ASTM D2983-02a

(Test Method)Standard Test Method for Low-Temperature Viscosity of Lubricants Measured by Brookfield Viscometer

Standard Test Method for Low-Temperature Viscosity of Lubricants Measured by Brookfield Viscometer

SCOPE

1.1 This test method describes the use of the Brookfield viscometer and a low-temperature bath for the determination of the low-shear-rate viscosity of lubricants. The test may operate in the viscosity range of 500 to 1 000 000 mPa·s (cP). The bath-controlled temperature is selected within the range of +5° to -40°C.

1.2 The test method uses the SI unit, milliPascal-second (mPa·s), as the unit of viscosity. (1 cP = 1 mPa·s).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2983 – 02a

Standard Test Method for

Low-Temperature Viscosity of Lubricants Measured by

1

Brookfield Viscometer

This standard is issued under the fixed designation D 2983; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

4

1. Scope * 3.1.2 reference viscosity —the viscosity of a Newtonian

standard reference fluid specified at each of several user-

1.1 This test method describes the use of the Brookfield

specified temperatures. Reference viscosities of typical stan-

viscometer and a low-temperature bath for the determination of

dard reference fluids are listed in Appendix X2.

the low-shear-rate viscosity of lubricants. The test may operate

in the viscosity range of 500 to 1 000 000 mPa·s (cP). The

4. Summary of Test Method

bath-controlled temperature is selected within the range of +5°

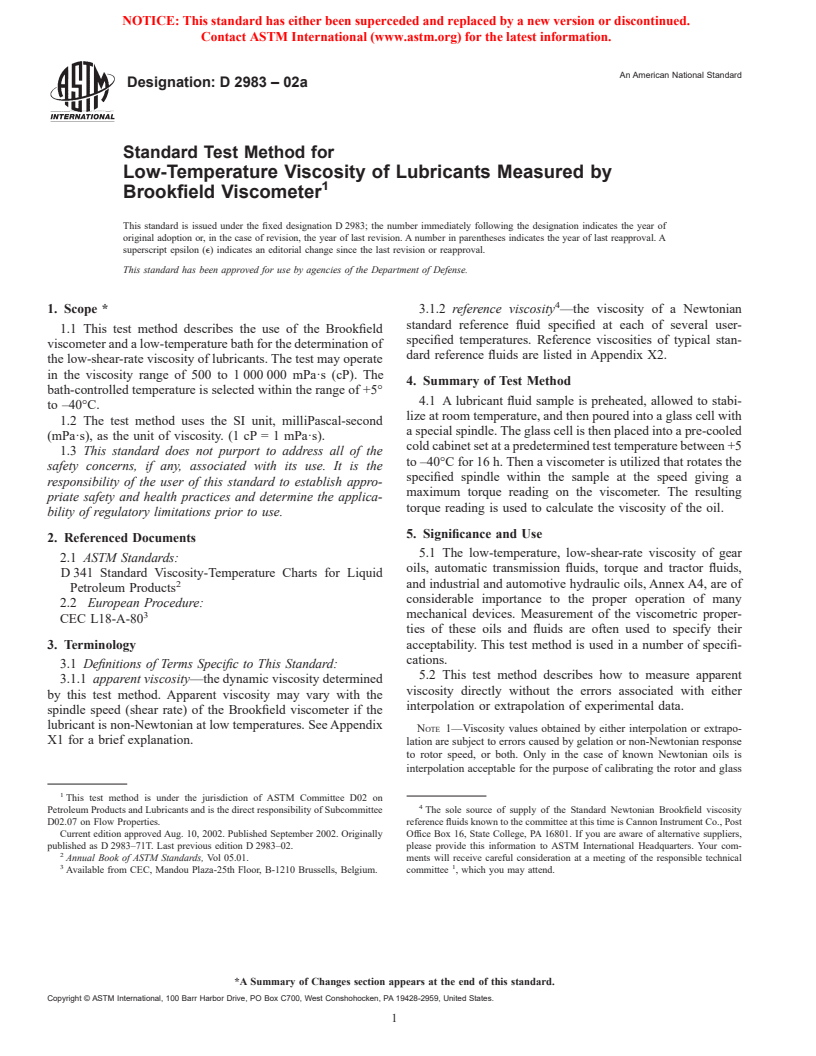

4.1 A lubricant fluid sample is preheated, allowed to stabi-

to –40°C.

lize at room temperature, and then poured into a glass cell with

1.2 The test method uses the SI unit, milliPascal-second

a special spindle. The glass cell is then placed into a pre-cooled

(mPa·s), as the unit of viscosity. (1 cP = 1 mPa·s).

cold cabinet set at a predetermined test temperature between +5

1.3 This standard does not purport to address all of the

to –40°C for 16 h. Then a viscometer is utilized that rotates the

safety concerns, if any, associated with its use. It is the

specified spindle within the sample at the speed giving a

responsibility of the user of this standard to establish appro-

maximum torque reading on the viscometer. The resulting

priate safety and health practices and determine the applica-

torque reading is used to calculate the viscosity of the oil.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 The low-temperature, low-shear-rate viscosity of gear

2.1 ASTM Standards:

oils, automatic transmission fluids, torque and tractor fluids,

D 341 Standard Viscosity-Temperature Charts for Liquid

2 and industrial and automotive hydraulic oils, Annex A4, are of

Petroleum Products

considerable importance to the proper operation of many

2.2 European Procedure:

3 mechanical devices. Measurement of the viscometric proper-

CEC L18-A-80

ties of these oils and fluids are often used to specify their

3. Terminology acceptability. This test method is used in a number of specifi-

cations.

3.1 Definitions of Terms Specific to This Standard:

5.2 This test method describes how to measure apparent

3.1.1 apparent viscosity—the dynamic viscosity determined

viscosity directly without the errors associated with either

by this test method. Apparent viscosity may vary with the

interpolation or extrapolation of experimental data.

spindle speed (shear rate) of the Brookfield viscometer if the

lubricant is non-Newtonian at low temperatures. See Appendix

NOTE 1—Viscosity values obtained by either interpolation or extrapo-

X1 for a brief explanation. lation are subject to errors caused by gelation or non-Newtonian response

to rotor speed, or both. Only in the case of known Newtonian oils is

interpolation acceptable for the purpose of calibrating the rotor and glass

1

This test method is under the jurisdiction of ASTM Committee D02 on

4

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee The sole source of supply of the Standard Newtonian Brookfield viscosity

D02.07 on Flow Properties. reference fluids known to the committee at this time is Cannon Instrument Co., Post

Current edition approved Aug. 10, 2002. Published September 2002. Originally Office Box 16, State College, PA 16801. If you are aware of alternative suppliers,

published as D 2983–71T. Last previous edition D 2983–02. please provide this information to ASTM International Headquarters. Your com-

2

Annual Book of ASTM Standards, Vol 05.01. ments will receive careful consideration at a meeting of the responsible technical

3

1

Available from CEC, Mandou Plaza-25th Floor, B-1210 Brussells, Belgium. committee , which you may attend.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2983 – 02a

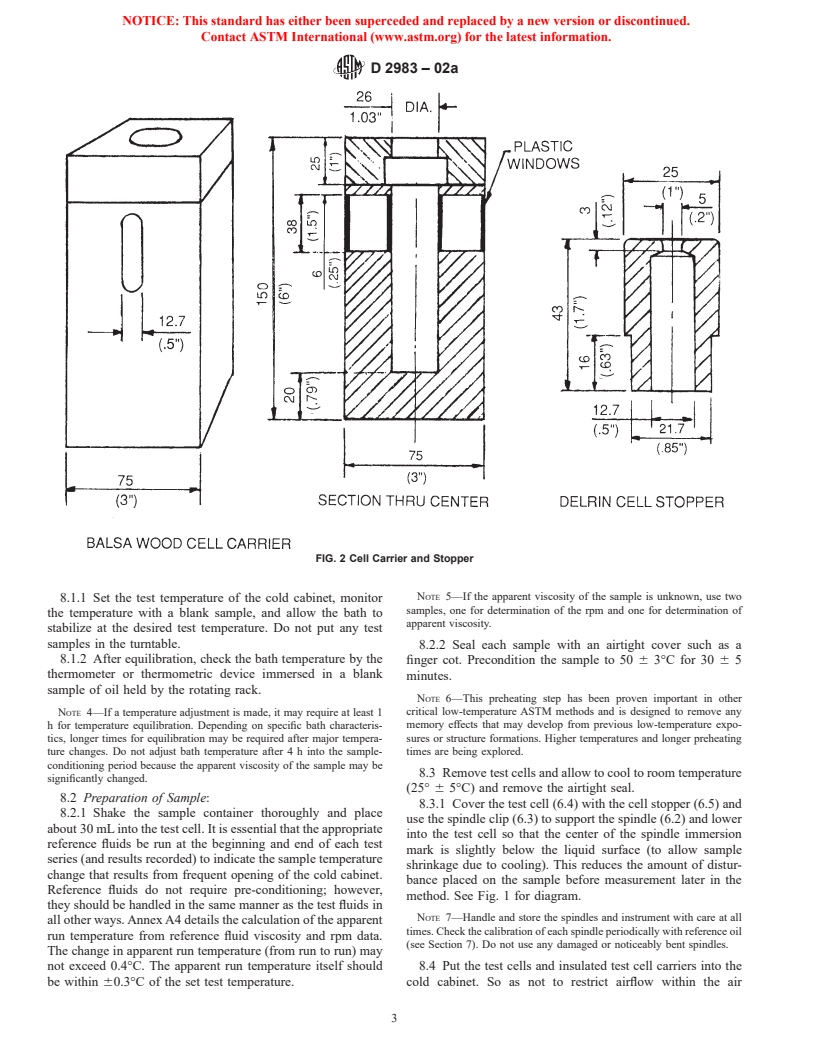

cell. If such viscosity versus temperature plots are requ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.