ASTM D7320-18e1

(Test Method)Standard Test Method for Evaluation of Automotive Engine Oils in the Sequence IIIG, Spark-Ignition Engine

Standard Test Method for Evaluation of Automotive Engine Oils in the Sequence IIIG, Spark-Ignition Engine

SIGNIFICANCE AND USE

5.1 This test method was developed to evaluate automotive engine oils for protection against oil thickening and engine wear during moderately high-speed, high-temperature service.

5.2 The increase in oil viscosity obtained in this test indicates the tendency of an oil to thicken because of oxidation. In automotive service, such thickening can cause oil pump starvation and resultant catastrophic engine failures.

5.3 The deposit ratings for an oil indicate the tendency for the formation of deposits throughout the engine, including those that can cause sticking of the piston rings in their grooves. This can be involved in the loss of compression pressures in the engine.

5.4 The camshaft and lifter wear values obtained in this test provide a measure of the anti-wear quality of an oil under conditions of high unit pressure mechanical contact.

5.5 The test method was developed to correlate with oils of known good and poor protection against oil thickening and engine wear. Specially formulated oils that produce less than desirable results with unleaded fuels were also used during the development of this test.

5.6 The Sequence IIIG engine oil test has replaced the Sequence IIIF test and can be used in specifications and classifications of engine lubricating oils, such as the following:

5.6.1 Specification D4485,

5.6.2 Military Specification MIL-PRF-2104, and

5.6.3 SAE Classification J183.

SCOPE

1.1 This test method covers an engine test procedure for evaluating automotive engine oils for certain high-temperature performance characteristics, including oil thickening, varnish deposition, oil consumption, as well as engine wear. Such oils include both single viscosity grade and multiviscosity grade oils that are used in both spark-ignition, gasoline-fueled engines, as well as in diesel engines.

1.1.1 Additionally, with nonmandatory supplemental requirements, a IIIGA Test (Mini Rotary Viscometer and Cold Cranking Simulator measurements), a IIIGVS Test (EOT viscosity increase measurement), or a IIIGB Test (phosphorous retention measurement) can be conducted. These supplemental test procedures are contained in Appendix X1, Appendix X2, and Appendix X3, respectively.

Note 1: Companion test methods used to evaluate engine oil performance for specification requirements are discussed in SAE J304.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—Where there is no direct SI equivalent such as screw threads, national pipe threads/diameters, and tubing size.

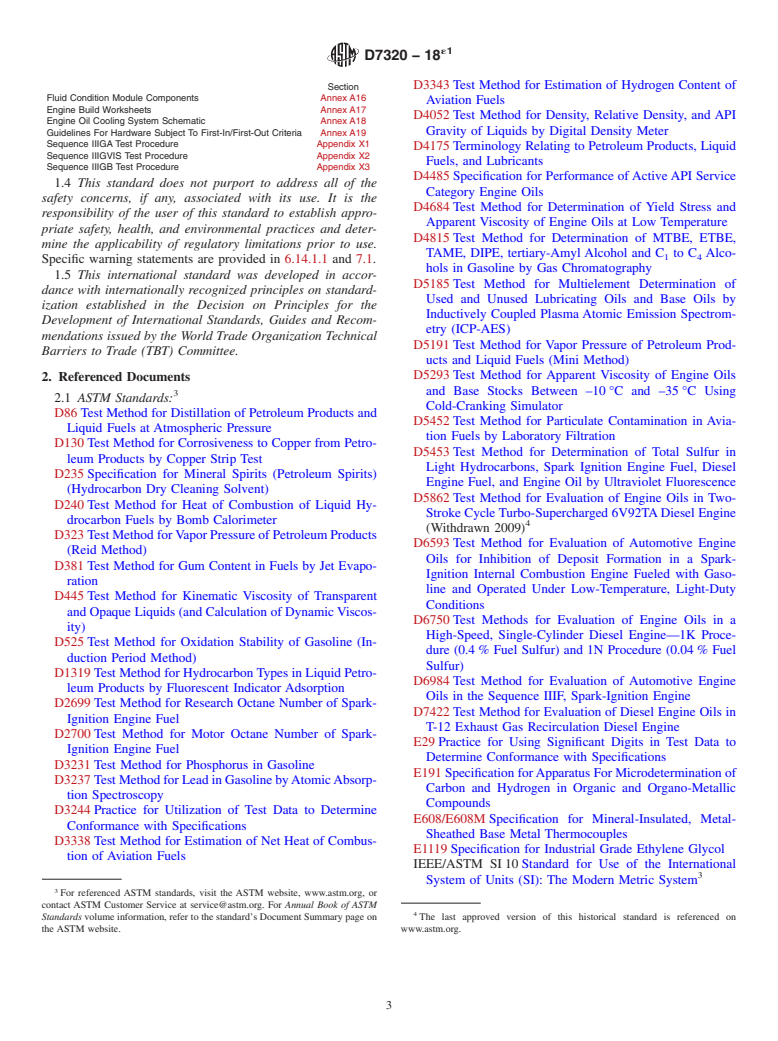

1.3 This test method is arranged as follows:

Section

Introduction

Scope

1

Referenced Documents

2

Terminology

3

Summary of Test Methods

4

Significance and Use

5

Apparatus

6

Laboratory

6.1

Drawings

6.2

Specified Equipment

6.3

Test Engine

6.4

Engine Parts

6.4.1

Engine Speed and Load Control

6.5

Fluid Conditioning Module

6.6

Engine Cooling System

6.6.1

Flushing Tank

6.7

Coolant Mixing Tank

6.8

Condenser Cooling Systems

6.9

Engine Oil-Cooling System

6.10

Fuel System

6.11

Induction Air Supply Humidity, Temperature, and Pressure

6.12

Temperature Measurement

6.13

Thermocouple Location

6.13.1

Air-to-Fuel Ratio Determination

6.14

Injector Flow Testing

6.14.1

Exhaust and Exhaust Back Pressure Systems

6.15

Blowby Flow Rate Measurement

6.16

Pressure Measurement and Pressure Sensor Location

6.17

Reagents and Materials

7

Test Fuel

7.1

Engine and Condenser Coolant

7.2

Coolant Additive

7.3

Coolant Preparation

7.4

Pre-Test Cleaning Materials

7.5

Sealing and Anti-seize Compounds

7.6

Test Oil Sample Requirements

8

Preparation of Apparatus

9

Condenser C...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D7320 − 18

Standard Test Method for

Evaluation of Automotive Engine Oils in the Sequence IIIG,

1

Spark-Ignition Engine

This standard is issued under the fixed designation D7320; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially updated TMC governance information in June 2022.

INTRODUCTION

Portions of this test method are written for use by laboratories that make use of ASTM Test

2

Monitoring Center (TMC) services (see Annex A1 – Annex A4).

TheTMC provides reference oils, and engineering and statistical services to laboratories that desire

to produce test results that are statistically similar to those produced by laboratories previously

calibrated by the TMC.

In general, the Test Purchaser decides if a calibrated test stand is to be used. Organizations such as

theAmerican Chemistry Council require that a laboratory utilize theTMC services as part of their test

registration process. In addition, the American Petroleum Institute and the Gear Lubricant Review

Committee of the Lubricant Review Institute (SAE International) require that a laboratory use the

TMC services in seeking qualification of oils against their specifications.

The advantage of using the TMC services to calibrate test stands is that the test laboratory (and

hence the Test Purchaser) has an assurance that the test stand was operating at the proper level of test

severity. It should also be borne in mind that results obtained in a non-calibrated test stand may not

be the same as those obtained in a test stand participating in the ASTM TMC services process.

Laboratories that choose not to use the TMC services may simply disregard these portions.

1. Scope* test procedures are contained in Appendix X1, Appendix X2,

and Appendix X3, respectively.

1.1 This test method covers an engine test procedure for

NOTE 1—Companion test methods used to evaluate engine oil perfor-

evaluating automotive engine oils for certain high-temperature

mance for specification requirements are discussed in SAE J304.

performance characteristics, including oil thickening, varnish

1.2 The values stated in SI units are to be regarded as

deposition, oil consumption, as well as engine wear. Such oils

standard. No other units of measurement are included in this

include both single viscosity grade and multiviscosity grade

standard.

oils that are used in both spark-ignition, gasoline-fueled

1.2.1 Exception—Where there is no direct SI equivalent

engines, as well as in diesel engines.

such as screw threads, national pipe threads/diameters, and

1.1.1 Additionally, with nonmandatory supplemental

tubing size.

requirements, a IIIGATest (Mini Rotary Viscometer and Cold

Cranking Simulator measurements), a IIIGVS Test (EOT

1.3 This test method is arranged as follows:

viscosity increase measurement), or a IIIGBTest (phosphorous

Section

retention measurement) can be conducted. These supplemental

Introduction

Scope 1

Referenced Documents 2

1

This test method is under the jurisdiction of ASTM Committee D02 on

Terminology 3

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Summary of Test Methods 4

Subcommittee D02.B0.01 on Passenger Car Engine Oils.

Significance and Use 5

Current edition approved April 1, 2018. Published April 2018. Originally Apparatus 6

approved in 2006. Last previous edition approved in 2017 as D7320 – 17a. DOI: Laboratory 6.1

Drawings 6.2

10.1520/D7320-18E01.

2

Specified Equipment 6.3

Until the next revision of this test method, the ASTM Test Monitoring Center

Test Engine 6.4

will update changes in the test method by means of information letters. Information

Engine Parts 6.4.1

letters may be obtained from the ASTM Test Monitoring Center, 203 Armstrong

Engine Speed and Load Control 6.5

Drive, Freeport, PA 16229. Attention: Director. This edition incorporates revisions

Fluid Conditioning Module 6.6

in all information letters through No. 17-3.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7320 − 18

Section Section

Engine Cooling System 6.6.1 Lifting of Assembled Engines 9.44

Flushing Tank 6.7 Mounting the Engine on the Test Stand 9.45

Coolant Mixing Tank 6.8 External Cooling System Cleaning 9.46

Condenser Cooling Systems 6.9 Engine Coolant Jacket Cleanin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.