ASTM D6465-99(2005)

(Guide)Standard Guide for Selecting Aerospace and General Purpose Adhesives and Sealants

Standard Guide for Selecting Aerospace and General Purpose Adhesives and Sealants

SIGNIFICANCE AND USE

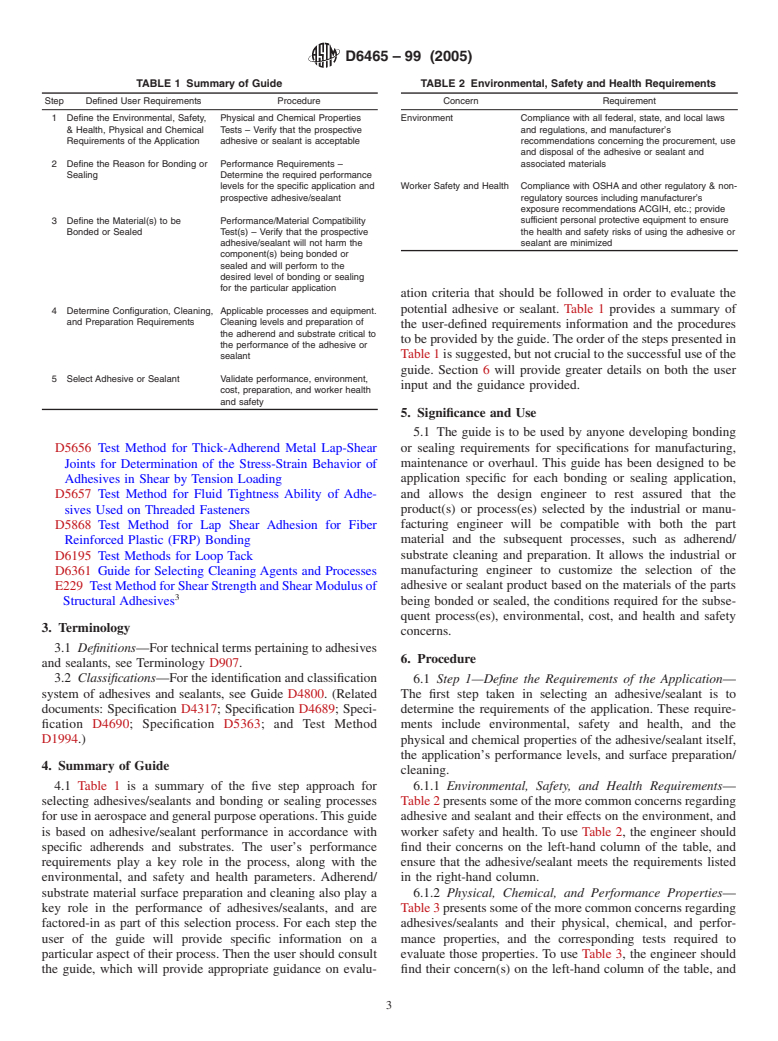

The guide is to be used by anyone developing bonding or sealing requirements for specifications for manufacturing, maintenance or overhaul. This guide has been designed to be application specific for each bonding or sealing application, and allows the design engineer to rest assured that the product(s) or process(es) selected by the industrial or manufacturing engineer will be compatible with both the part material and the subsequent processes, such as adherend/substrate cleaning and preparation. It allows the industrial or manufacturing engineer to customize the selection of the adhesive or sealant product based on the materials of the parts being bonded or sealed, the conditions required for the subsequent process(es), environmental, cost, and health and safety concerns.

SCOPE

1.1 This guide is intended to assist design engineers, manufacturing/industrial engineers, and production managers in selecting the best-fit adhesive/sealant or bonding/sealing process. The guide takes into account environmental pollution prevention and occupational health and safety factors in a selection process.

1.2 This guide is not to be considered as a database of acceptable materials. It will guide the engineers and managers through the adhesive/sealant material selection process, calling for engineers to customize their selection based on the bonding or sealing performance requirements for the specified application. A comprehensive selection process will allow for the establishment of a more efficient production process, and may eliminate unnecessary process steps. A total life cycle cost analysis or performance/cost of implementation study is recommended to compare the available alternatives.

1.3 This guide is for aerospace and general purpose operations. It is not intended to be used for automotive, carpet, construction, electronics, medical/dental, optical, or structural and nonstructural wood applications. Note that this guide is not specifically for these applications, but the general methodology may be used in the selection process for these applications.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6465–99(Reapproved2005)

Standard Guide for

Selecting Aerospace and General Purpose Adhesives and

1

Sealants

This standard is issued under the fixed designation D6465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D896 Practice for Resistance ofAdhesive Bonds to Chemi-

cal Reagents

1.1 This guide is intended to assist design engineers,

D897 Test Method for Tensile Properties of Adhesive

manufacturing/industrial engineers, and production managers

Bonds

in selecting the best-fit adhesive/sealant or bonding/sealing

D903 Test Method for Peel or Stripping Strength of Adhe-

process. The guide takes into account environmental pollution

sive Bonds

prevention and occupational health and safety factors in a

D905 Test Method for Strength Properties of Adhesive

selection process.

Bonds in Shear by Compression Loading

1.2 This guide is not to be considered as a database of

D907 Terminology of Adhesives

acceptable materials. It will guide the engineers and managers

D950 Test Method for Impact Strength of Adhesive Bonds

through the adhesive/sealant material selection process, calling

D1002 Test Method forApparent Shear Strength of Single-

for engineers to customize their selection based on the bonding

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

or sealing performance requirements for the specified applica-

sion Loading (Metal-to-Metal)

tion. A comprehensive selection process will allow for the

D1062 Test Method for Cleavage Strength of Metal-to-

establishment of a more efficient production process, and may

Metal Adhesive Bonds

eliminate unnecessary process steps. A total life cycle cost

D1084 Test Methods for Viscosity of Adhesives

analysis or performance/cost of implementation study is rec-

D1144 Practice for Determining Strength Development of

ommended to compare the available alternatives.

Adhesive Bonds

1.3 This guide is for aerospace and general purpose opera-

D1146 Test Method for Blocking Point of Potentially Ad-

tions. It is not intended to be used for automotive, carpet,

hesive Layers

construction, electronics, medical/dental, optical, or structural

D1151 Practice for Effect of Moisture and Temperature on

andnonstructuralwoodapplications.Notethatthisguideisnot

Adhesive Bonds

specificallyfortheseapplications,butthegeneralmethodology

D1183 Practices for Resistance of Adhesives to Cyclic

may be used in the selection process for these applications.

Laboratory Aging Conditions

1.4 This standard does not purport to address all of the

D1184 Test Method for Flexural Strength of Adhesive

safety concerns, if any, associated with its use. It is the

Bonded Laminated Assemblies

responsibility of the user of this standard to establish appro-

D1310 Test Method for Flash Point and Fire Point of

priate safety and health practices and determine the applica-

Liquids by Tag Open-Cup Apparatus

bility of regulatory limitations prior to use.

D1337 Practice for Storage Life of Adhesives by Viscosity

2. Referenced Documents

and Bond Strength

2

D1338 Practice for Working Life of Liquid or Paste Adhe-

2.1 ASTM Standards:

sives by Consistency and Bond Strength

D56 Test Method for Flash Point by Tag Closed Cup Tester

D1780 Practice for Conducting Creep Tests of Metal-to-

Metal Adhesives

1

ThisguideisunderthejurisdictionofASTMCommitteeD14onAdhesivesand

D1781 Test Method for Climbing Drum Peel forAdhesives

is the direct responsibility of Subcommittee D14.60 on Adhesive Material Classi-

D1828 Practice for Atmospheric Exposure of Adhesive-

fication System.

Bonded Joints and Structures

Current edition approved April 1, 2005. Published May 2005. Originally

approved in 1999. Last previous edition approved in 1999 as D6465 – 99. DOI:

D1875 Test Method for Density ofAdhesives in Fluid Form

10.1520/D6465-99R05.

D1876 Test Method for Peel Resistance of Adhesives (T-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Peel Test)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6465–99 (2005)

D1879 Practice for Exposure of Adhesive Specimens to Scale Closed-Cup Apparatus

Ionizing Radiation D3310 Test Method for Determining Corrosivity of Adhe-

3

D1916 Test Method for Penetration of Adhesives

sive Materials

D1994 Test Method for Determination of Acid Numbers of D3433 Test Method for Fracture Strength in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.