ASTM D6699-01

(Practice)Standard Practice for Sampling Liquids Using Bailers

Standard Practice for Sampling Liquids Using Bailers

SCOPE

1.1 This practice covers the procedure for sampling stratified or un-stratified waters and liquid waste using bailers.

1.2 Three specific bailers are discussed in this practice. The bailers are the single and double check valve and differential pressure.

1.3 This standard does not cover all of the bailing devices available to the user. The bailers chosen for this practice are typical of those commercially available.

1.4 This practice should be used in conjunction with Guide D4687, Practice D5088, and Practice D5283.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6699–01

Standard Practice for

Sampling Liquids Using Bailers

This standard is issued under the fixed designation D 6699; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the procedure for sampling strati-

fied or un-stratified waters and liquid waste using bailers.

1.2 Three specific bailers are discussed in this practice. The

bailers are the single and double check valve and differential

pressure.

1.3 This standard does not cover all of the bailing devices

available to the user. The bailers chosen for this practice are

typical of those commercially available.

1.4 This practice should be used in conjunction with Guide

D 4687, Practice D 5088, and Practice D 5283.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 4448 Guide to Sampling Ground Water Wells

D 4687 Guide for General Planning of Sampling

D 4750 Test Method for Determining Subsurface Liquid

Levels in a Borehole or Monitoring Well (Observation

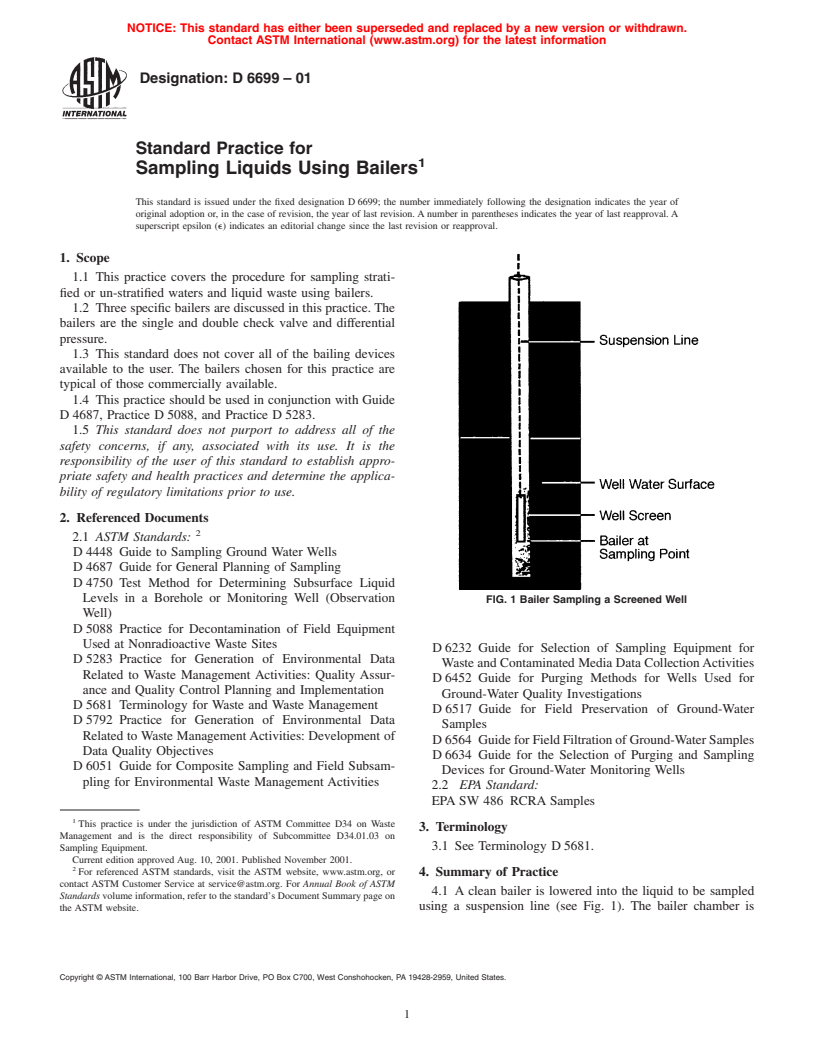

FIG. 1 Bailer Sampling a Screened Well

Well)

D 5088 Practice for Decontamination of Field Equipment

Used at Nonradioactive Waste Sites

D 6232 Guide for Selection of Sampling Equipment for

D 5283 Practice for Generation of Environmental Data

Waste and Contaminated Media Data CollectionActivities

Related to Waste Management Activities: Quality Assur-

D 6452 Guide for Purging Methods for Wells Used for

ance and Quality Control Planning and Implementation

Ground-Water Quality Investigations

D 5681 Terminology for Waste and Waste Management

D 6517 Guide for Field Preservation of Ground-Water

D 5792 Practice for Generation of Environmental Data

Samples

Related to Waste ManagementActivities: Development of

D 6564 GuideforFieldFiltrationofGround-WaterSamples

Data Quality Objectives

D 6634 Guide for the Selection of Purging and Sampling

D 6051 Guide for Composite Sampling and Field Subsam-

Devices for Ground-Water Monitoring Wells

pling for Environmental Waste Management Activities

2.2 EPA Standard:

EPA SW 486 RCRA Samples

This practice is under the jurisdiction of ASTM Committee D34 on Waste

3. Terminology

Management and is the direct responsibility of Subcommittee D34.01.03 on

3.1 See Terminology D 5681.

Sampling Equipment.

Current edition approved Aug. 10, 2001. Published November 2001.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4. Summary of Practice

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 A clean bailer is lowered into the liquid to be sampled

Standards volume information, refer to the standard’s Document Summary page on

using a suspension line (see Fig. 1). The bailer chamber is

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6699–01

TABLE 1 General Advantages and Limitations of Bailers

allowed to fill with the sample. The check valve or valves on

bailers close when the bailer stops. The bailer is raised to the Advantages Limitations

surface where the sample is discharged into a clean sample

Simple to use Time consuming to use

Some have a low initial cost Valves may leak

confiner.

Can be made almost any size Tend to expose sample to the

atmosphere

5. Significance and Use

Can be constructed of a variety May result in sample

of materials contamination

5.1 A bailer is a device for obtaining a sample from

No external power source Bailers are not suitable for

stratified or un-stratified waters and liquid wastes. The most

needed sampling thin surface layers

common use of a bailer is for sampling ground water from like thin layers of light non-

aqueous phase liquids

single-screened wells (Fig. 1) and well clusters (see Guide

D 4448).

5.2 This practice is applicable to sampling water and liquid

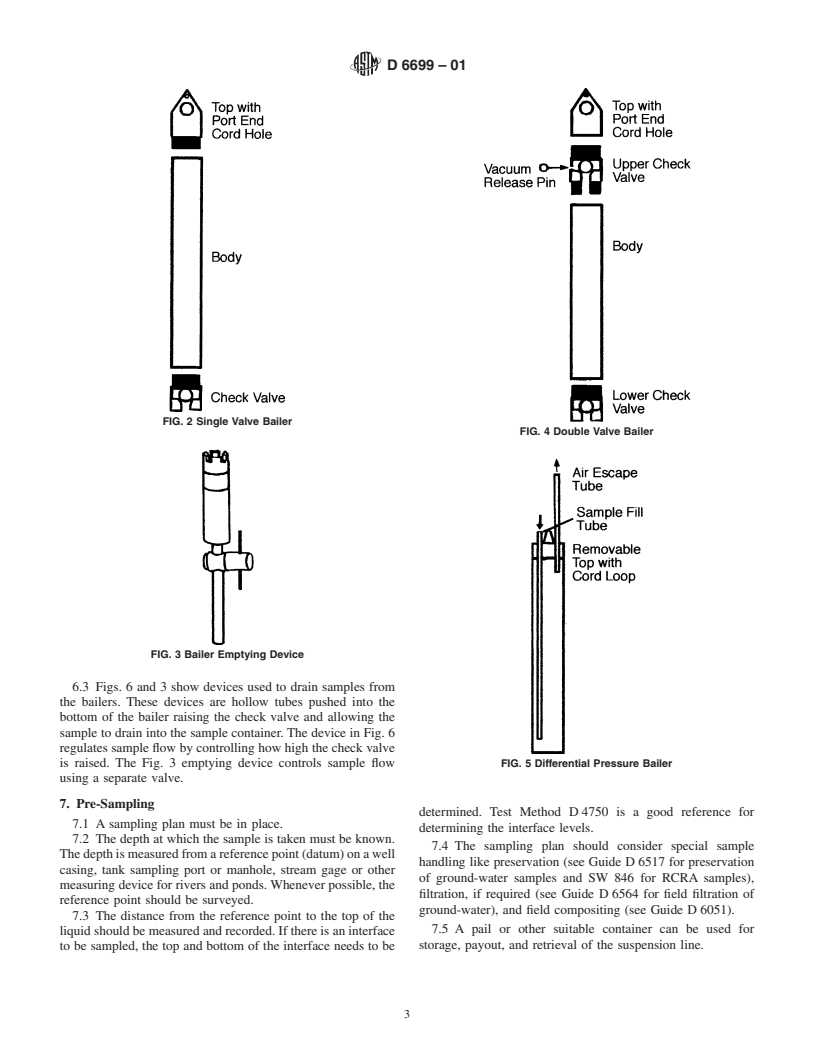

6.2.2 Single Valve Bailer (Fig. 2):

wastes. The sampling procedure will depend on sampling plan

6.2.2.1 Asingle check valve bailer is a length of tubing with

and the data quality objectives (DQOs) (Practice D 5792).

acheckvalveinthebottom.Thebottomvalveallowsthebailer

5.3 Bailersmaybeusedtopurgegroundwaterwellspriorto

to fill and retain the sample.

sampling, but bailers are poor devices for removing large

6.2.2.2 The bottom-emptying bailers with controlled flow

volumes of water.

valves (Fig. 3) are used for collecting samples for volatile

5.4 Bailers may be used to sample waters and liquid wastes

organic analyses.

in underground and above ground tanks and surface impound-

6.2.2.3 Advantages—Low initial cost, and it is mechani-

ments. However, the design of the unit and associated piping

cally simple.

should be well understood so that the bailer can access the

6.2.2.4 Limitations—Applicable to surface sampling only,

desired compartment and depth.Any stratification of the liquid

disturbs the sample, and exposes the samples to the atmo-

should be identified prior to sampling.

sphere.

NOTE 1—Viscous liquids and suspended solids may interfere with a

6.2.3 Double Valve Bailers (Fig. 4):

bailer’s designed operation.

6.2.3.1 Adouble check valve bailer has an additional check

5.5 Bailers do not subject the sample to pressure extremes.

valve at the top of the body that allows sampling at a specific

Bailing does disturb the water column and may cause changes

depth. As the bailer is lowered through the liquid column, the

totheparameterstobemeasured(forexample,turbidity,gases,

liquid flows through the bailer until the sampling level is

etc.).

reached. At the sampling point, the two check valves close to

contain the sample. Because the difference between each ball

6. Sampling Equipment

and check valve seat is the same, both check valves close

6.1 Bailers are versatile devices constructed in different simultaneously upon retrieval. The valve from the valve seat is

sizes and from a variety of materials. Some bailers are maintainedbyapinthatblocksverticalmovementofthecheck

designed using a threaded section that allows the user to ball. A drainage pin is placed into the bottom of the bailer to

change the volume of the bailer by connecting additional drain the sample directly into a sample bottle.

sections. When sampling for volatile organic compounds 6.2.3.2 Advantage—It can sample at any point in a liquid

(VOCs) in liquids, specialized bailers that have a sample column.

control or a draft valve near the bottom of the bailer are used. 6.2.3.3 Limitation—It can become contaminated with the

Thecontrolvalveallowsasampletobedrainedfromthebailer overlaying material as the sampler approaches the targeted

with minimal loss of volatile compounds. sampling point.

6.2 Three general types of bailers are a single check valve 6.2.4 Differential Pressure Bailer (Fig. 5):

bailer, a double check valve bailer, and a differential pressure 6.2.4.1 The differential pressure bailer is a canister with two

bailer (hydrostatic pressure allows the bailer to fill through the small diameter tubes of different heights built into the remov-

lower tube and release displaced air through the upper tube). able top. It is usually made from stainless steel to provide

Advantages and limitations of bailers are found in Guides sufficientweighttoallowittobeloweredrapidlytothedesired

D 6232 and D 6634. A description of the equipment and the sampling depth. Once the bailer is stopped, hydrostatic pres-

advantages and limitations of bailers in general and specific sure allows the bailer to fill through the lower tube at the same

limitations of the single and double check valve bailers and the time as air is displaced through the upper tube.

differential pressure bailer are as follows: 6.2.4.2 Advantages—There is a minimal cross contamina-

6.2.1 General Descr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.