ASTM D1434-82(2003)

(Test Method)Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

SIGNIFICANCE AND USE

These measurements give semiquantitative estimates for the gas transmission of single pure gases through film and sheeting. Correlation of measured values with any given use, such as packaged contents protection, must be determined by experience. The gas transmission rate is affected by conditions not specifically provided for in these tests, such as moisture content (Note 2), plasticizer content, and nonhomogeneities. These tests do not include any provision for testing seals that may be involved in packaging applications.

Note 2—The tests are run using gas with 0 % moisture changes.

Interlaboratory testing has revealed that permeances measured by these procedures exhibit a strong dependence on the procedure being used, as well as on the laboratory performing the testing. Agreement with other methods is sometimes poor and may be material-dependent. The materials being tested often affect the between-laboratory precision. The causes of these variations are not known at this time. It is suggested that this method not be used for referee purposes unless purchaser and seller can both establish that they are measuring the same quantity to a mutually agreed upon level of precision.

Use of the permeability coefficient (involving conversion of the gas transmission rate to a unit thickness basis) is not recommended unless the thickness-to-transmission rate relationship is known from previous studies. Even in essentially homogeneous structures, variations in morphology (as indicated, for example, by density) and thermal history may influence permeability.

SCOPE

1.1 This test method covers the estimation of the steady-state rate of transmission of a gas through plastics in the form of film, sheeting, laminates, and plastic-coated papers or fabrics. This test method provides for the determination of (1) gas transmission rate (GTR), (2) permeance, and, in the case of homogeneous materials, (3) permeability.

1.2 Two procedures are provided:

1.2.1 Procedure M Manometric.

1.2.2 Procedure V Volumetric.

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1434–82 (Reapproved 2003)

Standard Test Method for

Determining Gas Permeability Characteristics of Plastic Film

and Sheeting

This standard is issued under the fixed designation D1434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope used unit of GTR, is 1 mL (STP)/(m ·d) at a pressure

differential of one atmosphere.

1.1 This test method covers the estimation of the steady-

3.1.2 permeance, P—the ratio of the gas transmission rate

state rate of transmission of a gas through plastics in the form

to the difference in partial pressure of the gas on the two sides

of film, sheeting, laminates, and plastic-coated papers or

of the film. The SI unit of permeance is 1 mol/ (m ·s·Pa). The

fabrics. This test method provides for the determination of (1)

test conditions (see 5.1) must be stated.

gastransmissionrate(GTR),(2)permeance,and,inthecaseof

3.1.3 permeability,P—theproductofthepermeanceandthe

homogeneous materials, (3) permeability.

thickness of a film. The permeability is meaningful only for

1.2 Two procedures are provided:

homogeneous materials, in which it is a property characteristic

1.2.1 Procedure M— Manometric.

of the bulk material. This quantity should not be used unless

1.2.2 Procedure V— Volumetric.

the constancy of the permeability has been verified using

1.3 The values stated in SI units are to be regarded as the

severaldifferentthicknessesofthematerial.TheSIunitofPis

standard.

1 mol/(m·s·Pa). The test conditions (see 3.1) must be stated.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

NOTE 1—One millilitre (STP) is 44.62 µmol, one atmosphere is 0.1013

responsibility of the user of this standard to establish appro- MPa, and one day is 86.4 310 s. GTR in SI units is obtained by

−10

multiplying the value in inch-pound units by 5.160 310 . Additional

priate safety and health practices and determine the applica-

units and conversions are shown in Appendix X1.

bility of regulatory limitations prior to use.

3.1.4 steady state—the state attained when the amount of

2. Referenced Documents

gas absorbed in the film is in equilibrium with the flux of gas

2.1 ASTM Standards:

through the film. For MethodVthis is obtained when the GTR

D618 Practice for Conditioning Plastics for Testing

is constant.

D1898 Practice for Sampling of Plastics

4. Summary of Test Method

3. Terminology

4.1 The sample is mounted in a gas transmission cell so as

3.1 Definitions of Terms Specific to This Standard:

to form a sealed semibarrier between two chambers. One

3.1.1 gas transmission rate, GTR— the quantity of a given

chamber contains the test gas at a specific high pressure, and

gas passing through a unit of the parallel surfaces of a plastic

theotherchamber,atalowerpressure,receivesthepermeating

film in unit time under the conditions of test. The SI unit of

gas. Either of the following procedures is used:

GTR is 1 mol/(m ·s). The test conditions, including tempera-

4.1.1 Procedure M— In Procedure M the lower pressure

ture and partial pressure of the gas on both sides of the film,

chamber is initially evacuated and the transmission of the gas

must be stated. Other factors, such as relative humidity and

through the test specimen is indicated by an increase in

hydrostatic pressure, that influence the transport of the gas

pressure.

must also be stated.The inch-pound unit of GTR, a commonly

4.1.2 Procedure V— In Procedure V the lower pressure

chamber is maintained near atmospheric pressure and the

transmission of the gas through the test specimen is indicated

ThistestmethodisunderthejurisdictionofASTMCommitteeF02onFlexible

by a change in volume.

Barrier Materials and is the direct responsibility of Subcommittee F02.10 on

Permeation.

Current edition approved July 30, 1982. Published November 1982. Originally 5. Significance and Use

published as D1434–56T. Last previous edition D1434–75.

5.1 Thesemeasurementsgivesemiquantitativeestimatesfor

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the gas transmission of single pure gases through film and

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

Standards volume information, refer to the standard’s Document Summary page on

sheeting. Correlation of measured values with any given use,

the ASTM website.

such as packaged contents protection, must be determined by

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1434–82 (2003)

experience. The gas transmission rate is affected by conditions

not specifically provided for in these tests, such as moisture

content (Note 2), plasticizer content, and nonhomogeneities.

These tests do not include any provision for testing seals that

may be involved in packaging applications.

NOTE 2—The tests are run using gas with 0% moisture changes.

5.2 Interlaboratory testing has revealed that permeances

measured by these procedures exhibit a strong dependence on

the procedure being used, as well as on the laboratory

performing the testing. Agreement with other methods is

sometimes poor and may be material-dependent.The materials

being tested often affect the between-laboratory precision. The

causes of these variations are not known at this time. It is

suggested that this method not be used for referee purposes

unless purchaser and seller can both establish that they are

measuringthesamequantitytoamutuallyagreeduponlevelof

FIG. 1 Manometric Gas Transmission Cell

precision.

5.3 Use of the permeability coefficient (involving conver-

sionofthegastransmissionratetoaunitthicknessbasis)isnot

material. Enough specimens must be tested to ensure that the

recommended unless the thickness-to-transmission rate rela-

information obtained is representative of the batch or other lot

tionship is known from previous studies. Even in essentially

size being tested.

homogeneous structures, variations in morphology (as indi-

PROCEDURE M

cated, for example, by density) and thermal history may

influence permeability.

(Pressurechangesinthemanometriccellmaybedetermined

by either visual or automatic recording.)

6. Test Specimen

MANOMETRIC VISUAL DETERMINATION

6.1 Thetestspecimenshallberepresentativeofthematerial,

free of wrinkles, creases, pinholes, and other imperfections,

9. Apparatus

and shall be of uniform thickness. The test specimen shall be

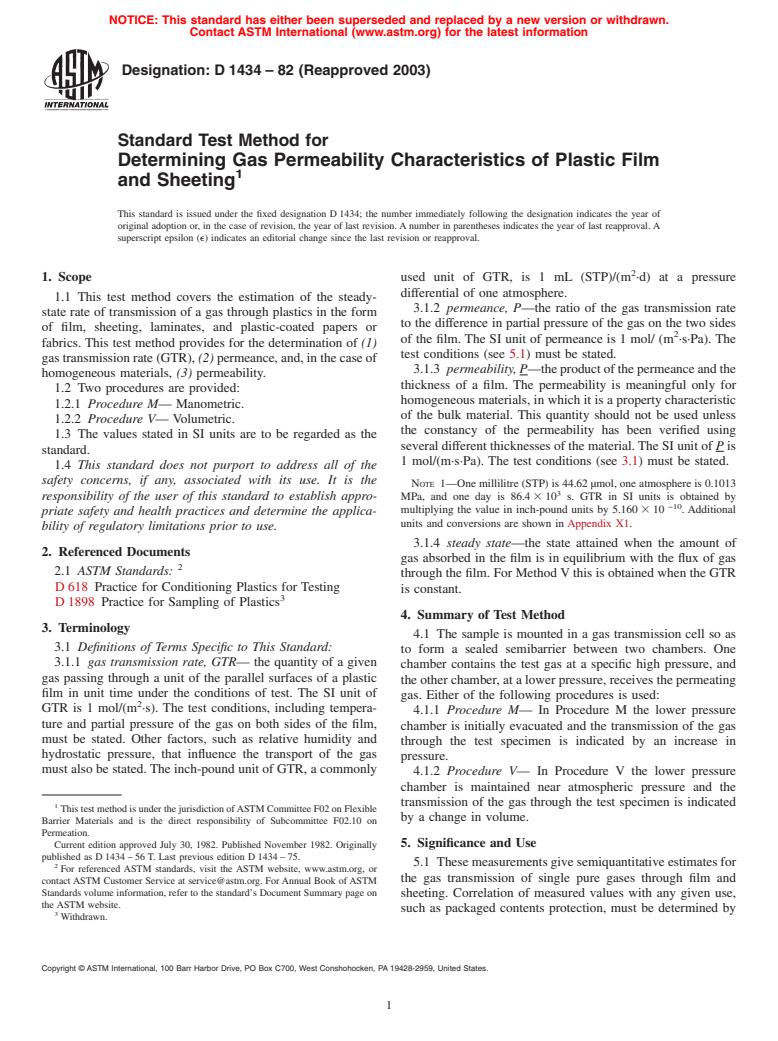

9.1 The apparatus shown in Fig. 1 and Fig. 2 consists of the

cuttoanappropriatesize(generallycircular)tofitthetestcell.

following items:

6.2 The thickness of the specimen shall be measured to the

9.1.1 Cell Manometer System—The calibrated cell manom-

nearest 2.5 µm (0.1 mil) with a calibrated dial gage (or

eter leg, which indicates the pressure of transmitted gas, shall

equivalent) at a minimum of five points distributed over the

consist of precision-bore glass capillary tubing at least 65 mm

entire test area. Maximum, minimum, and average values

long with an inside diameter of 1.5 mm.

should be recorded. An alternative measure of thickness

9.1.2 Cell Reservoir System, consisting of a glass reservoir

involving the weighing of a known area of specimens having a

of sufficient size to contain all the mercury required in the cell.

known density is also suitable for homogeneous materials.

9.1.3 Adapters—Solid and hollow adapters for measure-

ment of widely varying gas transmission rates. The solid

7. Conditioning

adapter provides a minimum void volume for slow transmis-

7.1 Standard Conditioning—Condition all test specimens at

sion rates. The hollow adapter increases the void volume by

23 6 2°C (73.4 6 3.6°F) in a desiccator over calcium chloride

about a factor of eight for faster transmission rates.

or other suitable desiccant for not less than 48 h prior to test in

9.1.4 Cell Vacuum Valve, capable of maintaining a vacuum-

accordance with Practice D618, for those tests where condi-

tight seal.

tioning is required. In cases of disagreement, the tolerances

9.1.5 Plate Surfaces, that contact the specimen and filter

shall be 6 1°C (6 1.8°F).

paper shall be smooth and flat.

7.2 Alternative Conditioning—Alternatives to 7.1 may be 9.1.6 O-Ring, for sealing the upper and lower plates.

9.1.7 Pressure Gage, mechanical or electrical type with a

used for conditioning the specimens provided that these

conditions are described in the report. range from 0 to 333 kPa absolute. Used for measuring

upstream gas pressure.

8. Sampling 9.1.8 Barometer, suitable for measuring the pressure of the

atmosphere to the nearest 133 Pa.

8.1 The techniques used in sampling a batch of material to

be tested by these procedures must depend upon the kind of

information that is sought. Care should be taken to ensure that

TheDowgastransmissioncellsuppliedbyCustomScientificInstruments,Inc.,

samples represent conditions across the width and along the

Whippany, NJ, has been found satisfactory for this purpose.

length of rolls of film. Practice D1898 provides guidelines for 1

The Demi-G Valve ( ⁄4-in. IPS) manufactured by G. W. Dahl Co., Inc., Bristol,

deciding what procedures to use in sampling a batch of RI, or a precision-ground glass stopcock, meets this requirement.

D1434–82 (2003)

A—Supporting Legs

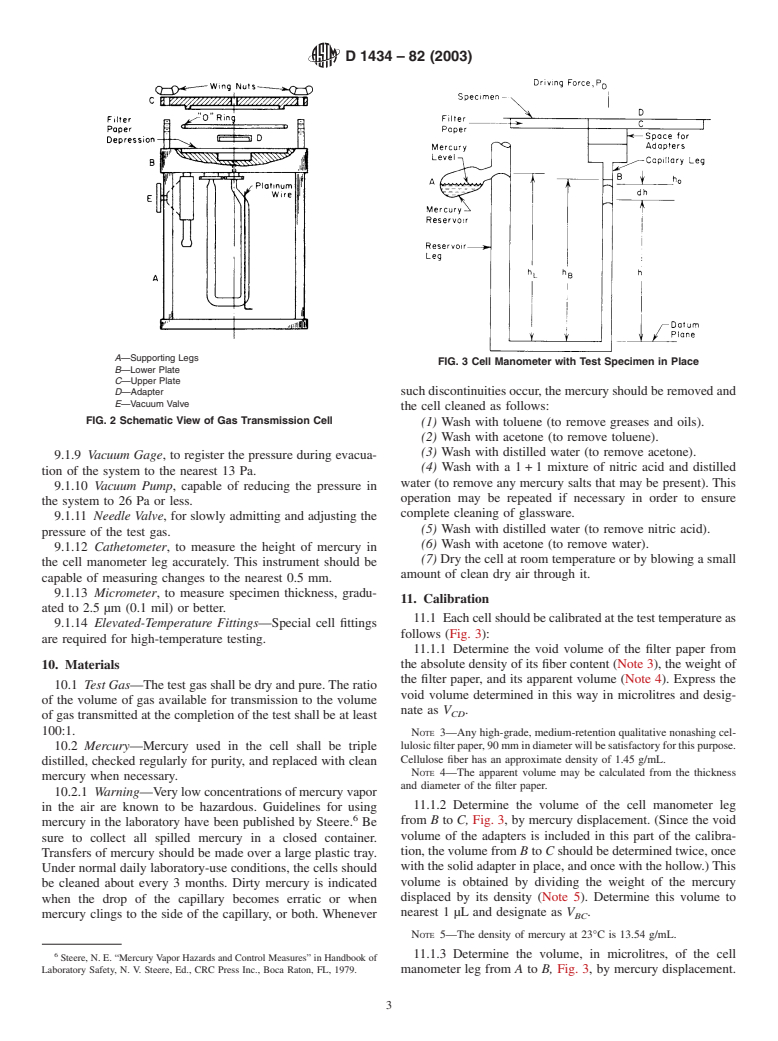

FIG. 3 Cell Manometer with Test Specimen in Place

B—Lower Plate

C—Upper Plate

D—Adapter suchdiscontinuitiesoccur,themercuryshouldberemovedand

E—Vacuum Valve

the cell cleaned as follows:

FIG. 2 Schematic View of Gas Transmission Cell

(1) Wash with toluene (to remove greases and oils).

(2) Wash with acetone (to remove toluene).

(3) Wash with distilled water (to remove acetone).

9.1.9 Vacuum Gage, to register the pressure during evacua-

(4) Wash with a 1+1 mixture of nitric acid and distilled

tion of the system to the nearest 13 Pa.

water (to remove any mercury salts that may be present). This

9.1.10 Vacuum Pump, capable of reducing the pressure in

operation may be repeated if necessary in order to ensure

the system to 26 Pa or less.

complete cleaning of glassware.

9.1.11 Needle Valve, for slowly admitting and adjusting the

(5) Wash with distilled water (to remove nitric acid).

pressure of the test gas.

(6) Wash with acetone (to remove water).

9.1.12 Cathetometer, to measure the height of mercury in

(7) Dry the cell at room temperature or by blowing a small

the cell manometer leg accurately. This instrument should be

amount of clean dry air through it.

capable of measuring changes to the nearest 0.5 mm.

9.1.13 Micrometer, to measure specimen thickness, gradu-

11. Calibration

ated to 2.5 µm (0.1 mil) or better.

11.1 Eachcellshouldbecalibratedatthetesttemperatureas

9.1.14 Elevated-Temperature Fittings—Special cell fittings

follows (Fig. 3):

are required for high-temperature testing.

11.1.1 Determine the void volume of the filter paper from

the absolute density of its fiber content (Note 3), the weight of

10. Materials

the filter paper, and its apparent volume (Note 4). Express the

10.1 Test Gas—Thetestgasshallbedryandpure.Theratio

void volume determined in this way in microlitres and desig-

of the volume of gas available for transmission to the volume

nate as V .

CD

of gas transmitted at the completion of the test shall be at least

100:1.

NOTE 3—Any high-grade, medium-retention qualitative nonashing cel-

10.2 Mercury—Mercury used in the cell shall be triple lulosicfilterpaper,90mmindiameterwillbesatisfactoryforthispurpose.

Cellulose fiber has an approximate density of 1.45 g/mL.

distilled, checked regularly for purity, and replaced with clean

NOTE 4—The apparent volume may be calculated from the thickness

mercury when necessary.

and diameter of the filter paper.

10.2.1 Warning—Verylowconcentrationsofmercuryvapor

11.1.2 Determine the volume of the cell manometer leg

in the air are known to be hazardous. Guidelines for using

from B to C, Fig. 3, by mercury displacement. (Since the void

mercury in the laboratory have been published by Steere. Be

volume of the adapters is included in this part of the calibra-

sure to collect all spilled mercury in a closed container.

tion,thevolumefromBtoCshouldbedeterminedtwice,once

Transfers of mercury should be made over a large plastic tray.

withthesolidadapterinplace,andoncewiththehollow.)This

Under normal daily laboratory-use conditions, the cells should

volume is obtained by dividing the weight of the mercury

be cleaned about every 3 months. Dirty mercury is indicated

displaced by its density (Note 5). Determine this volume to

when the drop of the capillary becomes erratic or when

nearest 1 µL and designate as V .

mercury clings to the side of the capillary, or both. Whenever

BC

NOTE 5—The density of mercury at 23°C is 13.54 g/mL.

11.1.3 Determine the volume, in microlitres, of the cell

Steere, N. E. “Mercury Vapor Hazards and Control Measures” in Handbook of

Laboratory Safety, N. V. Steere, Ed., CRC Press Inc., Boca Raton, FL, 1979. manometer leg from A to B, Fig. 3, by mercury displacement.

D1434–82 (2003)

Determine the average cross-sectional area of the capillary by

dividingthisvolumebythelength(expressedtothenearest0.1

mm) from A to B. Determine this area to the nearest 0.01 mm

and designate as a .

c

11.1.4 Determine the area of the filter paper cavity to the

nearest 1 mm . Designate this area as A, the area of transmis-

sion.

11.1.5 Pourthemercuryfromthereservoirintothemanom-

eterofthecellbycarefullytippingthecell.Recordthedistance

from the datum plane to the upper calibration line B in the

capillary leg as h . Record the distance from the datum plane

B

to the top of the mercury meniscus in the reservoir leg as h .

L

Determine h and h to the nearest 0.5 mm.

B L

11.2 NBS Standard Reference Material 1470 is a polyester

film whose permeance to oxygen gas has been certified for a

range of experimental conditions. The calibration steps in 11.1

canbeverifiedbycomparingmeasurementsobtainedusingthis

methodoftestintheuser’slaboratorywiththevaluesprovided

on the certificate accompanying the SRM. FIG. 4 Component Arrangement of Gas Transmission Equipment

12. Procedure

entire procedure. (If a leak occurs on a second trial, this may indicate a

12.1 Transfer all the mercury into the reservoir of the cell

mechanical failure of the equipment.)

manometer system by carefully tipping the cell in such a way

12.12 Record the height of the mercury in the capillary leg,

that the mercury pours into the reservoir.

h , at the start of each test, that is, immediately before the test

o

12.2 Ins

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.