ASTM E1268-01(2016)

(Practice)Standard Practice for Assessing the Degree of Banding or Orientation of Microstructures

Standard Practice for Assessing the Degree of Banding or Orientation of Microstructures

SIGNIFICANCE AND USE

5.1 This practice is used to assess the nature and extent of banding or orientation of microstructures of metals and other materials where deformation and processing produce a banded or oriented condition.

5.2 Banded or oriented microstructures can arise in single phase, two phase or multiphase metals and materials. The appearance of the orientation or banding is influenced by processing factors such as the solidification rate, the extent of segregation, the degree of hot or cold working, the nature of the deformation process used, the heat treatments, and so forth.

5.3 Microstructural banding or orientation influence the uniformity of mechanical properties determined in various test directions with respect to the deformation direction.

5.4 The stereological methods can be applied to measure the nature and extent of microstructural banding or orientation for any metal or material. The microindentation hardness test procedure should only be used to determine the difference in hardness in banded heat-treated metals, chiefly steels.

5.5 Isolated segregation may also be present in an otherwise reasonably homogeneous microstructure. Stereological methods are not suitable for measuring individual features, instead use standard measurement procedures to define the feature size. The microindentation hardness method may be used for such structures.

5.6 Results from these test methods may be used to qualify material for shipment in accordance with guidelines agreed upon between purchaser and manufacturer, for comparison of different manufacturing processes or process variations, or to provide data for structure-property-behavior studies.

SCOPE

1.1 This practice describes a procedure to qualitatively describe the nature of banded or oriented microstructures based on the morphological appearance of the microstructure.

1.2 This practice describes stereological procedures for quantitative measurement of the degree of microstructural banding or orientation.

Note 1: Although stereological measurement methods are used to assess the degree of banding or alignment, the measurements are only made on planes parallel to the deformation direction (that is, a longitudinal plane) and the three-dimensional characteristics of the banding or alignment are not evaluated.

1.3 This practice describes a microindentation hardness test procedure for assessing the magnitude of the hardness differences present in banded heat-treated steels. For fully martensitic carbon and alloy steels (0.10–0.65 %C), in the as-quenched condition, the carbon content of the matrix and segregate may be estimated from the microindentation hardness values.

1.4 This standard does not cover chemical analytical methods for evaluating banded structures.

1.5 This practice deals only with the recommended test methods and nothing in it should be construed as defining or establishing limits of acceptability.

1.6 The measured values are stated in SI units, which are regarded as standard. Equivalent inch-pound values, when listed, are in parentheses and may be approximate.

1.7 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1268 − 01 (Reapproved 2016)

Standard Practice for

Assessing the Degree of Banding or Orientation of

Microstructures

This standard is issued under the fixed designation E1268; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Segregation occurs during the dendritic solidification of metals and alloys and is aligned by

subsequent deformation. Solid-state transformations may be influenced by the resulting microsegre-

gation pattern leading to development of a layered or banded microstructure. The most common

example of banding is the layered ferrite-pearlite structure of wrought low-carbon and low-carbon

alloy steels. Other examples of banding include carbide banding in hypereutectoid tool steels and

martensite banding in heat-treated alloy steels. This practice covers procedures to describe the

appearance of banded structures, procedures for characterizing the extent of banding, and a

microindentationhardnessprocedurefordeterminingthedifferenceinhardnessbetweenbandsinheat

treated specimens. The stereological methods may also be used to characterize non-banded

microstructures with second phase constituents oriented (elongated) in varying degrees in the

deformation direction.

1. Scope 1.5 This practice deals only with the recommended test

methods and nothing in it should be construed as defining or

1.1 This practice describes a procedure to qualitatively

establishing limits of acceptability.

describethenatureofbandedororientedmicrostructuresbased

on the morphological appearance of the microstructure. 1.6 The measured values are stated in SI units, which are

regarded as standard. Equivalent inch-pound values, when

1.2 This practice describes stereological procedures for

listed, are in parentheses and may be approximate.

quantitative measurement of the degree of microstructural

1.7 This standard does not purport to address all of the

banding or orientation.

safety problems, if any, associated with its use. It is the

NOTE 1—Although stereological measurement methods are used to

responsibility of the user of this standard to establish appro-

assess the degree of banding or alignment, the measurements are only

priate safety and health practices and determine the applica-

madeonplanesparalleltothedeformationdirection(thatis,alongitudinal

plane) and the three-dimensional characteristics of the banding or align- bility of regulatory limitations prior to use.

ment are not evaluated.

2. Referenced Documents

1.3 This practice describes a microindentation hardness test

procedure for assessing the magnitude of the hardness differ-

2.1 ASTM Standards:

ences present in banded heat-treated steels. For fully marten-

A370Test Methods and Definitions for Mechanical Testing

sitic carbon and alloy steels (0.10–0.65%C), in the as-

of Steel Products

quenched condition, the carbon content of the matrix and

A572/A572MSpecification for High-Strength Low-Alloy

segregate may be estimated from the microindentation hard-

Columbium-Vanadium Structural Steel

ness values.

A588/A588MSpecification for High-Strength Low-Alloy

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

1.4 This standard does not cover chemical analytical meth-

Point, with Atmospheric Corrosion Resistance

ods for evaluating banded structures.

E3Guide for Preparation of Metallographic Specimens

E7Terminology Relating to Metallography

This practice is under the jurisdiction of ASTM Committee E04 on Metallog-

raphy and is the direct responsibility of Subcommittee E04.14 on Quantitative

Metallography. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2016. Published April 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2007 as E1268–01(2007). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E1268-01R16 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1268 − 01 (2016)

NOTE 1—The test grid lines have been shown oriented perpendicular (A) to the deformation axis and parallel (B) to the deformation axis. The counts

for N , N , P , and P are shown for counts made from top to bottom (A) or from left to right (B).

' || ' ||

NOTE 2—T indicates a tangent hit and E indicates that the grid line ended within the particle; both situations are handled as shown.

FIG. 1 Illustration of the Counting of Particle Interceptions (N) and Boundary Intersections (P) for an Oriented Microstructure

E140Hardness Conversion Tables for Metals Relationship isolated particles in a matrix, the number of feature intersec-

Among Brinell Hardness, Vickers Hardness, Rockwell tions will equal twice the number of feature interceptions.

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

3.2.4 oriented constituents—one or more second-phases

scope Hardness, and Leeb Hardness

(constituents) elongated in a non-banded (that is, random

E384Test Method for Knoop and Vickers Hardness of

distribution) manner parallel to the deformation axis; the

Materials

degree of elongation varies with the size and deformability of

E407Practice for Microetching Metals and Alloys

the phase or constituent and the degree of hot- or cold-work

E562Test Method for Determining Volume Fraction by

reduction.

Systematic Manual Point Count

3.2.5 stereological methods—procedures used to character-

E883Guide for Reflected–Light Photomicrography

ize three-dimensional microstructural features based on mea-

3. Terminology surements made on two-dimensional sectioning planes.

3.1 Definitions—For definitions of terms used in this

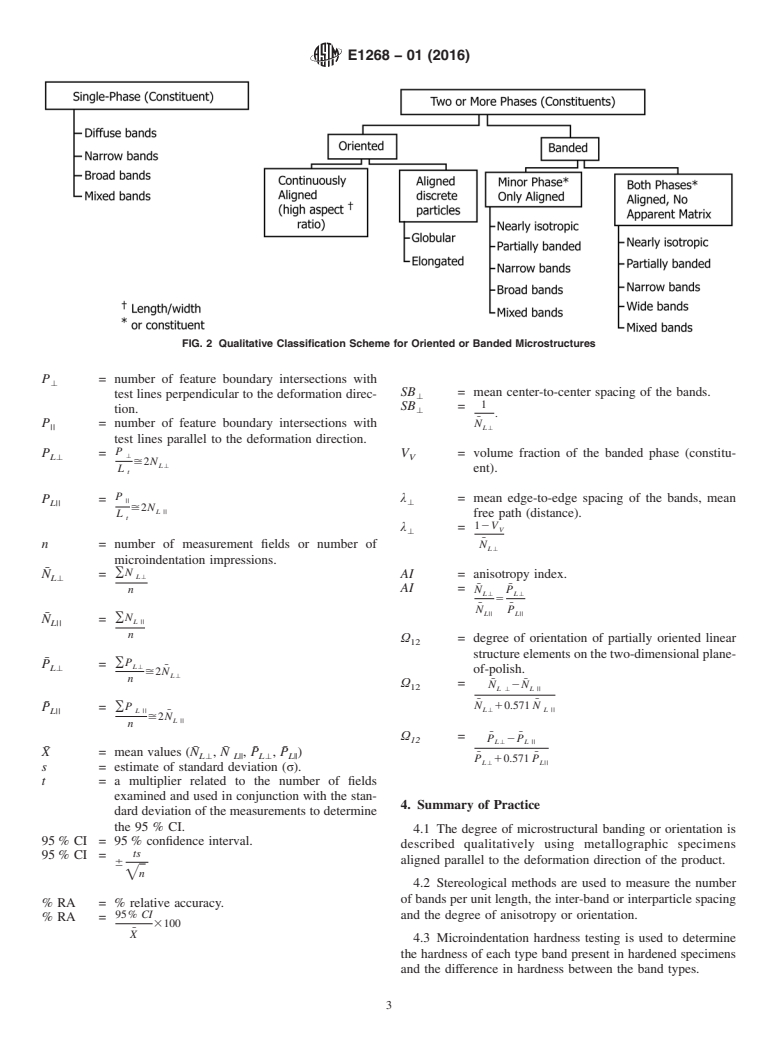

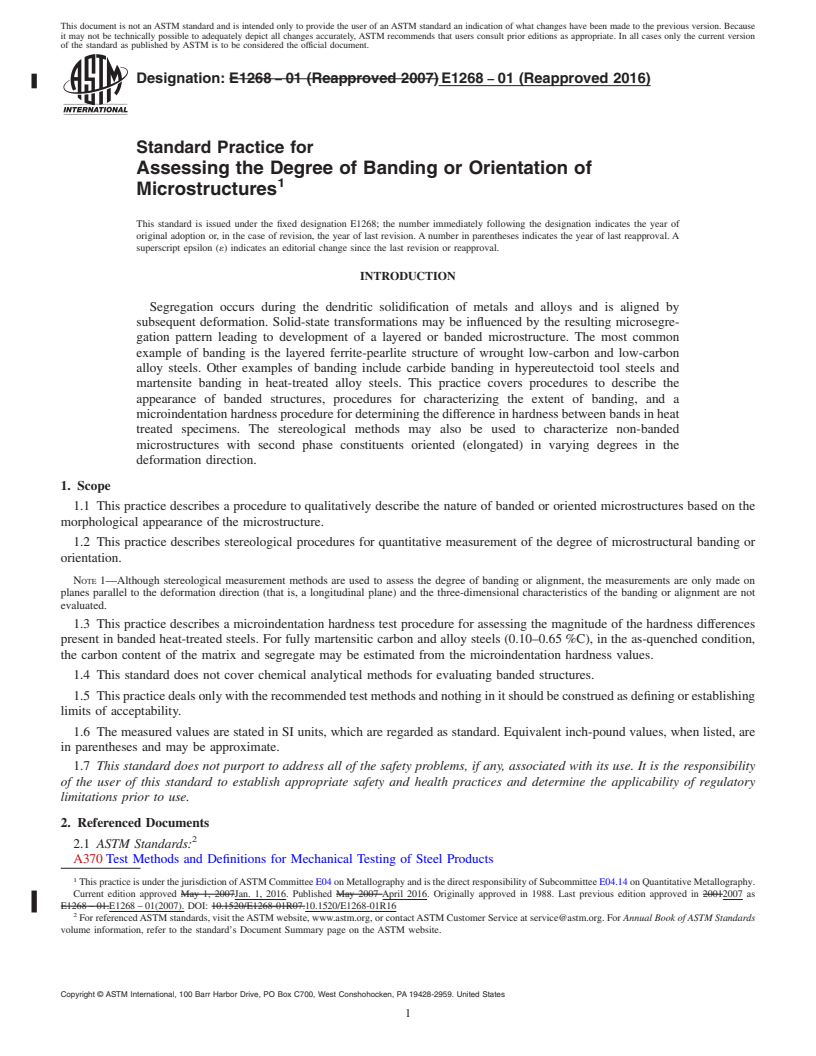

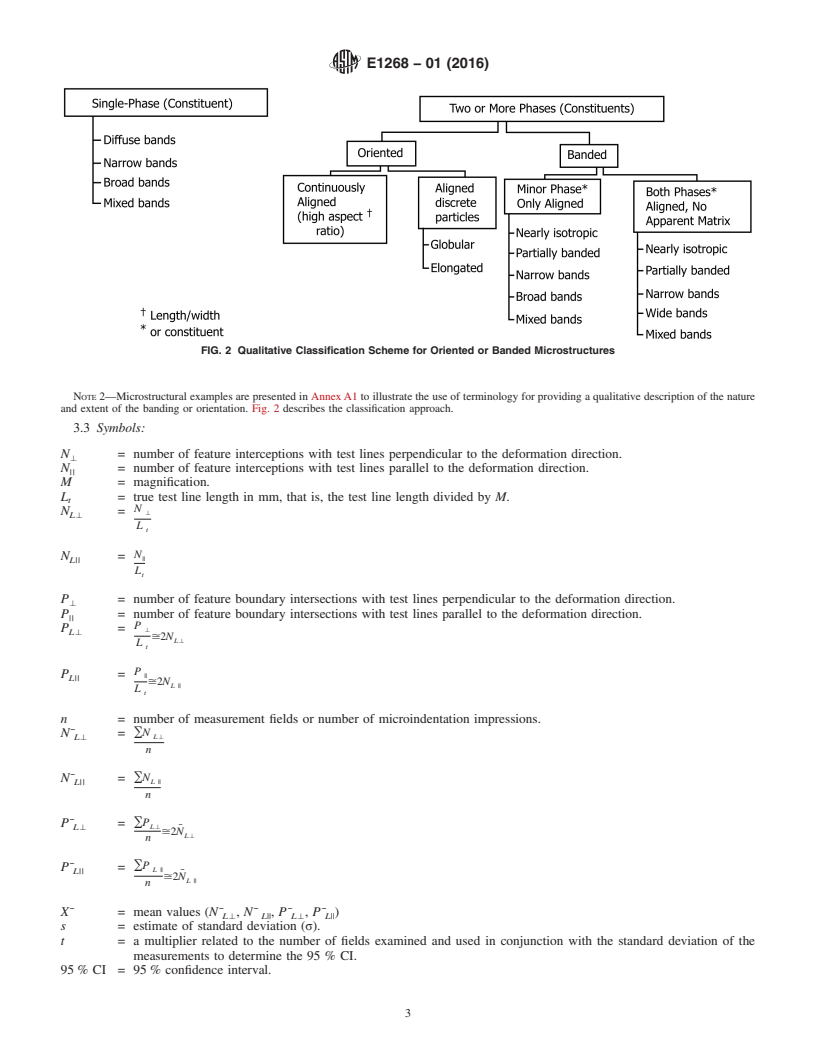

NOTE 2—Microstructural examples are presented in Annex A1 to

practice, see Terminology E7.

illustrate the use of terminology for providing a qualitative description of

the nature and extent of the banding or orientation. Fig. 2 describes the

3.2 Definitions of Terms Specific to This Standard:

classification approach.

3.2.1 banded microstructure—separation, of one or more

3.3 Symbols:

phases or constituents in a two-phase or multiphase

microstructure, or of segregated regions in a single phase or

N = number of feature interceptions with test lines

'

constituent microstructure, into distinct layers parallel to the

perpendicular to the deformation direction.

deformation axis due to elongation of microsegregation; other

N = number of feature interceptions with test lines

||

factorsmayalsoinfluencebandformation,forexample,thehot

parallel to the deformation direction.

working finishing temperature, the degree of hot- or cold-work

M = magnification.

reduction, or split transformations due to limited hardenability

L = true test line length in mm, that is, the test line

t

or insufficient quench rate.

length divided by M.

N

3.2.2 feature interceptions—the number of particles (or N = '

L'

L

clusters of particles) of a phase or constituent of interest that

t

are crossed by the lines of a test grid. (see Fig. 1).

N

N = ||

L||

3.2.3 feature intersections—the number of boundaries be-

L

t

tween the matrix phase and the phase or constituent of interest

that are crossed by the lines of a test grid (see Fig. 1). For

E1268 − 01 (2016)

FIG. 2 Qualitative Classification Scheme for Oriented or Banded Microstructures

P = number of feature boundary intersections with

'

SB = mean center-to-center spacing of the bands.

test lines perpendicular to the deformation direc-

'

SB =

tion. '

.

¯

N

P = number of feature boundary intersections with

|| L'

test lines parallel to the deformation direction.

P

P = ' V = volume fraction of the banded phase (constitu-

L' V

>2N

L'

L ent).

t

P

λ = mean edge-to-edge spacing of the bands, mean

P = ||

'

L||

>2N

L ||

L free path (distance).

t

12V

λ =

V

'

¯

n = number of measurement fields or number of N

L'

microindentation impressions.

¯

N

N = AI = anisotropy index.

( L'

L'

¯ ¯

AI =

n N P

L' L'

¯ ¯

N P

L|| L||

¯

N

N = (

L ||

L||

n

Ω = degree of orientation of partially oriented linear

structureelementsonthetwo-dimensionalplane-

¯

P

P = (

L'

L'

¯

of-polish.

>2N

L'

n

¯ ¯

Ω =

N 2N

L ' L ||

¯ ¯

¯ P N 10.571 N

P = ( L' L ||

L ||

L||

¯

>2N

L ||

n

¯ ¯

Ω =

P 2P

L' L ||

¯ ¯ ¯ ¯ ¯

X = mean values (N , N , P , P )

¯ ¯

L' L|| L' L||

P 10.571 P

L' L||

s = estimate of standard deviation (σ).

t = a multiplier related to the number of fields

examined and used in conjunction with the stan-

4. Summary of Practice

dard deviation of the measurements to determine

the 95 % CI.

4.1 The degree of microstructural banding or orientation is

95% CI = 95% confidence interval.

described qualitatively using metallographic specimens

ts

95% CI =

aligned parallel to the deformation direction of the product.

=n

4.2 Stereological methods are used to measure the number

of bands per unit length, the inter-band or interparticle spacing

% RA = % relative accuracy.

95% CI and the degree of anisotropy or orientation.

% RA =

¯

X

4.3 Microindentation hardness testing is used to determine

the hardness of each type band present in hardened specimens

and the difference in hardness between the band types.

E1268 − 01 (2016)

5. Significance and Use generated test grids , or other methods, for a digitized image,

are used rather than the grid lines of the plastic overlay or

5.1 This practice is used to assess the nature and extent of

reticle.

banding or orientation of microstructures of metals and other

materials where deformation and processing produce a banded 6.5 Amicroindentation hardness tester is used to determine

or oriented condition. thehardnessofeachtypeofbandinheat-treatedsteelsorother

metals. The Knoop indenter is particularly well suited for this

5.2 Banded or oriented microstructures can arise in single

work.

phase, two phase or multiphase metals and materials. The

appearance of the orientation or banding is influenced by

7. Sampling and Test Specimens

processing factors such as the solidification rate, the extent of

7.1 In general, specimens should be taken from the final

segregation,thedegreeofhotorcoldworking,thenatureofthe

product form after all processing steps have been performed,

deformation process used, the heat treatments, and so forth.

particularly those that would influence the nature and extent of

5.3 Microstructural banding or orientation influence the

banding. Because the degree of banding or orientation may

uniformity of mechanical properties determined in various test

vary through the product cross section, the test plane should

directions with respect to the deformation direction.

sample the entire cross section. If the section size is too large

5.4 Thestereologicalmethodscanbeappliedtomeasurethe

to permit full cross sectioning, samples should be taken at

nature and extent of microstructural banding or orientation for

standard locations, for example, subsurface, mid-radius (or

any metal or material. The microindentation hardness test

quarter-point), and center, or at specific locations based upon

procedure should only be used to determine the difference in

producer-purchaser agreements.

hardness in banded heat-treated metals, chiefly steels.

7.2 The degree of banding or orientation present is deter-

5.5 Isolatedsegregationmayalsobepresentinanotherwise

mined using longitudinal test specimens, that is, specimens

reasonably homogeneous microstructure. Stereological meth-

where the plane of polish is parallel to the deformation

ods are not suitable for measuring individual features, instead

direction.Forplateorsheetproducts,aplanaroriented(thatis,

use standard measurement procedures to define the feature

polishedsurfaceparalleltothesurfaceoftheplateorsheet)test

size. The microindentation hardness method may be used for

specimen, at subsurface, mid-thickness, or center locations,

such structures.

mayalsobepreparedandtesteddependingonthenatureofthe

product application.

5.6 Results from these test methods may be used to qualify

material for shipment in accordance with guidelines agreed

7.3 Banding or orientation may also be assessed on inter-

upon between purchaser and manufacturer, for comparison of

mediate product forms, such as billets or bars, for material

different manufacturing processes or process variations, or to

qualification or quality control purposes. These test results,

provide data for structure-property-behavior studies.

however, may not correlate directly with test results on final

productforms.Testspecimensshouldbepreparedasdescribed

6. Apparatus

in 7.1 and 7.2 but with the added requirement of choosing test

locations with respect to ingot or continuously cast slab/strand

6.1 A metallurgical (reflected-light) microscope is used to

locations. The number and location of such test specimens

examine the microstructure of test specimens. Banding or

should be defined by producer-purchaser agreement.

orientation is best observed using low magnifications, for

example, 50× to 200×.

7.4 Individual metallographic test specimens should have a

polished surface area covering the entire cross section if

6.2 Stereologicalmeasurementsaremadebysuperimposing

possible. The length of full cross-section samples, in the

a test grid (consisting of a number of closely spaced parallel

deformationdirection,shouldbeatleast10mm(0.4in.).Ifthe

lines of known length) on the projected image of the micro-

product form is too large to permit preparation of full cross

structure or on a photomicrograph. Measurements are made

sections, the samples prepared at the desired locations should

withthetestlinesparallelandperpendiculartothedeformation

2 2

have a minimum polished surface area of 100 mm (0.16 in. )

direction. The total length of the grid lines should be at least

with the sample length in the longitudinal direction at least 10

500 mm.

mm (0.4 in.).

6.3 These stereological measurements may be made using a

semiautomatic tracing type image analyzer. The test grid is

8. Specimen Preparation

placed over the image projected onto the digitizing tablet and

8.1 Metallographic specimen preparation should be per-

a cursor is used for counting.

formed in accordance with the guidelines and recommended

6.4 For certain microstructures where the contrast between

practices given in Methods E3. The preparation procedure

the banded or oriented constituents is adequate, an automatic

must reveal the microstructure without excessive influence

image analyzer may be used for counting, where the TV scan

from prepar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1268 − 01 (Reapproved 2007) E1268 − 01 (Reapproved 2016)

Standard Practice for

Assessing the Degree of Banding or Orientation of

Microstructures

This standard is issued under the fixed designation E1268; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Segregation occurs during the dendritic solidification of metals and alloys and is aligned by

subsequent deformation. Solid-state transformations may be influenced by the resulting microsegre-

gation pattern leading to development of a layered or banded microstructure. The most common

example of banding is the layered ferrite-pearlite structure of wrought low-carbon and low-carbon

alloy steels. Other examples of banding include carbide banding in hypereutectoid tool steels and

martensite banding in heat-treated alloy steels. This practice covers procedures to describe the

appearance of banded structures, procedures for characterizing the extent of banding, and a

microindentation hardness procedure for determining the difference in hardness between bands in heat

treated specimens. The stereological methods may also be used to characterize non-banded

microstructures with second phase constituents oriented (elongated) in varying degrees in the

deformation direction.

1. Scope

1.1 This practice describes a procedure to qualitatively describe the nature of banded or oriented microstructures based on the

morphological appearance of the microstructure.

1.2 This practice describes stereological procedures for quantitative measurement of the degree of microstructural banding or

orientation.

NOTE 1—Although stereological measurement methods are used to assess the degree of banding or alignment, the measurements are only made on

planes parallel to the deformation direction (that is, a longitudinal plane) and the three-dimensional characteristics of the banding or alignment are not

evaluated.

1.3 This practice describes a microindentation hardness test procedure for assessing the magnitude of the hardness differences

present in banded heat-treated steels. For fully martensitic carbon and alloy steels (0.10–0.65 %C), in the as-quenched condition,

the carbon content of the matrix and segregate may be estimated from the microindentation hardness values.

1.4 This standard does not cover chemical analytical methods for evaluating banded structures.

1.5 This practice deals only with the recommended test methods and nothing in it should be construed as defining or establishing

limits of acceptability.

1.6 The measured values are stated in SI units, which are regarded as standard. Equivalent inch-pound values, when listed, are

in parentheses and may be approximate.

1.7 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

This practice is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.14 on Quantitative Metallography.

Current edition approved May 1, 2007Jan. 1, 2016. Published May 2007 April 2016. Originally approved in 1988. Last previous edition approved in 20012007 as

E1268 – 01.E1268 – 01(2007). DOI: 10.1520/E1268-01R07.10.1520/E1268-01R16

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1268 − 01 (2016)

NOTE 1—The test grid lines have been shown oriented perpendicular (A) to the deformation axis and parallel (B) to the deformation axis. The counts

for N , N , P , and P are shown for counts made from top to bottom (A) or from left to right (B).

' || ' ||

NOTE 2—T indicates a tangent hit and E indicates that the grid line ended within the particle; both situations are handled as shown.

FIG. 1 Illustration of the Counting of Particle Interceptions (N) and Boundary Intersections (P) for an Oriented Microstructure

A572/A572M Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel

A588/A588M Specification for High-Strength Low-Alloy Structural Steel, up to 50 ksi [345 MPa] Minimum Yield Point, with

Atmospheric Corrosion Resistance

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

E384 Test Method for Microindentation Hardness of Materials

E407 Practice for Microetching Metals and Alloys

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

E883 Guide for Reflected–Light Photomicrography

3. Terminology

3.1 Definitions—For definitions of terms used in this practice, see Terminology E7.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 banded microstructure—separation, of one or more phases or constituents in a two-phase or multiphase microstructure,

or of segregated regions in a single phase or constituent microstructure, into distinct layers parallel to the deformation axis due

to elongation of microsegregation; other factors may also influence band formation, for example, the hot working finishing

temperature, the degree of hot- or cold-work reduction, or split transformations due to limited hardenability or insufficient quench

rate.

3.2.2 feature interceptions—the number of particles (or clusters of particles) of a phase or constituent of interest that are crossed

by the lines of a test grid. (see Fig. 1).

3.2.3 feature intersections—the number of boundaries between the matrix phase and the phase or constituent of interest that are

crossed by the lines of a test grid (see Fig. 1). For isolated particles in a matrix, the number of feature intersections will equal twice

the number of feature interceptions.

3.2.4 oriented constituents—one or more second-phases (constituents) elongated in a non-banded (that is, random distribution)

manner parallel to the deformation axis; the degree of elongation varies with the size and deformability of the phase or constituent

and the degree of hot- or cold-work reduction.

3.2.5 stereological methods—procedures used to characterize three-dimensional microstructural features based on measure-

ments made on two-dimensional sectioning planes.

E1268 − 01 (2016)

FIG. 2 Qualitative Classification Scheme for Oriented or Banded Microstructures

NOTE 2—Microstructural examples are presented in Annex A1 to illustrate the use of terminology for providing a qualitative description of the nature

and extent of the banding or orientation. Fig. 2 describes the classification approach.

3.3 Symbols:

N = number of feature interceptions with test lines perpendicular to the deformation direction.

'

N = number of feature interceptions with test lines parallel to the deformation direction.

||

M = magnification.

L = true test line length in mm, that is, the test line length divided by M.

t

N

N = '

L'

L

t

N

N = ||

L||

L

t

P = number of feature boundary intersections with test lines perpendicular to the deformation direction.

'

P = number of feature boundary intersections with test lines parallel to the deformation direction.

||

P

P =

'

L'

>2N

L'

L

t

P

P = ||

L||

>2N

L ||

L

t

n = number of measurement fields or number of microindentation impressions.

N

N¯ = (

L'

L'

n

N

N¯ =

( L ||

L||

n

P

P¯ = (

L'

L'

¯

>2N

L'

n

P

P¯ = (

L ||

L||

¯

>2N

L ||

n

X¯ = mean values (N¯ , N¯ , P¯ , P¯ )

L' L|| L' L||

s = estimate of standard deviation (σ).

t = a multiplier related to the number of fields examined and used in conjunction with the standard deviation of the

measurements to determine the 95 % CI.

95 % CI = 95 % confidence interval.

E1268 − 01 (2016)

ts

95 % CI =

=

n

% RA = % relative accuracy.

95 % CI

% RA =

¯

X

SB = mean center-to-center spacing of the bands.

'

SB =

'

.

¯

N

L'

V = volume fraction of the banded phase (constituent).

V

λ = mean edge-to-edge spacing of the bands, mean free path (distance).

'

12V

λ = V

'

¯

N

L'

AI = anisotropy index.

¯ ¯

AI =

N P

L' L'

¯ ¯

N P

L|| L||

Ω = degree of orientation of partially oriented linear structure elements on the two-dimensional plane-of-polish.

¯ ¯

Ω =

N 2N

L ' L ||

¯ ¯

N 10.571 N

L' L ||

¯ ¯

Ω =

P 2P

L' L ||

¯ ¯

P 10.571 P

L' L||

4. Summary of Practice

4.1 The degree of microstructural banding or orientation is described qualitatively using metallographic specimens aligned

parallel to the deformation direction of the product.

4.2 Stereological methods are used to measure the number of bands per unit length, the inter-band or interparticle spacing and

the degree of anisotropy or orientation.

4.3 Microindentation hardness testing is used to determine the hardness of each type band present in hardened specimens and

the difference in hardness between the band types.

5. Significance and Use

5.1 This practice is used to assess the nature and extent of banding or orientation of microstructures of metals and other

materials where deformation and processing produce a banded or oriented condition.

5.2 Banded or oriented microstructures can arise in single phase, two phase or multiphase metals and materials. The appearance

of the orientation or banding is influenced by processing factors such as the solidification rate, the extent of segregation, the degree

of hot or cold working, the nature of the deformation process used, the heat treatments, and so forth.

5.3 Microstructural banding or orientation influence the uniformity of mechanical properties determined in various test

directions with respect to the deformation direction.

5.4 The stereological methods can be applied to measure the nature and extent of microstructural banding or orientation for any

metal or material. The microindentation hardness test procedure should only be used to determine the difference in hardness in

banded heat-treated metals, chiefly steels.

5.5 Isolated segregation may also be present in an otherwise reasonably homogeneous microstructure. Stereological methods

are not suitable for measuring individual features, instead use standard measurement procedures to define the feature size. The

microindentation hardness method may be used for such structures.

5.6 Results from these test methods may be used to qualify material for shipment in accordance with guidelines agreed upon

between purchaser and manufacturer, for comparison of different manufacturing processes or process variations, or to provide data

for structure-property-behavior studies.

E1268 − 01 (2016)

6. Apparatus

6.1 A metallurgical (reflected-light) microscope is used to examine the microstructure of test specimens. Banding or orientation

is best observed using low magnifications, for example, 50× to 200×.

6.2 Stereological measurements are made by superimposing a test grid (consisting of a number of closely spaced parallel lines

of known length) on the projected image of the microstructure or on a photomicrograph. Measurements are made with the test lines

parallel and perpendicular to the deformation direction. The total length of the grid lines should be at least 500 mm.

6.3 These stereological measurements may be made using a semiautomatic tracing type image analyzer. The test grid is placed

over the image projected onto the digitizing tablet and a cursor is used for counting.

6.4 For certain microstructures where the contrast between the banded or oriented constituents is adequate, an automatic image

analyzer may be used for counting, where the TV scan lines for a live image, or image convolutions , electronically-generated test

grids , or other methods, for a digitized image, are used rather than the grid lines of the plastic overlay or reticle.

6.5 A microindentation hardness tester is used to determine the hardness of each type of band in heat-treated steels or other

metals. The Knoop indenter is particularly well suited for this work.

7. Sampling and Test Specimens

7.1 In general, specimens should be taken from the final product form after all processing steps have been performed,

particularly those that would influence the nature and extent of banding. Because the degree of banding or orientation may vary

through the product cross section, the test plane should sample the entire cross section. If the section size is too large to permit

full cross sectioning, samples should be taken at standard locations, for example, subsurface, mid-radius (or quarter-point), and

center, or at specific locations based upon producer-purchaser agreements.

7.2 The degree of banding or orientation present is determined using longitudinal test specimens, that is, specimens where the

plane of polish is parallel to the deformation direction. For plate or sheet products, a planar oriented (that is, polished surface

parallel to the surface of the plate or sheet) test specimen, at subsurface, mid-thickness, or center locations, may also be prepared

and tested depending on the nature of the product application.

7.3 Banding or orientation may also be assessed on intermediate product forms, such as billets or bars, for material qualification

or quality control purposes. These test results, however, may not correlate directly with test results on final product forms. Test

specimens should be prepared as described in 7.1 and 7.2 but with the added requirement of choosing test locations with respect

to ingot or continuously cast slab/strand locations. The number and location of such test specimens should be defined by

producer-purchaser agreement.

7.4 Individual metallographic test specimens should have a polished surface area covering the entire cross section if possible.

The length of full

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.