ASTM D7279-18e1

(Test Method)Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer

Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer

SIGNIFICANCE AND USE

4.1 Many petroleum products and some non-petroleum products are used as lubricants in the equipment, and the correct operation of the equipment depends upon the appropriate viscosity of the lubricant being used. Additionally, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

4.2 The viscosity of used oils is a commonly determined parameter in the oil industry to assess the effect of engine wear on the lube oils used, as well as the degradation of the engine parts during operation.

4.3 The Houillon viscometer tube method offers automated determination of kinematic viscosity. Typically a sample volume of less than 1 mL is required for the analysis.

SCOPE

1.1 This test method covers the measurement of the kinematic viscosity of transparent and opaque liquids; such as base oils, formulated oils, diesel oil, biodiesel, biodiesel blends, residual fuel oils, marine fuels, and used lubricating oils using a Houillon viscometer in automated mode.

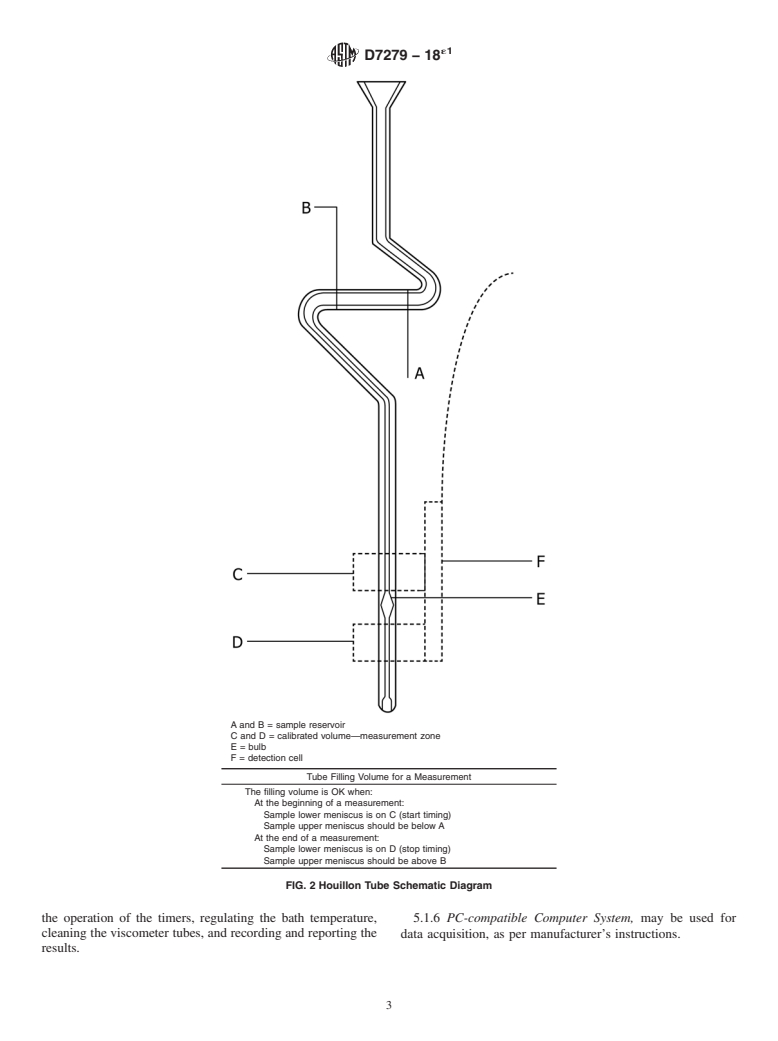

1.2 The range of kinematic viscosity capable of being measured by this test method is from 2 mm2/s to 2500 mm2/s (see Fig. 1). The range is dependent on the tube constant utilized. The temperature range that the apparatus is capable of achieving is between 20 °C and 150 °C, inclusive. However, the precision has only been determined for the viscosity range; 2 mm2/s to 478 mm2/s at 40 °C for base oils, formulated oils, diesel oil, biodiesel, and biodiesel blends; 3 mm2/s to 106 mm2/s at 100 °C for base oils and formulated oils; 25 mm2/s to 150 mm2/s at 40 °C and 5 mm2/s to 16 mm2/s at 100 °C for used lubricating oils; 25 mm2/s to 2500 mm2/s at 50 °C and 6 mm2/s to 110 mm2/s at 100 °C for residual fuels. As indicated for the materials listed in the precision section.

FIG. 1 Houillon Viscometer Typical Viscosity Range of Tube Constants

Note 1: Viscosity range of a Houillon tube is based on most practical flow time of 30 s to 200 s.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D7279 − 18

Standard Test Method for

Kinematic Viscosity of Transparent and Opaque Liquids by

1

Automated Houillon Viscometer

This standard is issued under the fixed designation D7279; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially corrected Eq 1 in December 2019.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method covers the measurement of the kine-

matic viscosity of transparent and opaque liquids; such as base

2. Referenced Documents

oils, formulated oils, diesel oil, biodiesel, biodiesel blends,

2

residual fuel oils, marine fuels, and used lubricating oils using 2.1 ASTM Standards:

a Houillon viscometer in automated mode. D445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and Calculation of Dynamic Viscos-

1.2 The range of kinematic viscosity capable of being

ity)

2 2

measured by this test method is from 2 mm /s to 2500 mm /s

D2162 Practice for Basic Calibration of Master Viscometers

(see Fig. 1). The range is dependent on the tube constant

and Viscosity Oil Standards

utilized.The temperature range that the apparatus is capable of

D4057 Practice for Manual Sampling of Petroleum and

achieving is between 20 °C and 150 °C, inclusive. However,

Petroleum Products

the precision has only been determined for the viscosity range;

D4177 Practice for Automatic Sampling of Petroleum and

2 2

2mm /s to 478 mm /s at 40 °C for base oils, formulated oils,

Petroleum Products

2

diesel oil, biodiesel, and biodiesel blends; 3 mm /s to

D6299 Practice for Applying Statistical Quality Assurance

2

106 mm /s at 100 °C for base oils and formulated oils;

and Control Charting Techniques to Evaluate Analytical

2 2 2 2

25 mm /s to 150 mm /s at 40 °C and 5 mm /s to 16 mm /s at

Measurement System Performance

2 2

100 °C for used lubricating oils; 25 mm /s to 2500 mm /s at

D6300 Practice for Determination of Precision and Bias

2 2

50 °C and 6 mm /s to 110 mm /s at 100 °C for residual fuels.

Data for Use in Test Methods for Petroleum Products and

As indicated for the materials listed in the precision section.

Lubricants

1.3 The values stated in SI units are to be regarded as

D6708 Practice for StatisticalAssessment and Improvement

standard. No other units of measurement are included in this

of Expected Agreement Between Two Test Methods that

standard.

Purport to Measure the Same Property of a Material

D6792 Practice for Quality Management Systems in Petro-

1.4 This standard does not purport to address all of the

leum Products, Liquid Fuels, and Lubricants Testing

safety concerns, if any, associated with its use. It is the

Laboratories

responsibility of the user of this standard to establish appro-

D7962 Practice for Determination of Minimum Immersion

priate safety, health, and environmental practices and deter-

Depth and Assessment of Temperature Sensor Measure-

mine the applicability of regulatory limitations prior to use.

ment Drift

For specific warning statements, see Section 6.

E563 Practice for Preparation and Use of an Ice-Point Bath

1.5 This international standard was developed in accor-

as a Reference Temperature

dance with internationally recognized principles on standard-

E644 Test Methods for Testing Industrial Resistance Ther-

ization established in the Decision on Principles for the

mometers

Development of International Standards, Guides and Recom-

E1750 Guide for Use of Water Triple Point Cells

E2877 Guide for Digital Contact Thermometers

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.07 on Flow Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2018.PublishedJuly2018.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2006. Last previous edition approved in 2016 as D7279 – 16. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7279-18E01. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7279 − 18

NOTE 1—Viscosity range of a Houillon tube is based on most practical flow time of 30 s to 200 s.

FIG. 1 Houillon Viscometer Typical Viscosity Range of Tube Constants

2.2 ISO Standards: 4. Significance and Use

I

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D7279 − 18 D7279 − 18

Standard Test Method for

Kinematic Viscosity of Transparent and Opaque Liquids by

1

Automated Houillon Viscometer

This standard is issued under the fixed designation D7279; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially corrected Eq 1 in December 2019.

1. Scope*

1.1 This test method covers the measurement of the kinematic viscosity of transparent and opaque liquids; such as base oils,

formulated oils, diesel oil, biodiesel, biodiesel blends, residual fuel oils, marine fuels, and used lubricating oils using a Houillon

viscometer in automated mode.

2 2

1.2 The range of kinematic viscosity capable of being measured by this test method is from 2 mm /s to 2500 mm /s (see Fig.

1). The range is dependent on the tube constant utilized. The temperature range that the apparatus is capable of achieving is

2

between 20 °C and 150 °C, inclusive. However, the precision has only been determined for the viscosity range; 2 mm /s to

2 2 2

478 mm /s at 40 °C for base oils, formulated oils, diesel oil, biodiesel, and biodiesel blends; 3 mm /s to 106 mm /s at 100 °C for

2 2 2 2

base oils and formulated oils; 25 mm /s to 150 mm /s at 40 °C and 5 mm /s to 16 mm /s at 100 °C for used lubricating oils;

2 2 2 2

25 mm /s to 2500 mm /s at 50 °C and 6 mm /s to 110 mm /s at 100 °C for residual fuels. As indicated for the materials listed in

the precision section.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific warning statements, see Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D2162 Practice for Basic Calibration of Master Viscometers and Viscosity Oil Standards

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

D6708 Practice for Statistical Assessment and Improvement of Expected Agreement Between Two Test Methods that Purport

to Measure the Same Property of a Material

D6792 Practice for Quality Management Systems in Petroleum Products, Liquid Fuels, and Lubricants Testing Laboratories

D7962 Practice for Determination of Minimum Immersion Depth and Assessment of Temperature Sensor Measurement Drift

E563 Practice for Preparation and Use of an Ice-Point Bath as a Reference Temperature

E644 Test Methods for Testing Industrial Resistance Thermometers

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

Current edition approved June 1, 2018. Published July 2018. Originally approved in 2006. Last previous edition approved in 2016 as D7279 – 16. DOI:

10.1520/D7279-18.10.1520/D7279-18E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7279 − 18

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.