ASTM F290-94(2020)

(Specification)Standard Specification for Round Wire for Winding Electron Tube Grid Laterals

Standard Specification for Round Wire for Winding Electron Tube Grid Laterals

ABSTRACT

This specification covers round wires made from UNS N02211, UNS N10001, or N03300 nickel alloy or molybdenum, with diameters within a specified range, for winding electron tube grid laterals. The wires are classified into five classes based on tensile properties. All wires should conform to the required values of tensile strength, yield strength, working range, and elongation properties. The surface of each bare wire should be bright and free from cracks, slivers, fissures, lubricants, or other detrimental defects, while all platings should be free from bubbles, flakes, blisters, porosity, and plating salts. Wires should be spooled in one continuous length and in such a manner that it can be unwound under reasonable tension without binding or becoming distorted.

SCOPE

1.1 This specification covers round wire up to 0.006 in. (0.15 mm) in diameter for use as electron tube grid lateral winding wire.

1.2 Five classes of wire are covered based on their tensile properties (see 5.2 and 5.3).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F290 −94 (Reapproved 2020)

Standard Specification for

1

Round Wire for Winding Electron Tube Grid Laterals

ThisstandardisissuedunderthefixeddesignationF290;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F16Test Methods for Measuring Diameter or Thickness of

Wire and Ribbon for Electronic Devices and Lamps

1.1 This specification covers round wire up to 0.006 in.

F205Test Method for Measuring Diameter of Fine Wire by

(0.15 mm) in diameter for use as electron tube grid lateral

Weighing

winding wire.

F288Specification for Tungsten Wire for Electron Devices

1.2 Five classes of wire are covered based on their tensile

and Lamps

properties (see 5.2 and 5.3).

F289Specification for Molybdenum Wire and Rod for

Electronic Applications

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

and are not considered standard.

3.1 Description of Terms:

1.4 This standard does not purport to address all of the 3.1.1 The following description of terms shall apply to the

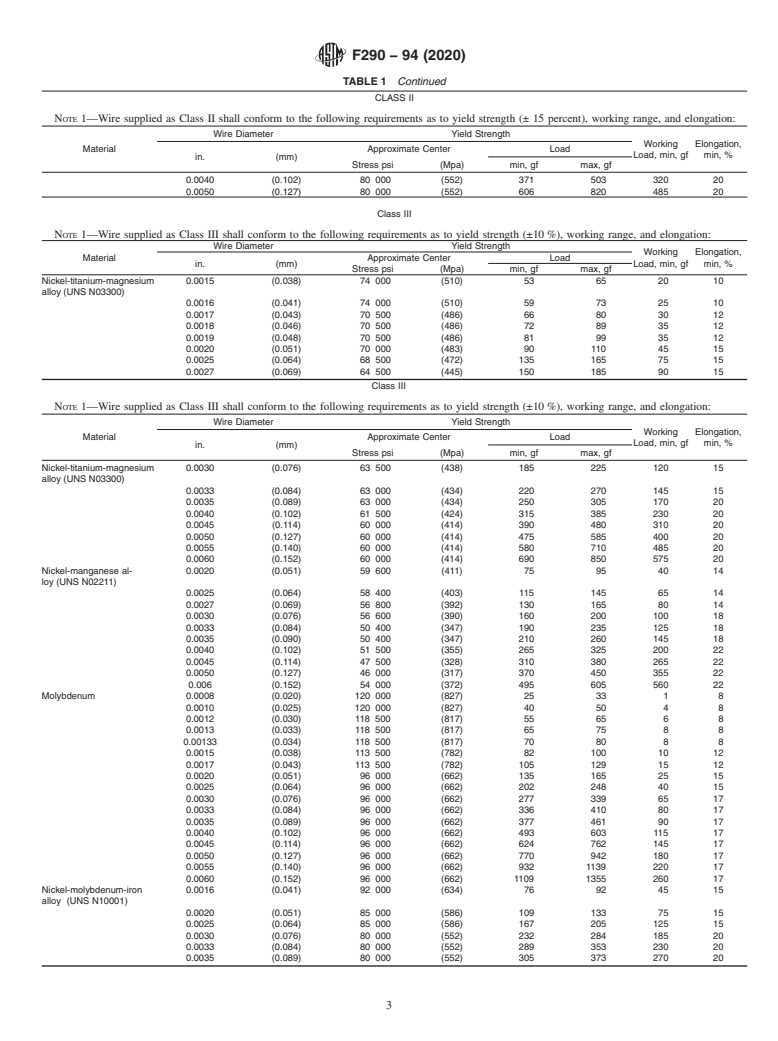

safety concerns, if any, associated with its use. It is the requirements specified in Table 1:

responsibility of the user of this standard to establish appro- 3.1.1.1 breakingstrength—Thestressatwhichthespecimen

priate safety, health, and environmental practices and deter- breaks.

mine the applicability of regulatory limitations prior to use. 3.1.1.2 elongation—The maximum percent of stretch in a

1.5 This international standard was developed in accor- specimen of 10-in. (250-mm) gage length.

dance with internationally recognized principles on standard- 3.1.1.3 tensile strength—The ultimate strength of the mate-

ization established in the Decision on Principles for the rialexpressedeitherasgramspermilligramper200mmlength

Development of International Standards, Guides and Recom- of wire or pounds per square inch.

mendations issued by the World Trade Organization Technical 3.1.1.4 ultimate strength—The maximum stress developed

Barriers to Trade (TBT) Committee. in a specimen.

3.1.1.5 work load—The difference between the yield load

2. Referenced Documents

and the ultimate load.

2

3.1.1.6 yield strength—The stress developed at 1 percent

2.1 ASTM Standards:

elongation when testing a specimen of 10-in. (250-mm) gage

E39Methods for Chemical Analysis of Nickel (Withdrawn

3

length.

1995)

E107Test Methods for Chemical Analysis of Electronic

3

4. Chemical Composition

Nickel (Withdrawn 2003)

E129Test Method for Spectrographic Analysis of Thermi- 4.1 The wire shall conform to the requirements as to

onicNickelAlloysbythePowderTechniques(Withdrawn

chemical composition as prescribed in Table 2.

3

1999)

5. Tensile Properties

5.1 The wire shall conform to the requirements as to tensile

1

This specification is under the jurisdiction of ASTM Committee F01 on

strength, yield strength, working range, and elongation prop-

Electronicsand is the direct responsibility of Subcommittee F01.03 on Metallic

erties as prescribed in Table 1 for the class of wire designated.

Materials, Wire Bonding, and Flip Chip.

Current edition approved May 1, 2020. Published June 2020. Originally

5.2 The class designations for the nickel-titanium-

approved in 1954 as B290–54T; redesignated F290 in 1955. Last previous edition

magnesium alloy UNS N03300; the nickel-manganese alloy

approved in 2015 as F290–94 (2015). DOI: 10.1520/F0290-94R20.

2

UNSN02211;molybdenumwire,andthenickel-molybdenum-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ironalloyUNSN10001;arebasedontheirtensilepropertiesas

Standards volume information, refer to the standard’s Document Summary page on

follows:

the ASTM website.

3

5.2.1 Class I—The wire shall conform to elongation prop-

The last approved version of this historical standard is referenced on

www.astm.org. erties as specified in ranges in Table 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F290−94 (2020)

TABLE 1 Tensile Properties for Nickel-Titanium-Magnesium Alloy (UNS N03300), Nickel-Manganese Alloy (UNS N02211),

Molybdenum Wire, and Nickel-Molybdenum-Iron Alloy (UNS N10001) Wire

CLASS I

NOTE 1—Wire supplied as Class I shall conform to the following elongation v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.