ASTM E1114-92(1997)e1

(Test Method)Standard Test Method for Determining the Focal Size of Iridium-192 Industrial Radiographic Sources

Standard Test Method for Determining the Focal Size of Iridium-192 Industrial Radiographic Sources

SCOPE

1.1 This test method covers the determination of the focal size of an iridium-192 radiographic source. The determination is based upon measurement of the image of the iridium metal source in a projection radiograph of the source assembly and comparison to the measurement of the image of a reference sample in the same radiograph.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

e1

Designation: E 1114 – 92 (Reapproved 1997)

Standard Test Method for

Determining the Focal Size of Iridium-192 Industrial

Radiographic Sources

This standard is issued under the fixed designation E 1114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 10 was added editorially in February 1997.

1. Scope object and object to film distances appropriate for maintaining

the desired degree of geometric unsharpness.

1.1 This test method covers the determination of the focal

size of an iridium-192 radiographic source. The determination

5. Apparatus

is based upon measurement of the image of the iridium metal

5.1 Subject Iridium-192 Source, the focal size of which is to

source in a projection radiograph of the source assembly and

be determined. The appropriate apparatus and equipment for

comparison to the measurement of the image of a reference

the safe storage, handling, and manipulation of the subject

sample in the same radiograph.

source, such as a radiographic exposure device (also referred to

1.2 This standard does not purport to address all of the

as a gamma ray projector or camera), remote control, source

safety concerns, if any, associated with its use. It is the

guide tube, and source stop are also required.

responsibility of the user of this standard to establish appro-

5.2 Reference Sample (see Figs. 1-3)—The reference

priate safety and health practices and determine the applica-

sample shall be of material which is not radioactive. The

bility of regulatory limitations prior to use.

recommended material is iridium. However, substitutes such as

2. Referenced Documents platinum, tungsten or other material of similar radiopacity may

be used. The sample should be of the same geometric shape as

2.1 ASTM Standards:

the subject source, should be approximately the same size as

E 999 Guide for Controlling the Quality of Industrial Ra-

the subject source, and should be positioned on or within a

diographic Film Processing

shim or envelope to simulate the source capsule wall. The

E 1316 Terminology for Nondestructive Testing

resulting radiographic contrast, with reference to adjacent

3. Terminology

background density of the image of the reference sample,

should be approximately the same as that of the subject source.

3.1 For definitions of terms relating to this test method, refer

The actual dimensions of the reference sample should be

to Terminology E 1316.

determined to the nearest 0.025 mm (0.001 in.).

4. Significance and Use

5.3 X-ray Generator, capable of producing a radiation

intensity (roentgen per hour at one metre) at least ten times

4.1 One of the factors affecting the quality of a radiographic

greater than that produced by the subject source. Examples of

image is geometric unsharpness. The degree of geometric

typical X-ray generator output requirements that satisfy this

unsharpness is dependent upon the focal size of the source, the

criterion are presented in Table 1.

distance between the source and the object to be radiographed,

5.4 Film, industrial type fine grain, extra fine grain, or ultra

and the distance between the object to be radiographed and the

fine grain as defined by the film manufacturer shall be used.

film. This test method allows the user to determine the focal

Selection of film type should be determined by such factors as

size of the source and to use this result to establish source to

the required radiographic quality level, equipment capability,

materials, and so forth. The films selected must be capable of

This test method is under the jurisdictioin of ASTM Committee E-7 on

demonstrating the required image quality. No intensifying

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

screens should be used. The film should be processed in

Radiographic Practice and Penetrameters.

accordance with Guide E 999.

Current edition approved Sept. 15, 1992. Published November 1992. Originally

published as E1114 – 86. Last previous edition E1114 – 86.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

E 1114 – 92 (1997)

FIG. 1 Reference Sample in Standard Source Encapsulation

FIG. 2 Alternate Reference Sample Arrangement

FIG. 3 Alternate Reference Sample Arrangement

TABLE 1 Examples of Typical X-ray Generator Output

5.5 Image Measurement Apparatus—This apparatus is used 192

Requirements for Related Iridium Source Activities

to measure the size of the image of the focal spot. The

Subject Iridium Source Typical X-ray Generator

apparatus shall be an optical comparator with built-in graticule

Radiation Output Requirements

with 0.1 mm divisions or 0.001 in. divisions and magnification

Activity Output

Potential Current

of 53 to 103. (Curie) (R/h at 1 m)

6. Procedure

30 14.4 160 kV 5 mA

or 200 kV 3 mA

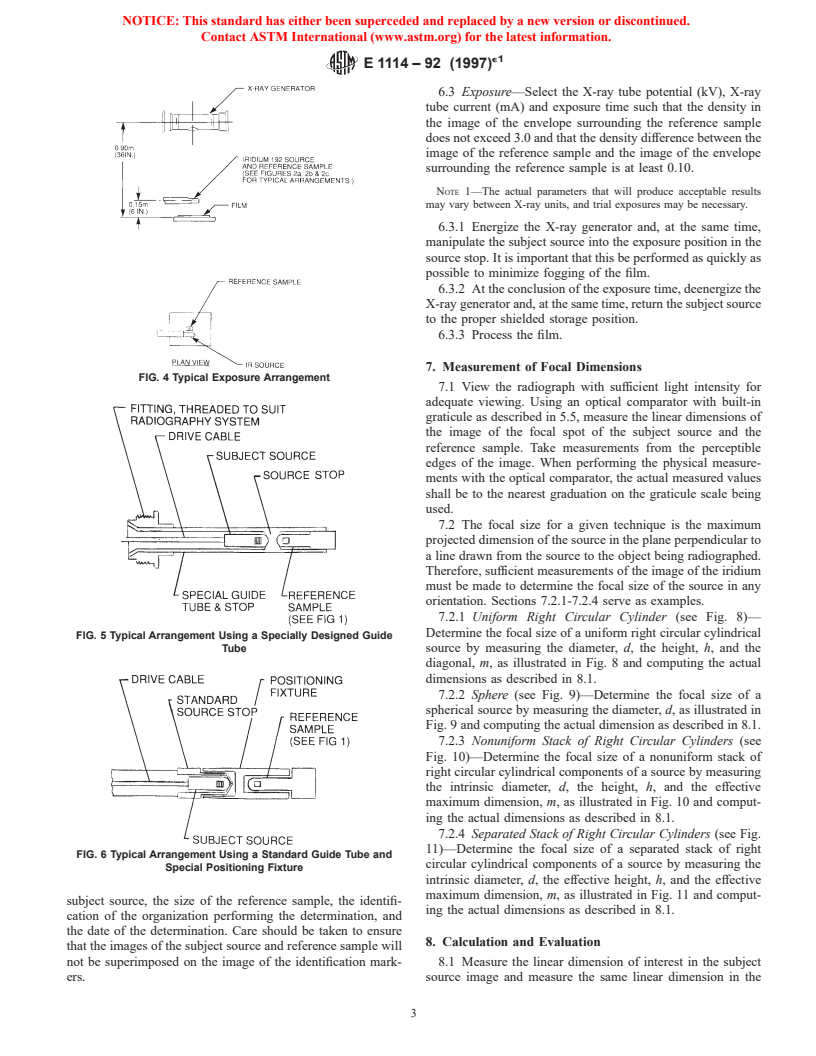

6.1 Set up the exposure arrangement as shown in Figs. 4-7.

100 48.0 160 kV 10 mA

Position the X-ray tube directly over the center of the film. The or 250 kV 4 mA

200 96.0 160 kV 20 mA

film plane must be normal to the central ray of the X-ray beam.

or 250 kV 8 mA

The X-ray focal spot should be 0.90 m (36 in.) from the film.

or 300 kV 6 mA

Position the reference sample and apparatus used to locate the

subject source (source stop) as close together as possible and

directly over the center of the film. The plane of the source stop

and reference sample must be parallel to the film and normal to device by the shortest source guide tube practicable in order to

the central ray of the X-ray beam. The source stop and minimize fogging of the film during source transit.

reference sample should be 0.15 m (6 in.) from the film. The 6.2 Place identification markers to be imaged on the film to

source stop should be connected to the radiographic exposure identify, as a minimum, the identification (serial number) of the

NOTICE: This standard has either been superceded an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.