ASTM D4170-10

(Test Method)Standard Test Method for Fretting Wear Protection by Lubricating Greases

Standard Test Method for Fretting Wear Protection by Lubricating Greases

SIGNIFICANCE AND USE

This test method is used to evaluate the property of lubricating greases to protect oscillating bearings from fretting wear. This method, used for specification purposes, differentiates among greases allowing low, medium, and high amounts of fretting wear under the prescribed test conditions. The test has been used to predict the fretting performance of greases in wheel bearings of passenger cars shipped long distances. Test results do not necessarily correlate with results from other types of service. It is the responsibility of the user to determine whether test results correlate with other types of service.

SCOPE

1.1 This test method evaluates the fretting wear protection provided by lubricating greases.

1.2 The values stated in SI units are to be regarded as the standard. Other units are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.2 and 9.2.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4170 − 10

Standard Test Method for

1

Fretting Wear Protection by Lubricating Greases

This standard is issued under the fixed designation D4170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* ance of rust, which gives rise to the nearly synonymous terms,

fretting corrosion and friction oxidation. A related, but some-

1.1 This test method evaluates the fretting wear protection

what different phenomenon often accompanies fretting wear.

provided by lubricating greases.

False brinelling is localized fretting wear that occurs when the

1.2 The values stated in SI units are to be regarded as the

rolling elements of a bearing vibrate or oscillate with small

standard. Other units are for information only.

amplitude while pressed against the bearing race. The mecha-

1.3 This standard does not purport to address all of the

nism proceeds in stages: (1) asperities weld, are torn apart, and

safety concerns, if any, associated with its use. It is the form wear debris that is subsequently oxidized; (2) due to the

responsibility of the user of this standard to establish appro-

small-amplitude motion, the oxidized detritus cannot readily

priate safety and health practices and determine the applica- escape, and being abrasive, the oxidized wear debris acceler-

bility of regulatory limitations prior to use. For specific

ates the wear. As a result, wear depressions are formed in the

warning statements, see 7.2 and 9.2. bearing race. These depressions appear similar to the Brinell

depressions obtained with static overloading. Although false

2. Referenced Documents

brinelling can occur in this test, it is not characterized as such,

2

and instead, it is included in the determination of fretting wear.

2.1 ASTM Standards:

Test Methods for Rating Motor, Diesel, andAviation Fuels;

4. Summary of Test Method

Motor Fuels (Section I), Reference Materials and Blend-

ing Accessories (Annex 2), Reference Fuels (A2.7.3.3), 4.1 The tester is operated with two ball thrust bearings,

and Table 32 (Specification for n-Heptane Motor Fuel)

lubricatedwiththetestgrease,oscillatedthroughanarcof0.21

3

rad (12°), at a frequency of 30.0 Hz (1800 cpm), under a load

2.2 Military Standard:

of 2450 N (550 lbf), for 22 h at room temperature (Note 1).

MIL-S-22473D Sealing, Locking and Retaining

Fretting wear is determined by measuring the mass loss of the

Compounds, Single-Component

bearing races.

3. Terminology

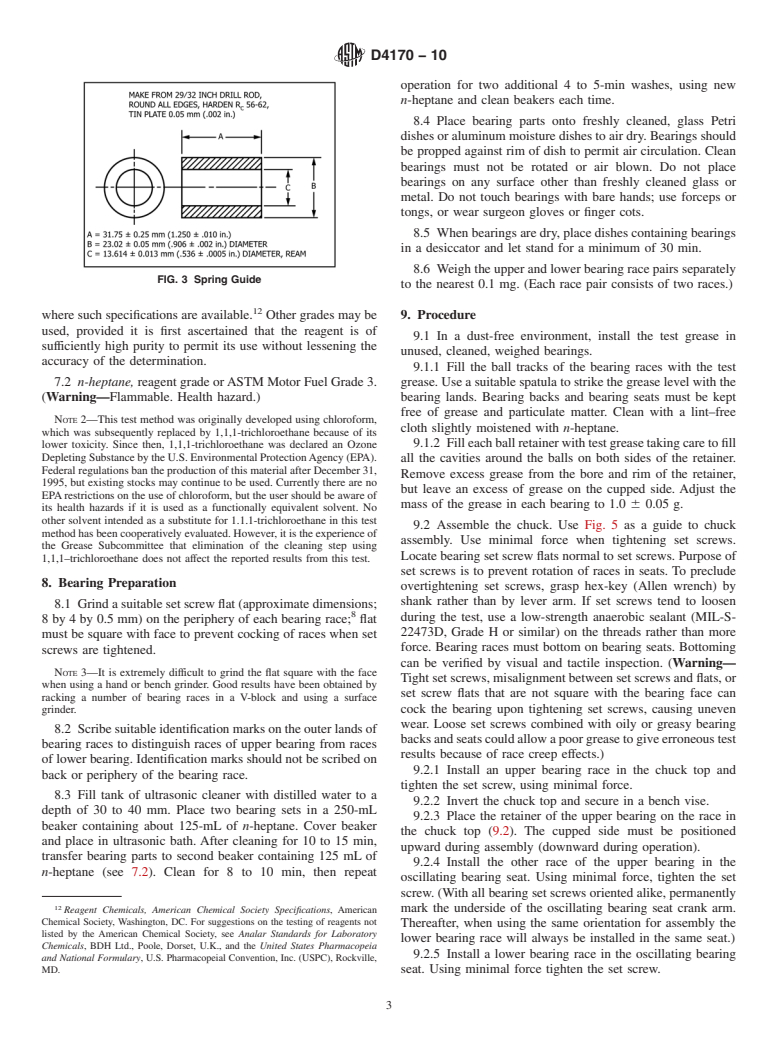

NOTE 1—Arc, frequency, and load are factory-set operating conditions

and should not be altered. The load spring constant may change over an

3.1 Definitions:

extended time period. Spring calibration should be checked periodically

3.1.1 fretting wear, n—a form of attritive wear caused by

and, if necessary, a suitable shim should be fabricated to obtain the

vibratory or oscillatory motion of limited amplitude character-

required load (63 %) at the assembled length of the spring.

ized by the removal of finely-divided particles from the

4

rubbing surfaces.

5. Significance and Use

3.1.1.1 Discussion—Air can cause immediate local oxida-

5.1 This test method is used to evaluate the property of

tion of the wear particles produced by fretting wear. In

lubricating greases to protect oscillating bearings from fretting

addition, environmental moisture or humidity can hydrate the

wear. This method, used for specification purposes, differenti-

oxidation product. In the case of ferrous metals, the oxidized

ates among greases allowing low, medium, and high amounts

wear debris is abrasive iron oxide (Fe O ) having the appear-

2 3

of fretting wear under the prescribed test conditions. The test

has been used to predict the fretting performance of greases in

5

wheel bearings of passenger cars shipped long distances. Test

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of results do not necessarily correlate with results from other

Subcommittee D02.G0.04 on Functional Tests - Tribology.

types of service. It is the responsibility of the user to determine

Current edition approved May 1, 2010. Published June 2010. Originally

whether test results correlate with other types of service.

ε1

approved in 1982. Last previous edition approved in 2002 as D4170–97(2002) .

DOI: 10.1520/D4170-10.

2

See 1998 Annual Book of ASTM Standards, Vol 05.04.

3 5

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Verdura, T. M., “Development of a Standard Test to Evaluate Fretting

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098. Protection Qual

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D4170–97 (Reapproved 2002) Designation:D4170–10

Standard Test Method for

1

Fretting Wear Protection by Lubricating Greases

This standard is issued under the fixed designation D4170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Warning statements were moved from notes into text editorially in March 2003.

1. Scope*

1.1 This test method evaluates the fretting wear protection provided by lubricating greases.

1.2 The values stated in SI units are to be regarded as the standard. Other units are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, See For specific warning statements, see 7.2 , 7.3, 7.3.1, and and 9.2.

2. Referenced Documents

2

2.1 ASTM Standards:

Test Methods for Rating Motor, Diesel, and Aviation Fuels; Motor Fuels (Section I), Reference Materials and Blending

Accessories (Annex 2), Reference Fuels (A2.7.3.3), and Table 32 (Specification for n-Heptane Motor Fuel)

3

2.2 Military Standard:

MIL-S-22473D Sealing, Locking and Retaining Compounds, Single-Component

3. Terminology

3.1 Definitions:

3.1.1 fretting wear, n—a form of attritive wear caused by vibratory or oscillatory motion of limited amplitude characterized by

4

the removal of finely-divided particles from the rubbing surfaces.

3.1.1.1 Discussion—Air can cause immediate local oxidation of the wear particles produced by fretting wear. In addition,

environmental moisture or humidity can hydrate the oxidation product. In the case of ferrous metals, the oxidized wear debris is

abrasive iron oxide (Fe O ) having the appearance of rust, which gives rise to the nearly synonymous terms, fretting corrosion

2 3

andfrictionoxidation.Arelated,butsomewhatdifferentphenomenonoftenaccompaniesfrettingwear.Falsebrinellingislocalized

fretting wear that occurs when the rolling elements of a bearing vibrate or oscillate with small amplitude while pressed against the

bearing race. The mechanism proceeds in stages: (1) asperities weld, are torn apart, and form wear debris that is subsequently

oxidized; (2) due to the small-amplitude motion, the oxidized detritus cannot readily escape, and being abrasive, the oxidized wear

debris accelerates the wear. As a result, wear depressions are formed in the bearing race. These depressions appear similar to the

Brinell depressions obtained with static overloading.Although false brinelling can occur in this test, it is not characterized as such,

and instead, it is included in the determination of fretting wear.

4. Summary of Test Method

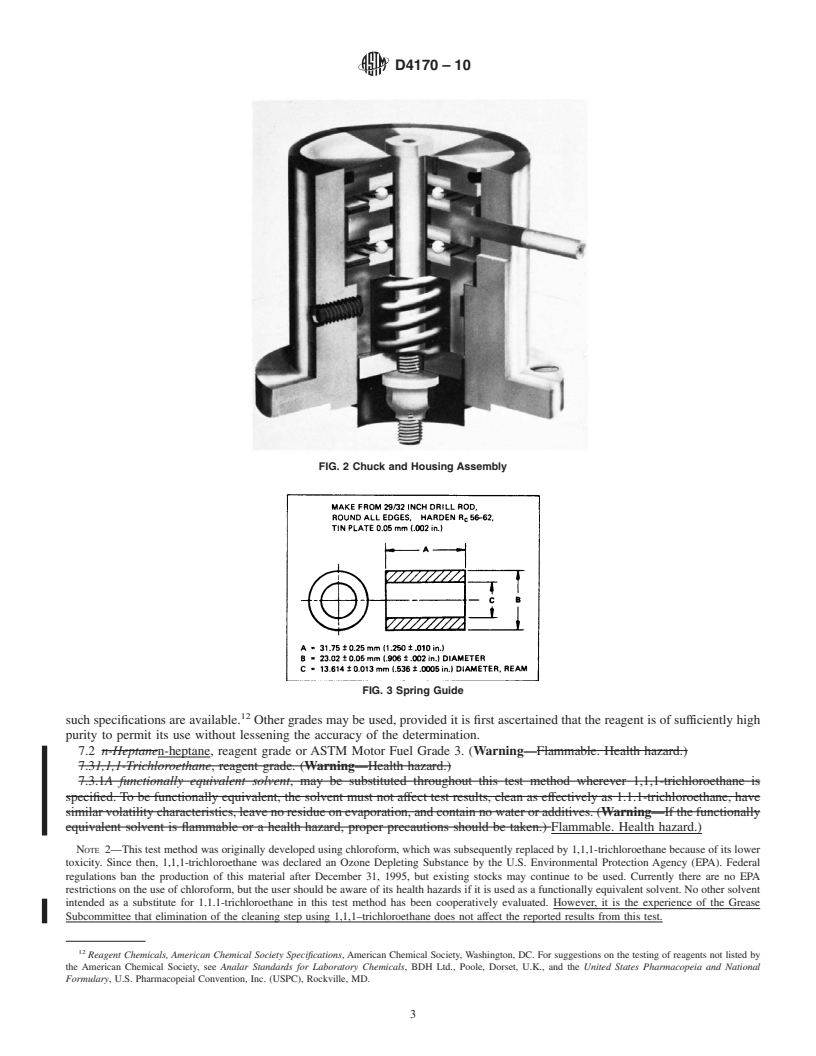

4.1 The tester is operated with two ball thrust bearings, lubricated with the test grease, oscillated through an arc of 0.21 rad

(12°), at a frequency of 30.0 Hz (1800 cpm), under a load of 2450 N (550 lbf), for 22 h at room temperature (Note 1). Fretting

wear is determined by measuring the mass loss of the bearing races.

NOTE 1—Arc,frequency,andloadarefactory-setoperatingconditionsandshouldnotbealtered.Theloadspringconstantmaychangeoveranextended

time period. Spring calibration should be checked periodically and, if necessary, a suitable shim should be fabricated to obtain the required load (63%)

at the assembled length of the spring.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G0 on

Lubricating Grease.

Current edition approved Nov. 10, 2002. Published March 2003. Originally approved in 1982. Last previous edition approved in 1997 as D4170–97. DOI:

10.1520/D4170-97R02E01.on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G0.04 on Functional Tests - Tribology.

´1

Current edition approved May 1, 2010. Published June 2010. Originally approved in 1982. Last previous edition approved in 2002 as D4170–97(2002) . DOI:

10.1520/D4170-10.

2

See 1998 Annual Book of ASTM Standards, Vol 05.04.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

4

NLGI Lubricating Grease Guide, 3rd edition.

*A Summ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.