ASTM F1844-97(2002)

(Practice)Standard Practice for Measuring Sheet Resistance of Thin Film Conductors For Flat Panel Display Manufacturing Using a Noncontact Eddy Current Gage

Standard Practice for Measuring Sheet Resistance of Thin Film Conductors For Flat Panel Display Manufacturing Using a Noncontact Eddy Current Gage

SIGNIFICANCE AND USE

Resistivity is a primary quantity for characterization and specification of coated glass plates used for flat panel displays. Sheet resistance is also a primary quantity for characterization, specification, and monitoring of thin film fabrication processes.

This practice requires no specimen preparation.

The eddy current method is non-destructive to the thin film being measured. Special geometrical correction factors, needed for some four-point probe electrical resistivity measurements, are not required to derive the true sheet resistance so long as the transducers have a continuous layer of conductive thin film between them.

Test Methods F 673 refers to a testing arrangement in which the transducers and specimen (a semiconductor grade silicon wafer) are rigidly positioned. Similar apparatus is commercially available for testing large glass or plastic substrates, not envisioned in the scope of Test Methods F 673. A hand held probe can also be used, depending on throat depth required.

For use as a referee method, the probe and measuring apparatus must first be checked and qualified before use by the procedures of Test Methods F 673 (9.1.1 through 9.1.3 and 9.1.4.2 through 9.1.4.5), then this practice is used.

For use as a routine quality assurance method, this practice may be employed with periodic qualifications of probe and measuring apparatus by the procedures of Test Methods F 673 (9.1.1 through 9.1.3 and 9.1.4.2 through 9.1.4.5). The parties to the test must agree upon adequate qualification intervals for the test apparatus.

SCOPE

1.1 This practice describes methods for measuring the sheet electrical resistance of sputtered thin conductive films deposited on large insulating substrates (glass or plastic), used in making flat panel information displays.

1.2 This practice is intended to be used with Test Methods F 673. This practice pertains to a "manual" measurement procedure in which an operator positions the measuring head on the test specimen and then personally activates the test apparatus. The resulting test data may be tabulated by the operator, or, alternatively, sent to a computer-based data logging system. Both Methods I and II of Test Methods F 673 (paragraphs 3.1 through 3.3.3 of Test Methods F 673) are applicable to this practice.

1.3 Sheet resistivity in the range 0.020 to 3000 per square (sheet conductance in the range 3 by 10-4 to 50 mhos per square) may be measured by this practice. The sheet resistance is assumed to be uniform in the area being probed.

Note 1—Typical manual test units, as described in this practice, measure and report in the units "mhos per square"; this is the inverse of "ohms per square."

1.4 This practice is applicable to flat surfaces only.

1.5 This practice is non-destructive. It may be used on production panels to help assure production uniformity.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1844–97 (Reapproved 2002)

Standard Practice for

Measuring Sheet Resistance of Thin Film Conductors For

Flat Panel Display Manufacturing Using a Noncontact Eddy

Current Gage

This standard is issued under the fixed designation F 1844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ductor Slices or Sheet Resistance of Semiconductor Films

with a Noncontact Eddy-Current Gage

1.1 This practice describes methods for measuring the sheet

electrical resistance of sputtered thin conductive films depos-

3. Summary of Practice

ited on large insulating substrates (glass or plastic), used in

3.1 This practice describes the preferred means of applying

making flat panel information displays.

Test Methods F 673 to measure the electrical sheet resistance

1.2 This practice is intended to be used with Test Methods

of thin films on very large, flat, nonconducting substrates. The

F 673. This practice pertains to a “manual” measurement

substrate, oriented with the conducting thin film up, is placed

procedure in which an operator positions the measuring head

between the transducers of the eddy current sensor assembly at

on the test specimen and then personally activates the test

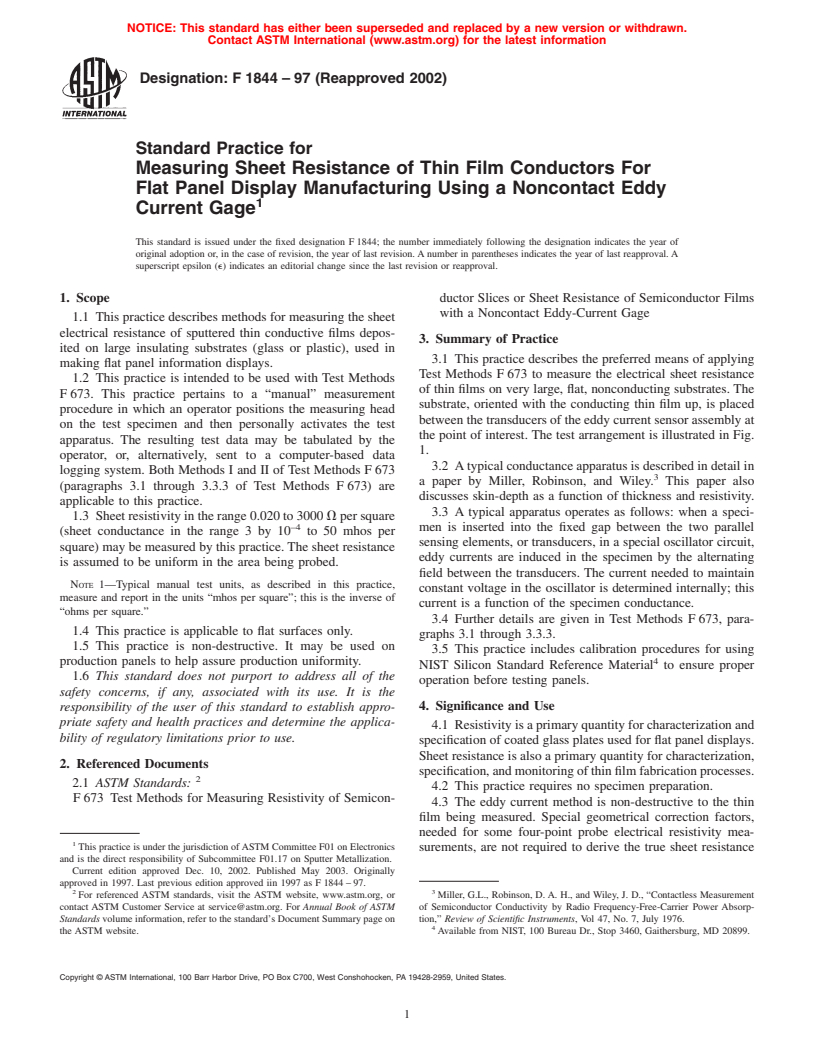

the point of interest. The test arrangement is illustrated in Fig.

apparatus. The resulting test data may be tabulated by the

1.

operator, or, alternatively, sent to a computer-based data

3.2 Atypical conductance apparatus is described in detail in

logging system. Both Methods I and II of Test Methods F 673

a paper by Miller, Robinson, and Wiley. This paper also

(paragraphs 3.1 through 3.3.3 of Test Methods F 673) are

discusses skin-depth as a function of thickness and resistivity.

applicable to this practice.

3.3 A typical apparatus operates as follows: when a speci-

1.3 Sheet resistivity in the range 0.020 to 3000 V per square

–4

men is inserted into the fixed gap between the two parallel

(sheet conductance in the range 3 by 10 to 50 mhos per

sensing elements, or transducers, in a special oscillator circuit,

square) may be measured by this practice. The sheet resistance

eddy currents are induced in the specimen by the alternating

is assumed to be uniform in the area being probed.

field between the transducers. The current needed to maintain

NOTE 1—Typical manual test units, as described in this practice,

constant voltage in the oscillator is determined internally; this

measure and report in the units “mhos per square”; this is the inverse of

current is a function of the specimen conductance.

“ohms per square.”

3.4 Further details are given in Test Methods F 673, para-

1.4 This practice is applicable to flat surfaces only.

graphs 3.1 through 3.3.3.

1.5 This practice is non-destructive. It may be used on

3.5 This practice includes calibration procedures for using

production panels to help assure production uniformity.

NIST Silicon Standard Reference Material to ensure proper

1.6 This standard does not purport to address all of the

operation before testing panels.

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 Resistivity is a primary quantity for characterization and

bility of regulatory limitations prior to use.

specification of coated glass plates used for flat panel displays.

Sheet resistance is also a primary quantity for characterization,

2. Referenced Documents

specification,andmonitoringofthinfilmfabricationprocesses.

2.1 ASTM Standards:

4.2 This practice requires no specimen preparation.

F 673 Test Methods for Measuring Resistivity of Semicon-

4.3 The eddy current method is non-destructive to the thin

film being measured. Special geometrical correction factors,

needed for some four-point probe electrical resistivity mea-

This practice is under the jurisdiction ofASTM Committee F01 on Electronics

surements, are not required to derive the true sheet resistance

and is the direct responsibility of Subcommittee F01.17 on Sputter Metallization.

Current edition approved Dec. 10, 2002. Published May 2003. Originally

approved in 1997. Last previous edition approved iin 1997 as F 1844 – 97.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Miller, G.L., Robinson, D. A. H., and Wiley, J. D., “Contactless Measurement

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM of Semiconductor Conductivity by Radio Frequency-Free-Carrier Power Absorp-

Standards volume information, refer to the standard’s Document Summary page on tion,” Review of Scientific Instruments, Vol 47, No. 7, July 1976.

the ASTM website. Available from NIST, 100 Bureau Dr., Stop 3460, Gaithersburg, MD 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1844–97 (2002)

5.3 Specimen Support—The flat panel to be tested must be

supported firmly to ensure that the thin film is parallel with the

transducer surfaces.

5.4 Reagents and Materials in accordance with Test Meth-

ods F 673, Section 7.

6. Test Specimen

6.1 The test article shall be a display substrate that has been

sputter coated with the conductive thin film of interest or ion

implanted and annealed, or made conductive by another

process.

6.2 The conductive film must be thick enough that it is

continuous. Generally this requires that the film be at least

15-nm thick.

6.3 The area to be tested shall be free of contamination and

mechanical damage, but shall not be cleaned or otherwise

prepared.

6.4 Note that a sputtered film may also coat the edge of the

glass and can coat the back side of the substrate (“overspray”).

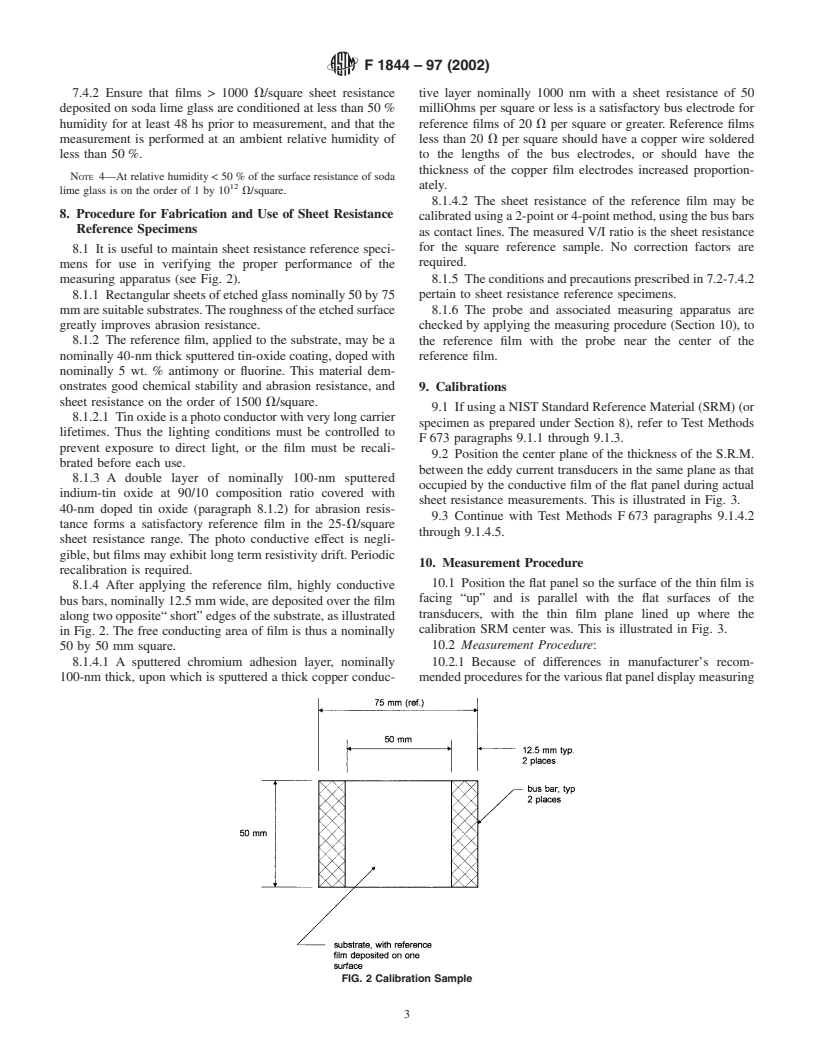

NOTE—This figure is partially copied from Fig. 1 of Test Methods

All overspray, for example, coating on back of glass, must be

F 673.

removed before measurement.

FIG. 1 Schematic Diagram of Eddy-Current Sensor Assembly

6.4.1 Any remaining overspray will be included in the

measurement, lowering the measured film resistivity.

so long as the transducers have a continuous layer of conduc-

6.4.2 Scribing the substrate near the edge using a glass

tive thin film between them.

scribe is not a reliable remedy.

4.4 Test Methods F 673 refers to a testing arrangement in

6.4.3 Useasimple2-pointprobeohmmetertoverifythatthe

which the transducers and specimen (a semiconductor grade

back side of glass or plastic substrate is insulating.

silicon wafer) are rigidly positioned. Similar apparatus is

commercially available for testing large glass or plastic sub-

7. Interferences

strates, not envisioned in the scope of Test Methods F 673. A

7.1 Cautionmustbetakenthatthetransducergapisfixed,in

hand held probe can also be used, depending on throat depth

accordance with the recommendations of the equipment sup-

required.

plier. This may be ensured by firmly tightening the gap

4.5 For use as a referee method, the probe and measuring

adjustment screws after checking the spacing with gages. Use

apparatus must first be checked and qualified before use by the

caution, too, that the electrostatic covers (see Miller, et. al. )

procedures of Test Methods F 673 (9.1.1 through 9.1.3 and

arenotdamagedbythepanelundertest.Theelectrostaticcover

9.1.4.2 through 9.1.4.5), then this practice is used.

should be located approximately 0.02 mm below the support

4.6 For use as a routine quality assurance method, this

surface.

practicemaybeemployedwithperiodicqualificationsofprobe

7.2 Radial resistivity variations or other resistivity nonuni-

and measuring apparatus by the procedures of Test Methods

formity under the transducer are averaged by this practice in a

F 673 (9.1.1 through 9.1.3 and 9.1.4.2 through 9.1.4.5). The

manner that may be different from that of other types of

parties to the test must agree upon adequate qualification

resistivity or sheet resistance techniques, which are responsive

intervals for the test apparatus.

to a finite lateral area. The results may therefore differ from

5. Apparatus those of four-probe measurements depending on film proper-

ties and the four-probe spacing used (see Test Methods F 673

5.1 Eddy Current Sensor Assembly—See Fig. 1 and Test

paragraph 5.1).

Methods F 673.

7.3 Spurious currents can be introduced in the test equip-

5.1.1 Different transducer designs may be required to cover

ment when it is located near high-frequency generators. If the

the full range of sheet resistance values.

equipment is located near such sources, adequate shielding

NOTE 2—Three transducers will generally cover the ranges of interest.

must be provided. Power line filtering may also be required.

For convenience these are denoted “High” (15 to 3000 V per square),

(Note the precautions in Test Methods F 673 paragraph 5.4)

“Low” (0.2 to 15 V per square) and “E

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.