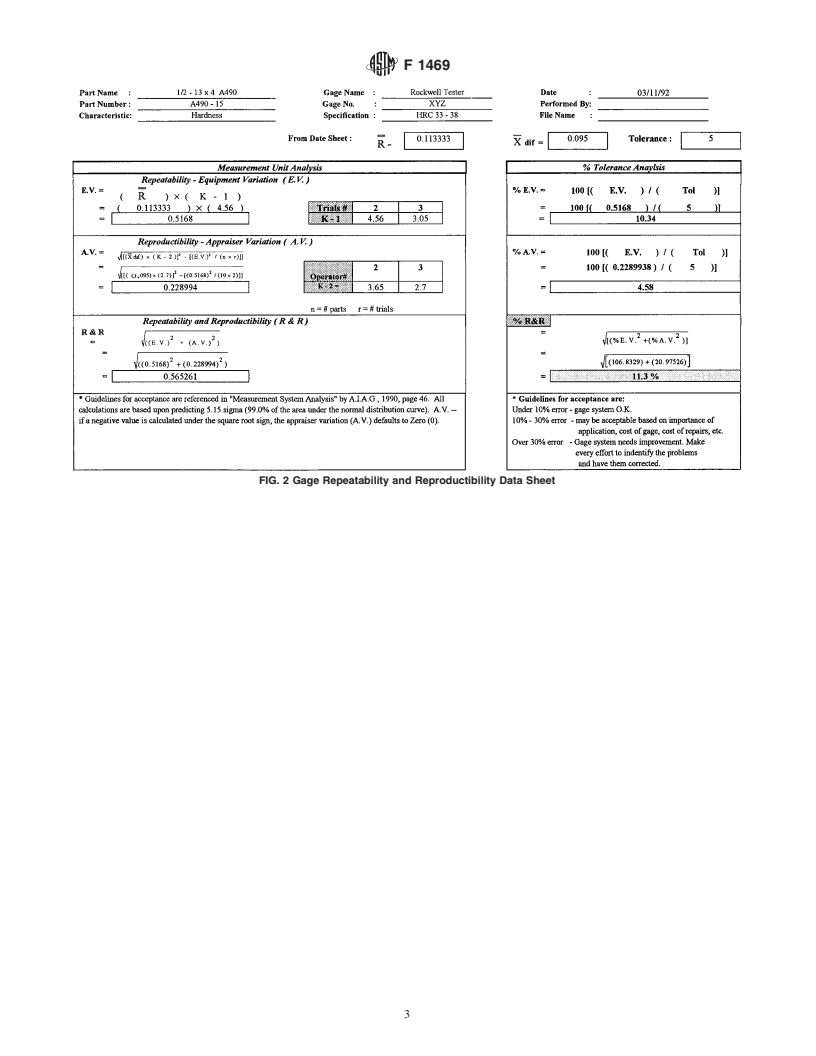

2.1.1 repeatability—the variation in the values of measure- 5.1 Although the number of operators, trials, and parts may

ments obtained when one operator uses the same gage for be varied, the following guidelines represent the optimum

measuring identical characteristics of the same parts. conditions for conducting a study using the forms in Figs. 1

2.1.2 reproducibility—the variation in the average of mea- and 2.

surements made by different operators using the same parts. 5.2 Select three operators and identify them as Operators A,

B, and C.

3. Significance and Use

5.3 Calibrate the test equipment with a certified standard.

3.1 This guide is recommended for the purpose of evaluat- 5.4 Select ten parts for measurements and number them

ing test equipment that may be utilized in statistical process from 1 to 10, such that the numbers, if possible, are not visible

control, testing laboratories, and for in-process control of

to the operator. Place a mark on each part to indicate the

manufacturing operations. precise position at which the part shall be measured. This

3.2 Ask the question: What effect does the operator have on

eliminates the variation within the part from the study results

the measurement process? If possible, the operators who so that only the gage’s performance and operator variation

normally use the test equipment should be included in the

influences the study outcome.

study. If operator calibration of the equipment is likely to be a 5.5 Allow Operator A to inspect all ten parts in a sequential

significant cause of variation, then the operator should recali-

order by measuring each part at the designated location. Enter

brate the equipment prior to each group of readings. the results in the 1st trial column for Operator A of the

3.3 The test equipment should provide direct readings in

Repeatability and Reproducibility Data Sheet (Fig. 1). Part

which the smallest digit is no larger than one tenth of the identification and associated data entry shall be performed by

tolerance of the characteristic being evaluated.

an observer.

3.4 It is recommended that a test equipment repeatability 5.6 Repeat 5.5 with Operators B and C and enter the results

and reproducibility study be a mandatory part of all test

in the corresponding 1st trial column for each operator.

equipment purchases and that acceptance criteria be <10 % for 5.7 Repeat 5.5 and 5.6 using a random selection of the ten

certification and statistical process control (SPC) use.

parts. Enter data in the 2nd trial column for each operator. If

three trials are needed, repeat the cycle and enter data in the

corresponding 3rd trial column for each operator.

1

This guide is under the jurisdiction ofASTM Committee F-16 on Fasteners and

5.8 Steps 5.5, 5.6, and 5.7 may be changed to the following

isthedirectresponsibilityofSubcommitteeF16.93onQualityAssuranceProvisions

when large part size or simultaneous availability of parts is not

for Fasteners.

Current edition approved May 10, 1999. Published July 1999. Originally possible:

published as F 1469 – 93. Last previous edition F 1469 – 93.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1469

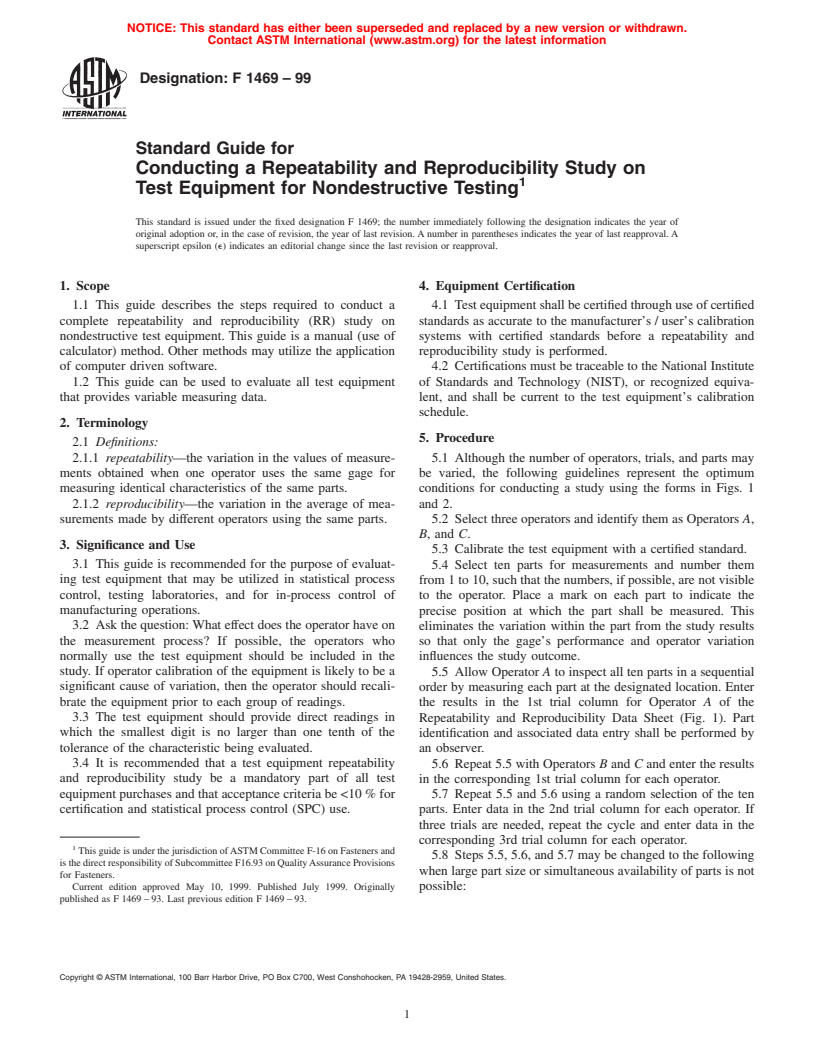

FIG. 1 Gage Repeatability and Reproductibility Data Sheet

5.8.1 Allow Operators A, B, and C to measure the first part application.The criteria for acceptability is dependent upon the

and record their rea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.