ASTM D2229-99

(Test Method)Standard Test Method for Adhesion Between Steel Tire Cords and Rubber

Standard Test Method for Adhesion Between Steel Tire Cords and Rubber

SCOPE

1.1 This test method covers the determination of the force required to pull a steel cord from a block of vulcanized rubber.

1.2 Although designed primarily for steel cord, this test method may be applied with modifications to wire used in rubber products.

1.3 This test method can also be used for evaluating rubber compound performance with respect to adhesion to steel cord.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2229 – 99

Standard Test Method for

Adhesion Between Steel Tire Cords and Rubber

This standard is issued under the fixed designation D 2229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope of strands or filaments and strands.

3.1.4 For definitions of other textile or rubber terms used in

1.1 This test method covers the determination of the force

this test method refer to Terminology D 123 or Terminology

required to pull a steel cord from a block of vulcanized rubber.

D 1566.

1.2 Although designed primarily for steel cord, this test

method may be applied with modifications to wire used in

4. Summary of Test Method

rubber products.

4.1 The steel cords are vulcanized into a block of rubber and

1.3 This test method can also be used for evaluating rubber

the force necessary to pull the cords linearly out of the rubber

compound performance with respect to adhesion to steel cord.

is measured.

1.4 The values stated in SI units are to be regarded as the

standard. No other units of measurement are included in this

5. Significance and Use

standard.

5.1 This test method is considered satisfactory for the

1.5 This standard does not purport to address all of the

acceptance testing of commercial shipments of steel tire cord

safety concerns, if any, associated with its use. It is the

because current estimates of between-laboratory precision for

responsibility of the user of this standard to establish appro-

single materials are considered acceptable and the method has

priate safety and health practices and determine the applica-

been used extensively in the trade for acceptance testing.

bility of regulatory limitations prior to use.

5.1.1 If there are differences or practical significances be-

tween reported test results for two laboratories (or more),

2. Referenced Documents

comparative tests should be performed to determine if there is

2.1 ASTM Standards:

a statistical bias between them, using competent statistical

D 76 Specification for Tensile Testing Machines for Tex-

assistance. As a minimum, the test samples should be used that

tiles

2 are as homogenous as possible, that are drawn from the

D 123 Terminology Relating to Textiles

material from which the disparate test results were obtained,

D 1566 Terminology Relating to Rubber

and that are randomly assigned in equal numbers to each

D 2904 Practice for Interlaboratory Testing of a Textile Test

laboratory for testing. Other materials with established test

Method that Produces Normally Distributed Data

4 values may be used for this purpose. The test results from the

E 105 Practice for Probability Sampling of Materials

two laboratories should be compared using a statistical test for

E 122 Practice for Choice of Sample Size to Estimate a

4 unpaired data, at a probability level chosen prior to the testing

Measure of Quality for a Lot or Process

series. If a bias is found, either its cause must be found and

3. Terminology corrected, or future test results must be adjusted in consider-

ation of the known bias.

3.1 Definitions

5.2 The mold described in this test method is primarily

3.1.1 adhesion, n—in tire fabrics, the force required to

designed for quality acceptance testing for steel cord where the

separate a textile material from rubber or other elastomer by a

sample size for each cord is 4 or a multiple thereof, but any

definite prescribed method.

mold/cavity combination which will provide the required test

3.1.2 rubber compound, n—as used in the manufacture of

block dimensions (Figs. 1 and 2) is acceptable.

rubber articles, an intimate mixture of elastomer(s) with all

5.3 Appendix X1 contains suggested ranges of environmen-

materials necessary for the finished article.

tal conditions for aging tests.

3.1.3 steel cord, n—a formed structure made of two or more

5.4 The property measured by this test method indicates

steel filaments when used as an end product or a combination

whether the adhesion of the steel cord to the rubber is greater

than the cohesion of the rubber, that is, complete rubber

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

coverage of the steel cord, or less than the cohesion of the

and is the direct responsibility of Subcommittee D13.19 on Tire Cord and Fabrics.

Current edition approved Nov. 10, 1999. Published January 2000. Originally

rubber, that is, lack of rubber coverage.

published as D 2229 –63 T. Last previous edition D 2229 – 98.

Annual Book of ASTM Standards, Vol 07.01.

6. Apparatus

Annual Book of ASTM Standards, Vol 09.01.

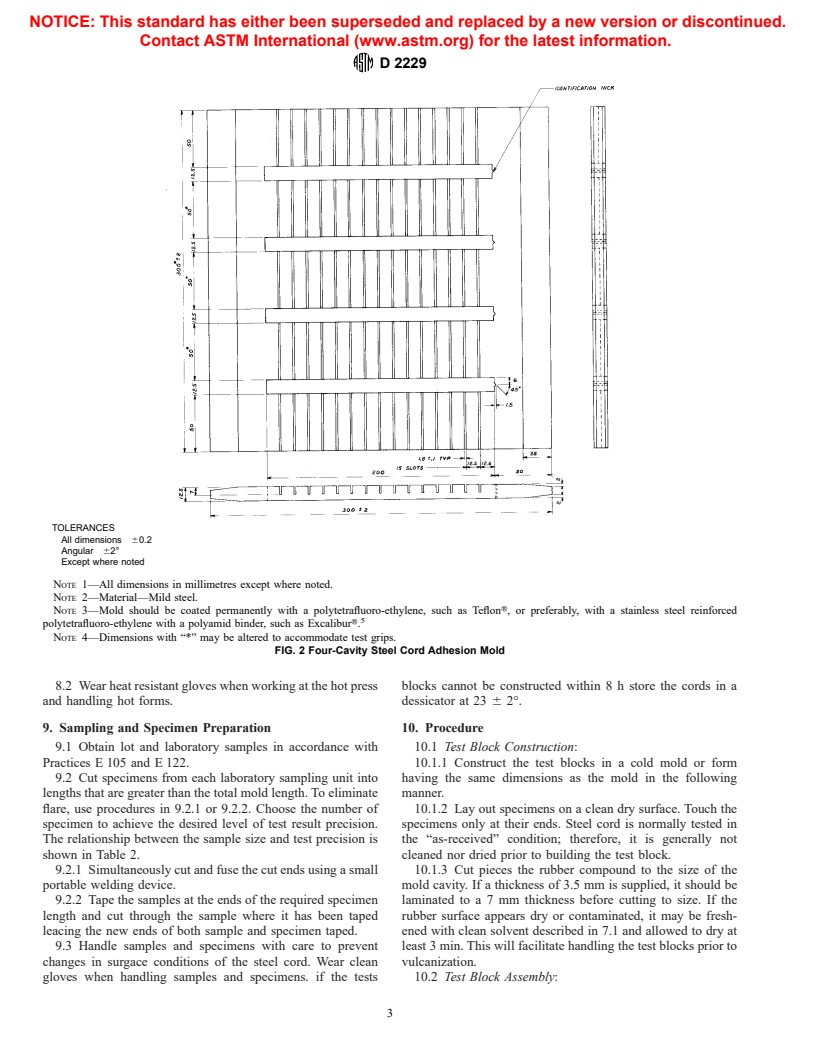

Annual Book of ASTM Standards, Vol 14.02. 6.1 Mold (Figs. 2 and 3)—The mold is designed to produce

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2229

FIG. 1 Definition of Test Block Dimensions

four test blocks with the preferred dimensions, each containing does not affect adhesion of the cord in the vulcanized block. A

15 steel cords. The blocks are 200 mm long and 12.5 mm thick suitable solvent has been found to be a special lead-free

(embedded cord length). When testing cords equal to or less gasoline (normal heptane), with a distillation range from 40 to

than 1.7-mm diameter, the mold in Fig. 2 and Fig. 3 should be 141°C and a maximum recovery of 97 %.

used to produce blocks, and when testing cords with a diameter 7.2 Rubber Compound—The rubber compound shall be

greater than 1.7 mm, the mold should be suitably modified. furnished by the user of the cord, together with pertinent

Molds designed to produce any other number of test blocks of information of the temperature and time for the vulcanization

the required dimensions are acceptable, and molds designed to of the particular rubber, as well as the conditioning period

produce blocks with different embedded cord length are between vulcanization and testing. Because the performance of

permitted. the rubber stock is affected by its age and storage conditions,

6.2 If more than one third of the cords break at the 12.5-mm the user of the cord shall also specify storage conditions and

embedment, it may be advisable to reduce the embedment by any time limits for storage of a particular rubber, or approve the

use of a suitable mold insert. storage conditions utilized by the producer. The rubber shall be

6.3 Testing Machine: provided in sheet form at least 215 mm wide and either

6.3.1 A constant-rate-of-extension (CRE) type tensile test- 7 − 0, + 1 mm thick or 3.5 − 0, + 0.5 mm thick, sheeted onto

ing machine conforming to the requirements of Specification nonhygroscopic backing, such as a plasticizer-free plastic

D 76 for textiles shall be used for measuring the pull-out force. material.

The rate of travel of the power actuated grip shall be 50 7.3 Mold Release Lubricant—A suitable mold release lubri-

mm/min. Other rates of travel up to 150 mm/min may be used cant may be applied to the empty mold to facilitate test block

as agreed upon by the purchaser and the supplier. removal. Excess lubricant shall be wiped from the mold and

6.3.2 The top grip shall apply force to the cord during particularly from the slots provided for the cords. The lubricant

testing that is normal to the face of the test block. should not be applied when exposed cord is in the area, and

6.3.3 The bottom grip (Fig. 4) shall be a special holder made should only be used when absolutely necessary. Use of a mold

for the vulcanized test block. release lubricant should be recorded on the test report.

6.4 Press—A curing press, large enough to take the mold,

NOTE 1—The use of mold release lubricant is not recommended. The

and capable of a minimum pressure of 3.5 MPa over the total

mold should be permanently coated with Teflont or preferably, with a

area of the mold plate. Electrical or steam heat for the top and

stainless steel reinforced nonstick coating, such as Excaliburt.

bottom platens shall be provided, of sufficient capacity for

8. Hazards

maintaining the mold components at the temperatures required

for the rubber compound being used. 8.1 Refer to the maufacturer’s material safety data sheets

6.5 Desiccator.

(MSDS) for information on handling, use, storage, and dis-

posal of chemicals used in this test.

7. Materials and Reagents

7.1 Solvent—A solvent may be used to freshen the surface

Excaliburt is a registered trademark of the Whitford Corporation, West

of the rubber when necessary, provided such solvent treatment Chester, PA.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2229

TOLERANCES

All dimensions 60.2

Angular 62°

Except where noted

NOTE 1—All dimensions in millimetres except where noted.

NOTE 2—Material—Mild steel.

NOTE 3—Mold should be coated permanently with a polytetrafluoro-ethylene, such as Teflont, or preferably, with a stainless steel reinforced

polytetrafluoro-ethylene with a polyamid binder, such as Excaliburt.

NOTE 4—Dimensions with “*” may be altered to accommodate test grips.

FIG. 2 Four-Cavity Steel Cord Adhesion Mold

8.2 Wear heat resistant gloves when working at the hot press blocks cannot be constructed within 8 h store the cords in a

and handling hot forms. dessicator at 23 6 2°.

9. Sampling and Specimen Preparation 10. Procedure

9.1 Obtain lot and laboratory samples in accordance with 10.1 Test Block Construction:

Practices E 105 and E 122. 10.1.1 Construct the test blocks in a cold mold or form

9.2 Cut specimens from each laboratory sampling unit into having the same dimensions as the mold in the following

lengths that are greater than the total mold length. To eliminate manner.

flare, use procedures in 9.2.1 or 9.2.2. Choose the number of 10.1.2 Lay out specimens on a clean dry surface. Touch the

specimen to achieve the desired level of test result precision. specimens only at their ends. Steel cord is normally tested in

The relationship between the sample size and test precision is the “as-received” condition; therefore, it is generally not

shown in Table 2. cleaned nor dried prior to building the test block.

9.2.1 Simultaneously cut and fuse the cut ends using a small 10.1.3 Cut pieces the rubber compound to the size of the

portable welding device. mold cavity. If a thickness of 3.5 mm is supplied, it should be

9.2.2 Tape the samples at the ends of the required specimen laminated toa7mm thickness before cutting to size. If the

length and cut through the sample where

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.