ASTM F2299/F2299M-03(2017)

(Test Method)Standard Test Method for Determining the Initial Efficiency of Materials Used in Medical Face Masks to Penetration by Particulates Using Latex Spheres

Standard Test Method for Determining the Initial Efficiency of Materials Used in Medical Face Masks to Penetration by Particulates Using Latex Spheres

SIGNIFICANCE AND USE

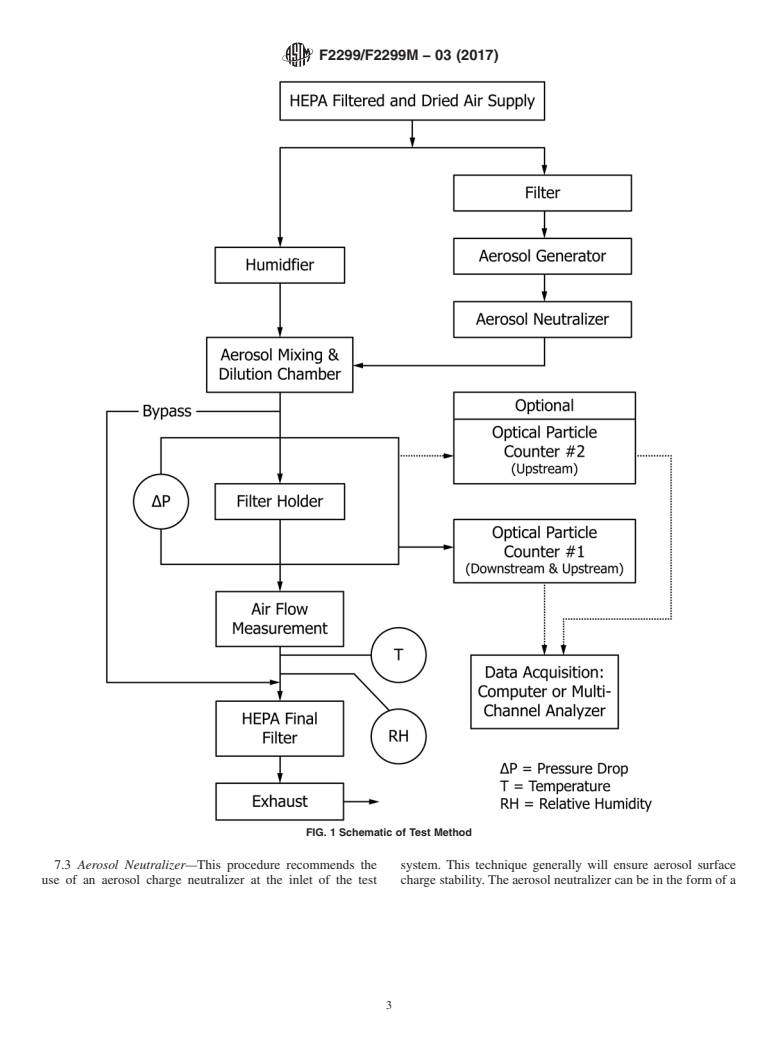

5.1 This test method measures the initial filtration efficiency of materials used in medical face masks by sampling representative volumes of the upstream and downstream latex aerosol concentrations in a controlled airflow chamber.

5.2 This test method provides specific test techniques for both manufacturers and users to evaluate materials when exposed to aerosol particle sizes between 0.1 and 5.0 μm.

5.2.1 This test method establishes a basis of efficiency comparison between medical face mask materials.

5.2.2 This test method does not establish a comprehensive characterization of the medical face mask material for a specific protective application.

5.3 This test method does not assess the overall effectiveness of medical face masks in preventing the inward leakage of harmful particles.

5.3.1 The design of the medical face mask and the integrity of the seal of the medical face mask to the wearer's face are not evaluated in this test.

5.4 This test method is not suitable for evaluating materials used in protective clothing for determining their effectiveness against particulate hazards.

5.4.1 In general, clothing design is a significant factor which must be considered in addition to the penetration of particulates.

SCOPE

1.1 This test method establishes procedures for measuring the initial particle filtration efficiency of materials used in medical facemasks using monodispersed aerosols.

1.1.1 This test method utilizes light scattering particle counting in the size range of 0.1 to 5.0 μm and airflow test velocities of 0.5 to 25 cm/s.

1.2 The test procedure measures filtration efficiency by comparing the particle count in the feed stream (upstream) to that in the filtrate (downstream).

1.3 The values stated in SI units or in other units shall be regarded separately as standard. The values stated in each system must be used independently of the other, without combining values in any way.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2299/F2299M − 03 (Reapproved 2017)

Standard Test Method for

Determining the Initial Efficiency of Materials Used in

Medical Face Masks to Penetration by Particulates Using

1

Latex Spheres

ThisstandardisissuedunderthefixeddesignationF2299/F2299M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1356Terminology Relating to Sampling and Analysis of

Atmospheres

1.1 This test method establishes procedures for measuring

D1777Test Method for Thickness of Textile Materials

the initial particle filtration efficiency of materials used in

D2905Practice for Statements on Number of Specimens for

medical facemasks using monodispersed aerosols.

3

Textiles (Withdrawn 2008)

1.1.1 This test method utilizes light scattering particle

D3776/D3776MTest Methods for Mass Per Unit Area

counting in the size range of 0.1 to 5.0 µm and airflow test

(Weight) of Fabric

velocities of 0.5 to 25 cm/s.

E691Practice for Conducting an Interlaboratory Study to

1.2 The test procedure measures filtration efficiency by

Determine the Precision of a Test Method

comparing the particle count in the feed stream (upstream) to

F50Practice for Continuous Sizing and Counting of Air-

that in the filtrate (downstream).

borne Particles in Dust-Controlled Areas and Clean

1.3 The values stated in SI units or in other units shall be Rooms Using Instruments Capable of Detecting Single

regarded separately as standard. The values stated in each

Sub-Micrometre and Larger Particles

system must be used independently of the other, without F328Practice for Calibration of anAirborne Particle Coun-

combining values in any way.

ter Using Monodisperse Spherical Particles (Withdrawn

3

2007)

1.4 The following precautionary caveat pertains only to the

F778Methods for Gas Flow ResistanceTesting of Filtration

test methods portion, Section 10, of this specification. This

Media

standard does not purport to address all of the safety concerns,

F1471Test Method for Air Cleaning Performance of a

if any, associated with its use. It is the responsibility of the user

High-Efficiency Particulate Air Filter System

of this standard to establish appropriate safety and health

F1494Terminology Relating to Protective Clothing

practices and determine the applicability of regulatory limita-

F2053Guide for Documenting the Results of Airborne

tions prior to use.

Particle Penetration Testing of Protective Clothing Mate-

1.5 This international standard was developed in accor-

rials

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 3. Terminology

mendations issued by the World Trade Organization Technical

3.1 Definitions:

Barriers to Trade (TBT) Committee.

3.1.1 aerosol, n—a suspension of a liquid or solid particles

in a gas with the particles being in the colloidal size range.

2. Referenced Documents

3.1.1.1 Discussion—In this test method, aerosols include

2

2.1 ASTM Standards:

solid particles having a diameter of 0.1 to 5 µm suspended or

dispersed in an airflow at concentrations of less than 102par-

3

ticles⁄cm .

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal

ProtectiveClothingandEquipmentandisthedirectresponsibilityofSubcommittee

3.1.2 isokinetic sampling, n—aconditionwherethevelocity

F23.40 on Biological.

of the airflow entering the sampling nozzle is the same as the

Current edition approved June 1, 2017. Published June 2017. Originally

velocity of the airflow passing around the sampling nozzle.

approved in 2003. Last previous edition approved in 2010 as F2299/F2299M–03

(2010). DOI: 10.1520/F2299_F2299M-03R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2299/F2299M − 03 (2017)

3.1.3 monodispersion, n—scattering of discrete particles in 6.2.3 Aerosol generator,

anairflowwherethesizeiscentralizedaboutaspecificparticle 6.2.4 Charge neutralizer,

size. 6.2.5 Humidifier,

3.1.3.1 Discussion—In this test method, the monodispersed 6.2.6 Tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.