ASTM D5884/D5884M-04A(2015)e1

(Test Method)Standard Test Method for Determining Tearing Strength of Internally Reinforced Geomembranes

Standard Test Method for Determining Tearing Strength of Internally Reinforced Geomembranes

SIGNIFICANCE AND USE

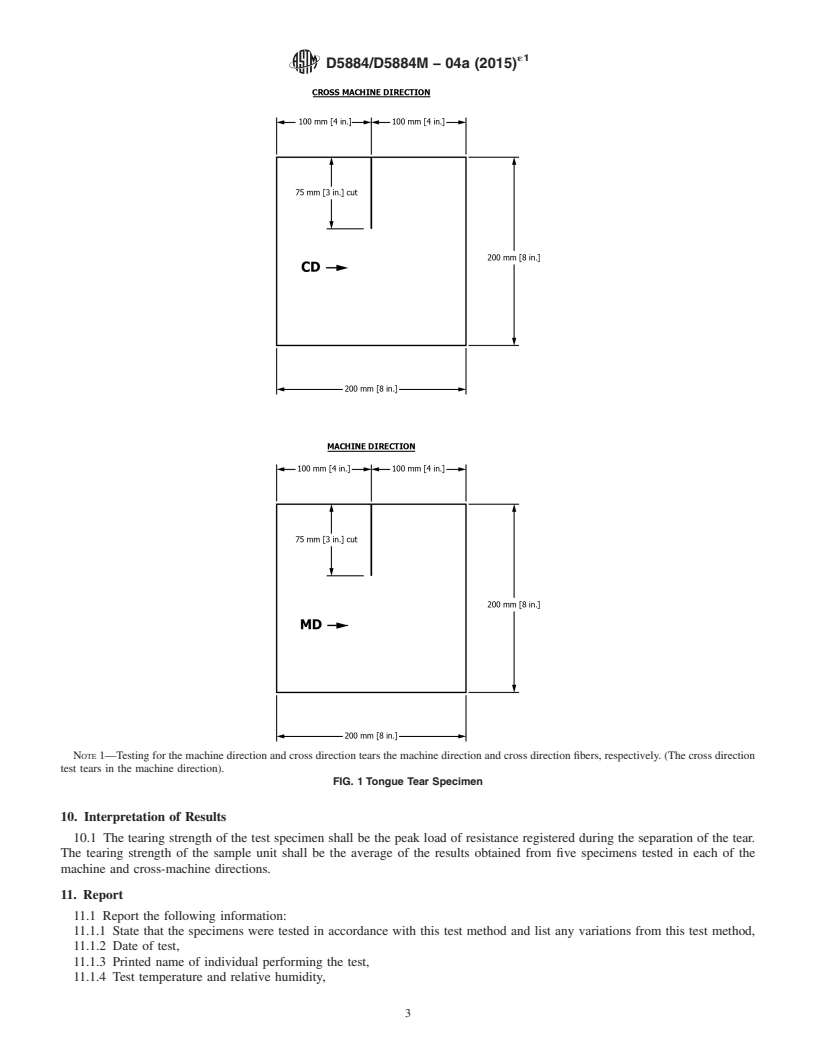

5.1 Since tear resistance may be affected to a large degree by mechanical fibering of the membrane under stress, as well as by stress distribution, strain rate, and size of specimen, the results obtained in a tear resistance test can only be regarded as a measure of the resistance under the conditions of that particular test and not necessarily as having any direct relation to service value. This test method measures the force required to tear a reinforced geomembrane along a reasonably defined course such as that the tear propagates across the width of the specimen. The values may vary between types of reinforcement used within a geomembrane.

5.2 The tongue tear method is useful for estimating the relative tear resistance of different reinforcing textiles or different directions in the same reinforcing textiles.

5.3 Disputes—In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical difference between their laboratories.

SCOPE

1.1 This test method covers a uniform procedure for determining the tear strength of flexible geomembranes internally reinforced with a textile, using the tongue tear method.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D5884/D5884M − 04a (Reapproved 2015)

Standard Test Method for

Determining Tearing Strength of Internally Reinforced

Geomembranes

This standard is issued under the fixed designation D5884/D5884M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Designation was changed to dual and units information was corrected editorially in June 2015.

1. Scope 3.1.3 reinforced geomembrane—a geomembrane internally

reinforced with a textile.

1.1 This test method covers a uniform procedure for deter-

3.1.4 tearing strength, (F, (F), kN), n—the force required

mining the tear strength of flexible geomembranes internally

either (1) to start or (2) to continue or propagate a tear in a

reinforced with a textile, using the tongue tear method.

fabric under specified conditions. D4439, D4533/D4533M

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

4. Summary of Test Method

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining 4.1 The tensile tear strength of a membrane in both machine

and cross-machine directions is determined by measuring the

values from the two systems may result in non-conformance

with the standard. maximum load when cut specimens of specific dimensions are

tested to failure, by tearing, at a fixed testing displacement rate.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 Since tear resistance may be affected to a large degree

bility of regulatory limitations prior to use.

by mechanical fibering of the membrane under stress, as well

as by stress distribution, strain rate, and size of specimen, the

2. Referenced Documents

results obtained in a tear resistance test can only be regarded as

2.1 ASTM Standards:

a measure of the resistance under the conditions of that

D4354 Practice for Sampling of Geosynthetics and Rolled

particular test and not necessarily as having any direct relation

Erosion Control Products(RECPs) for Testing

to service value. This test method measures the force required

D4439 Terminology for Geosynthetics

to tear a reinforced geomembrane along a reasonably defined

D4533/D4533M Test Method for Trapezoid Tearing

course such as that the tear propagates across the width of the

Strength of Geotextiles

specimen. The values may vary between types of reinforce-

ment used within a geomembrane.

3. Terminology

5.2 The tongue tear method is useful for estimating the

3.1 Definitions of Terms Specific to This Standard:

relative tear resistance of different reinforcing textiles or

3.1.1 atmosphere for testing geosynthetics, n—air main-

different directions in the same reinforcing textiles.

tained at a relative humidity between 50 to 70 % and a

temperature of 21 6 2°C [70 6 4°F]. D4439 5.3 Disputes—In case of a dispute arising from differences

in reported test results when using this test method for

3.1.2 geomembrane, n—anessentiallyimpermeablegeosyn-

acceptance testing of commercial shipments, the purchaser and

thetic composed of one or more synthetic sheets. D4439

the supplier should conduct comparative tests to determine if

there is a statistical difference between their laboratories.

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomem-

branes.

6. Apparatus

Current edition approved May 1, 2015. Published June 2015. Originally

6.1 The machine shall consist of three main parts:

approved in 1995. Last previous edition approved in 2010 as D5884–04a(2010).

DOI: 10.1520/D5884_D5884M-04AR15E01.

6.1.1 Straining Mechanism—A machine wherein the speci-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

men is held between the two clamps and strained by a uniform

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

movement of the pulling clamp shall be used. Unless otherwise

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specified in the material specification, the machine shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5884/D5884M − 04a (2015)

adjusted so that the pulling clamp shall have a uniform speed

of 50 6 2 mm/min [2 6 0.1 in./min].

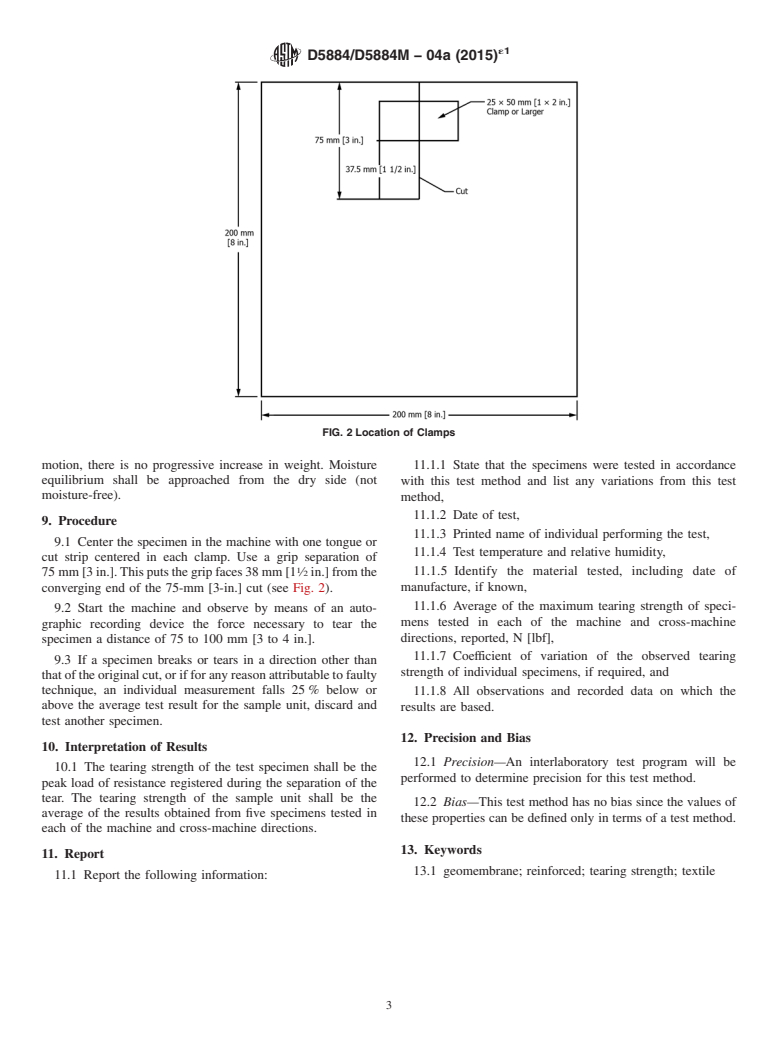

6.1.2 Clamps for Holding Specimen—The clamps for hold-

ing a reinforced flexible geomembrane specimen shall have

metallic gripping surfaces sufficiently smooth, flat, and parallel

as to prevent the test specimen from slipping or moving

between the gripping surfaces when held under the pressure

normal to operation. The dimension of all gripping surfaces

shall measure 25 by 50 mm [1 by 2 in.] or more with the long

dimension perpendicular to this direction of application of the

load. All edges that might cause a cutting action shall be

rounded to a radius of not over 0.4 mm [ ⁄64 in.]. The design of

the clamp shall be such that one gripping surface shall be an

integral part of the rigid frame of the clamp while the other

shall be on a part hinged or swiveled to the movable member

of the clamp. The pressure between the gripping surfaces,

sufficient to clamp the specimen firmly before testing load is

applied and to prevent slippage during the progress of the test,

shall be secured by any suitably constructed mechanical device

operating on the movable member of the clamp. The distance

between the clamps at the start of the test shall be 75 mm

[3 in.].

6.1.3 Load and Elongation Recording

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5884/D5884M − 04a (Reapproved 2015)

Standard Test Method for

Determining Tearing Strength of Internally Reinforced

Geomembranes

This standard is issued under the fixed designation D5884/D5884M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Designation was changed to dual and units information was corrected editorially in June 2015.

1. Scope 3.1.3 reinforced geomembrane—a geomembrane internally

reinforced with a textile.

1.1 This test method covers a uniform procedure for deter-

mining the tear strength of flexible geomembranes internally 3.1.4 tearing strength, (F, (F), kN), n—the force required

either (1) to start or (2) to continue or propagate a tear in a

reinforced with a textile, using the tongue tear method.

fabric under specified conditions. D4439, D4533/D4533M

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

4. Summary of Test Method

each system may not be exact equivalents; therefore, each

4.1 The tensile tear strength of a membrane in both machine

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance and cross-machine directions is determined by measuring the

maximum load when cut specimens of specific dimensions are

with the standard.

tested to failure, by tearing, at a fixed testing displacement rate.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.1 Since tear resistance may be affected to a large degree

bility of regulatory limitations prior to use.

by mechanical fibering of the membrane under stress, as well

as by stress distribution, strain rate, and size of specimen, the

2. Referenced Documents

results obtained in a tear resistance test can only be regarded as

2.1 ASTM Standards:

a measure of the resistance under the conditions of that

D4354 Practice for Sampling of Geosynthetics and Rolled

particular test and not necessarily as having any direct relation

Erosion Control Products(RECPs) for Testing

to service value. This test method measures the force required

D4439 Terminology for Geosynthetics

to tear a reinforced geomembrane along a reasonably defined

D4533/D4533M Test Method for Trapezoid Tearing

course such as that the tear propagates across the width of the

Strength of Geotextiles

specimen. The values may vary between types of reinforce-

ment used within a geomembrane.

3. Terminology

5.2 The tongue tear method is useful for estimating the

3.1 Definitions of Terms Specific to This Standard:

relative tear resistance of different reinforcing textiles or

3.1.1 atmosphere for testing geosynthetics, n—air main-

different directions in the same reinforcing textiles.

tained at a relative humidity between 50 to 70 % and a

temperature of 21 6 2°C [70 6 4°F]. D4439 5.3 Disputes—In case of a dispute arising from differences

in reported test results when using this test method for

3.1.2 geomembrane, n—an essentially impermeable geosyn-

acceptance testing of commercial shipments, the purchaser and

thetic composed of one or more synthetic sheets. D4439

the supplier should conduct comparative tests to determine if

there is a statistical difference between their laboratories.

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomem-

branes.

6. Apparatus

Current edition approved May 1, 2015. Published June 2015. Originally

6.1 The machine shall consist of three main parts:

approved in 1995. Last previous edition approved in 2010 as D5884–04a(2010).

DOI: 10.1520/D5884_D5884M-04AR15E01.

6.1.1 Straining Mechanism—A machine wherein the speci-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

men is held between the two clamps and strained by a uniform

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

movement of the pulling clamp shall be used. Unless otherwise

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specified in the material specification, the machine shall be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5884/D5884M − 04a (2015)

adjusted so that the pulling clamp shall have a uniform speed

of 50 6 2 mm/min [2 6 0.1 in./min].

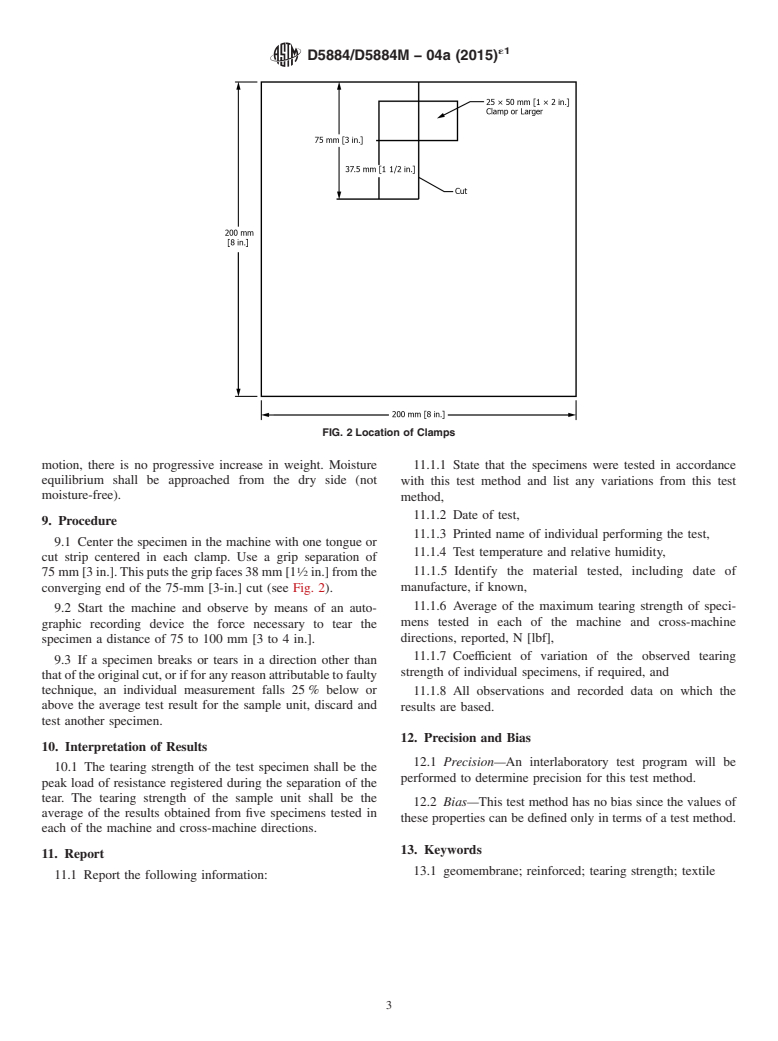

6.1.2 Clamps for Holding Specimen—The clamps for hold-

ing a reinforced flexible geomembrane specimen shall have

metallic gripping surfaces sufficiently smooth, flat, and parallel

as to prevent the test specimen from slipping or moving

between the gripping surfaces when held under the pressure

normal to operation. The dimension of all gripping surfaces

shall measure 25 by 50 mm [1 by 2 in.] or more with the long

dimension perpendicular to this direction of application of the

load. All edges that might cause a cutting action shall be

rounded to a radius of not over 0.4 mm [ ⁄64 in.]. The design of

the clamp shall be such that one gripping surface shall be an

integral part of the rigid frame of the clamp while the other

shall be on a part hinged or swiveled to the movable member

of the clamp. The pressure between the gripping surfaces,

sufficient to clamp the specimen firmly before testing load is

applied and to prevent slippage during the progress of the test,

shall be secured by any suitably constructed mechanical device

operating on the movable member of the clamp. The distance

between the clamps at the start of the test shall be 75 mm

[3 in.].

6.1.3 Load and Elongation Recording Mechanism(s)—

Calibrated dial, scale, or chart to indicate applied load and

elongation. Unless otherwi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D5884 − 04a (Reapproved 2010) D5884/D5884M − 04a (Reapproved 2015)

Standard Test Method for

Determining Tearing Strength of Internally Reinforced

Geomembranes

This standard is issued under the fixed designation D5884;D5884/D5884M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Designation was changed to dual and units information was corrected editorially in June 2015.

1. Scope

1.1 This test method covers a uniform procedure for determining the tear strength of flexible geomembranes internally

reinforced with a textile, using the tongue tear method.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. The inch-pound units

given in parentheses are for information only.values stated in each system may not be exact equivalents; therefore, each system

shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D4354 Practice for Sampling of Geosynthetics and Rolled Erosion Control Products(RECPs) for Testing

D4439 Terminology for Geosynthetics

D4533D4533/D4533M Test Method for Trapezoid Tearing Strength of Geotextiles

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 atmosphere for testing geosynthetics, n—air maintained at a relative humidity between 50 to 70 % and a temperature of

21 6 2°C (70[70 6 4°F).4°F]. D4439

3.1.2 geomembrane, n—an essentially impermeable geosynthetic composed of one or more synthetic sheets. D4439

3.1.3 reinforced geomembrane—a geomembrane internally reinforced with a textile.

3.1.4 tearing strength, (F, (F), kN), n—the force required either (1) to start or (2) to continue or propagate a tear in a fabric under

specified conditions. D4439, D4533D4533/D4533M

4. Summary of Test Method

4.1 The tensile tear strength of a membrane in both machine and cross-machine directions is determined by measuring the

maximum load when cut specimens of specific dimensions are tested to failure, by tearing, at a fixed testing displacement rate.

5. Significance and Use

5.1 Since tear resistance may be affected to a large degree by mechanical fibering of the membrane under stress, as well as by

stress distribution, strain rate, and size of specimen, the results obtained in a tear resistance test can only be regarded as a measure

of the resistance under the conditions of that particular test and not necessarily as having any direct relation to service value. This

test method measures the force required to tear a reinforced geomembrane along a reasonably defined course such as that the tear

propagates across the width of the specimen. The values may vary between types of reinforcement used within a geomembrane.

This test method is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved March 1, 2010May 1, 2015. Published April 2010June 2015. Originally approved in 1995. Last previous edition approved in 20042010 as

D5884–04a.D5884–04a(2010). DOI: 10.1520/D5884-04AR10. 10.1520/D5884_D5884M-04AR15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5884/D5884M − 04a (2015)

5.2 The tongue tear method is useful for estimating the relative tear resistance of different reinforcing textiles or different

directions in the same reinforcing textiles.

5.3 Disputes—In case of a dispute arising from differences in reported test results when using this test method for acceptance

testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a

statistical difference between their laboratories.

6. Apparatus

6.1 The machine shall consist of three main parts:

6.1.1 Straining Mechanism—A machine wherein the specimen is held between the two clamps and strained by a uniform

movement of the pulling clamp shall be used. Unless otherwise specified in the material specification, the machine shall be adjusted

so that the pulling clamp shall have a uniform speed of 50 6 2 mm/min (2[2 6 0.1 in./min).in./min].

6.1.2 Clamps for Holding Specimen—The clamps for holding a reinforced flexible geomembrane specimen shall have metallic

gripping surfaces sufficiently smooth, flat, and parallel as to prevent the test specimen from slipping or moving between the

gripping surfaces when held under the pressure normal to operation. The dimension of all gripping surfaces shall measure 25 by

50 mm (1[1 by 2 in.)in.] or more with the long dimension perpendicular to this direction of application of the load. All edges that

might cause a cutting action shall be rounded to a radius of not over 0.4 mm ([ ⁄64 in.).in.]. The design of the clamp shall be such

that one gripping surface shall be an integral part of the rigid frame of the clamp while the other shall be on a part hinged or

swiveled to the movable member of the clamp. The pressure between the gripping surfaces, sufficient to clamp the specimen firmly

before testing load is applied and to prevent slippage during the progress of the test, shall be secured by any suitably constructed

mechanical device operating on the movable member of the clamp. The distance between the clam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.