ASTM F2877/F2877M-13e1

(Test Method)Standard Test Method for Shock Testing of Structural Insulation of A-Class Divisions Constructed of Steel or Aluminum

Standard Test Method for Shock Testing of Structural Insulation of A-Class Divisions Constructed of Steel or Aluminum

SIGNIFICANCE AND USE

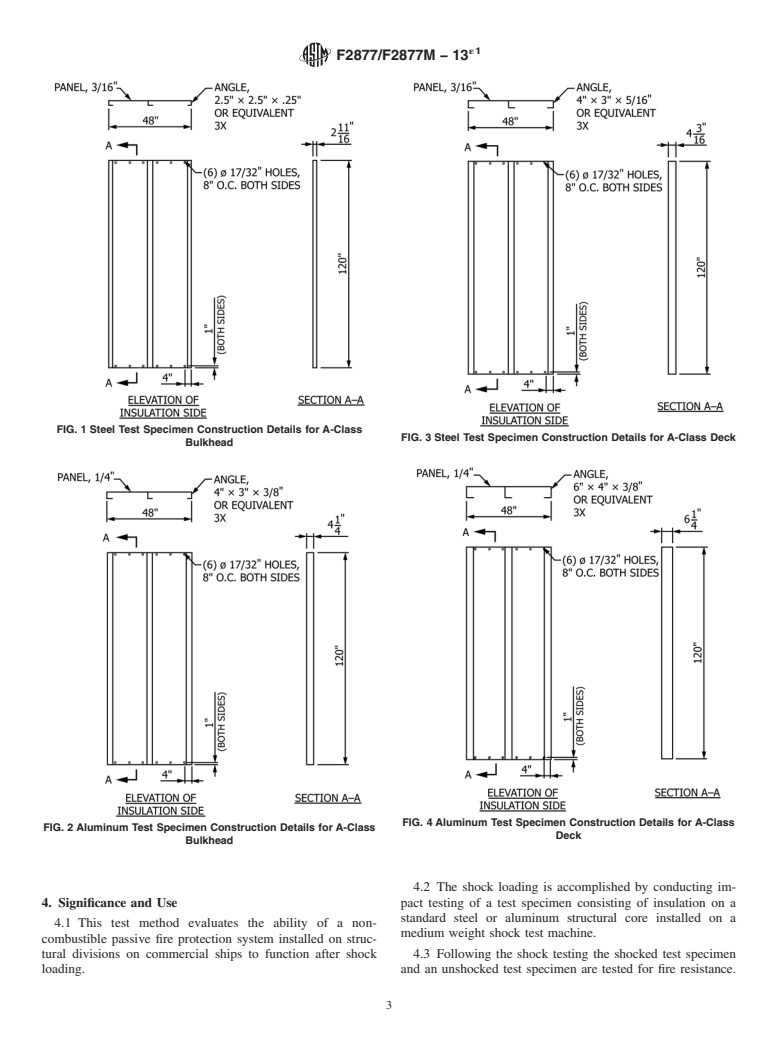

4.1 This test method evaluates the ability of a non-combustible passive fire protection system installed on structural divisions on commercial ships to function after shock loading.

4.2 The shock loading is accomplished by conducting impact testing of a test specimen consisting of insulation on a standard steel or aluminum structural core installed on a medium weight shock test machine.

4.3 Following the shock testing the shocked test specimen and an unshocked test specimen are tested for fire resistance. Both shocked and unshocked test specimens are installed side-by-side in a fixture and fire tested at the same time.

4.4 The fire resistance for both specimens is measured and recorded.

4.5 Other passive fire protection systems using the same insulation materials and attachment methods and having lower fire resistance ratings will be accepted without additional shock testing.

SCOPE

1.1 The purpose of the specification is to evaluate insulation installed on steel or aluminum structural division as defined in IMO resolution A.754 (18) to ensure the insulation is not degraded in the event of a shock.

1.2 The non-combustible passive fire protection insulation shall be installed, which will meet the highest level of commercial fire resistance expected. Lower levels of fire resistance will be allowed without additional shock testing.

1.3 This test method is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products or assemblies under actual fire conditions.

1.4 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2877/F2877M − 13 An American National Standard

Standard Test Method for

Shock Testing of Structural Insulation of A-Class Divisions

1

Constructed of Steel or Aluminum

ThisstandardisissuedunderthefixeddesignationF2877/F2877M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially corrected the designation to reflect dual units of measurement statement (1.5) in October 2013.

INTRODUCTION

Passive fire protection materials have been required and used on commercial ships for decades.The

passive systems include the non-combustible insulation material and its means of attachment to steel

or aluminum divisions. The passive system has been evaluated in a standard fire test using a standard

steel or aluminum structural core. No impact loading has been required prior to testing for fire

resistance.

The United States Navy requires shock testing of passive fire protection prior to fire resistance

testing; this test is defined in MIL-STD-3020, Fire Resistance of U.S. Naval Surface Ships, 7

November, 2007. The technology to economically shock test the passive fire protection systems was

developed 50 years ago, and equipment in commercial laboratories is available.

After the terrorist attack on September 11, 2001, it is our responsibility that we add a level of shock

2

protection to our passive fire protection systems on commercial ships where appropriate. Many of the

passive fire protection systems used today are mechanically fastened and will perform the intended

function after a shock event.

Passive fire protection insulation may have thermal or acoustic treatments added to the insulated

division. These treatments add mass to the fire protection system and their effect on shock is not

included in this specification.

TABLE OF CONTENTS

Introduction

Section 1 Scope

Section 2 Referenced Documents

Section 3 Terminology

Section 4 Significance and Use

Section 5 Shock Test Prior to Fire Resistance

Test

Section 6 Criteria to Evaluate Shock Test

Specimen

Section 7 Post Shock Fire Resistance Test

Section 8 Criteria to Evaluate the Fire

Resistance of the Shock Test

Specimen

Section 9 Test Report

Section 10 Precision and Bias

Section 11 Key Words

1. Scope

1.1 The purpose of the specification is to evaluate insulation

1

This test method is under the jurisdiction of ASTM Committee F25 on Ships

installed on steel or aluminum structural division as defined in

and Marine Technology and is the direct responsibility of Subcommittee F25.02 on

Insulation/Processes.

Current edition approved May 1, 2013. Published May 2013. Originally

ε1 2

approved in 2011. Last previous edition approved in 2011 as F2877 – 11 . JOM, 53(12), 2001 pp 8-12 and www.nist.gov/public.affairs/releases/wtc-

DOI:10.1520/F2877_F2877M-13E01. briefing-april0505.htm

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F2877/F2877M − 13

IMO resolution A.754 (18) to ensure the insulation is not 3. Terminology

degraded in the event of a shock.

3.1 Refer to Terminology E176 for general terms associated

1.2 The non-combustible passive fire protection insulation

with fire issues.

shall be installed, which will meet the highest level of

3.2 Definitions:

commercial fire resistance expected. Lower levels of fire

3.2.1 A-Class division—“A” class divisions in accordance

resistance will be allowed without additional shock testing.

with Part 3 of IMO FTP Code are those divisions formed by

1.3 This test method is used to measure and describe the

bulkheads and decks which comply with the following criteria:

responseofmaterials,products,orassembliestoheatandflame

(a) They are constructed of steel or other equivalent

under controlled conditions, but does not by itself incorporate

material;

all factors required for fire-hazard or fire-risk assessment of the

(b) They are suitably stiffened;

materials, products or assemblies under actual fire conditions.

(c) They are insulated with approved non-combustible

materials such that the average temperature of the unexposed

1.4 Fire testing is inherently hazardous. Adequate safe-

side will not rise more than 140°C above the original

guards for personnel and property shall be employed in

temperature, nor will the temperature, at any one point,

conducting these tests.

including any joint, rise more than 180°C above the original

1.5 The values stated in either SI units or inch-pound units

temperature, with the time listed below:

are to be regarded separately as standard. The values stated in

class “A-60” 60 min

each system ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.