ASTM F1844-97

(Practice)Standard Practice for Measuring Sheet Resistance of Thin Film Conductors For Flat Panel Display Manufacturing Using a Noncontact Eddy Current Gage

Standard Practice for Measuring Sheet Resistance of Thin Film Conductors For Flat Panel Display Manufacturing Using a Noncontact Eddy Current Gage

SCOPE

1.1 This practice describes methods for measuring the sheet electrical resistance of sputtered thin conductive films deposited on large insulating substrates (glass or plastic), used in making flat panel information displays.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: F 1844 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Measuring Sheet Resistance of Thin Film Conductors For

Flat Panel Display Manufacturing Using a Noncontact Eddy

1

Current Gage

This standard is issued under the fixed designation F 1844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Practice

1.1 This practice describes methods for measuring the sheet 3.1 This practice describes the preferred means of applying

electrical resistance of sputtered thin conductive films depos- Test Methods F 673 to measure the electrical sheet resistance

ited on large insulating substrates (glass or plastic), used in of thin films on very large, flat, nonconducting substrates. The

making flat panel information displays. substrate, oriented with the conducting thin film up, is placed

1.2 This practice is intended to be used with Test Methods between the transducers of the eddy current sensor assembly at

F 673. This practice pertains to a “manual” measurement the point of interest. The test arrangement is illustrated in Fig.

procedure in which an operator positions the measuring head 1.

on the test specimen and then personally activates the test 3.2 A typical conductance apparatus is described in detail in

3

apparatus. The resulting test data may be tabulated by the a paper by Miller, Robinson, and Wiley. This paper also

operator, or, alternatively, sent to a computer-based data discusses skin-depth as a function of thickness and resistivity.

logging system. Both Methods I and II of Test Methods F 673 3.3 A typical apparatus operates as follows: when a speci-

(paragraphs 3.1 through 3.3.3 of Test Methods F 673) are men is inserted into the fixed gap between the two parallel

applicable to this practice. sensing elements, or transducers, in a special oscillator circuit,

1.3 Sheet resistivity in the range 0.020 to 3000 V per square eddy currents are induced in the specimen by the alternating

–4

(sheet conductance in the range 3 by 10 to 50 mhos per field between the transducers. The current needed to maintain

square) may be measured by this practice. The sheet resistance constant voltage in the oscillator is determined internally; this

is assumed to be uniform in the area being probed. current is a function of the specimen conductance.

3.4 Further details are given in Test Methods F 673, para-

NOTE 1—Typical manual test units, as described in this practice,

graphs 3.1 through 3.3.3.

measure and report in the units “mhos per square”; this is the inverse of“

3.5 This practice includes calibration procedures for using

ohms per square”.

4

NIST Silicon Standard Reference Material to ensure proper

1.4 This practice is applicable to flat surfaces only.

operation before testing panels.

1.5 This practice is non-destructive. It may be used on

production panels to help assure production uniformity.

4. Significance and Use

1.6 This standard does not purport to address all of the

4.1 Resistivity is a primary quantity for characterization and

safety concerns, if any, associated with its use. It is the

specification of coated glass plates used for flat panel displays.

responsibility of the user of this standard to establish appro-

Sheet resistance is also a primary quantity for characterization,

priate safety and health practices and determine the applica-

specification, and monitoring of thin film fabrication processes.

bility of regulatory limitations prior to use.

4.2 This practice requires no specimen preparation.

4.3 The eddy current method is non-destructive to the thin

2. Referenced Documents

film being measured. Special geometrical correction factors,

2.1 ASTM Standards:

needed for some four-point probe electrical resistivity mea-

F 673 Test Methods for Measuring Resistivity of Semicon-

surements, are not required to derive the true sheet resistance

ductor Slices or Sheet Resistance of Semiconductor Films

so long as the transducers have a continuous layer of conduc-

2

with a Noncontact Eddy-Current Gage

tive thin film between them.

1 3

This practice is under the jurisdiction of ASTM Committee F-1 on Electronics Miller, G.L., Robinson, D. A. H., and Wiley, J. D., “Contactless Measurement

and is the direct responsibility of Subcommittee F01.17 on Sputtered Thin Films. of Semiconductor Conductivity by Radio Frequency-Free-Carrier Power Absorp-

Current edition approved December 10, 1997. Published March 1998. tion,” Review of Scientific Instruments, Vol 47, No. 7, July 1976.

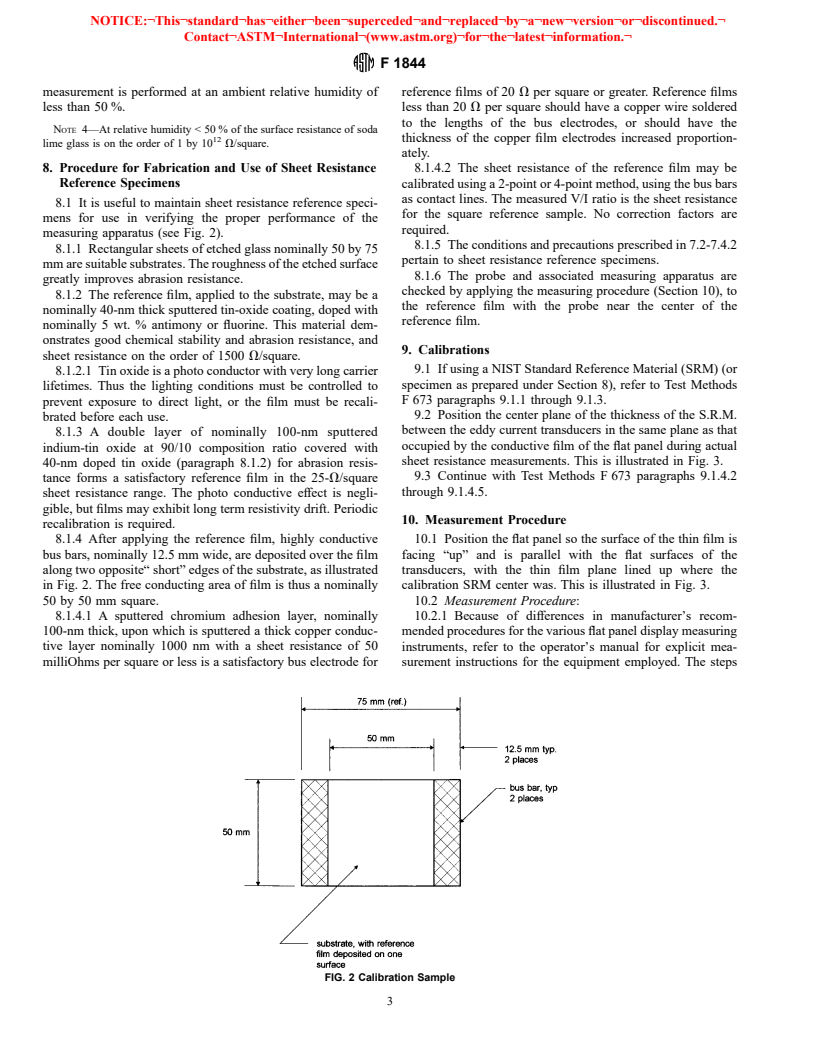

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.