ASTM G29-21

(Practice)Standard Practice for Determining Cyanobacterial Resistance of Polymeric Films

Standard Practice for Determining Cyanobacterial Resistance of Polymeric Films

SIGNIFICANCE AND USE

3.1 Bodies of water, such as swimming pools, artificial ponds, and irrigation ditches often are lined with polymeric films. Cyanobacteria tend to grow in such bodies of water under the proper atmospheric conditions, and they can produce slimy and unsightly deposits on the film. The method described herein is useful in evaluating the degree and permanency of protection against surface growth of cyanobacteria afforded by various additives incorporated in the film.

SCOPE

1.1 This practice covers the determination of the susceptibility of polymeric films to the attachment and proliferation of surface-growing cyanobacteria.

1.2 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G29 − 21

Standard Practice for

1

Determining Cyanobacterial Resistance of Polymeric Films

This standard is issued under the fixed designation G29; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope films. Cyanobacteria tend to grow in such bodies of water

under the proper atmospheric conditions, and they can produce

1.1 This practice covers the determination of the suscepti-

slimyandunsightlydepositsonthefilm.Themethoddescribed

bility of polymeric films to the attachment and proliferation of

herein is useful in evaluating the degree and permanency of

surface-growing cyanobacteria.

protection against surface growth of cyanobacteria afforded by

1.2 Units—The values stated in SI units are to be regarded

various additives incorporated in the film.

as standard. The values given in parentheses after SI units are

provided for information only and are not considered standard.

4. Apparatus

1.3 This standard does not purport to address all of the

4.1 Propagation Tank:

safety concerns, if any, associated with its use. It is the

4.1.1 A small fish tank (10 gal) is used to contain a

responsibility of the user of this standard to establish appro-

cyanobacteria propagation system where culture medium is

priate safety, health, and environmental practices and deter-

recirculated through a polymeric tube with holes punched in

mine the applicability of regulatory limitations prior to use.

the bottom over the top of a polymeric mesh screen inside of

1.4 This international standard was developed in accor-

the tank. This design was developed in order to provide ideal

dance with internationally recognized principles on standard-

conditions for propagation of the cyanobacteria that serve as

ization established in the Decision on Principles for the

inocula for each test. The polymeric mesh is supported in such

Development of International Standards, Guides and Recom-

a way that water cascades over the top from a distributor tube

mendations issued by the World Trade Organization Technical

above.Asmall, fully immersed recirculating pump rests on the

Barriers to Trade (TBT) Committee.

bottom of the tank and operates continuously to deliver the

tank contents to the distributor tube. The light required for

2. Summary of Practice

cyanobacterial propagation is provided by a 100 Wbulb placed

2.1 In this practice, test strips of polymeric film are sus-

300 mm (12 in.) away from the polymeric mesh. A timing

pended in glass jars maintained at room temperature. The test

device turns the light on for the desired light cycle each day.

strips are exposed to fluorescent light and in direct contact with

4.1.2 The propagation tank that is used as the permanent

a standardized inoculum of the filamentous blue-green cyano-

source of inoculum is filled to approximately one-third capac-

bacterium Oscillatoria in culture medium. The sample test jars

ity with the culture medium. Heavy growth of Oscillatoria

are re-inoculated with fresh cyanobacteria every second or

rapidlydevelopsonthepolymericmeshscreenand,atdifferent

third day.Acontrol using untreated polymeric film is used as a

phases, this growth appears light green, dark green, or black.

basis of comparison.The inoculum is prepared with the help of

NOTE 1—Culture medium in the propagation tank is discarded monthly

a propagation apparatus made from a small fish tank. The test

and replaced with fresh media.

is terminated at the end of two weeks, or whenever the

4.2 Test Chambers:

untreated control shows dense cyanobacterial growth.

4.2.1 One litre (1 qt) wide-mouth glass jars, 170 mm

3

3. Significance and Use

(6 ⁄4 in.) high by 76 mm (3 in.) in inside diameter, or

equivalent, serve as test chambers wherein water containing an

3.1 Bodies of water, such as swimming pools, artificial

inoculum of the cyanobacterial organisms and strips of the

ponds, and irrigation ditches often are lined with polymeric

polymeric film are maintained in contact.

4.2.2 The jars in 4.2.1 are placed in a suitable glass

1

container, such as a 38 L (10 gal) fish tank that is illuminated

This practice is under the jurisdiction ofASTM Committee G03 on Weathering

and Durability and is the direct responsibility of Subcommittee G03.04 on

by four 20 W “cool white” fluorescent bulbs, arranged two on

Biological Deterioration.

each long side of the tank, at the level of the growing

Current ed

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G29 − 16 G29 − 21

Standard Practice for

Determining AlgalCyanobacterial Resistance of Polymeric

1

Films

This standard is issued under the fixed designation G29; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This practice covers the determination of the susceptibility of polymeric films to the attachment and proliferation of

surface-growing algae.cyanobacteria.

1.2 Units—The values stated in SI units are to be regarded as the standard. The inch-pound units values given in parentheses are

for information only. after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Summary of Practice

2.1 In this practice, test strips of polymeric film are suspended in glass jars maintained at room temperature. The test strips are

exposed to fluorescent light and in direct contact with a standardized inoculum of the filamentous blue-green algacyanobacterium

Oscillatoria in culture medium. The sample test jars are re-inoculated with fresh algacyanobacteria every second or third day. A

control using untreated polymeric film is used as a basis of comparison. The inoculum is prepared with the help of a propagation

apparatus made from a small fish tank. The test is terminated at the end of two weeks, or whenever the untreated control shows

dense algalcyanobacterial growth.

3. Significance and Use

3.1 Bodies of water, such as swimming pools, artificial ponds, and irrigation ditches often are lined with polymeric films.

AlgaeCyanobacteria tend to grow in such bodies of water under the proper atmospheric conditions, and they can produce slimy

and unsightly deposits on the film. The method described herein is useful in evaluating the degree and permanency of protection

against surface growth of algaecyanobacteria afforded by various additives incorporated in the film.

4. Apparatus

4.1 Propagation Tank:

1

This practice is under the jurisdiction of ASTM Committee G03 on Weathering and Durability and is the direct responsibility of Subcommittee G03.04 on Biological

Deterioration.

Current edition approved Dec. 1, 2016Dec. 1, 2021. Published March 2017January 2022. Originally approved in 1971. Last previous edition approved in 20102016 as

G29 – 96 (2010).G29 – 16. DOI: 10.1520/G0029-16.10.1520/G0029-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

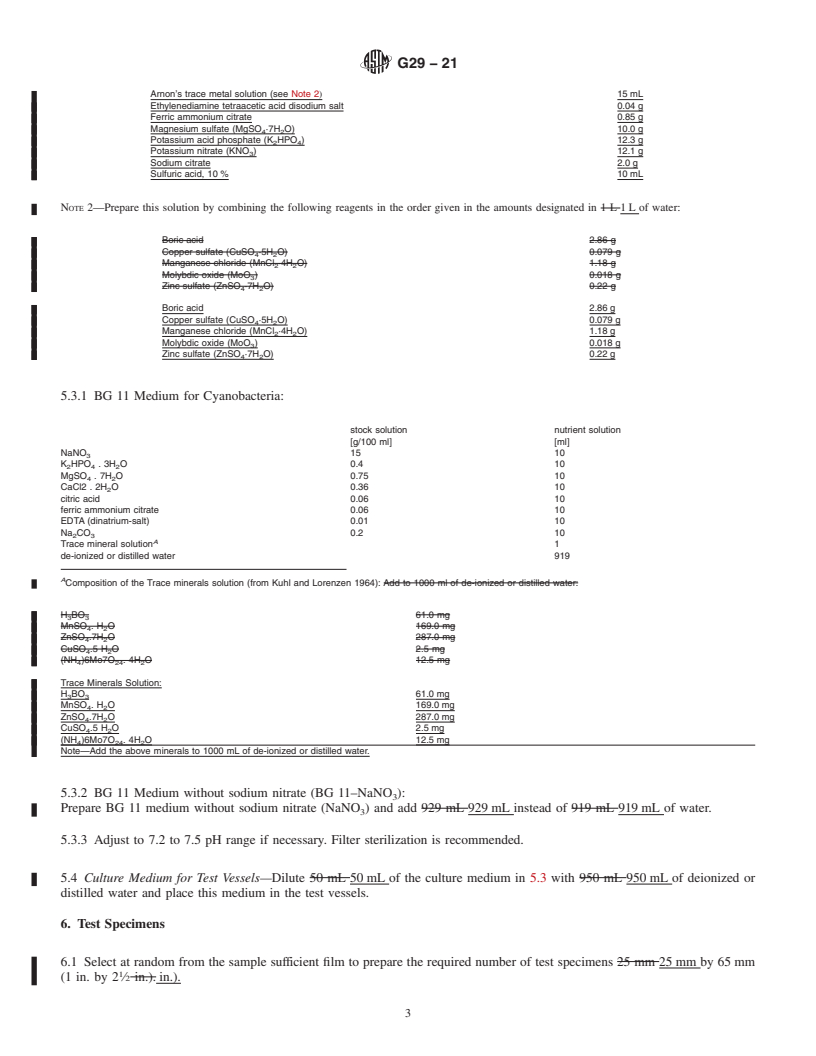

G29 − 21

4.1.1 A small fish tank (10 gal) is used to contain an algaea cyanobacteria propagation system where culture medium is

recirculated through a polymeric tube with holes punched in the bottom over the top of a polymeric mesh screen inside of the tank.

This design was developed in order to provide ideal conditions for propagation of the algaecyanobacteria that serve as inocula for

each test. The polymeric mesh is supported in such a way that water cascades over the top from a distributor tube above. A small,

fully immersed recirculating pump rests on the bottom of the tank and operates continuously to deliver the tank contents to the

distributor tube. The light required for algalcyanobacterial propagation is provided by a 100-W100 W bulb placed 300 mm 300 mm

(12 in.) away from the polymeric mesh. A timing device turns the light on for the desired light cycle each day.

4.1.2 The propagation tank that is used as the permanent source of inoculum is filled to approximately one-third capacity with the

culture medium. Heavy growth of Oscillatoria rapidly develops on the polymeric mesh screen and, at different phases, this growth

ap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.