ASTM D6984-12b

(Test Method)Standard Test Method for Evaluation of Automotive Engine Oils in the Sequence IIIF, Spark-Ignition Engine

Standard Test Method for Evaluation of Automotive Engine Oils in the Sequence IIIF, Spark-Ignition Engine

SIGNIFICANCE AND USE

5.1 This test method was developed to evaluate automotive engine oils for protection against oil thickening and engine wear during moderately high-speed, high-temperature service.

5.2 The increase in oil viscosity obtained in this test method indicates the tendency of an oil to thicken because of oxidation. In automotive service, such thickening can cause oil pump starvation and resultant catastrophic engine failures.

5.3 The deposit ratings for an oil indicate the tendency for the formation of deposits throughout the engine, including those that can cause sticking of the piston rings in their grooves. This can be involved in the loss of compression pressures in the engine.

5.4 The camshaft and lifter wear values obtained in this test method provide a measure of the anti-wear quality of an oil under conditions of high unit pressure mechanical contact.

5.5 The test method was developed to correlate with oils of known good and poor protection against oil thickening and engine wear. Specially formulated oils that produce less than desirable results with unleaded fuels were also used during the development of this test method.

5.6 The Sequence IIIF engine oil test has replaced the Sequence IIIE test and can be used in specifications and classifications of engine lubricating oils, such as:

5.6.1 Specification D4485,

5.6.2 Military Specification MIL-PRF-2104, and

5.6.3 SAE Classification J183.

SCOPE

1.1 This test method covers an engine test procedure for evaluating automotive engine oils for certain high-temperature performance characteristics, including oil thickening, varnish deposition, oil consumption, as well as engine wear. Such oils include both single viscosity grade and multiviscosity grade oils that are used in both spark-ignition, gasoline-fueled engines, as well as in diesel engines.Note 1—Companion test methods used to evaluate engine oil performance for specification requirements are discussed in SAE J304.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exceptions—The values stated in inches for ring gap measurements are to be regarded as standard, and where there is no direct SI equivalent such as screw threads, National Pipe Threads/diameters, tubing size, or single source supply equipment specifications.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

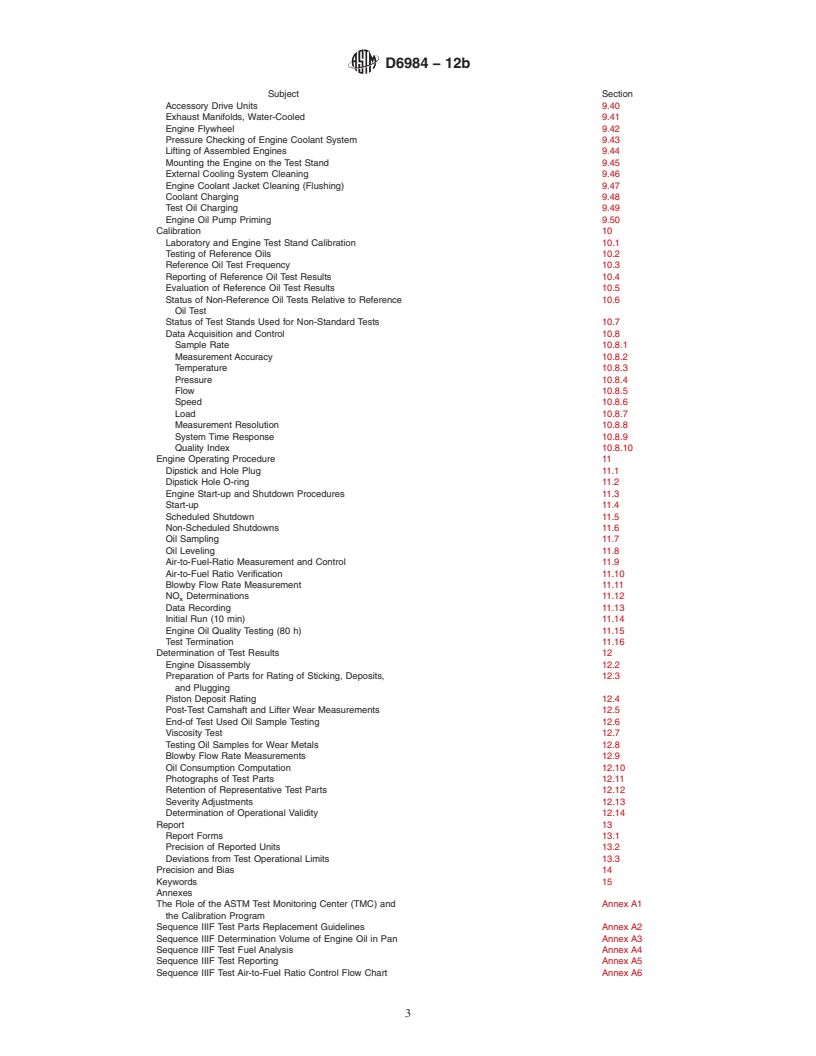

1.4 This test method is arranged as follows:

Subject

Section

Scope

1

Referenced Documents

2

Terminology

3

Summary of Test Method

4

Significance and Use

5

Apparatus

6

Laboratory

6.1

Drawings

6.2

Specified Equipment

6.3

Test Engine

6.4

Engine Parts

6.4.1

Engine Speed and Load Control

6.5

Sequence IIIF Fluid Conditioning Module

6.6

Engine Cooling System

6.6.1

Flushing Tank

6.7

Coolant Mixing Tank

6.8

Condenser Cooling Systems

6.9

Engine Oil-Cooling System

6.10

Fuel System

6.11

Induction Air Supply Humidity, Temperature, and Pressure

6.12

Temperature Measurement

6.13

Thermocouple Location

6.13.1

Air-to-Fuel Ratio Determination

6.14

Injector Flow Testing

6.14.1

Exhaust and Exhaust Back Pressure Systems

6.15

Blowby Flow Rate Measurement

6.16

Pressure Measurement and Sensor Location

6.17

Reagents and Materials

7

Test Fuel

7.1

Engine and Condenser Coolant

7.2

Coolant Additive

7.3

Coolant Preparation

7.4

Pre-Test Cleaning Materials

7.5

Sealing and Anti-seize Compounds

7.6

Test Oil Sample Requirements

8

Prepar...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6984 − 12b

StandardTest Method for

Evaluation of Automotive Engine Oils in the Sequence IIIF,

1

Spark-Ignition Engine

This standard is issued under the fixed designation D6984; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method described can be used by any properly equipped laboratory; it does not require the

2

assistance of anyone outside that laboratory. However, the ASTM Test Monitoring Center (TMC)

provides reference oils and an assessment of the test results obtained on those oils by the laboratory

(see AnnexA1). By these means, the laboratory will know whether their use of the test method gives

results statistically similar to those obtained by other laboratories. Furthermore, various agencies

requirethatalaboratoryutilizetheTMCservicesinseekingqualificationofoilsagainstspecifications.

For example, the U.S. Army imposes such a requirement in connection with several Army engine

lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of Information Letters issued by theTMC. In addition,

the TMC may issue supplementary memoranda related to the test method (see A1.8).

1. Scope* is no direct SI equivalent such as screw threads, National Pipe

Threads/diameters, tubing size, or single source supply equip-

1.1 This test method covers an engine test procedure for

ment specifications.

evaluating automotive engine oils for certain high-temperature

performance characteristics, including oil thickening, varnish

1.3 This standard does not purport to address all of the

deposition, oil consumption, as well as engine wear. Such oils

safety concerns, if any, associated with its use. It is the

include both single viscosity grade and multiviscosity grade

responsibility of the user of this standard to establish appro-

oils that are used in both spark-ignition, gasoline-fueled

priate safety and health practices and determine the applica-

engines, as well as in diesel engines.

bility of regulatory requirements prior to use.

NOTE 1—Companion test methods used to evaluate engine oil perfor-

1.4 This test method is arranged as follows:

mance for specification requirements are discussed in SAE J304.

Subject Section

1.2 The values stated in SI units are to be regarded as

Scope 1

Referenced Documents 2

standard. No other units of measurement are included in this

Terminology 3

standard.

Summary of Test Method 4

1.2.1 Exceptions—The values stated in inches for ring gap Significance and Use 5

Apparatus 6

measurements are to be regarded as standard, and where there

Laboratory 6.1

Drawings 6.2

Specified Equipment 6.3

Test Engine 6.4

1

This test method is under the jurisdiction of ASTM Committee D02 on

Engine Parts 6.4.1

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Engine Speed and Load Control 6.5

D02.B0.01 on Passenger Car Engine Oils.

Sequence IIIF Fluid Conditioning Module 6.6

Current edition approved Dec. 1, 2012. Published March 2013. Originally Engine Cooling System 6.6.1

approved in 2003. Last previous edition approved in 2012 as D6984–12a. DOI: Flushing Tank 6.7

Coolant Mixing Tank 6.8

10.1520/D6984-12B.

2

Condenser Cooling Systems 6.9

Until the next revision of this test method, the ASTM Test Monitoring Center

Engine Oil-Cooling System 6.10

will update changes in the test method by means of information letters. Information

Fuel System 6.11

lettersmaybeobtainedfromtheASTMTestMonitoringCenter,6555PennAvenue,

Induction Air Supply Humidity, Temperature, and Pressure 6.12

Pittsburgh, PA 15206-4489. Attention: Administrator. www.astmtmc.cmu.edu. This

Temperature Measurement 6.13

edition incorporates revisions contained in all information letters through 12-1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6984 − 12b

Subject Section Subject Section

Thermocouple Location 6.13.1 Reference Oil Test Frequency 10.3

Air-to-Fuel Ratio Determination 6.14 Reporting of Reference Oil Test Results 10.4

Injector Flow Testing 6.14.1 Evaluation of Reference Oil Test Results 10.5

Exhaust and Exhaust Back Pressure Systems 6.15 Status of Non-Reference Oil Tests Relative to Reference 10.6

Blowby Flow Rate Measurement 6.16 Oil Test

Pressure Measu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6984 − 12a D6984 − 12b

Standard Test Method for

Evaluation of Automotive Engine Oils in the Sequence IIIF,

1

Spark-Ignition Engine

This standard is issued under the fixed designation D6984; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method described can be used by any properly equipped laboratory; it does not require the

2

assistance of anyone outside that laboratory. However, the ASTM Test Monitoring Center (TMC)

provides reference oils and an assessment of the test results obtained on those oils by the laboratory

(see Annex A1). By these means, the laboratory will know whether their use of the test method gives

results statistically similar to those obtained by other laboratories. Furthermore, various agencies

require that a laboratory utilize the TMC services in seeking qualification of oils against specifications.

For example, the U.S. Army imposes such a requirement in connection with several Army engine

lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of Information Letters issued by the TMC. In addition,

the TMC may issue supplementary memoranda related to the test method (see A1.8).

1. Scope*

1.1 This test method covers an engine test procedure for evaluating automotive engine oils for certain high-temperature

performance characteristics, including oil thickening, varnish deposition, oil consumption, as well as engine wear. Such oils

include both single viscosity grade and multiviscosity grade oils that are used in both spark-ignition, gasoline-fueled engines, as

well as in diesel engines.

NOTE 1—Companion test methods used to evaluate engine oil performance for specification requirements are discussed in SAE J304.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exceptions—The values stated in inches for ring gap measurements are to be regarded as standard, and where there is no

direct SI equivalent such as screw threads, National Pipe Threads/diameters, tubing size, or single source supply equipment

specifications.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

1.4 This test method is arranged as follows:

Subject Section

Scope 1

Referenced Documents 2

Terminology 3

Summary of Test Method 4

Significance and Use 5

Apparatus 6

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.B0.01

on Passenger Car Engine Oils.

Current edition approved Nov. 1, 2012Dec. 1, 2012. Published February 2013March 2013. Originally approved in 2003. Last previous edition approved in 2012 as

D6984–12.–12a. DOI: 10.1520/D6984-12A.10.1520/D6984-12B.

2

Until the next revision of this test method, the ASTM Test Monitoring Center will update changes in the test method by means of information letters. Information letters

may be obtained from the ASTM Test Monitoring Center, 6555 Penn Avenue, Pittsburgh, PA 15206-4489. Attention: Administrator. www.astmtmc.cmu.edu. This edition

incorporates revisions contained in all information letters through 12-1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6984 − 12b

Subject Section

Laboratory 6.1

Drawings 6.2

Specified Equipment 6.3

Test Engine 6.4

Engine Parts 6.4.1

Engine Speed and Load Control 6.5

Sequence IIIF Fluid Conditioning Module 6.6

Engine Cooling System 6.6.1

Flushing Tank 6.7

Coolant Mixing Tank 6.8

Condenser Cooling Systems 6.9

Engine Oil-Cooling System 6.10

Fuel System 6.11

Induction Air Supply Humidity, Temperature, and Pressure 6.12

Temperature Measurement 6.13

Thermocouple Location 6.13.1

Air-to-Fuel R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.